Patents

Literature

52results about How to "Improve carburizing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth and carbon co-infiltration method in continuous furnace for automobile gearbox gear

InactiveCN1654700AChange other functionsOsmoticSolid state diffusion coatingHigh concentrationCarbon potential

The continuous micro deformation RE-carbon co-penetrating process for gear of automobile gear box is realized via making the pre-treated workpiece enter the different regions with RE co-penetrant in continuous carbonizing furnace at 840-890 deg.c. The workpiece is made to enter successively region-I for preheating and pre-penetrating; region-II and region-III with carbon potential of 1.15-1.25 % for carbonizing; region-IV with carbon potential of 0.8-1.05 % for diffusion treatment; and region-V with carbon potential of 0.8-1.05 % for waiting for discharging and quenching. The present invention is one controllable low temperature RE high concentration gas carbonizing process capable of resulting in optimal metallurgical structure, and has the advantages of high carbonizing rate, high efficiency and low power consumption.

Owner:HARBIN INST OF TECH

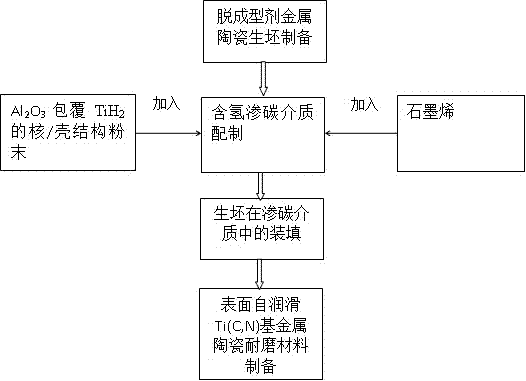

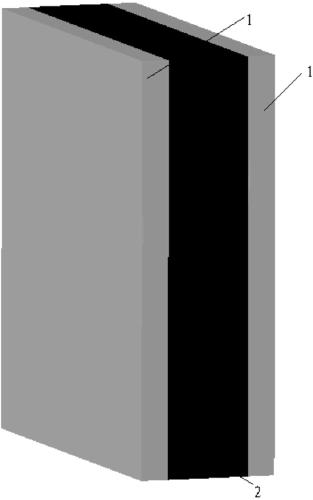

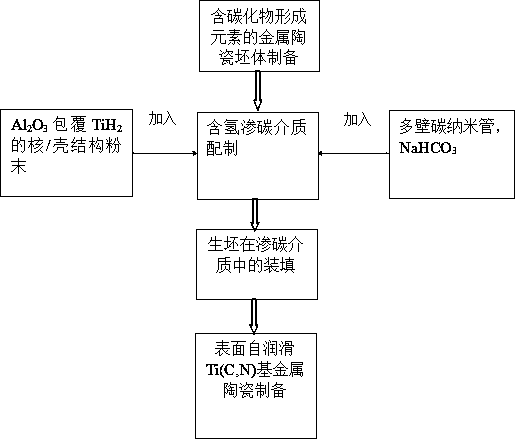

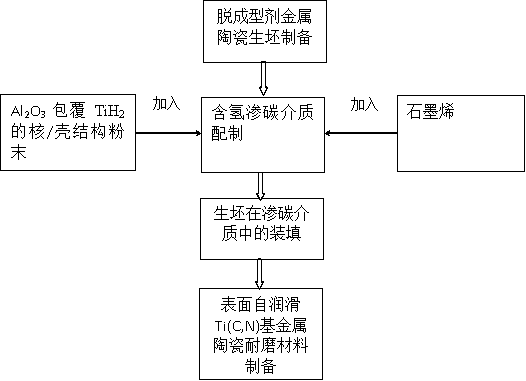

Preparation method of self-lubricating surface type Ti(C, N)-based cermet wear-proof material

ActiveCN107142407AIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorositySurface type

The invention discloses a preparation method of a self-lubricating surface type Ti(C, N)-based cermet wear-proof material. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is characterized in that the temperature is kept at 500-650 DEG C for 2-4 h, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2 and graphene are mixed at the weight percentage ratio of 2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is achieved. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is prepared in the sintering process.

Owner:SICHUAN UNIV

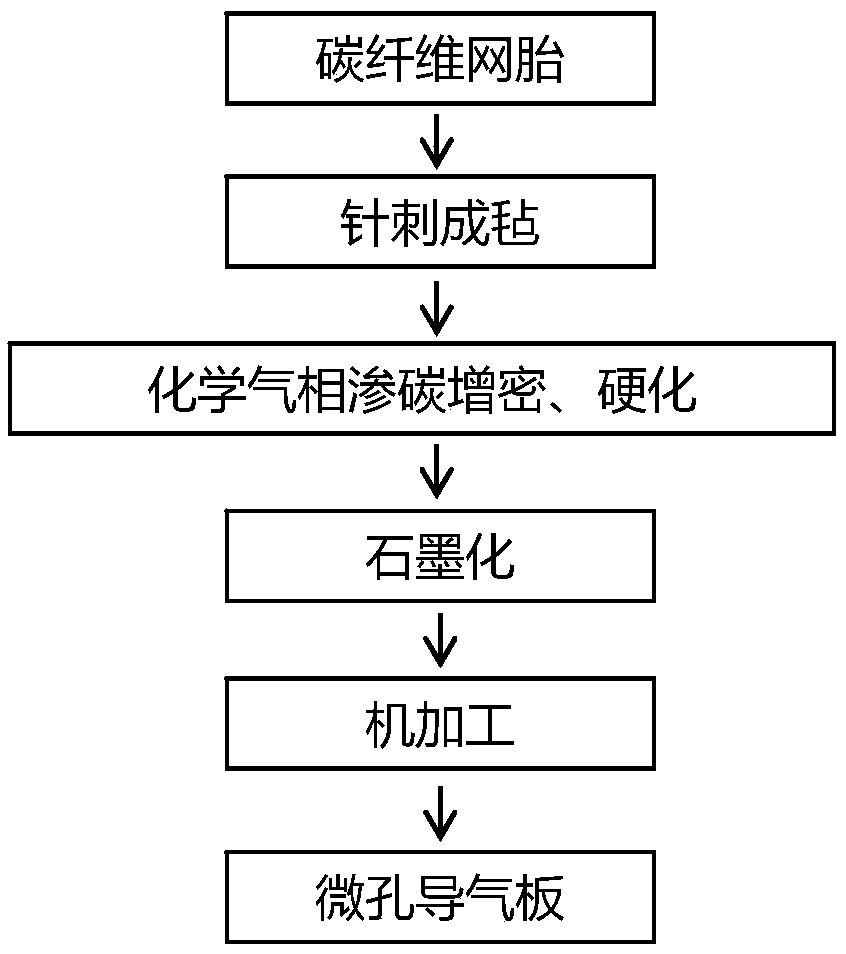

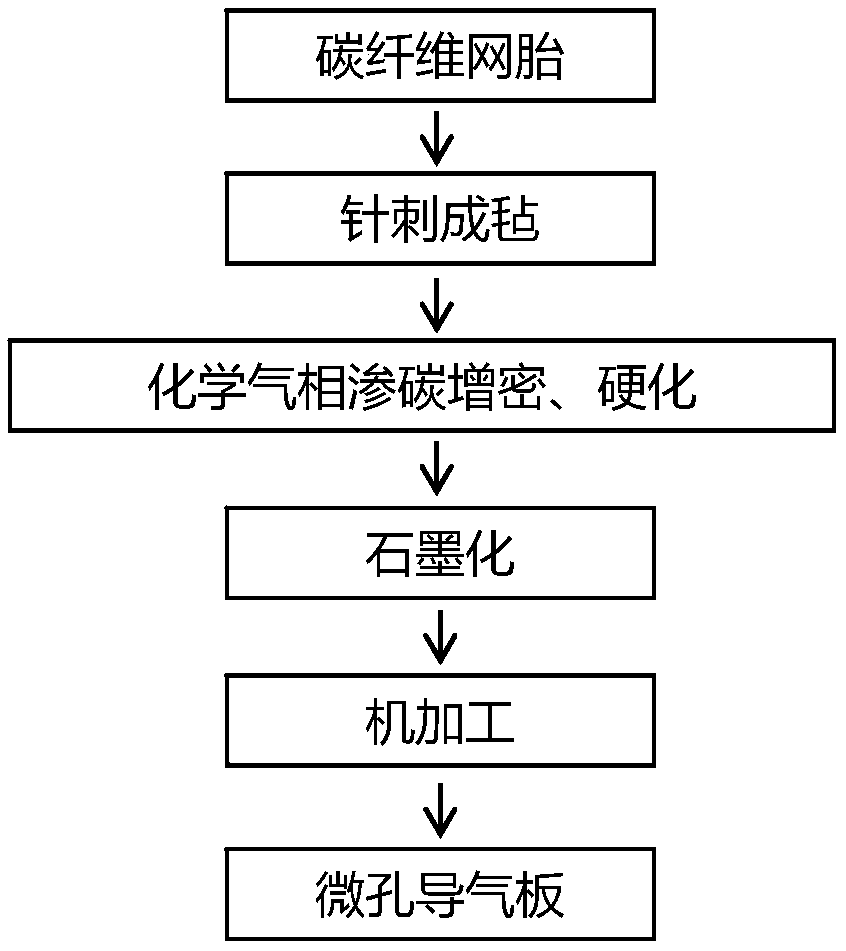

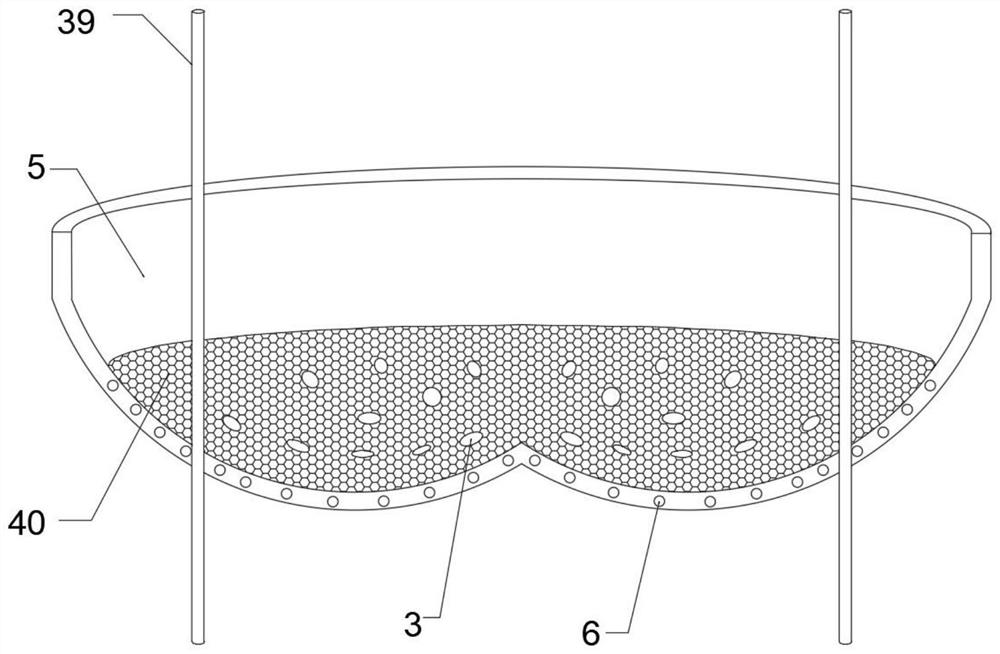

Preform structure of carbon/carbon composite material thick plate and thick plate preparation method

PendingCN109291544AHomogeneous chemical vapor carburizingReduce density differenceLamination ancillary operationsLaminationCarbon compositesFiber

The invention relates to a preform structure of a carbon / carbon composite material thick plate and a thick plate preparation method. The preform structure consists of a core layer and tire net layers.The core layer is a carbon fiber felt with a thickness of 20-40mm. The tire net layers are carbon fiber mesh tires needle punched on both sides of the core layer. The thick plate preparation method includes: placing the preform structure in a chemical vapor carburizing furnace, conducting chemical vapor carburizing densification, and then performing graphitization treatment and machining in order; and repeating the above technological process until the density of the carbon / carbon composite material reaches the design requirement. The preform structure of the carbon / carbon composite materialthick plate utilizes the mesh tire layers as the carbon source gas transmission medium to guide the carbon source gas evenly to the core layer, thus lowering the density difference of the core layer thickness direction, and solving the surface hole sealing problem of the core layer. The prepared the high density carbon / carbon composite material thick plate has a thickness of 20-40mm and a densityof 0.4-0.8g / cm<3>.

Owner:CENT SOUTH UNIV

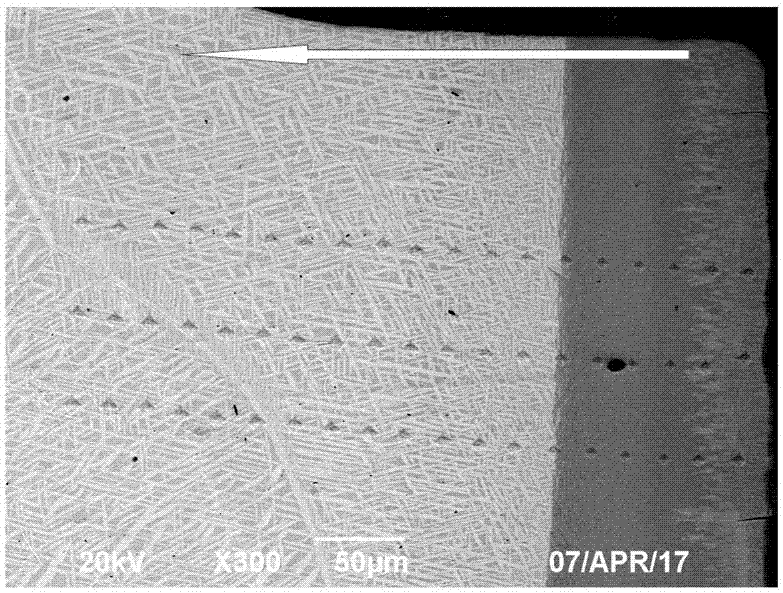

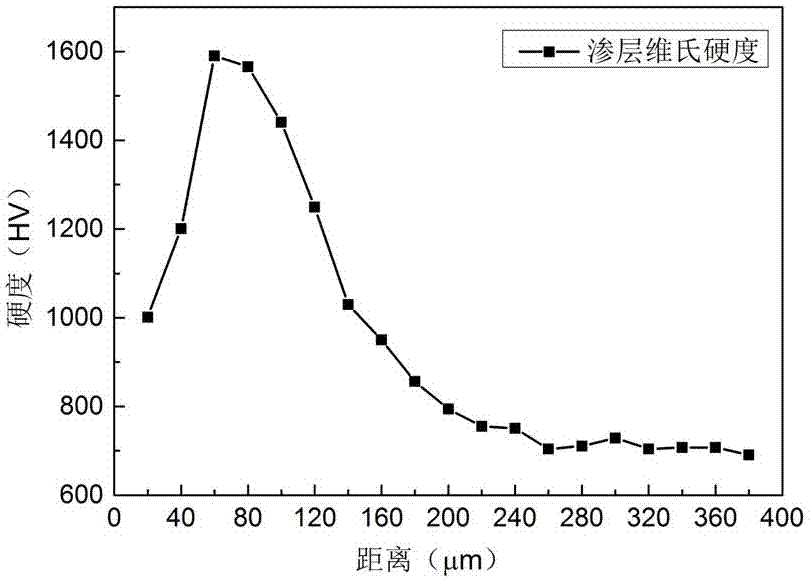

High-entropy alloy surface carburizing modification method

ActiveCN107955928AHigh surface hardnessInterface straightSolid state diffusion coatingActivated carbonAfter treatment

The invention discloses a high-entropy alloy surface carburizing modification method. The method comprises the steps that (1), an HfZrTiTa high-entropy alloy is pre-treated; (2), active carbon is selected as a carburizing agent, a carburizing container is naturally filled with the carburizing agent, and the pre-treated HfZrTiTa high-entropy alloy is buried into the upper middle portion of the carburizing agent; (3), the carburizing container is sealed; and (4), the sealed carburizing container is placed into a heating device, heating is conducted till the temperature is 700-900 DEG C, then heat preservation is conducted for 2-10 h, after treatment is finished, the carburizing container is taken out for air cooling, then a sample subjected to carburizing treatment is taken out to be subjected to ultrasonic washing and drying, and a high-entropy alloy with the surface subjected to carburizing modification is obtained. According to the high-entropy alloy surface carburizing modification method, the surface hardness and the high-temperature oxidation resistance of the HfZrTiTa high-entropy alloy can be effectively improved at the same time.

Owner:NAT UNIV OF DEFENSE TECH

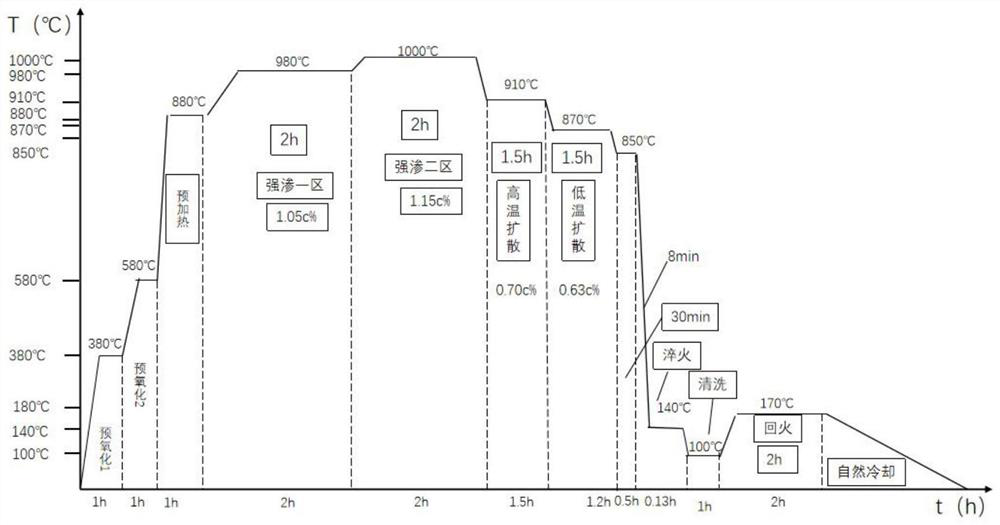

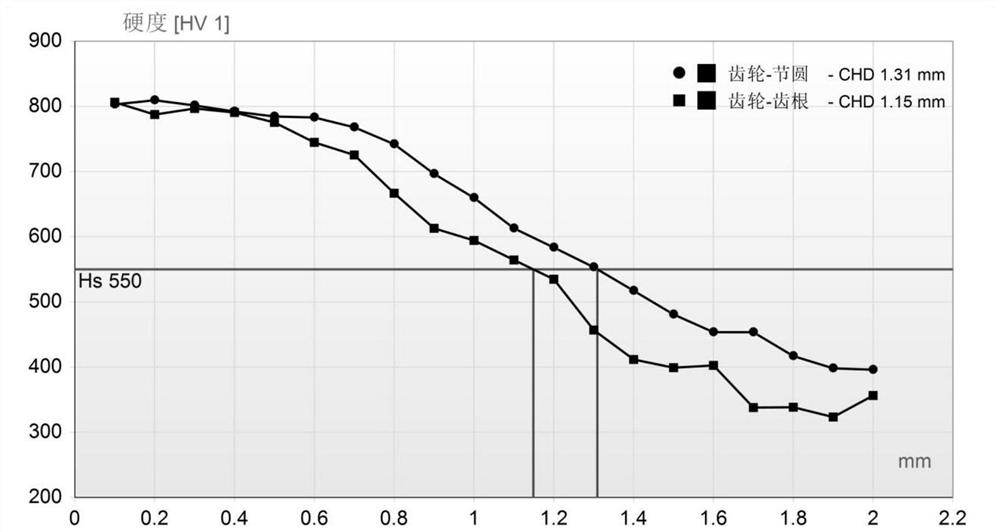

Cr-Mo steel for high-temperature carburizing, carburizing method of Cr-Mo steel and carburizing component

ActiveCN113913685ARealize the purpose of high temperature carburizingCarburizing High EfficiencySolid state diffusion coatingCarbon potentialImpurity

The invention relates to Cr-Mo steel for high-temperature carburizing, a carburizing method of the Cr-Mo steel and a carburizing component. The Cr-Mo steel for high-temperature carburizing comprises the following chemical components of, in percentage by weight, 0.13%-0.25% of C, less than or equal to 0.25% of Si, 0.55%-0.90% of Mn, less than or equal to 0.035% of P, 0.020%-0.040% of S, 0.85%-1.25% of Cr, 0.017%-0.037% of Al, 0.008%-0.015% of Ti, 0.040%-0.060% of Nb, less than or equal to 15ppm of O, 120ppm-170ppm of N, 0.010%-0.030% of Ni, 0.10%-0.20% of Cu, less than or equal to 0.06% of Mo, less than or equal to 0.04% of V, and the balance Fe and inevitable impurities. According to the Cr-Mo steel for high-temperature carburizing, when the carburizing temperature is larger than or equal to 980 DEG C, the grain size of a part is not larger than 7 grades; and according to the continuous furnace high-temperature carburizing method, the three-section preheating type and low-carbon potential diffusion high-temperature carburizing technology is adopted, high-efficiency carburizing of the part is achieved, on the premise that it is guaranteed that the carburizing layer depth of the part is 1.1-1.6 mm, the carburizing heat treatment period can be shortened to 13.2 h, the carburizing time is shortened to 7.2 h, and the carburizing efficiency is improved by 25%-30% relative to the carburizing efficiency at the temperature of 920-930 DEG C.

Owner:DONGFENG COMML VEHICLE CO LTD

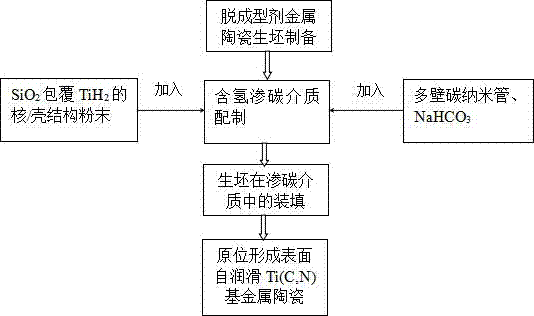

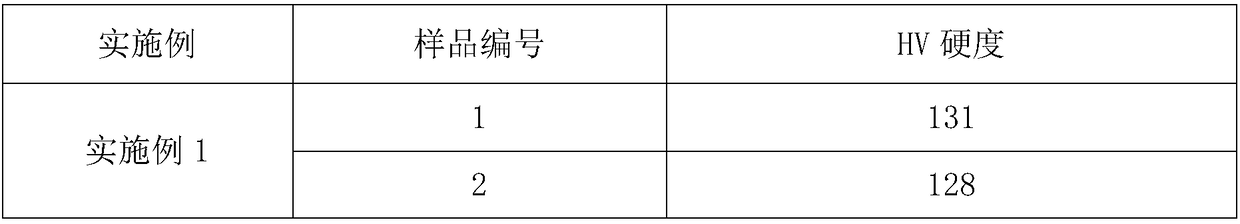

In-situ preparation method of Ti (C,N) based metal ceramic with self-lubricating surface

ActiveCN107142404AIncrease surface areaSmall granularitySolid state diffusion coatingPorosityHydrogen

The invention discloses an in-situ preparation method of Ti (C,N) based metal ceramic with a self-lubricating surface. The in-situ preparation method of Ti (C,N) based metal ceramic with self-lubricating surface is characterized by comprising the steps of firstly, keeping warm for 2 to 4h at the temperature of 500 to 650 DEG C, and forming a metal ceramic green body without a forming agent and with the porosity being 25 percent to 40 percent; then mixing SiO2-coated TiH2 core / shell structure powder, a multiwalled carbon nanotube with the outer diameter being less than 8nm, the length being less than 30mum and the specific surface area being larger than 350m<2> / g, and NaHCO3 according to the weight percent being 2:1:1 for preparing to obtain a hydrogen-containing carburizing medium; embedding the green body into the hydrogen-containing carburizing medium, and compacting under the pressure of 5 to 15MPa; and finally carrying out liquid-phase sintering so as to in-situ form the Ti (C,N) based metal ceramic with the self-lubricating surface. The in-situ preparation method provided by the invention solves the problems of severe grain growth, long carburizing time and low efficiency existed in an existing process, and the metal ceramic with the self-lubricating surface is in-situ formed during a sintering process.

Owner:SICHUAN UNIV

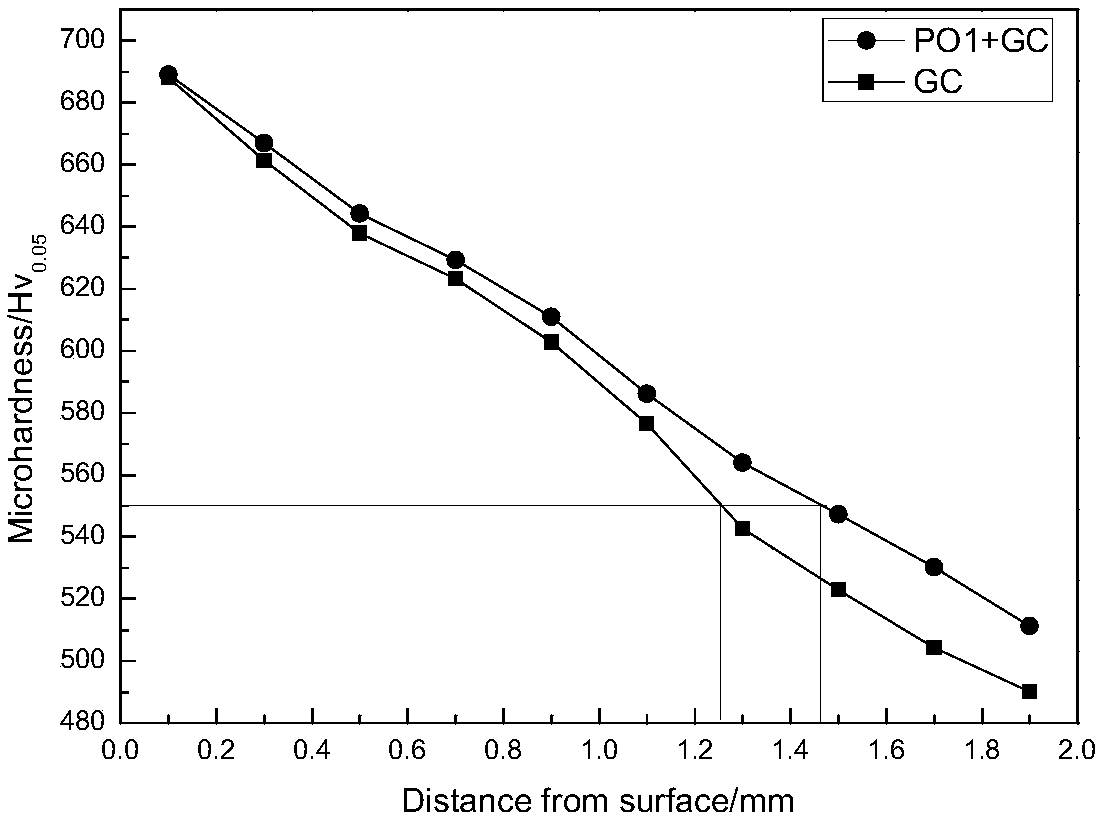

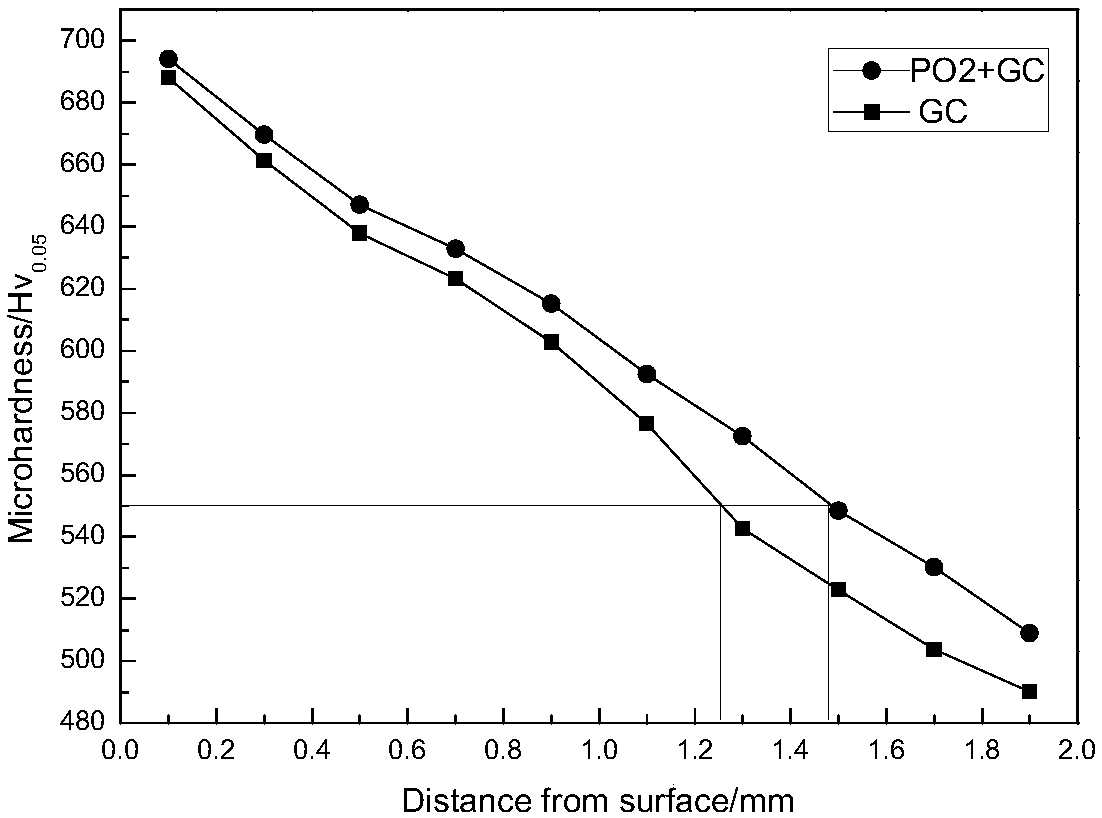

Pre-oxidation technology for improving wind power gear gas carburizing efficiency

InactiveCN108588387AImprove wettabilityImprove adsorption capacitySolid state diffusion coatingFurnace typesElectricityActivated carbon

The invention relates to a pre-oxidation technology for improving wind power gear gas carburizing efficiency. The pre-oxidation technology includes the following steps that carburizing steel is slicedinto a gear-shaped sample; the sample is subjected to thermal refining; the sample is subjected to ultrasonic cleaning and drying after grinding; the sample is placed in a program control box type electric stove and is subjected to the pre-oxidation treatment; and the sample is placed into a gas carburizing multipurpose stove, and is subjected to carburizing, quenching and tempering treatment. The pre-oxidation technology has the beneficial effects that the pre-oxidation treatment is carried out before the gas carburizing, an oxidation film layer is formed on the sample surface, wettability of the sample surface is increased and the pre-oxidation treatment is beneficial for absorbing activated carbon atoms; the oxidation film is preferentially restored during the process of gas carburizing, through the defect of existing a plurality of holes on the sample surface, permeating of the activated carbon atoms into the base body, and a quick channel is provided for diffusing the carbon atoms; and gas carburizing efficiency is greatly improved, carburizing time is greatly shortened in the condition of reaching the same layer depth of the carburizing and the energy is saved.

Owner:CHANGZHOU UNIV

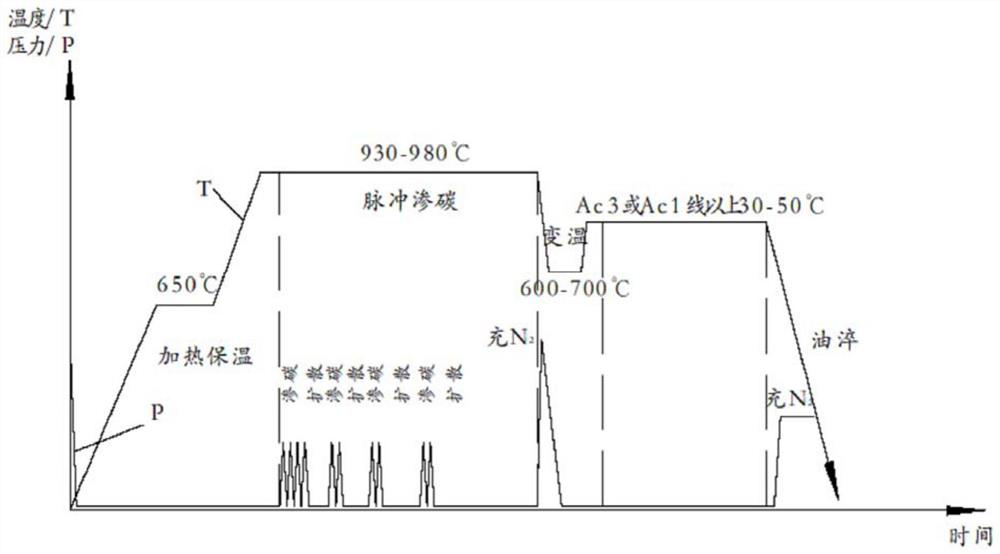

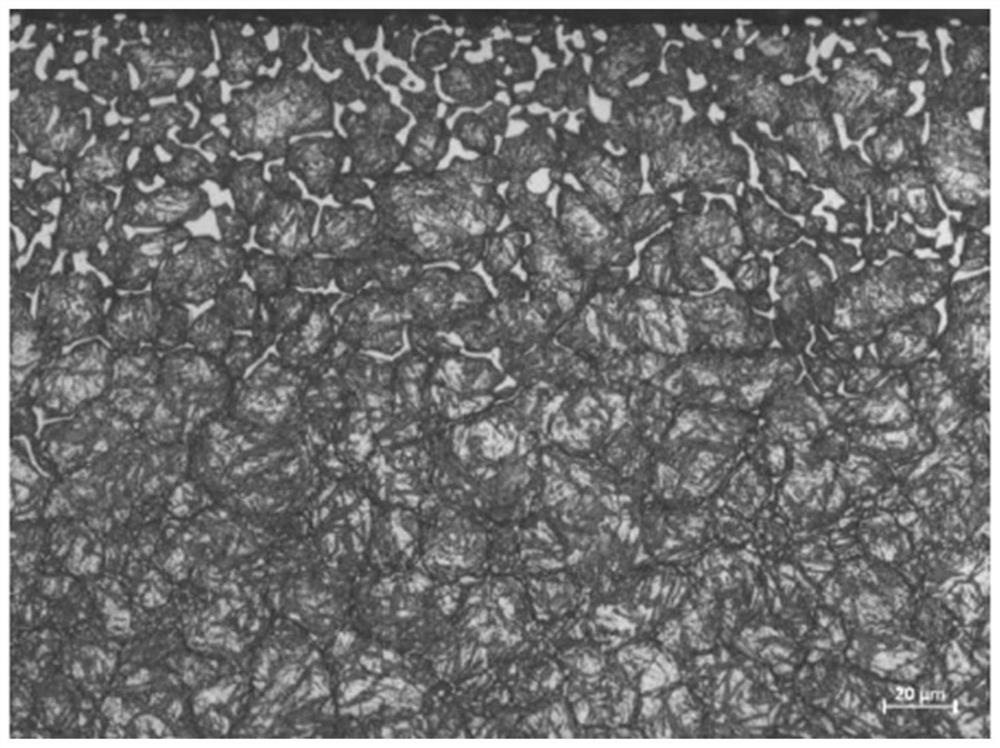

Vacuum carburizing method for obtaining dispersed fine carbides

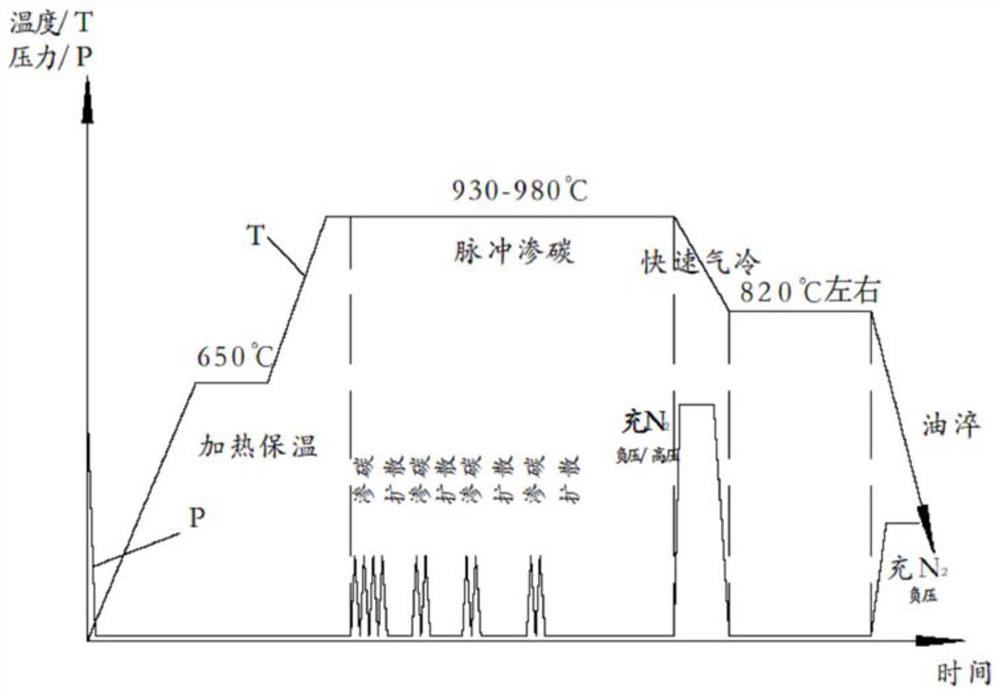

PendingCN113737125AReduce distortionIncrease surface carbon contentSolid state diffusion coatingHigh concentrationCarbide

The invention discloses a vacuum carburizing method for obtaining dispersed fine carbides. The vacuum carburizing method comprises a heating and heat preservation stage, a pulse carburizing stage, a carbide precipitation and spheroidizing stage and a quenching stage. The pulse carburizing stage refers to a high-concentration carburizing process in which carburizing / diffusion is alternated for multiple times, and a required surface carbon concentration gradient is formed; and the carbide precipitation and spheroidizing stage refers to immediately inflating to quickly cool the surface of a workpiece to a certain temperature above an Ac1 line and keeping the temperature for a period of time, so that carbides are precipitated in austenite and form dispersed distribution, and meanwhile, the workpiece reaches the quenching temperature by using the waste heat of the core part. According to the method, the structure performance and the deformation amount are both considered, on one hand, fine carbides which are high in carbon content (1%-1.5%) and are distributed in a dispersed mode are obtained, the effect that the outside is hard and the inside is tough is achieved, and on the other hand, quenching distortion is reduced, and size control is achieved; and the method is short in process time, high in carburizing efficiency, low in equipment operation cost, excellent in product surface performance and small in deformation, and the obdurability of the material is exerted to the maximum extent, so that the service performance of the workpiece is improved.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

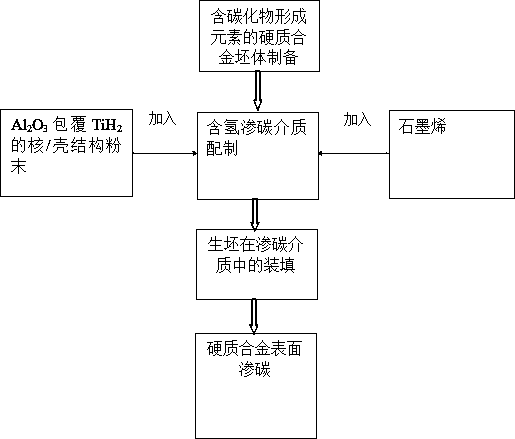

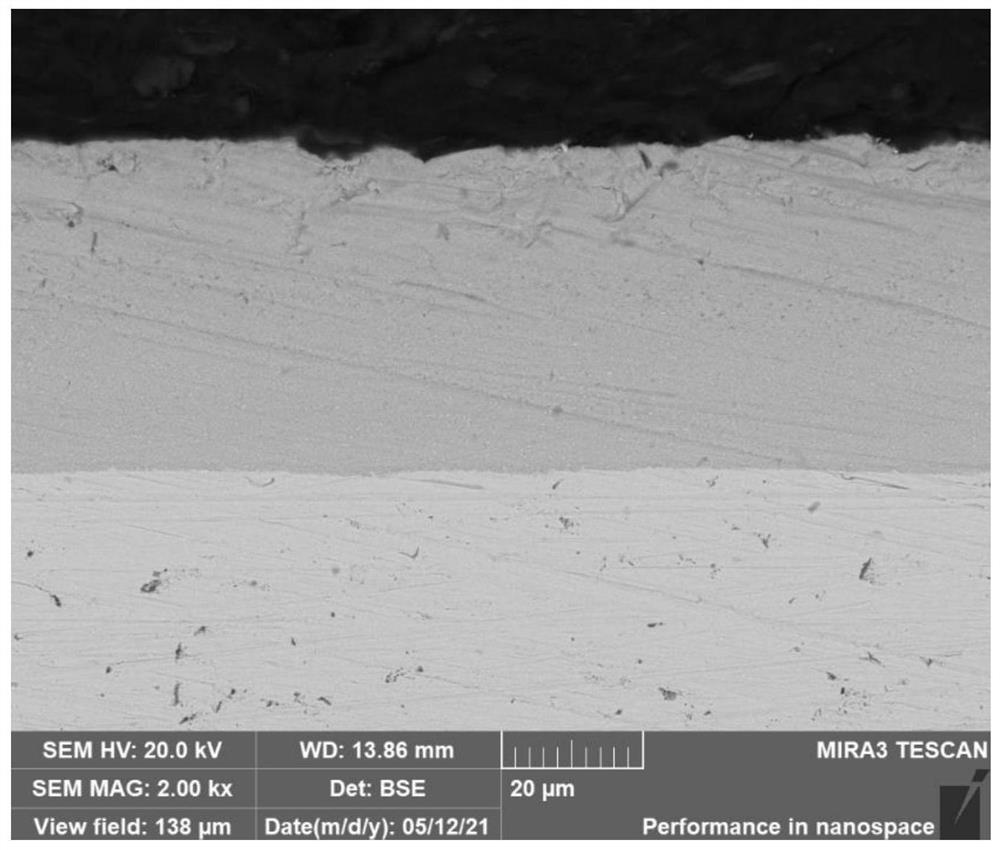

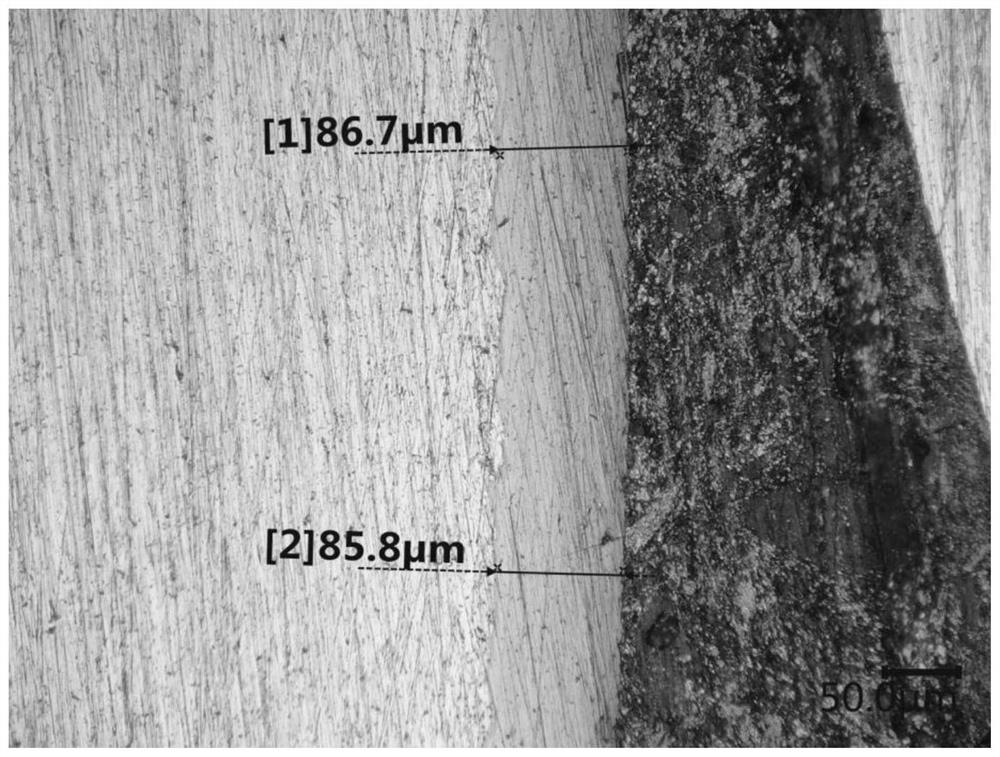

A kind of hard alloy surface carburizing method

ActiveCN107142445BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusHydrogenAlloy

The invention discloses a method for carburizing the surface of cemented carbide, which is characterized in that it first heats the temperature at 550-700°C for 1-2 hours to form a cemented carbide blank containing carbide-forming elements; 2 o 3 coated TiH 2 Core / shell structure powder with thickness less than 3nm, number of layers less than 3 and specific surface area greater than 250m 2 / g of graphene and two substances are mixed according to the weight percentage of 2:3 to prepare a hydrogen-containing carburizing medium; then the green body is embedded in the hydrogen-containing carburizing medium and compacted under a pressure of 5~15MPa; finally, the liquid phase Sintering to realize carburizing of cemented carbide surface. The invention overcomes the problems of severe crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes carburizing of the hard alloy surface in the sintering process.

Owner:SICHUAN UNIV

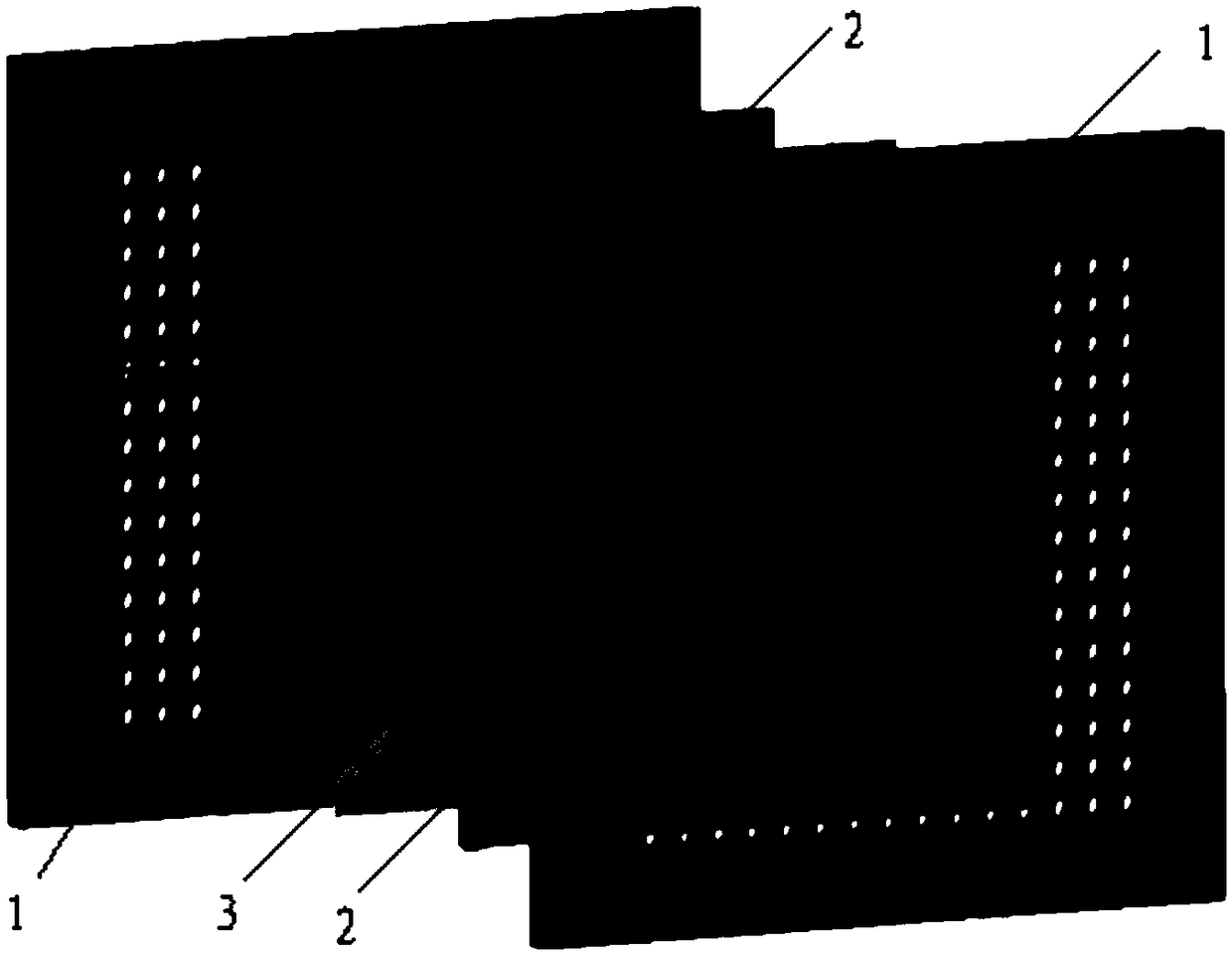

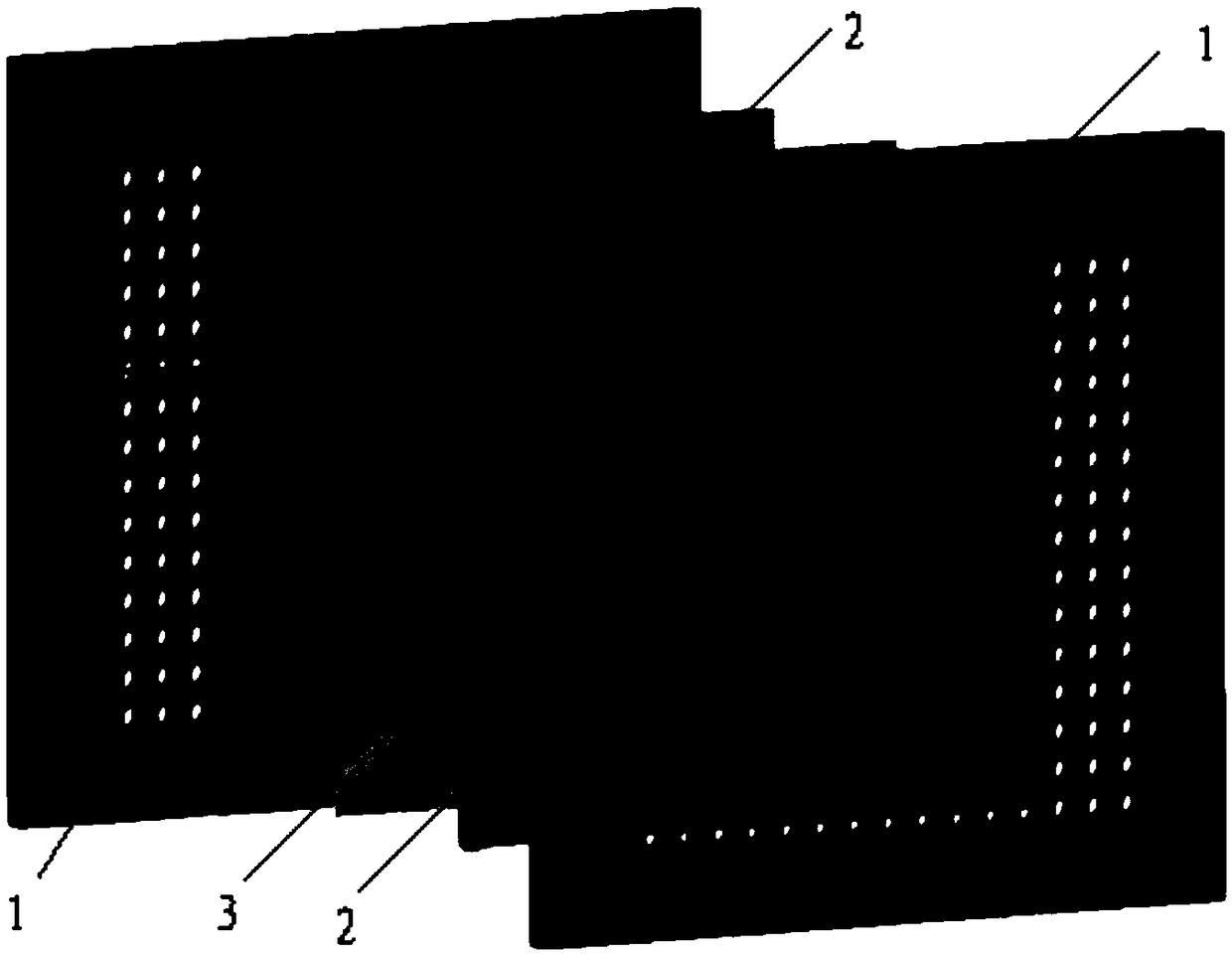

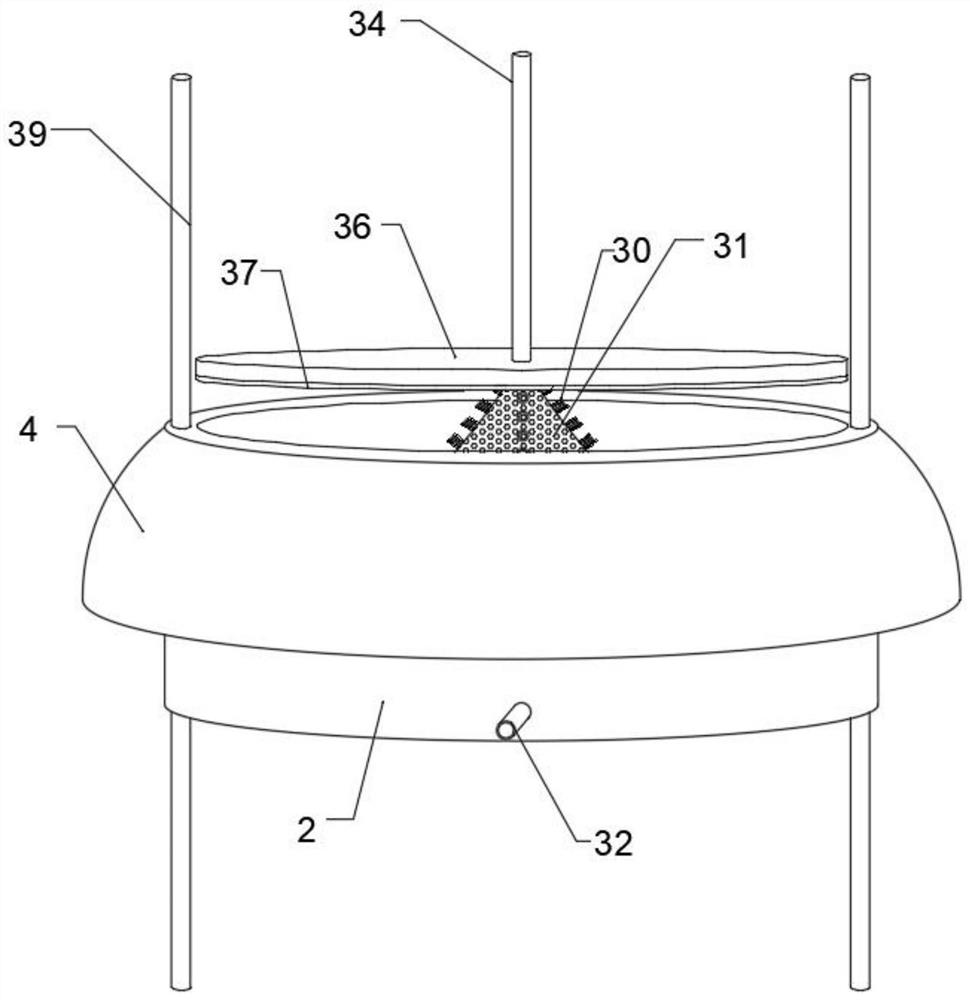

Clamping device for preparing ultrathin carbon/carbon composite panel

The invention relates to a clamping device for preparing an ultrathin carbon / carbon composite panel. The clamping device comprises hollow graphite plates and microporous gas guiding plates, wherein the clamping device is formed through superposing a hollow graphite plate, a microporous gas guiding plate, an ultrathin carbon / carbon composite blank with the thickness of 0.2mm to 0.8mm, a microporousgas guiding plate and a hollow graphite plate, and the hollow graphite plates located at two sides are clamped along a superposition direction. According to the clamping device disclosed by the invention, the structure is simple and reasonable, effective passages of carbon source gas can be constructed between the hollow graphite plates and the ultrathin carbon / carbon composite blank, and the carbon source gas is uniformly guided to the ultrathin carbon / carbon composite blank, so that the problems in density uniformity and deformation of chemical vapor carburization of the blank are solved; and the ultrathin carbon / carbon composite panel with uniform density and smooth surface is prepared and has the density of 1.7g / cm<3> to 2.0g / cm<3> and the thickness of 0.2mm to 0.8mm.

Owner:CENT SOUTH UNIV

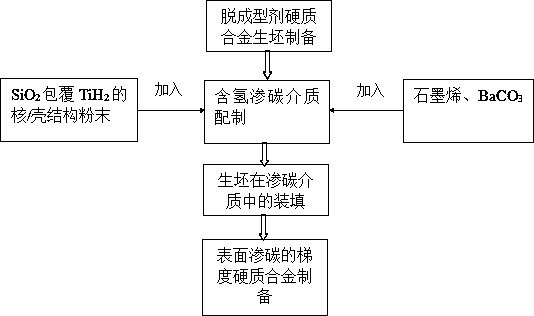

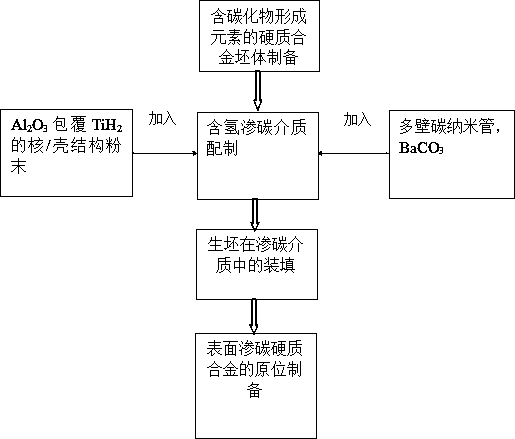

A kind of surface carburized gradient cemented carbide preparation method

ActiveCN106987752BIncrease surface areaImprove adsorption capacityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a method for preparing surface carburized gradient cemented carbide, which is characterized in that it first heats the temperature at 550-750°C for 2-4 hours to form a cemented carbide product with a porosity of 25%-40% and removes the forming agent. blank; then SiO2-coated TiH2 core / shell structure powder, graphene with a thickness of less than 3nm, a number of layers less than 3 layers and a specific surface area greater than 250m2 / g, and BaCO3 are prepared by mixing 1:2:1 by weight percentage Hydrogen-containing carburizing medium; then the green body is buried in the hydrogen-containing carburizing medium and compacted under a pressure of 5-15MPa; finally, liquid-phase sintering is carried out to prepare a surface-carburized gradient cemented carbide. The invention overcomes the problems of serious grain growth, long carburizing time and low efficiency in the prior art, and prepares surface carburized gradient hard alloy in the sintering process.

Owner:SICHUAN UNIV

Device for preparing ultrathin carbon/carbon composite material panel and preparation method of panel

The invention provides a device for preparing an ultrathin carbon / carbon composite material panel and a preparation method of the panel. The device comprises a hollowed graphite plate and a micro-poreair guide plate, wherein the hollowed graphite plate and the micro-pore air guide plate are stacked to form one supporting plate; one ultrathin carbon / carbon composite material blank is clamped between the micro-pore air guide plates of the two supporting plates; the two supporting plates are fastened by utilizing a fastening part to form the device for preparing the ultrathin carbon / carbon composite material panel. The preparation method of the panel comprises the steps of putting the device into a chemical vapor deposition furnace and carrying out chemical vapor carburization and densification. According to the device provided by the invention, an effective channel of carbon source gas is constructed between the hollowed graphite plate and the ultrathin carbon / carbon composite materialblank, and the carbon source gas is uniformly guided to the ultrathin carbon / carbon composite material blank, so that the problems of density uniformity and deformation of the chemical vapor carburization of the blank are solved; the ultrathin carbon / carbon composite material panel with uniform density and flat surface is prepared, the density is 1.7 to 2.0g / cm<3> and the thickness is 0.2 to 0.8mm.

Owner:CENT SOUTH UNIV

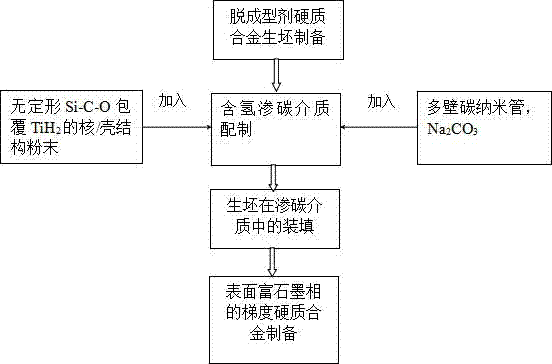

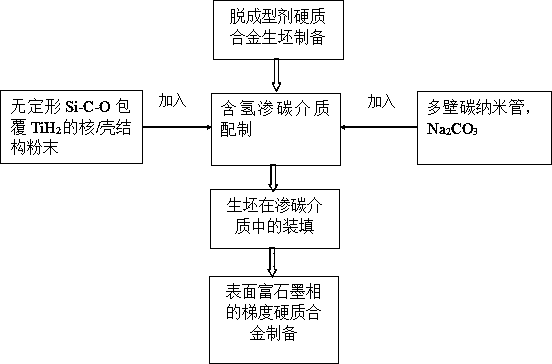

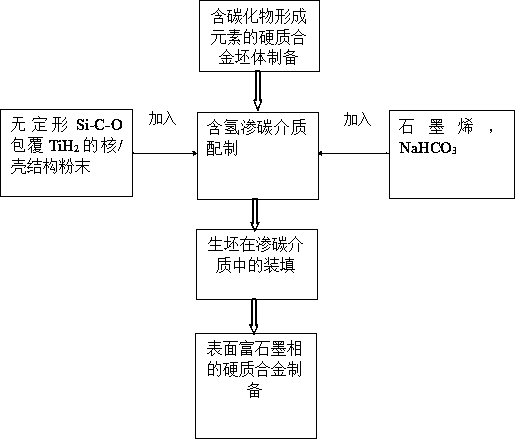

Preparing method for gradient hard alloy with surface rich in graphite phase

ActiveCN107058843AIncrease surface areaLarge granularityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a preparing method for a gradient hard alloy with the surface rich in graphite phase. The preparing method is characterized in that firstly, heat preservation is conducted for 2-4 h at the temperature ranging from 550 DEG C to 750 DEG C, and a hard alloy raw blank removing a forming agent is formed, wherein the porosity of the hard alloy raw blank ranges from 25% to 40%; then, the three substances including amorphous Si-C-O wrapping TiH2 core / shell structure powder, a multi-wall carbon nano tube and Na2CO3 are mixed according to the weight percent of 1:2:1, and then a hydrogen-containing carburizing medium is prepared, wherein the outer diameter is smaller than 8 nm, the length is smaller than 30 microns, and the specific surface area is larger than 350 m<2> / g; then, the raw blank is embedded in the hydrogen-containing carburizing medium and is compacted under the pressure of 5-15 MPa; and finally, liquid phase sintering is conducted, and the gradient hard alloy with the surface rich in graphite phase is prepared. The preparing method solves the problems that in the existing technology, grain growth is serious, the carburization time is long, and efficiency is low; and in the sintering process, the gradient hard alloy with the surface rich in graphite phase is prepared in the sintering process.

Owner:SICHUAN UNIV

Metal ceramic wear resisting material and preparation method thereof

The invention provides a metal ceramic wear resisting material. The metal ceramic wear resisting material is characterized by comprising the following components in parts by weight: 20-30 parts of boron nitride, 25-35 parts of chromium carbide, 5-10 parts of scandium nitride, 5-10 parts of molybdenum nitride, 8-10 parts of niobium boride, 8-10 parts of titanium silicide, 4-6 parts of boron silicide, 1-3 parts of carbon fiber, 1-4 parts of amido montmorillonoid, 1-5 parts of cerium powder, 1-3 parts of strontium powder, and 3-6 parts of zirconium powder. The invention further discloses a preparation method of the metal ceramic wear resisting material. The metal ceramic wear resisting material is low in preparation cost, high in toughness and wear resistance, excellent in high-temperature resistance and corrosion resistance and long in service life.

Owner:HUNAN CHANGZHONG MACHINERY

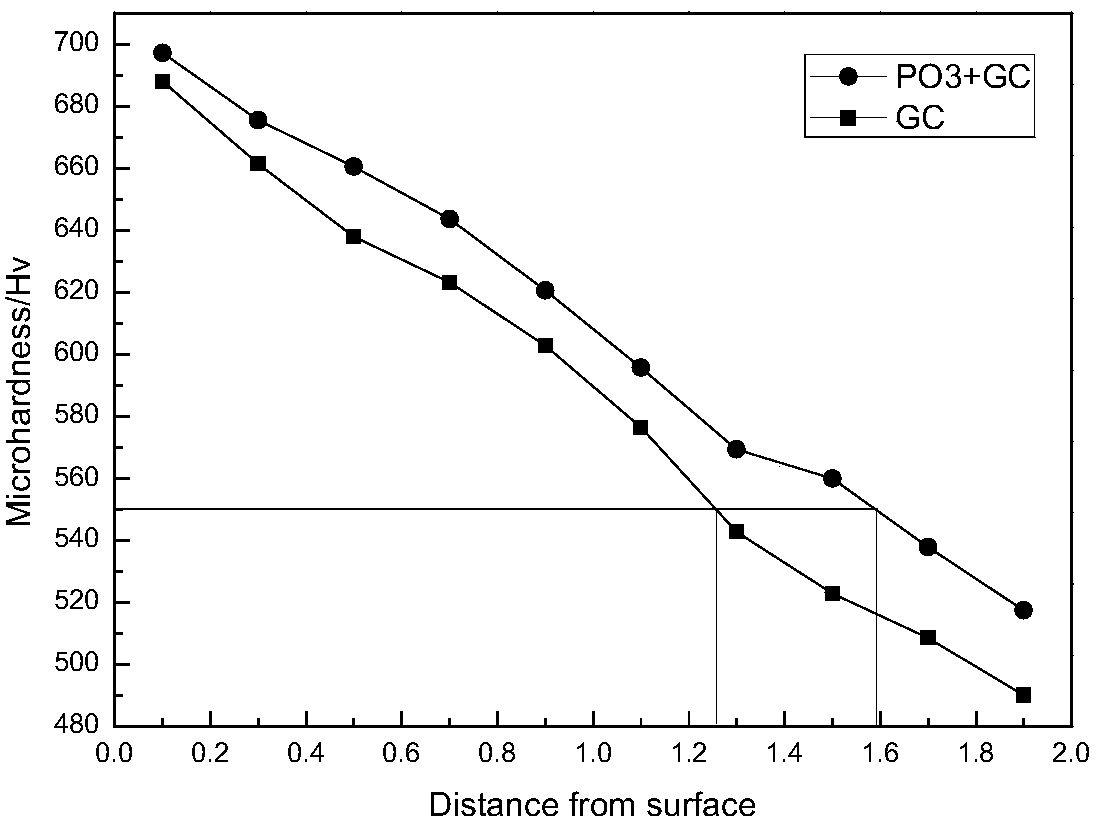

Laser shock technology for improving gas carburizing efficiency of wind power gear

InactiveCN108441624AImprove efficiencyIncreasing the thicknessSolid state diffusion coatingDislocationMicrostructure

The invention relates to a laser shock technology for improving the gas carburizing efficiency of a wind power gear. The technology comprises the following steps: processing and cutting carburized steel to form a sample; hardening and tempering the sample; placing the sample on a laser shock peening test platform, and performing laser shock; and adding the sample in a gas carburizing multipurposefurnace, and successively carburizing, quenching and tempering the sample. The technology has the following advantages: the laser shock pretreatment carried out before gas carburization makes the surface of the sample deformed and strengthened in order to increase the surface roughness, increase the dislocation density in the microstructure, refine the crystal grain and form a high residual stress; and high-density dislocations and other defects in the carburizing process provide many adsorption sites and diffusion channels for carbon atoms in order to significantly increase the gas carburization efficiency, increase the thickness of the obtained carburized layer and greatly shorten the carburizing time on the basis of obtaining the same carburized layer depth, so energy is saved, and theproduction cost is reduced.

Owner:CHANGZHOU UNIV

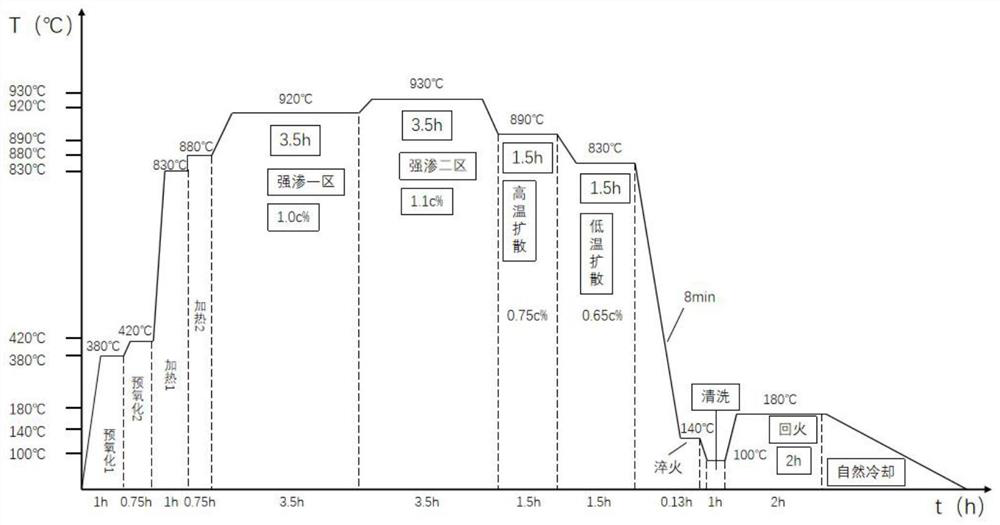

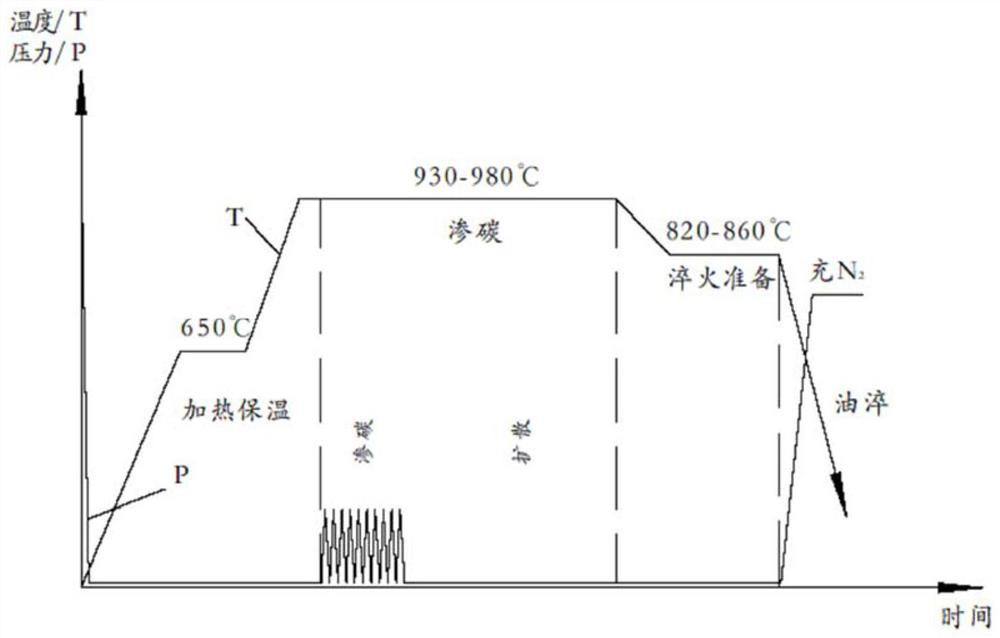

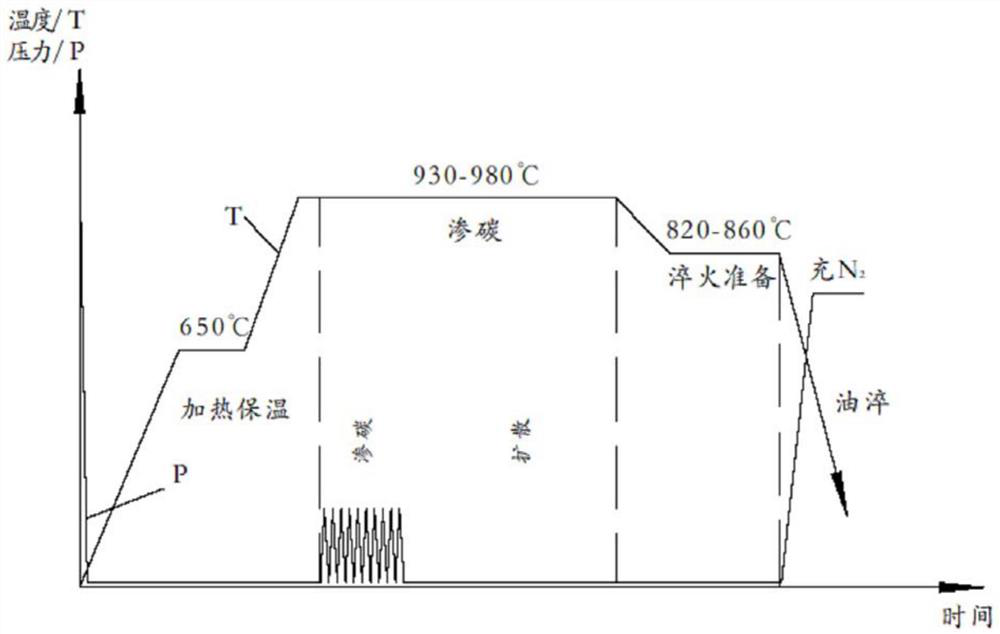

A rapid carburizing heat treatment process for drive gears used in automobile differentials

ActiveCN105154633BIncrease pressureIncrease carbon concentrationSolid state diffusion coatingGear driveQuenching

The invention provides a rapid carburizing heat treatment process for a driving gear used in an automobile differential, comprising the following steps: 1) heating up; 2) strong infiltration; 3) diffusion; 4) quenching; 5) cleaning; 6) tempering. The carburizing period of the treatment process is obviously shortened, the production efficiency is improved, the output is increased, the energy saving effect is achieved, the carburizing cost is obviously reduced, and the economic benefit is significantly improved.

Owner:JIANGSU BAOJIE FORGING

Vacuum carburizing method for obtaining dispersed fine carbides

PendingCN113737126AShort processImprove carburizing efficiencySolid state diffusion coatingHeat treatment process controlCarburizingHeat conservation

The invention discloses a vacuum carburizing method for obtaining dispersed fine carbides. The vacuum carburizing method comprises a heating and heat preservation stage, a pulse carburizing stage, a temperature changing stage and a quenching stage; the pulse carburizing stage refers to a high-concentration carburizing process in which carburizing and diffusion are alternated for multiple times; in the temperature changing stage, after carburizing is finished, heating is stopped, air inflation and rapid cooling are carried out to reach a certain temperature below the Ac1 line, in addition, heat preservation is carried out for a period of time, then the temperature is immediately increased to the quenching temperature, namely 30-50 DEG C above the Ac3 line or the Ac1 line, and heat preservation is carried out till a workpiece is uniformly austenitized; and the quenching stage is carried out by adopting one of high-pressure gas quenching or oil quenching. According to the vacuum carburizing method, the structure can be refined, meanwhile, the surface carbon content is increased, the dispersed fine carbides (mainly spherical) are obtained, the obdurability of the material is exerted to the maximum degree, and therefore the service performance of the workpiece is improved.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

A kind of preparation method of gradient cemented carbide with graphite-rich phase on the surface

ActiveCN107058843BIncrease surface areaLarge granularityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a preparation method of a gradient cemented carbide with a graphite-rich surface, which is characterized in that it first heats the cemented carbide at 550-750°C for 2-4 hours to form a cemented carbide with a porosity of 25%-40%. Green body; then amorphous Si-C-O-coated TiH2 core / shell structure powder, multi-walled carbon nanotubes with outer diameter less than 8nm, length less than 30μm and specific surface area greater than 350m2 / g, Na2CO3 three kinds of substances by weight The ratio of 1:2:1 is mixed to prepare a hydrogen-containing carburizing medium; then the green body is embedded in the hydrogen-containing carburizing medium and compacted under a pressure of 5~15MPa; finally, liquid phase sintering is carried out to prepare a surface graphite-rich phase gradient cemented carbide. The invention overcomes the problems of severe grain growth, long carburizing time and low efficiency in the prior art, and prepares gradient hard alloy with graphite-rich phase on the surface during the sintering process.

Owner:SICHUAN UNIV

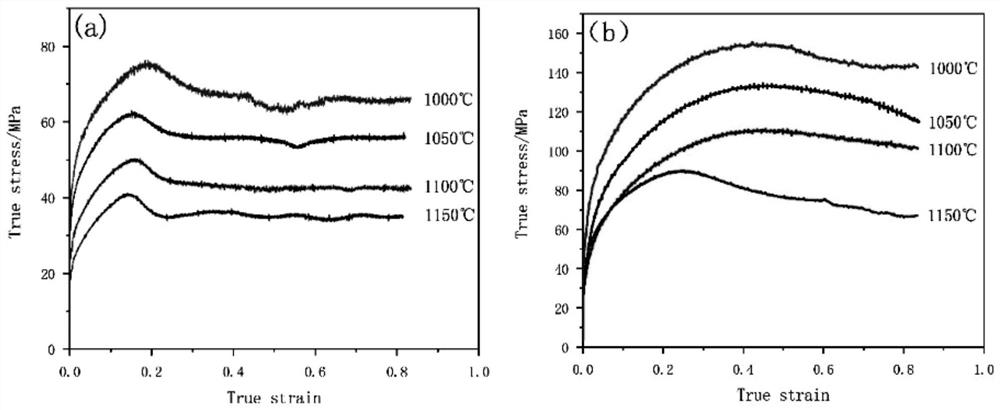

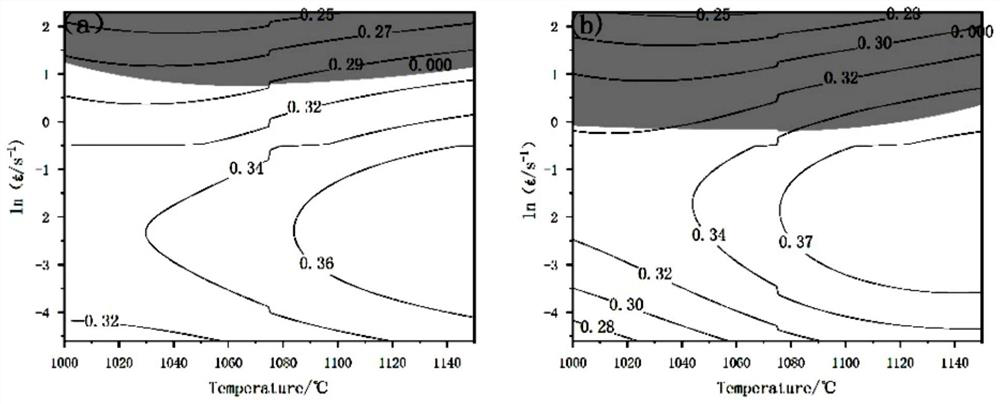

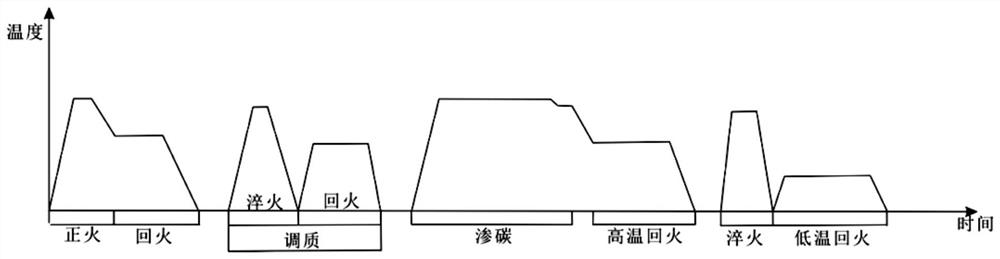

Hot working method of high-performance small-distortion carburized outer ring

PendingCN113862445AFully brokenReduce growth timeSolid state diffusion coatingFurnace typesTemperingHot working

The invention discloses a hot working method of a high-performance small-distortion carburized outer ring, relates to the technical field of hot working methods, and solves the technical problems of complex manufacturing process, non-uniform carburized layer depth and poor quality consistency of the existing outer ring, and is suitable for forging and heat treatment of the outer ring made of 17Cr2Ni2MoVNb steel, the diameter of the outer ring is 150-200 mm, and the wall thickness of the outer ring is 8-10 mm. The hot working method comprises the following steps of constructing a true stress-strain curve and a hot working diagram, forging, normalizing and tempering at a high temperature, roughly machining, thermal refining, roughly machining a tooth shape and the like, performing gas / liquid composite carburizing and tempering at a high temperature, quenching and tempering at a low temperature. According to the hot working method, the ovality of the carburized and quenched outer ring is controlled to be less than or equal to 0.15 mm, the grain size is greater than or equal to 8.5 grades, and the rotating bending fatigue strength of a furnace sample is greater than or equal to 1000 MPa; and the part has high performance, meanwhile, only small heat treatment deformation exists, and good industrial application value is achieved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

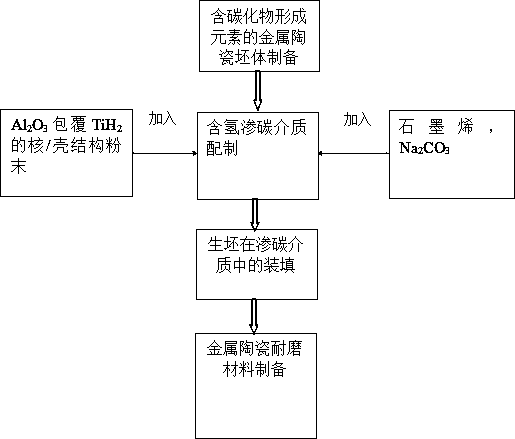

Preparation method of cermet wear-resistant material based on carbide-forming elements promoting carbon migration

ActiveCN107099721BFacilitated DiffusionImprove adsorption capacitySolid state diffusion coatingHydrogenWear resistant

The invention discloses a preparation method of metal ceramic wear resistant material based on carbide forming elements promoting carbon migration. The method is characterized by comprising the following steps: firstly performing heat preservation for 1 to 2 h at 500 to 700 DEG C, so as to form a metal ceramic body containing the carbide forming elements; then mixing core / shell structure powder of Al2O3 coated TiH2, graphene with the thickness being smaller than 3 nm, the number of layers being smaller than 3 and the specific surface area being greater than 250 m<2> / g, and Na2CO3 according to a weight percentage of 3:2:1, so as to prepare a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15 MPa; and finally performing liquid-phase sintering, so as to prepare the metal ceramic wear resistant material based on the carbide forming elements promoting carbon migration. The method overcomes the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the metal ceramic wear resistant material during a sintering process.

Owner:SICHUAN UNIV

A kind of in-situ preparation method of surface carburizing cemented carbide

ActiveCN106987751BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusHydrogenCarbon nanotube

Owner:SICHUAN UNIV

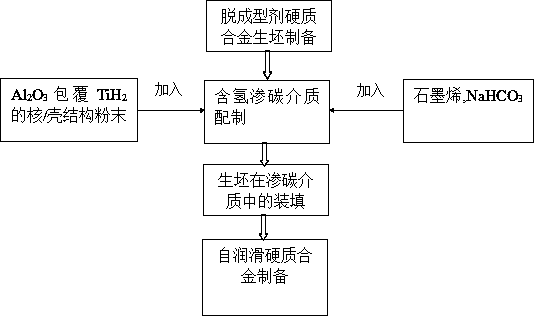

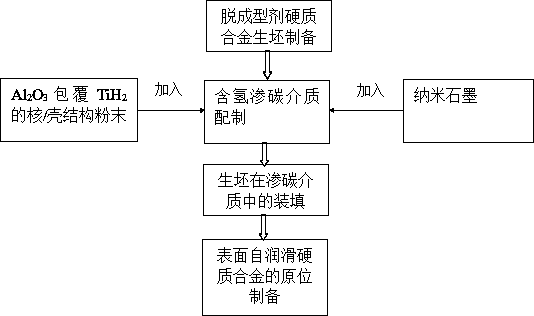

A kind of self-lubricating cemented carbide preparation method

ActiveCN107142409BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityAlloy

The invention discloses a preparation method of a self-lubricating hard alloy. The preparation method of the self-lubricating hard alloy is characterized in that the temperature is kept at 550-750 DEG C for 2-4 hours, so that a forming-agent-free hard alloy green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2, graphene and NaHCO3 are mixed at the weight percentage ratio of 1:2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating hard alloy is achieved in the sintering process. The preparation method of the self-lubricating hard alloy solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating hard alloy is prepared in the sintering process.

Owner:SICHUAN UNIV

Carburizing agent and platinum carburizing method utilizing carburizing agent

InactiveCN108660410AImprove surface strengthQuality improvementSolid state diffusion coatingPlatinumBoron carbide

The invention relates to the technical field of metal treatment, and discloses a carburizing agent. The carburizing agent comprises a carbon supply agent, a seeping catalysis agent, a filling agent and an adhesion agent; and the carbon supply agent is boron carbide, the seeping catalysis agent is barium carbonate, the filling agent is calcium carbonate, and the adhesion agent is dextrin, wherein the boron carbide is 40-50 parts, the barium carbonate is 5-15 parts, the calcium carbonate is 1-2 parts, and the dextrin is 1-2 parts. The carburizing agent has the beneficial effects of being high incarburizing efficiency and capable of easily controlling the carburizing degree; and the carburizing agent is utilized for performing carburizing on platinum, the surface strength of a platinum product can be effectively improved, and therefore the quality of the platinum product is improved, the service life is prolonged, and the surface of the platinum product is smooth, clean and attractive.

Owner:浙江明牌珠宝科技有限公司

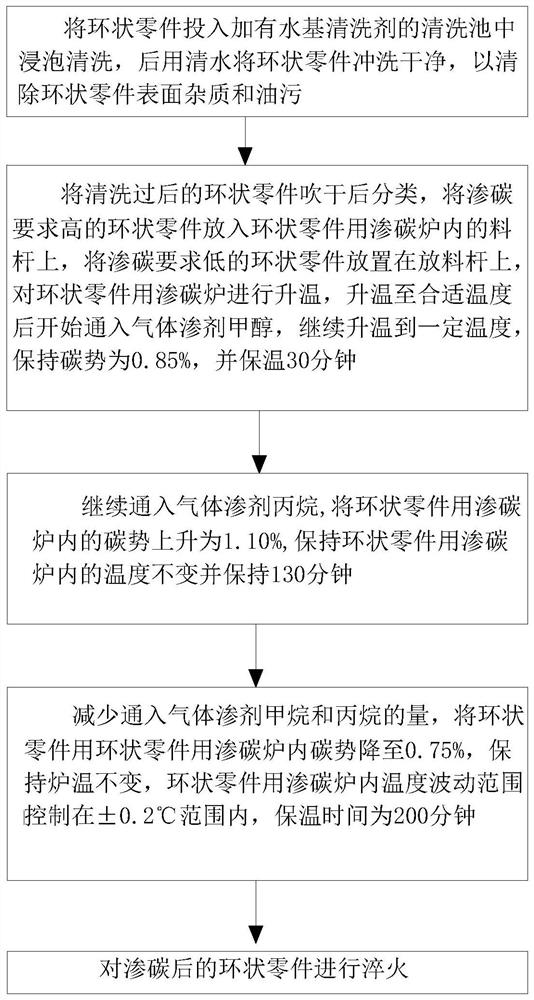

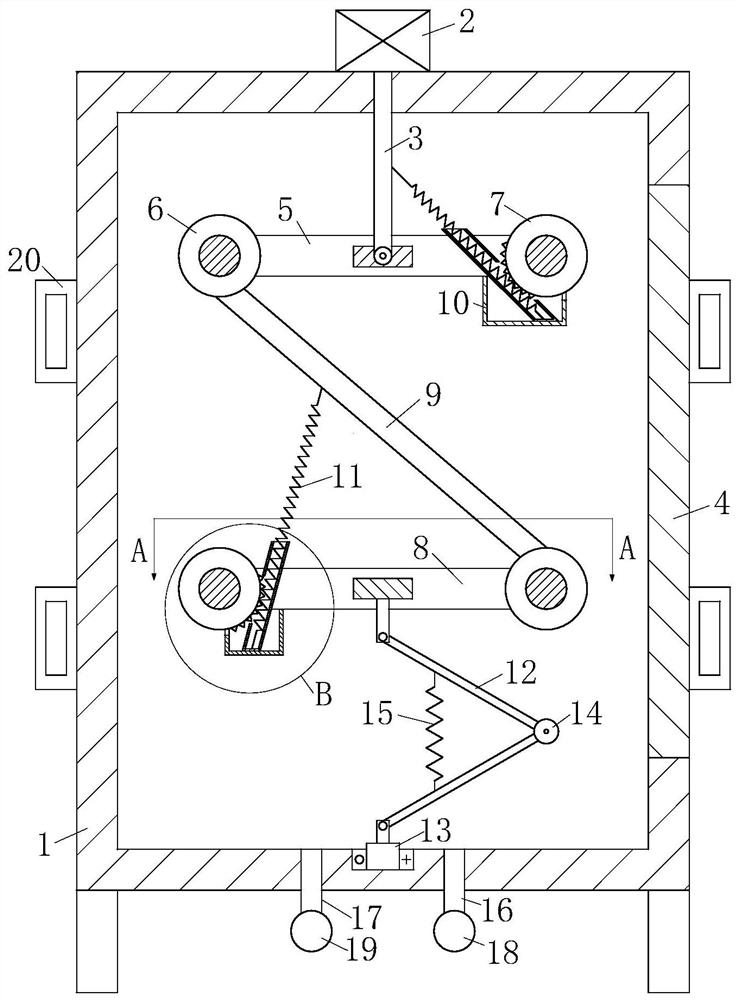

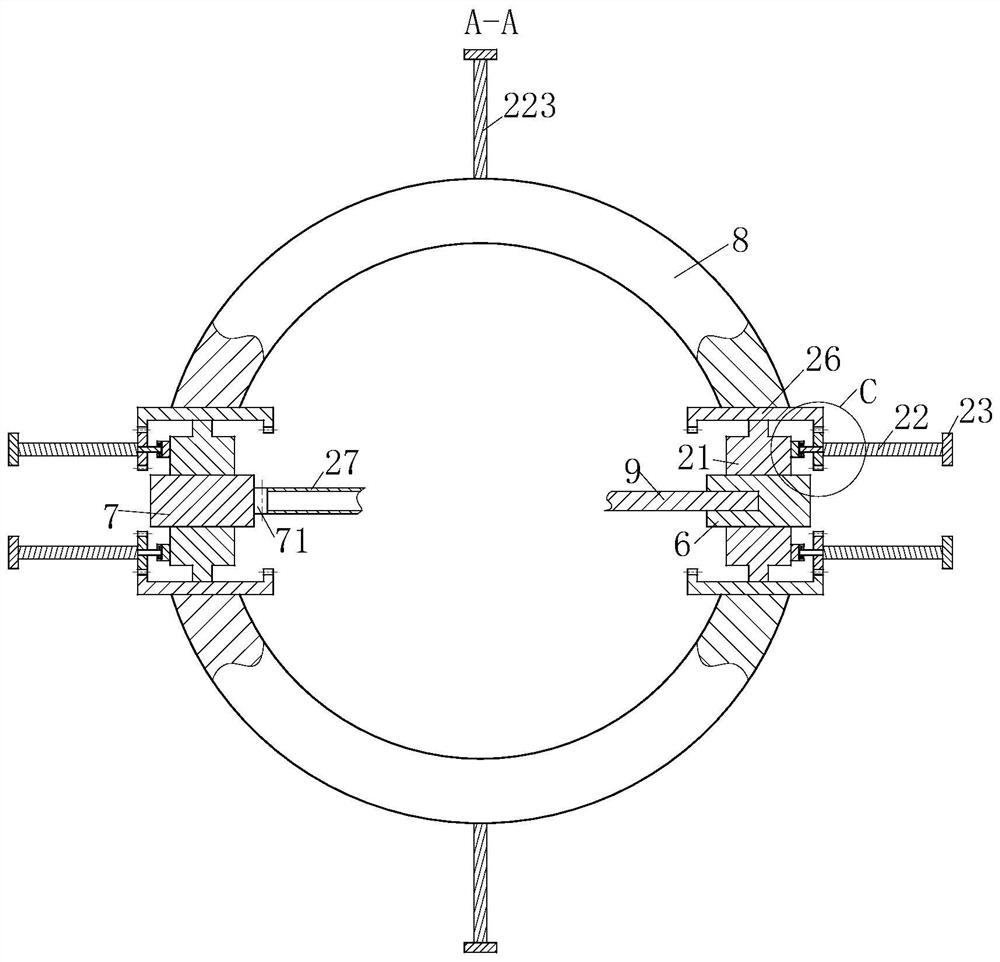

A Carburizing and Quenching Process for Ring Parts

ActiveCN109468577BSimple structureEasy to operateSolid state diffusion coatingFurnace typesCarbon potentialCleansing Agents

The invention relates to the field of heat treatment, in particular to an annular component carburizing and quenching technology. The technology comprises the following steps that annular components are thrown into a cleaning pond to be immersed and cleaned, a water-based cleaning agent is added in the cleaning pond, then, clean water is used for flushing the annular components thoroughly, accordingly, surface impurities and oil dirt of the annular components are removed, and the cleaned annular components are classified after being blown dry; the annular components with the high carburizing requirement are placed in material rods in an annular component carburizing furnace; the annular components with the low carburizing requirement are placed on material containing rods, the space in theannular component carburizing furnace can be sufficiently utilized, the carburizing efficiency is improved, the annular component carburizing furnace is subjected to temperature rise, and gas seepageagent methyl alcohol inflation starts after the temperature is increased to the proper temperature. Through changing of the carbon potential and the temperature in a furnace body, the annular component surface carburizing depth and surface hardness are guaranteed, annular component carburizing and quenching are continuously conducted, accordingly, the technology process is shortened, the transferring and heat treatment cost is reduced, and the production efficiency is improved.

Owner:阜阳全科智能技术设计有限公司

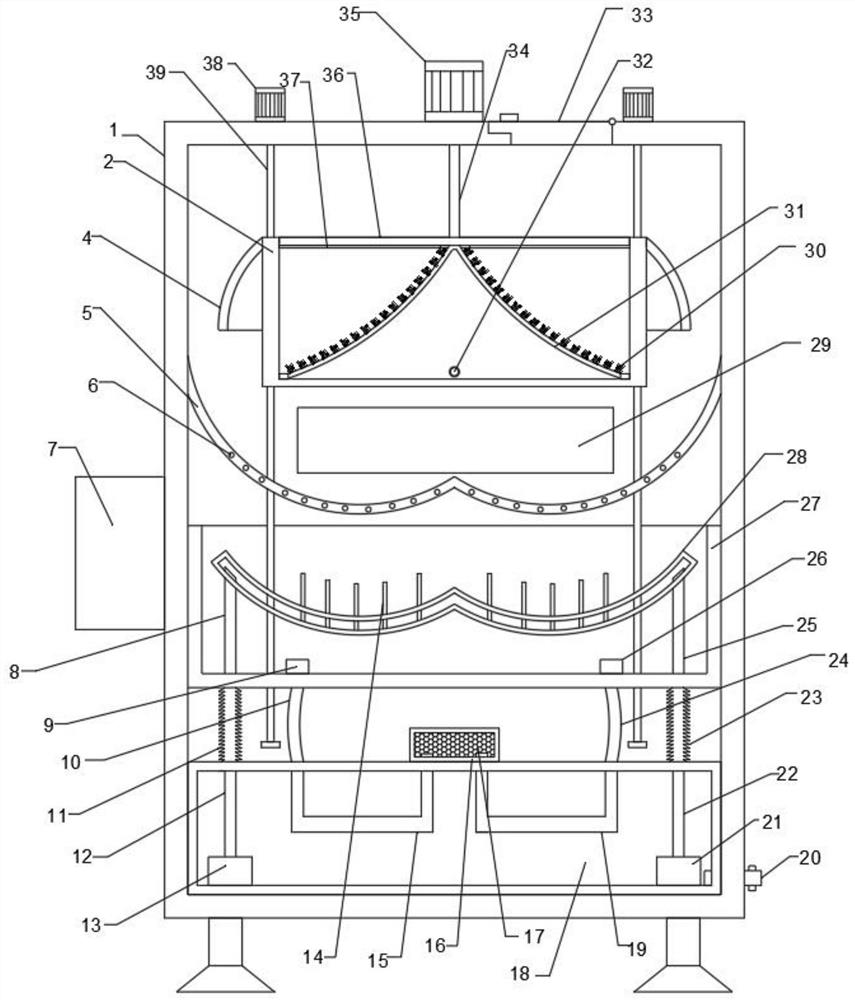

Gear heat treatment system

InactiveCN113373402AHighly integrated heat treatmentAffect the effect of quenching and coolingSolid state diffusion coatingFurnace typesThermodynamicsGear wheel

The invention belongs to the technical field of gear heat treatment, particularly relates to a gear heat treatment system, and aims at solving the problems that most of existing gear heat treatment devices adopt a plurality of mechanisms to carry out multi-transfer treatment on gears, the integration degree of the treatment mode is low, and the gear production efficiency is low. According to the scheme, the gear heat treatment system comprises a tank, a feeding cover plate is rotatably connected to the top of the tank, an electric control mechanism is fixedly connected to the outer wall of one end of the tank, a discharging cover plate is rotatably connected to the outer wall of one side of the tank, and a carburizing box is arranged at the bottom of the feeding cover plate. According to the gear heat treatment system, a cooling mechanism arranged in a cooling tank is used for conducting oil liquid soaking cooling treatment on a gear on a quenching plate, an oil liquid filtering mechanism arranged in the cooling tank is used for conducting filtering treatment on oil liquid in the cooling tank, and thus the subsequent gear quenching cooling effect is prevented from being affected by impurities; and through the arrangement, high-integration heat treatment on the gear can be realized, the production space is saved, and the production efficiency is also ensured.

Owner:胡红波

Preparation method of surface self-lubricating ti(c,n)-based cermet based on metal hydride

The invention discloses a preparation method of self-lubricating surface Ti (C, N)-based metal ceramic based on a metal hydride. The method is characterized by comprising the following steps: firstly performing heat preservation for 1 to 2 h at 500 to 700 DEG C, so as to form a metal ceramic body containing carbide forming elements; and then mixing core / shell structure powder of Al2O3 coated TiH2, a multiwalled carbon nanotube with the external diameter being smaller than 8 nm, the length being smaller than 30 micrometers and the specific surface area being greater than 350 m<2> / g, and NaHCO3 according to a weight percentage of 3:2:1, so as to prepare a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15 MPa; and finally performing liquid-phase sintering, so as to prepare the self-lubricating surface Ti (C, N)-based metal ceramic. The method overcomes the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the self-lubricating surface Ti (C, N)-based metal ceramic during a sintering process.

Owner:SICHUAN UNIV

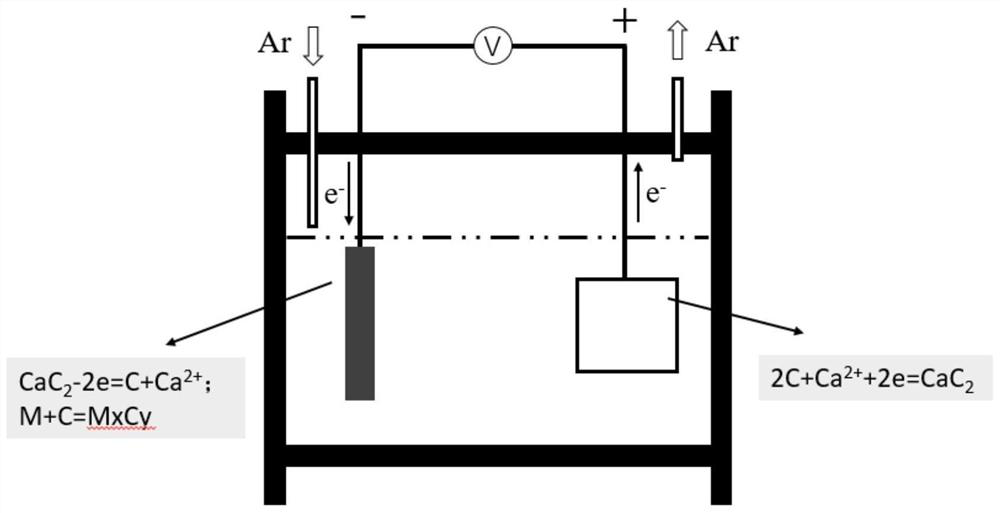

Carbide coating based on high-melting-point metal and preparation method thereof

ActiveCN113584427AImprove carburizing efficiencyNot easy to crackSolid state diffusion coatingCarbon sourceInorganic salts

The invention provides a carbide coating based on high-melting-point metal and a preparation method thereof.The method comprises the steps: preheating a high-melting-point metal workpiece to obtain a pretreated metal workpiece; drying an anhydrous chloride inorganic salt, melting the salt in an inert atmosphere, adding CaC2 to dissolve so as to obtain a molten salt in a molten state; and by taking a graphite electrode as a cathode and the pretreated metal workpiece as an anode, putting the graphite electrode and the pretreated metal workpiece into the molten salt, carrying out electrolysis in a constant current density or constant voltage electrolysis mode, taking out the anode after electrolysis is completed, and cleaning and drying the anode to obtain the carbide coating based on the high-melting-point metal. The high-melting-point metal workpiece serves as the anode, the anhydrous chloride inorganic salt molten salt serves as an electrolyte, CaC2 is added to serve as a carbon source, the anode is subjected to oxidation reaction, carbon ions lose electrons to generate carbon atoms and chemically react with a base material, the tantalum carbide coating is generated on the surface, the carburizing efficiency is high, cracks are not prone to being generated, and the self-cleaning degree is high.

Owner:WUHAN UNIV

A kind of in-situ preparation method of surface self-lubricating cemented carbide

ActiveCN107043883BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityHydrogen

The invention discloses an in-situ preparation method of a hard alloy achieving surface self-lubrication. The in-situ preparation method of the hard alloy achieving surface self-lubrication is characterized in that forming-agent-free hard alloy green bodies with the porosity being 25%-40% are formed under the condition that the temperature of 550-750 DEG C is kept for 2-4 h; core / shell structure powder with Al2O3 covering TiH2 and nanometer graphite with the thickness granularity being 30-50 nm are mixed at the weight percentage ratio of 1:2 so as to prepare a carburizing medium containing hydrogen; the green bodies are embedded into the carburizing medium containing hydrogen and are compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and in-situ preparation of the hard alloy achieving surface self-lubrication is achieved based on carbon migration. The in-situ preparation method of the hard alloy achieving surface self-lubrication overcomes the problems that in the prior art, grains grow severely, the carburizing time is long and efficiency is low, and in-situ preparation of the hard alloy achieving surface self-lubrication is achieved in the sintering process.

Owner:SICHUAN UNIV

A kind of preparation method of cemented carbide with graphite-rich phase on the surface

ActiveCN107058842BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusGraphiteAlloy

Owner:SICHUAN UNIV

A preparation method of surface self-lubricating ti(c,n) based cermet wear-resistant material

ActiveCN107142407BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityWear resistant

The invention discloses a preparation method of a self-lubricating surface type Ti(C, N)-based cermet wear-proof material. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is characterized in that the temperature is kept at 500-650 DEG C for 2-4 h, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2 and graphene are mixed at the weight percentage ratio of 2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is achieved. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is prepared in the sintering process.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com