Vacuum carburizing method for obtaining dispersed fine carbides

A dispersion distribution and vacuum carburizing technology, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve the problems of poor product surface performance, high equipment operating cost, long process time, etc., to achieve deformation The effect of small size, low equipment operating cost and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

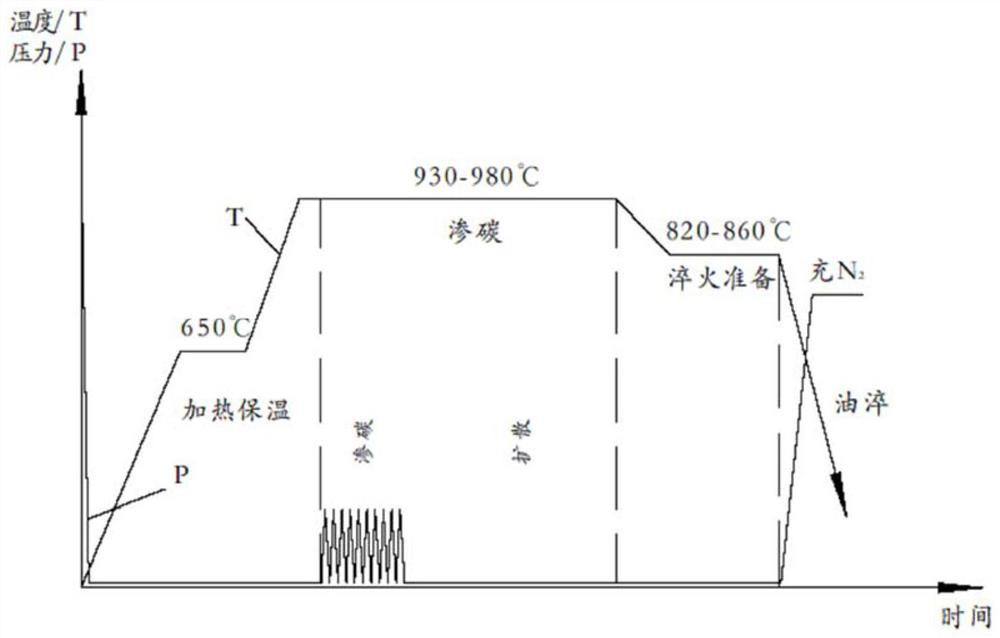

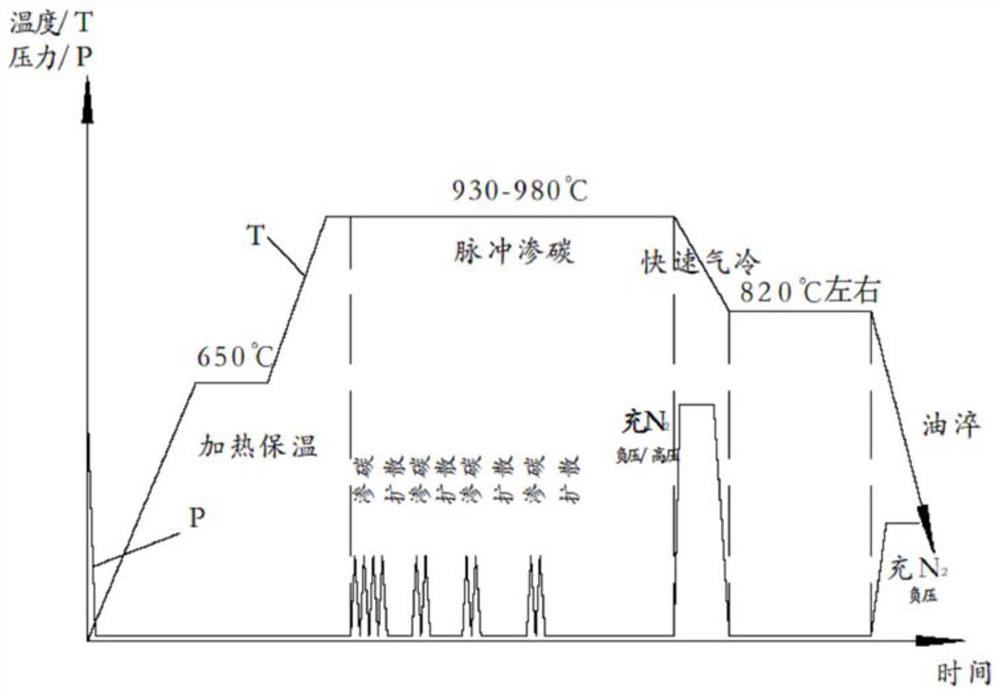

[0038] see figure 2 , in an embodiment of the present invention, a vacuum carburizing method for obtaining dispersed fine carbides, comprising the following stages:

[0039](1) Heating and heat preservation stage: Determine whether the heating process is segmented according to the material and size of the workpiece, and set the heating temperature, heating time, and holding time of each segment. After the process curve is compiled, the workpiece is placed in a vacuum furnace to evacuate and run for heating. The final carburizing temperature is usually 930-980°C.

[0040] (2) Pulse carburizing stage: According to the carburizing layer depth of the workpiece or the carbon concentration gradient requirements of the carburizing layer, set the number of carburizing / diffusion alternate operations and the time of each operation, and compile them in the process curve. The carburizing gas is pulsed into the carburizing chamber. The gas type is usually acetylene or propane. The carbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com