Copper-clad aluminium composite flat cable induction continuous annealing equipment and process using equipment

A copper-clad aluminum and flat row technology, applied in the field of induction heating continuous annealing equipment and its process, can solve the problems of small interface thickness and interface bonding strength, shorten the holding time of copper-clad aluminum flat rows, and reduce the electrical conductivity, and achieve interface bonding. The effect of high strength, easy control of temperature stability and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

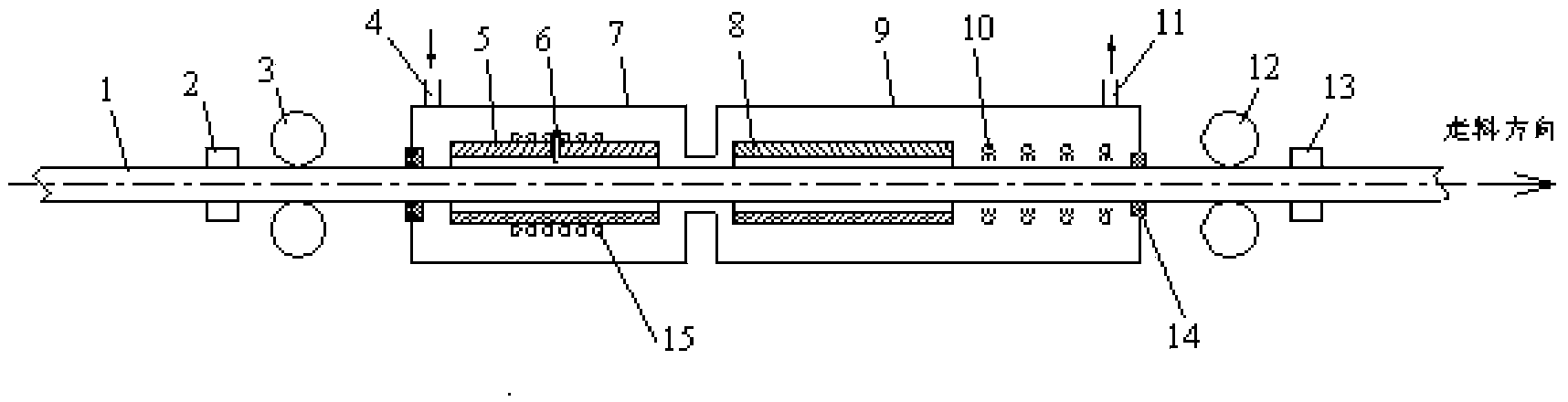

[0033] Example 1: Induction continuous annealing process of copper-clad aluminum flat row with a cross-sectional size of 40mm×10mm and a copper cladding ratio of 30%.

[0034] (1) Pass the copper-clad aluminum flat row with a cross-sectional size of 40mm×10mm through the guide roller 2 and the driving roller 3 at the entrance, the insulation pipe 5 in the induction heating coil 15, the insulation pipe 8 of the subsequent insulation section, and the cooling system 10. Drive roller 12 and guide roller 13 at the exit end, and adjust the position of the guide roller so that the axis of the copper-clad aluminum flat row coincides with the axis of the induction heating coil as much as possible;

[0035] (2) Pass protective gas into the gas protection system, so that the system is in a good gas protection state;

[0036] (3) Start the temperature measuring device 6 and the driving devices 3 and 12, set the feeding speed to 10m / min and the annealing temperature to 460°C; start the i...

Embodiment 2

[0038] Example 2: Induction continuous annealing process of copper-clad aluminum flat row with a cross-sectional size of 60mm×10mm and a copper cladding ratio of 30%.

[0039] (1) Pass the copper-clad aluminum flat row with a cross-sectional size of 60mm×10mm through the guide roller 2 and the driving roller 3 at the entrance, the insulation pipe 5 in the induction heating coil 15, the insulation pipe 8 of the subsequent insulation section, and the cooling system 10. Drive roller 12 and guide roller 13 at the exit end, and adjust the position of the guide roller so that the axis of the copper-clad aluminum flat row coincides with the axis of the induction heating coil as much as possible;

[0040] (2) Pass protective gas into the gas protection system, so that the system is in a good gas protection state;

[0041] (3) Start the temperature measuring device 6 and the driving devices 3 and 12, set the feeding speed to 20m / min and the annealing temperature to 500°C; start the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com