Pre-oxidation technology for improving wind power gear gas carburizing efficiency

A gas carburizing and pre-oxidation technology, which is applied in the coating process of metal materials, manufacturing tools, coatings, etc., can solve the problems of high labor intensity, long process cycle, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

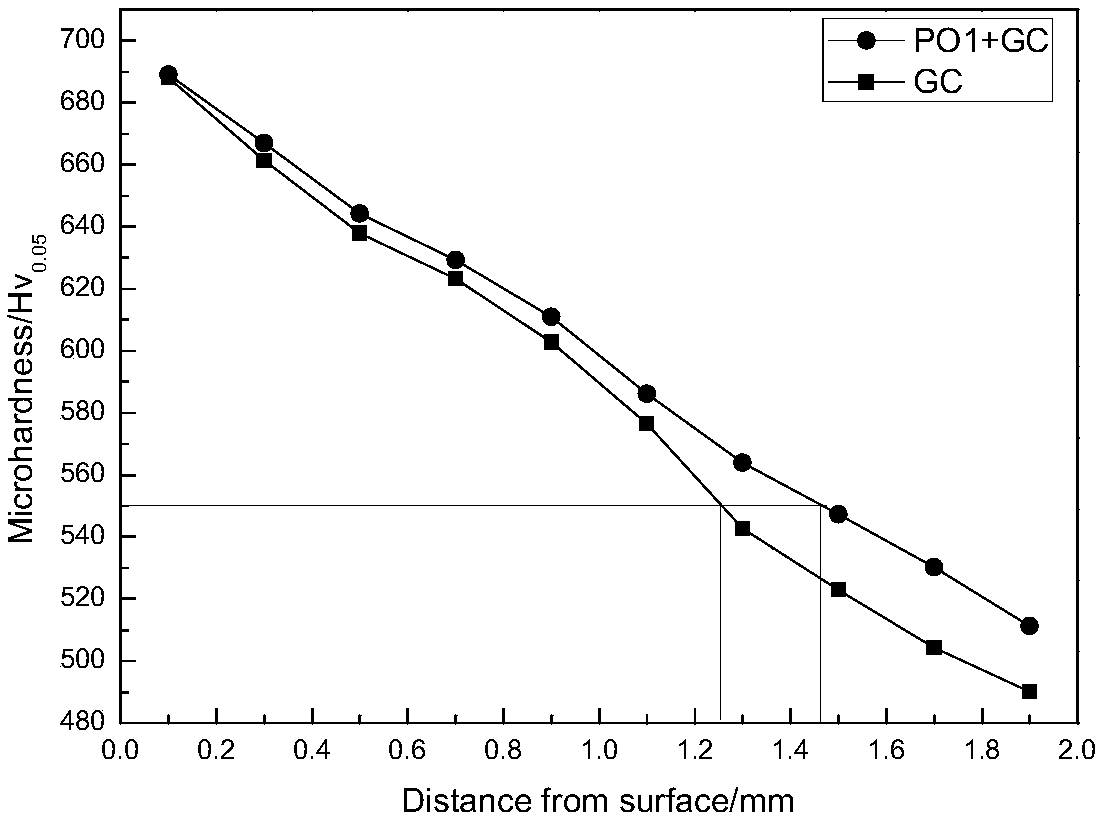

Embodiment 1

[0021] (1) Process 20CrMnMo steel into M12 tooth-shaped samples;

[0022] (2) Refining and tempering the sample, first raising the temperature to 840°C for 30 minutes, then putting the sample in oil to cool immediately, then raising the temperature to 680°C for 30 minutes, taking it out and air cooling to room temperature.

[0023] (3) Place the sample in a program-controlled box-type electric furnace for pre-oxidation treatment, set the furnace temperature to 350°C, and hold the temperature for 45 minutes;

[0024] (4) Put the pre-oxidized sample into the multi-purpose gas carburizing furnace, raise the temperature to 800°C, keep it warm for 2h, keep the carbon potential of 0.4% for carburizing, then raise the temperature to 920°C, keep the carbon potential of 1.2% for 4h Intense carburizing, then reduce the carbon potential to 0.68% for 4h diffusion, then cool the furnace to 820°C, hold for 2h and then cool down with the furnace; then take out the sample and put it in oil to...

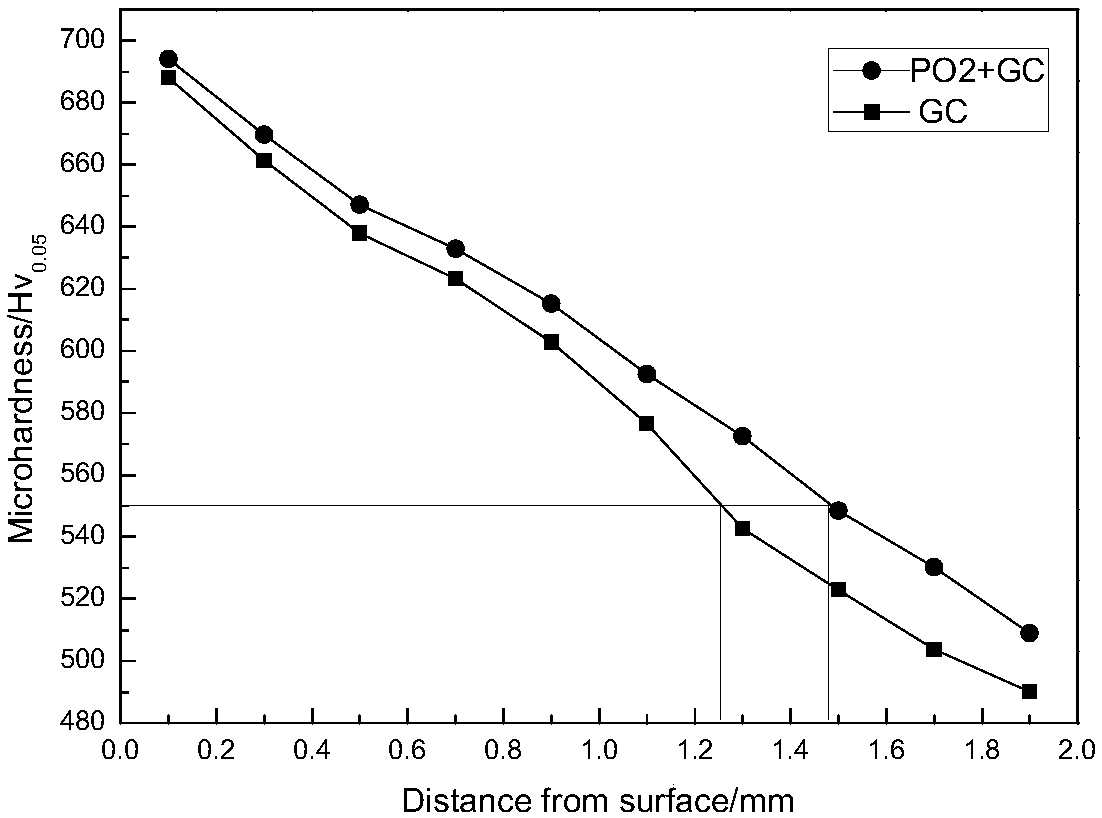

Embodiment 2

[0029] (1) Process 20CrMnMo steel into M12 tooth-shaped samples;

[0030] (2) Refining and tempering the sample, first raising the temperature to 840°C for 30 minutes, then putting the sample in oil to cool immediately, then raising the temperature to 680°C for 30 minutes, taking it out and air cooling to room temperature.

[0031] (3) Place the sample in a program-controlled box-type electric furnace for pre-oxidation treatment, set the furnace temperature to 350°C, and hold the temperature for 60 minutes;

[0032] (4) Put the pre-oxidized sample into the multi-purpose gas carburizing furnace, raise the temperature to 800°C, keep it warm for 2h, keep the carbon potential of 0.4% for carburizing, then raise the temperature to 920°C, keep the carbon potential of 1.2% for 4h Intense carburizing, then reduce the carbon potential to 0.68% for 4h diffusion, then cool the furnace to 820°C, hold for 2h and then cool down with the furnace; then take out the sample and put it in oil to...

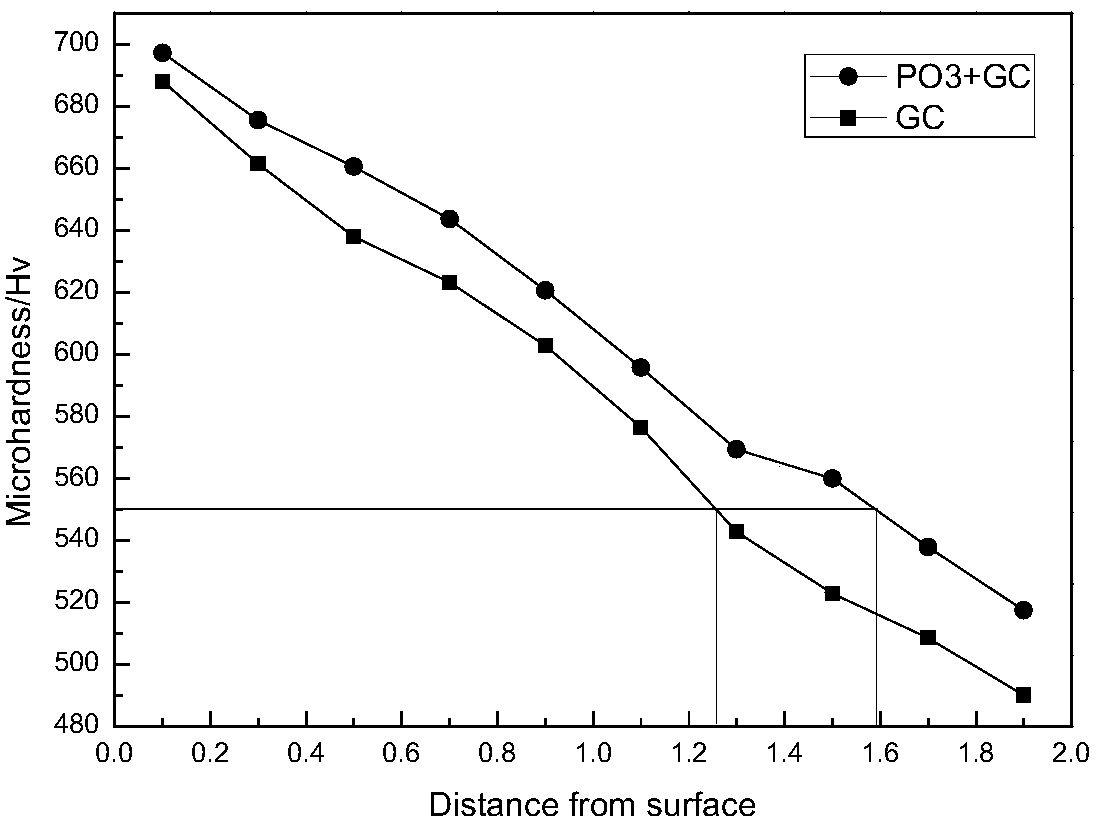

Embodiment 3

[0037] (1) Process 20CrMnMo steel into M12 tooth-shaped samples;

[0038] (2) Refining and tempering the sample, first raising the temperature to 840°C for 30 minutes, then putting the sample in oil to cool immediately, then raising the temperature to 680°C for 30 minutes, taking it out and air cooling to room temperature;

[0039] (3) Place the sample in a program-controlled box-type electric furnace for pre-oxidation treatment, set the furnace temperature to 500°C, and hold the temperature for 45 minutes;

[0040] (4) Put the pre-oxidized sample into the multi-purpose gas carburizing furnace, raise the temperature to 800°C, keep it warm for 2h, keep the carbon potential of 0.4% for carburizing, then raise the temperature to 920°C, keep the carbon potential of 1.2% for 4h Intense carburizing, then reduce the carbon potential to 0.68% for 4h diffusion, then cool the furnace to 820°C, hold for 2h and then cool down with the furnace; then take out the sample and put it in oil to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com