Metal ceramic wear resisting material and preparation method thereof

A wear-resistant material and cermet technology, which is applied in the field of wear-resistant materials, can solve the problems of easy falling off of ceramic materials, easy aging of adhesives, failure of wear-resistant parts, etc., and achieves a simple and easy preparation method, good carburizing effect, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

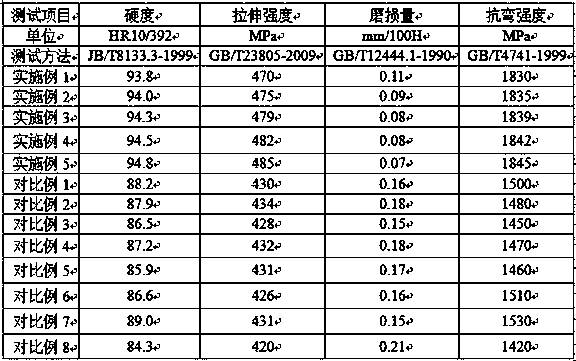

Examples

Embodiment 1

[0029] A cermet wear-resistant material, which is composed of the following components in parts by weight: 20 parts of boron nitride, 25 parts of chromium carbide, 5 parts of scandium nitride, 5 parts of molybdenum nitride, 8 parts of niobium boride, silicide 8 parts of titanium, 4 parts of boron silicide, 1 part of carbon fiber, 1 part of aminomontmorillonite, 1 part of cerium powder, 1 part of strontium powder, and 3 parts of zirconium powder.

[0030] The preparation method of the cermet wear-resistant material comprises the following steps:

[0031] Step S1: Take boron nitride, chromium carbide, scandium nitride, molybdenum nitride, niobium boride, titanium silicide, boron silicide, carbon fiber and amino montmorillonite in proportion by weight, and mix them evenly to obtain a mixture, and then The mixture and the ball milling medium are put into a ball mill for ball milling, and then dried and sieved in sequence to obtain a ball mill; the ball mill medium is absolute etha...

Embodiment 2

[0036] A cermet wear-resistant material, which is composed of the following components in parts by weight: 23 parts of boron nitride, 27 parts of chromium carbide, 6.5 parts of scandium nitride, 6.5 parts of molybdenum nitride, 8.5 parts of niobium boride, silicide 8.5 parts of titanium, 4.5 parts of boron silicide, 1.5 parts of carbon fiber, 2 parts of aminomontmorillonite, 2 parts of cerium powder, 1.5 parts of strontium powder, and 4 parts of zirconium powder.

[0037] The preparation method of the cermet wear-resistant material comprises the following steps:

[0038] Step S1: Take boron nitride, chromium carbide, scandium nitride, molybdenum nitride, niobium boride, titanium silicide, boron silicide, carbon fiber and amino montmorillonite in proportion by weight, and mix them evenly to obtain a mixture, and then The mixture and the ball milling medium are put into a ball mill for ball milling, followed by drying and sieving to obtain a ball mill; the ball milling medium is...

Embodiment 3

[0043] A cermet wear-resistant material, which is composed of the following components in parts by weight: 25 parts of boron nitride, 30 parts of chromium carbide, 7.5 parts of scandium nitride, 7 parts of molybdenum nitride, 9 parts of niobium boride, silicide 9 parts of titanium, 5 parts of boron silicide, 2 parts of carbon fiber, 2.5 parts of aminomontmorillonite, 3.5 parts of cerium powder, 2 parts of strontium powder, and 4.5 parts of zirconium powder.

[0044] The preparation method of the cermet wear-resistant material comprises the following steps:

[0045] Step S1: Take boron nitride, chromium carbide, scandium nitride, molybdenum nitride, niobium boride, titanium silicide, boron silicide, carbon fiber and amino montmorillonite in proportion by weight, and mix them evenly to obtain a mixture, and then The mixture and the ball milling medium are put into a ball mill for ball milling, and then dried and sieved successively to obtain a ball mill; the ball mill medium is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com