A method for rapidly preparing gradient cemented carbide by adding rare earth elements

A technology of cemented carbide and rare earth elements, applied in the field of cemented carbide material manufacturing, can solve the problem of adding few alloy members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

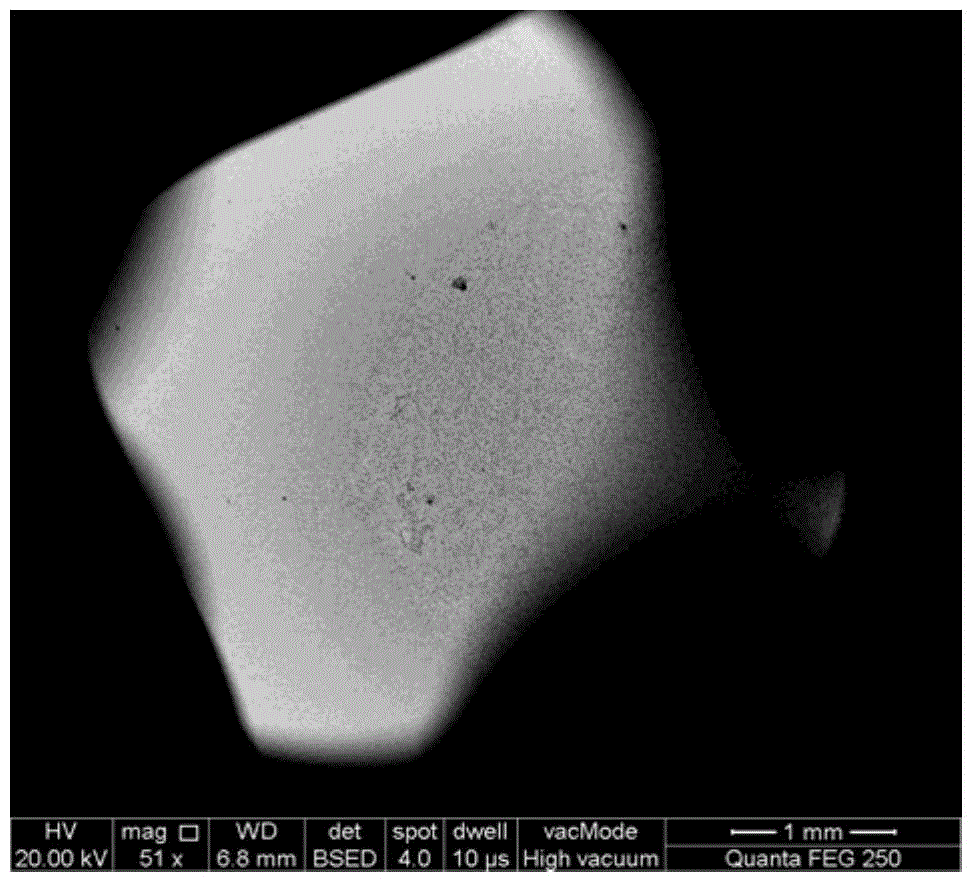

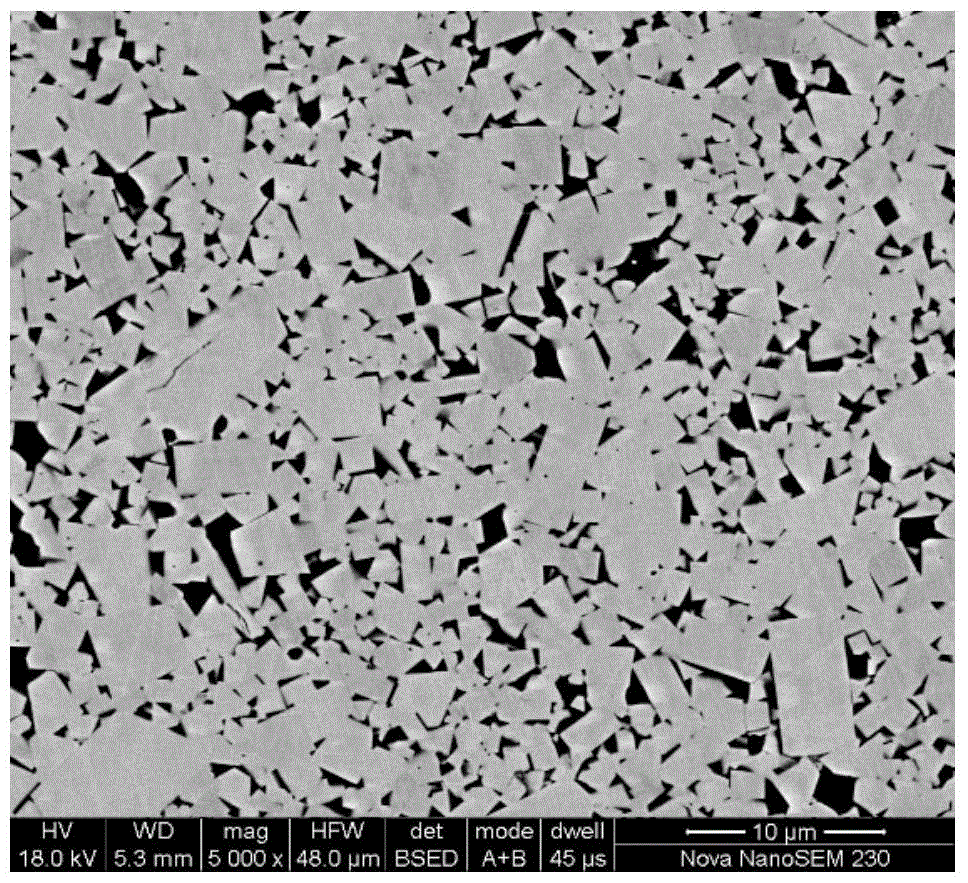

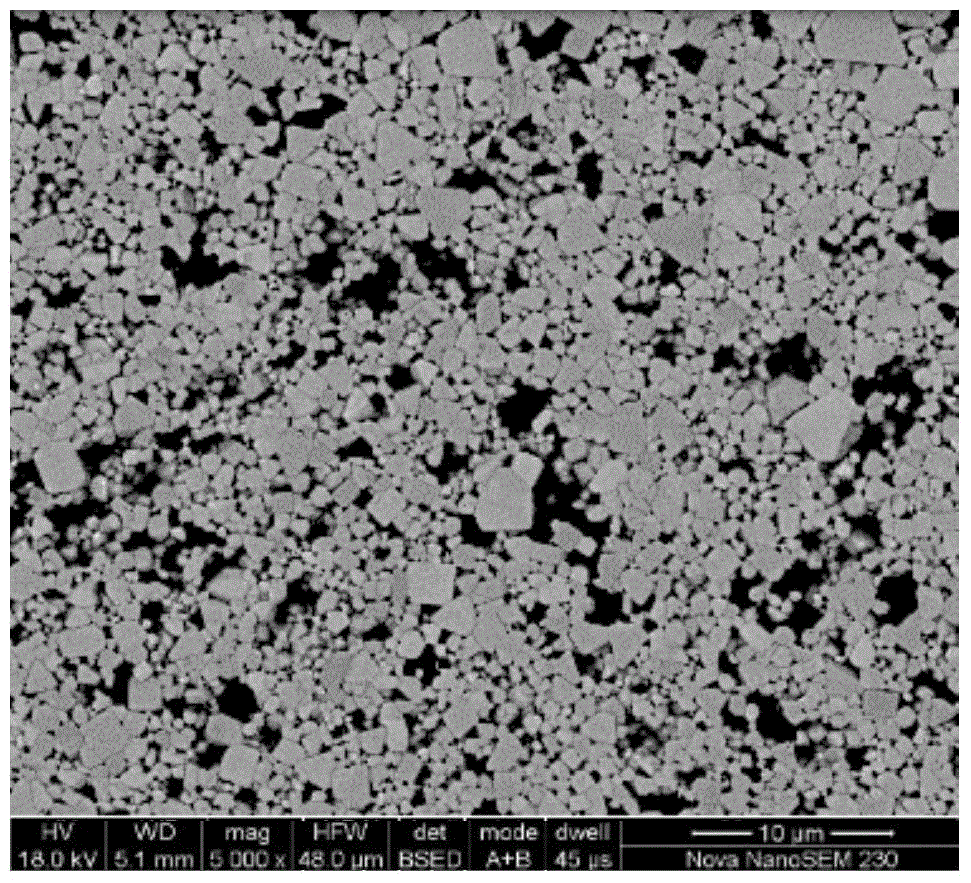

Image

Examples

Embodiment 1

[0056] step one

[0057] Configuration of carbon-poor cemented carbide powder containing rare earth elements: in the carbon-poor cemented carbide powder containing rare earth elements, it includes by mass percentage:

[0058] WC powder 87.5%; Co powder 6%; W powder 6%; rare earth oxide Y 2 o 3 , wherein Y accounts for 0.5% of the total mass of the carbon-poor cemented carbide powder containing rare earth elements; the total content of carbon in the carbon-poor cemented carbide powder containing rare earth elements is 5.22wt.%; the rare earth element Y is by Y 2 o 3 obtained after reduction; the particle size of the WC powder is 2 μm; the particle size of the Co powder is 2.0 μm; the particle size of the W powder is 1.5 μm; the Y 2 o 3 The particle size of the powder is 1.5μm; the preparation process is as follows: the prepared WC powder, Co powder, W powder, Y powder 2 o 3 Dry mill for 2 hours, mix well, in order to make Y 2 o 3 Reduction to Y, heating in a hydrogen a...

Embodiment 2

[0075] Other conditions are completely consistent with embodiment 1, just the rare earth element is changed into La, and its content is 0.7wt%, and Y 2 o 3 changed to La 2 o 3 , reducing La 2 o 3 The temperature is 1050°C, the time is 40 minutes, and the carburizing temperature is 1450°C; the specific test items and test results are shown in Table 3

[0076] table 3

[0077]

Embodiment 3

[0084] Other conditions are exactly the same as in Example 1, except that the rare earth element is replaced by Ce, and its content is 0.6wt%, and Y 2 o 3 replaced by CeO 2 , reducing CeO 2 The temperature is 1100°C, the heating time is 30 minutes, the forming pressure is 300MPa, and the carburizing temperature is 1460°C; the specific test items and test results are shown in Table 5.

[0085] table 5

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com