Preparation method of self-lubricating surface type Ti(C, N)-based cermet wear-proof material

A cermet and wear-resistant material technology, applied in the field of wear-resistant materials, can solve the problems of low efficiency, long carburizing time, grain growth, etc., and achieve the effect of simple process, improved carburizing efficiency, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

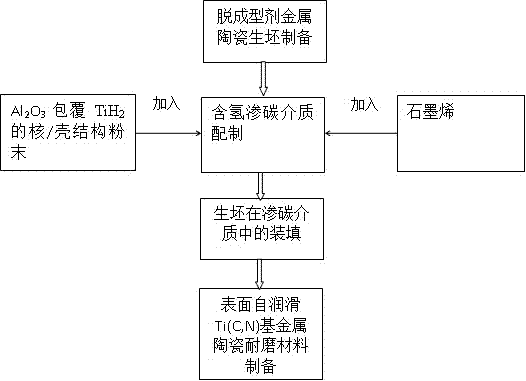

Image

Examples

example 1

[0018] Example 1: Prepare the surface self-lubricating Ti(C,N)-based cermet wear-resistant material according to the following steps:

[0019] (1) Preparation of the release agent cermet green body: Weigh various raw material powder ingredients by weight percentage, of which Ni accounts for 6wt%, Co accounts for 8wt%, Mo 2 C accounts for 5wt%, WC accounts for 7wt%, TiC 0.7 N 0.3 as the balance; mix the weighed powders and pass through 36h ball milling, 400-mesh sieve filtration, drying at 88°C, adding 70% of the weight of cermet powder into a butadiene rubber molding agent, and pressing at 320MPa to obtain a cermet green body ;The cermet green body is kept in a vacuum sintering furnace at 580°C for 2 hours, the heating rate is 3°C / min, and the vacuum degree is 15Pa, forming a cermet green body with a porosity of 25% and removing the forming agent;

[0020] (2) Preparation of hydrogen-containing carburizing medium: first weigh TiH with a particle size of 0.7 μm 2 The powder ...

example 2

[0023] Example 2: Prepare the surface self-lubricating Ti(C,N)-based cermet wear-resistant material according to the following steps:

[0024] (1) Preparation of the release agent cermet green body: Weigh various raw material powder ingredients by weight percentage, of which Ni accounts for 8wt%, Co accounts for 4wt%, Mo 2 C accounts for 15wt%, WC accounts for 20wt%, TiC 0.7 N 0.3 as the balance; mix the weighed powders and pass through 68h ball milling, filter with 400 mesh screen, dry at 92°C, mix 110% of the weight of the cermet powder with Buna-Na rubber molding agent, and press at 380MPa to obtain a cermet green body ; The cermet green body is kept in a vacuum sintering furnace at 620°C for 4h, the heating rate is 4°C / min, and the vacuum degree is 25Pa, forming a cermet green body with a porosity of 35% and a molding agent removed;

[0025] (2) Preparation of hydrogen-containing carburizing medium: first weigh TiH with a particle size of 1.3 μm 2 The powder is added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com