Carburizing agent and platinum carburizing method utilizing carburizing agent

A carburizing agent, platinum technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as damage to the appearance and luster of platinum jewelry, shorten the service life of the jewelry, and reduce the aesthetics. The degree of carburization is easy to control, prolongs the service life, and improves the effect of surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

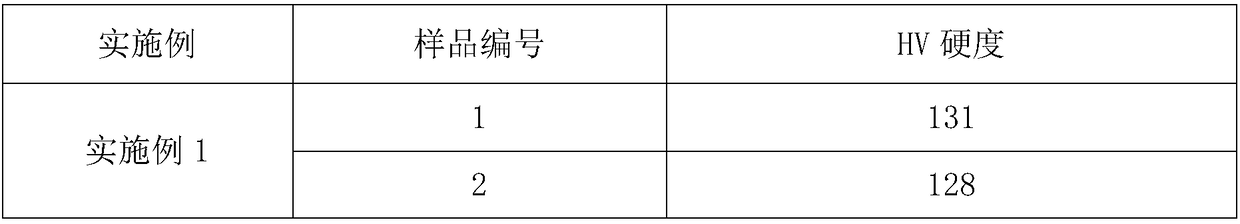

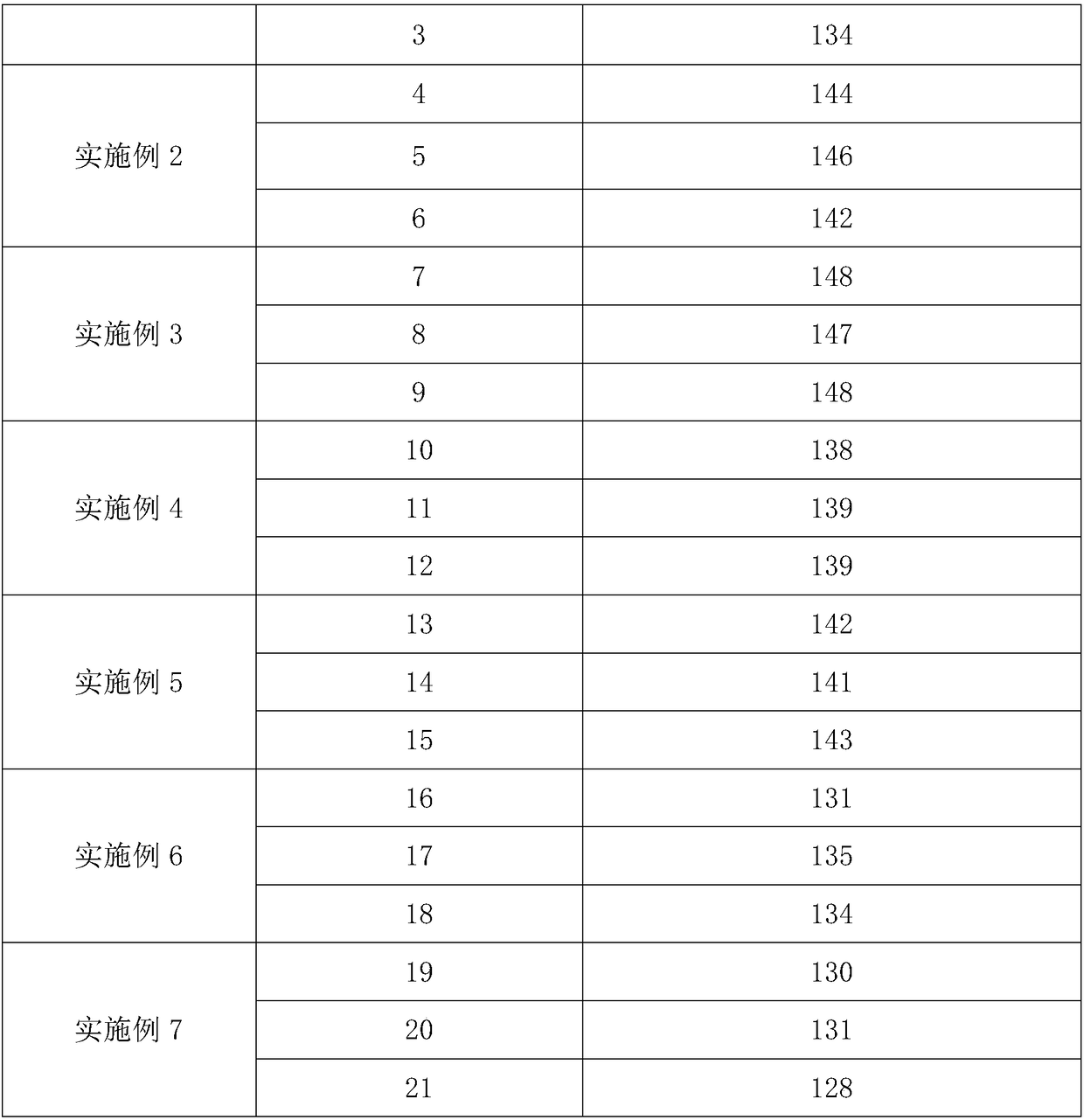

Embodiment 1

[0034] Embodiment 1: a kind of carburizing agent, comprises carburizing agent, infiltrating agent, filler and binding agent, and carburizing agent is boron carbide, and infiltrating agent is barium carbonate, and filler is calcium carbonate, and binding agent is Dextrin, its parts are respectively 40 parts of boron carbide, 5 parts of barium carbonate, 2 parts of calcium carbonate, and 2 parts of dextrin.

Embodiment 2

[0035] Embodiment 2: The difference between embodiment 2 and embodiment 1 is only that the content of boron carbide is 45 parts.

Embodiment 3

[0036] Embodiment 3: The difference between embodiment 3 and embodiment 1 is only that the content of boron carbide is 50 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com