Patents

Literature

32results about How to "Avoid running out quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

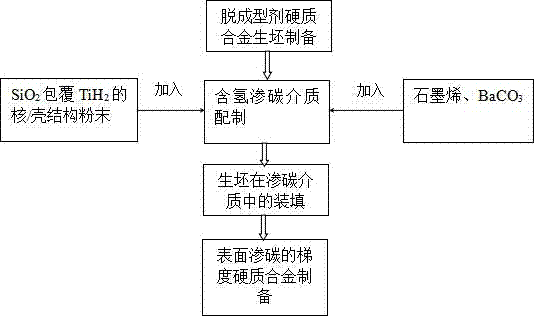

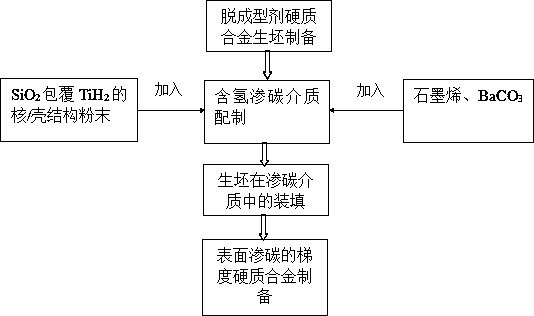

Preparation method of surface-carburizing gradient hard alloy

ActiveCN106987752ASimple processAvoid running out quicklyTransportation and packagingMetal-working apparatusCemented carbideCrystallite

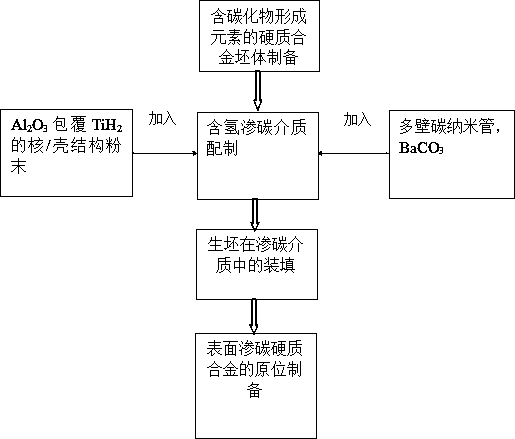

The invention discloses a preparation method of a surface-carburizing gradient hard alloy. The preparation method is characterized in that heat preservation is conducted for 2-4 h at the temperature ranging from 550 DEG C to 750 DEG C, and a hard alloy green body of a removal forming agent with the porosity ranging from 25% to 40% is formed; then, core / shell structure powder, graphene and BaCO3 are mixed according to the weight percentage being 1 to 2 to 1 to prepare a hydrogen-containing carburizing medium, wherein TiH2 is wrapped by SiO2 in the core / shell structure powder, the thickness of the graphene is smaller than 3 nm, the layer number of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; then, the green body is buried in the hydrogen-containing carburizing medium and is compacted under the pressure ranging from 5 MPa to 15 MPa; and finally, liquid-phase sintering is conducted, and the surface-carburizing gradient hard alloy is prepared. The preparation method solves the problems that an existing process is serious in grain growth, long in carburizing time and low in efficiency, and the surface-carburizing gradient hard alloy is prepared in the sintering process.

Owner:SICHUAN UNIV

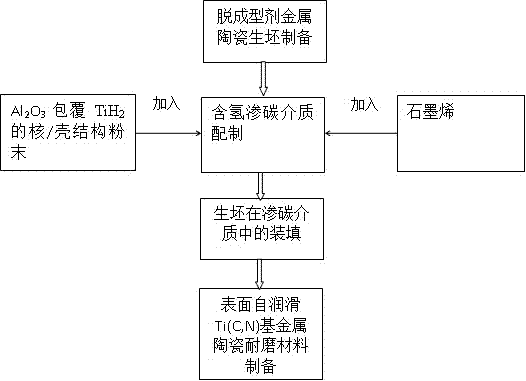

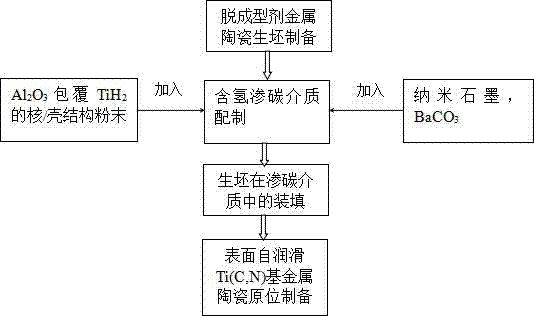

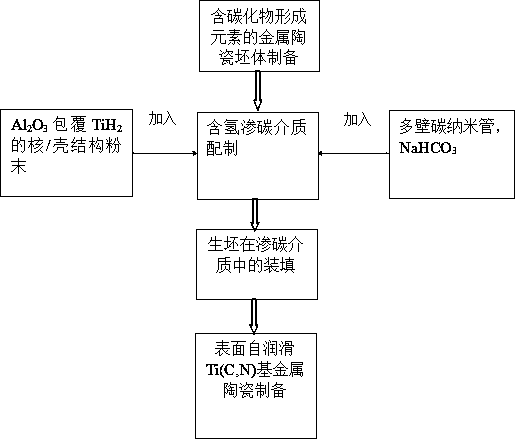

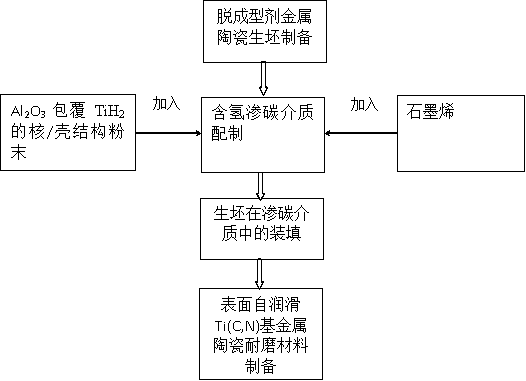

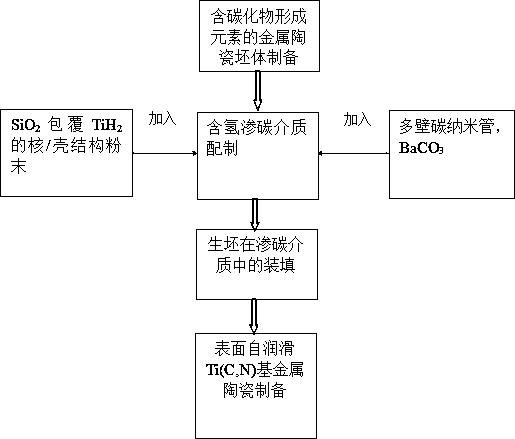

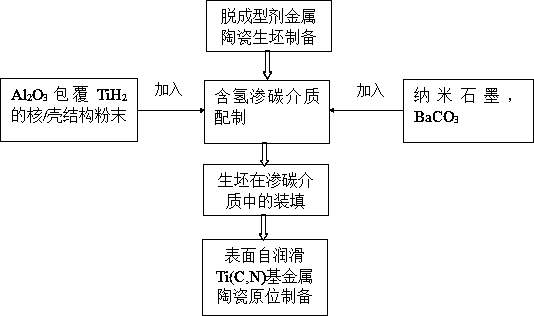

Preparation method of self-lubricating surface type Ti(C, N)-based cermet wear-proof material

ActiveCN107142407AIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorositySurface type

The invention discloses a preparation method of a self-lubricating surface type Ti(C, N)-based cermet wear-proof material. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is characterized in that the temperature is kept at 500-650 DEG C for 2-4 h, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2 and graphene are mixed at the weight percentage ratio of 2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is achieved. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is prepared in the sintering process.

Owner:SICHUAN UNIV

Shooting device for outdoor large wild animals

InactiveCN102685391AImprove personal securityAvoid running out quicklyTelevision system detailsColor television detailsVibration sensorComputer module

The invention relates to a shooting device for outdoor large wild animals, and the shooting device mainly consists of a vibration sensor, a control module, a shooting and recording device, a storage device, a wireless transmission module and a power supply. When the control module detects the vibration of the ground and detects that the vibration amplitude reaches a preset value, the shooting and recording device performs the shooting and recording, and after the vibration of the ground disappears, the shooting and recording device is postponed for a period of time to be closed; and the obtained data is stored in the storage device, when the storage space of the storage device is about to use up, the working personnel is notified to replace the storage device through the wireless transmission module. Due to the adoption of the shooting device, on one hand, the personal safety guarantee of the working personnel can be improved; and on the other hand, the living state of the large wild animal can be efficiently recorded for a long time, and the quick use-up of the electric quantity of a battery can be avoided.

Owner:ANHUI NORMAL UNIV

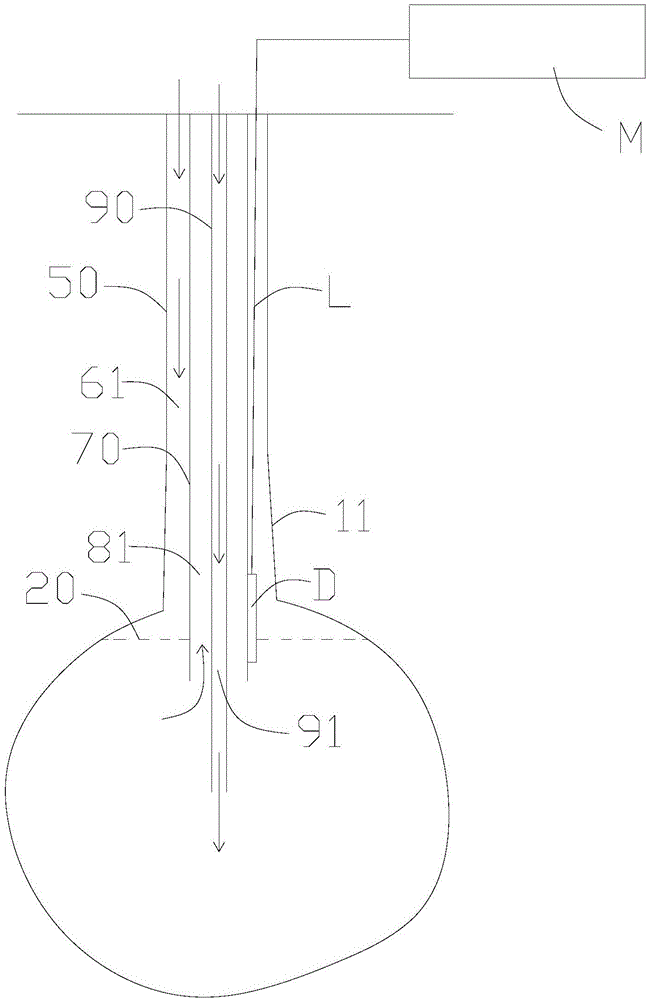

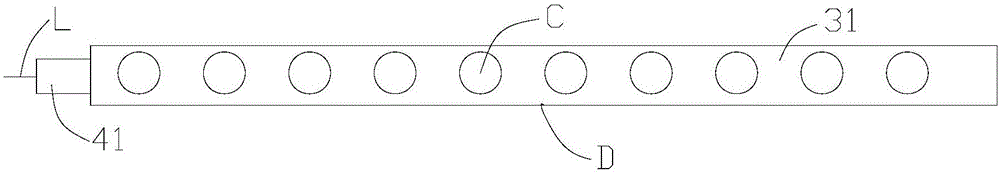

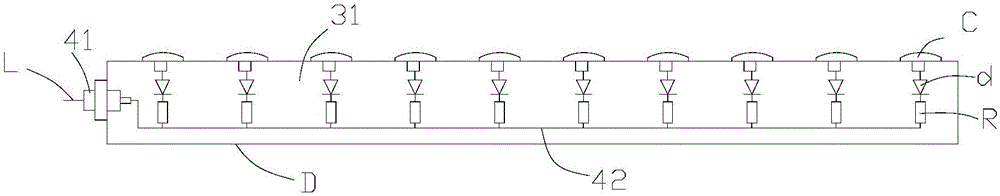

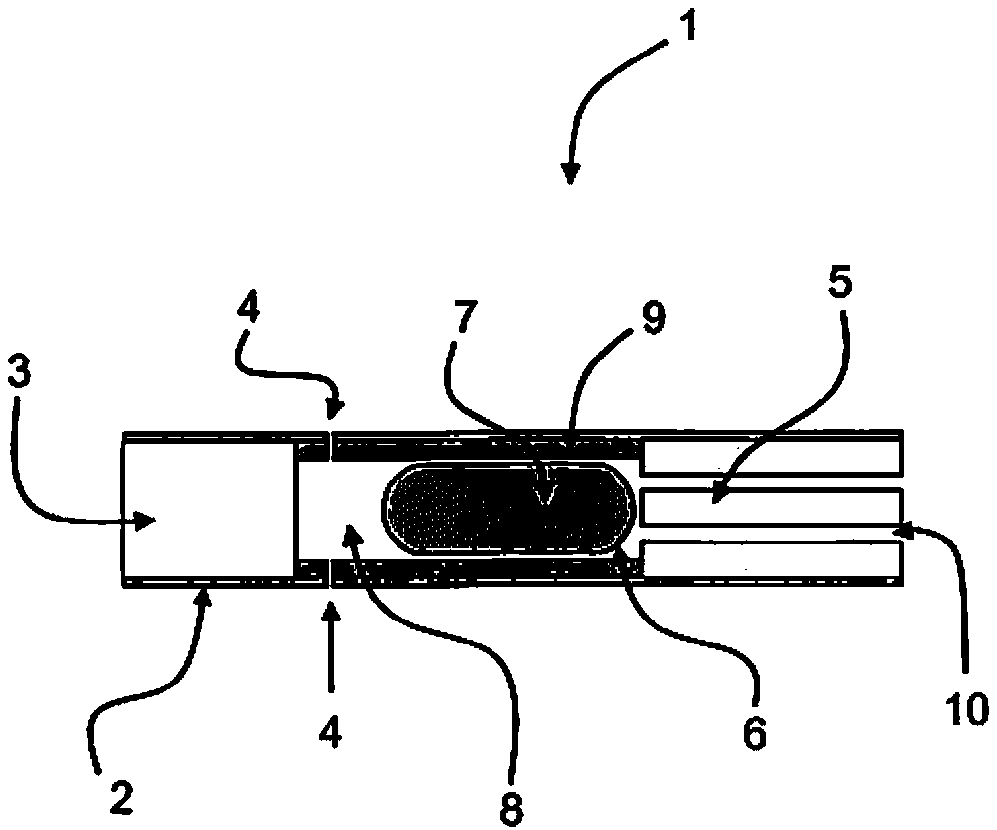

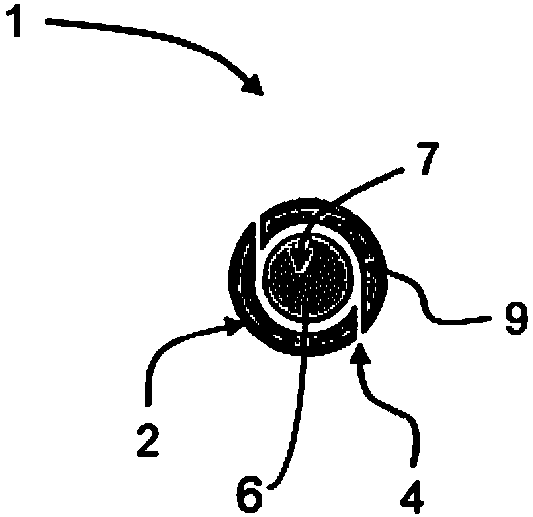

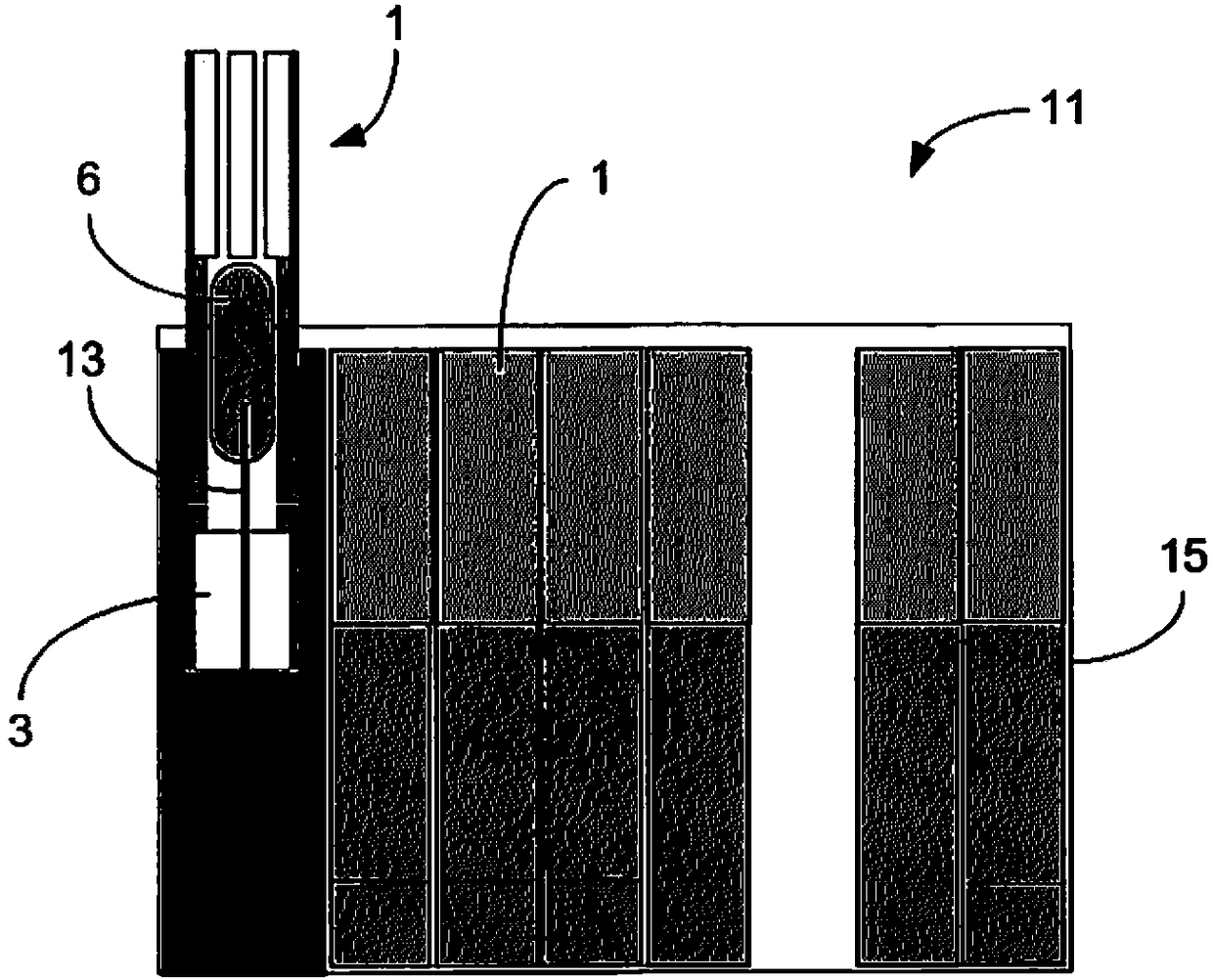

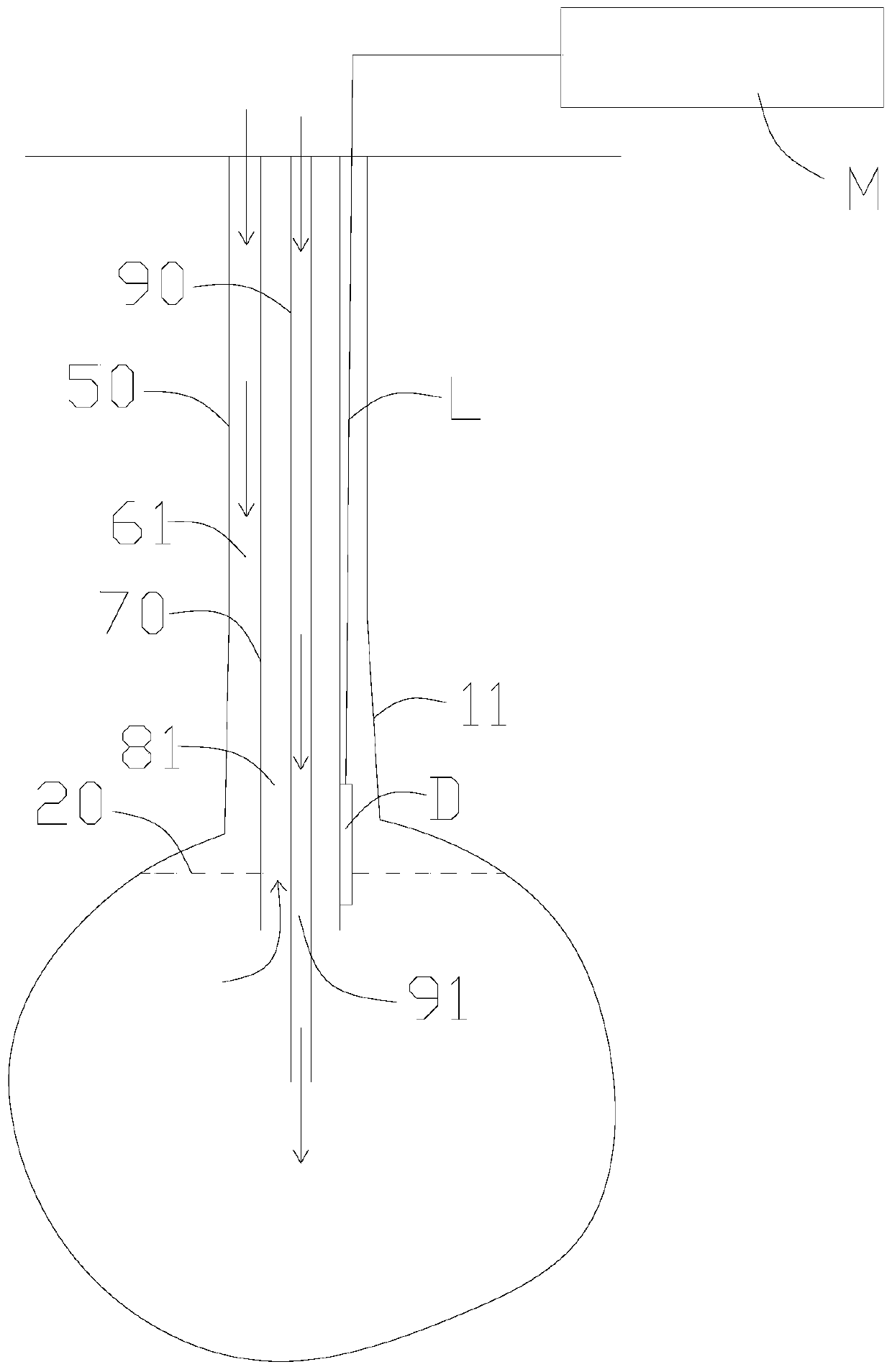

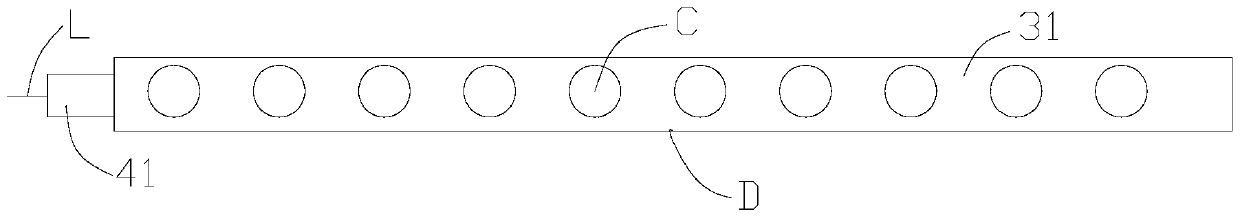

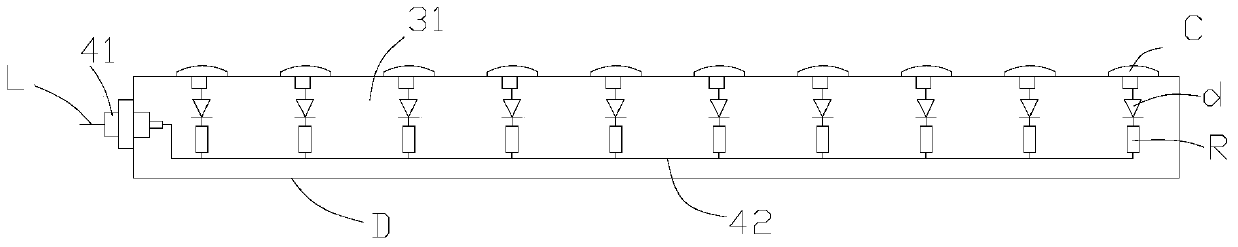

Downhole oil-water interface detector

ActiveCN106092256AAccurate measurementHigh measurement accuracyLevel indicators by physical variable measurementElectricityOil water

The invention provides a downhole oil-water interface detector which comprises a detection sensor D and a ground detector M. A plurality of detection structures are arranged on the detection sensor D, first ends of the multiple detection structures are electrically connected with one another, second ends of the multiple detection structures are connection contact points which are sequentially arranged along the height directions of the detection structures at intervals, and each detection structure comprises a detection resistor R; the ground detector M is connected with the detection sensor D, measurement voltages Vc can be outputted to the detection sensor D by the ground detector M, and measurement currents Ic which flow through the detection sensor D can be detected by the ground detector M, so that the heights of oil-water interfaces can be judged according to the measurement currents Ic. The downhole oil-water interface detector has the advantage that detection effects can be improved by the downhole oil-water interface detector.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

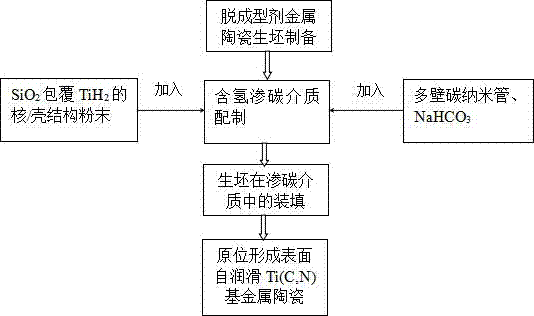

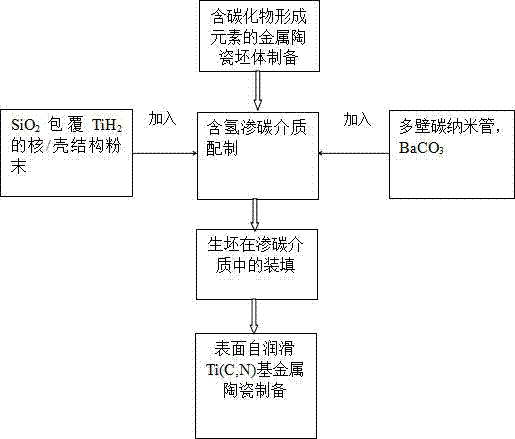

In-situ preparation method of Ti (C,N) based metal ceramic with self-lubricating surface

ActiveCN107142404AIncrease surface areaSmall granularitySolid state diffusion coatingPorosityHydrogen

The invention discloses an in-situ preparation method of Ti (C,N) based metal ceramic with a self-lubricating surface. The in-situ preparation method of Ti (C,N) based metal ceramic with self-lubricating surface is characterized by comprising the steps of firstly, keeping warm for 2 to 4h at the temperature of 500 to 650 DEG C, and forming a metal ceramic green body without a forming agent and with the porosity being 25 percent to 40 percent; then mixing SiO2-coated TiH2 core / shell structure powder, a multiwalled carbon nanotube with the outer diameter being less than 8nm, the length being less than 30mum and the specific surface area being larger than 350m<2> / g, and NaHCO3 according to the weight percent being 2:1:1 for preparing to obtain a hydrogen-containing carburizing medium; embedding the green body into the hydrogen-containing carburizing medium, and compacting under the pressure of 5 to 15MPa; and finally carrying out liquid-phase sintering so as to in-situ form the Ti (C,N) based metal ceramic with the self-lubricating surface. The in-situ preparation method provided by the invention solves the problems of severe grain growth, long carburizing time and low efficiency existed in an existing process, and the metal ceramic with the self-lubricating surface is in-situ formed during a sintering process.

Owner:SICHUAN UNIV

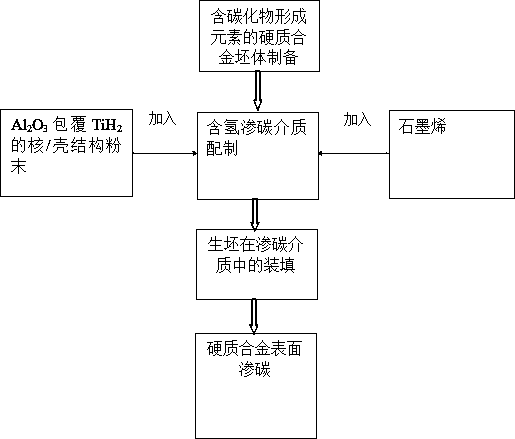

A kind of hard alloy surface carburizing method

ActiveCN107142445BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusHydrogenAlloy

The invention discloses a method for carburizing the surface of cemented carbide, which is characterized in that it first heats the temperature at 550-700°C for 1-2 hours to form a cemented carbide blank containing carbide-forming elements; 2 o 3 coated TiH 2 Core / shell structure powder with thickness less than 3nm, number of layers less than 3 and specific surface area greater than 250m 2 / g of graphene and two substances are mixed according to the weight percentage of 2:3 to prepare a hydrogen-containing carburizing medium; then the green body is embedded in the hydrogen-containing carburizing medium and compacted under a pressure of 5~15MPa; finally, the liquid phase Sintering to realize carburizing of cemented carbide surface. The invention overcomes the problems of severe crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes carburizing of the hard alloy surface in the sintering process.

Owner:SICHUAN UNIV

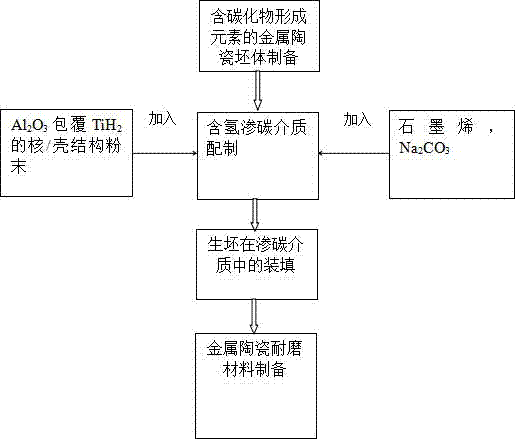

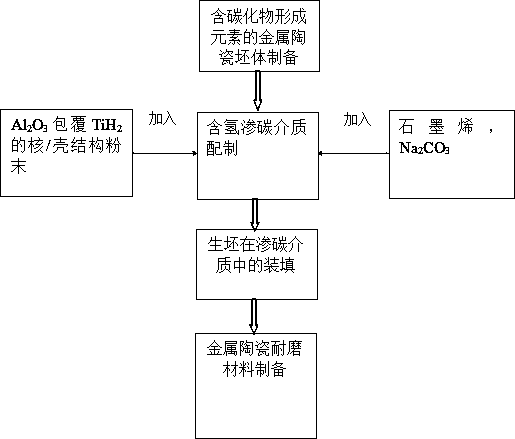

Preparation method of metal ceramic wear resistant material based on carbide forming elements promoting carbon migration

ActiveCN107099721ASimple processAvoid running out quicklySolid state diffusion coatingTin ElementGraphene

The invention discloses a preparation method of metal ceramic wear resistant material based on carbide forming elements promoting carbon migration. The method is characterized by comprising the following steps: firstly performing heat preservation for 1 to 2 h at 500 to 700 DEG C, so as to form a metal ceramic body containing the carbide forming elements; then mixing core / shell structure powder of Al2O3 coated TiH2, graphene with the thickness being smaller than 3 nm, the number of layers being smaller than 3 and the specific surface area being greater than 250 m<2> / g, and Na2CO3 according to a weight percentage of 3:2:1, so as to prepare a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15 MPa; and finally performing liquid-phase sintering, so as to prepare the metal ceramic wear resistant material based on the carbide forming elements promoting carbon migration. The method overcomes the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the metal ceramic wear resistant material during a sintering process.

Owner:SICHUAN UNIV

A kind of surface carburized gradient cemented carbide preparation method

ActiveCN106987752BIncrease surface areaImprove adsorption capacityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a method for preparing surface carburized gradient cemented carbide, which is characterized in that it first heats the temperature at 550-750°C for 2-4 hours to form a cemented carbide product with a porosity of 25%-40% and removes the forming agent. blank; then SiO2-coated TiH2 core / shell structure powder, graphene with a thickness of less than 3nm, a number of layers less than 3 layers and a specific surface area greater than 250m2 / g, and BaCO3 are prepared by mixing 1:2:1 by weight percentage Hydrogen-containing carburizing medium; then the green body is buried in the hydrogen-containing carburizing medium and compacted under a pressure of 5-15MPa; finally, liquid-phase sintering is carried out to prepare a surface-carburized gradient cemented carbide. The invention overcomes the problems of serious grain growth, long carburizing time and low efficiency in the prior art, and prepares surface carburized gradient hard alloy in the sintering process.

Owner:SICHUAN UNIV

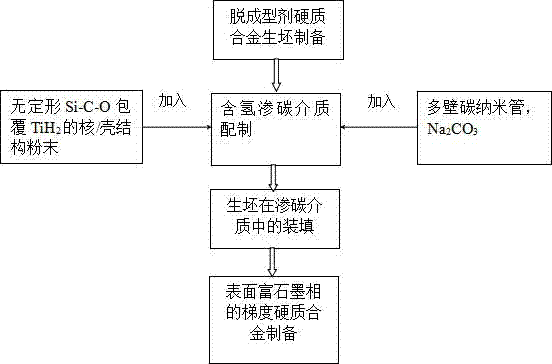

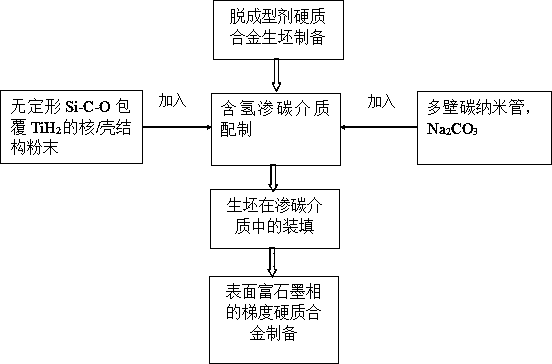

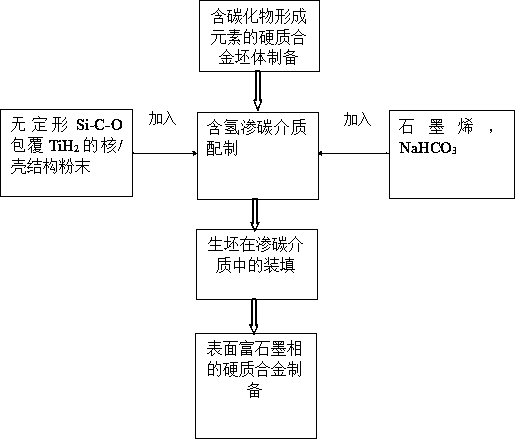

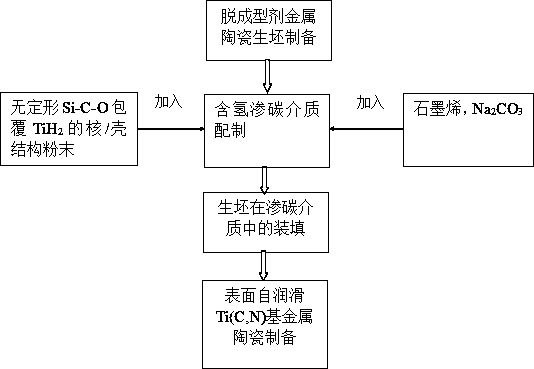

Preparing method for gradient hard alloy with surface rich in graphite phase

ActiveCN107058843AIncrease surface areaLarge granularityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a preparing method for a gradient hard alloy with the surface rich in graphite phase. The preparing method is characterized in that firstly, heat preservation is conducted for 2-4 h at the temperature ranging from 550 DEG C to 750 DEG C, and a hard alloy raw blank removing a forming agent is formed, wherein the porosity of the hard alloy raw blank ranges from 25% to 40%; then, the three substances including amorphous Si-C-O wrapping TiH2 core / shell structure powder, a multi-wall carbon nano tube and Na2CO3 are mixed according to the weight percent of 1:2:1, and then a hydrogen-containing carburizing medium is prepared, wherein the outer diameter is smaller than 8 nm, the length is smaller than 30 microns, and the specific surface area is larger than 350 m<2> / g; then, the raw blank is embedded in the hydrogen-containing carburizing medium and is compacted under the pressure of 5-15 MPa; and finally, liquid phase sintering is conducted, and the gradient hard alloy with the surface rich in graphite phase is prepared. The preparing method solves the problems that in the existing technology, grain growth is serious, the carburization time is long, and efficiency is low; and in the sintering process, the gradient hard alloy with the surface rich in graphite phase is prepared in the sintering process.

Owner:SICHUAN UNIV

Method for preparing surface self-lubrication type Ti(C, N)-based cermet in situ based on carbon diffusion

ActiveCN107142405ASimple processAvoid running out quicklySolid state diffusion coatingLubricationCrystallite

The invention discloses a method for preparing surface self-lubrication type Ti(C, N)-based cermet in situ based on carbon diffusion. The method for preparing the surface self-lubrication type Ti(C, N)-based cermet in situ based on carbon diffusion is characterized in that firstly, the temperature is kept at 500-650 DEG C for 2-4 hours, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; Al2O3 core / shell structure powder covered with TiH2, graphene with the particle sizing being 30-50 nm and BaCO3 are mixed according to the weight percentage ratio of 2:1:1 to be prepared into a hydrogenous carburizing medium; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and the self-lubrication surface type Ti(C, N)-based cermet is prepared in situ based on carbon diffusion. The method for preparing the self-lubrication surface type Ti(C, N)-based cermet in situ based on carbon diffusion solves the problems that in the prior art, grains grow severely, the carburizing time is long and efficiency is low, and in-site preparation of the surface self-lubrication type Ti(C, N)-based cermet is achieved in the sintering process.

Owner:SICHUAN UNIV

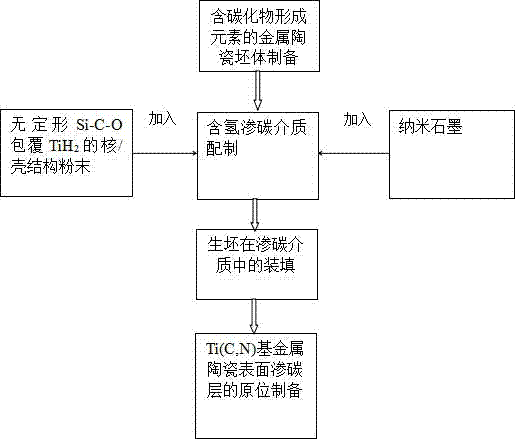

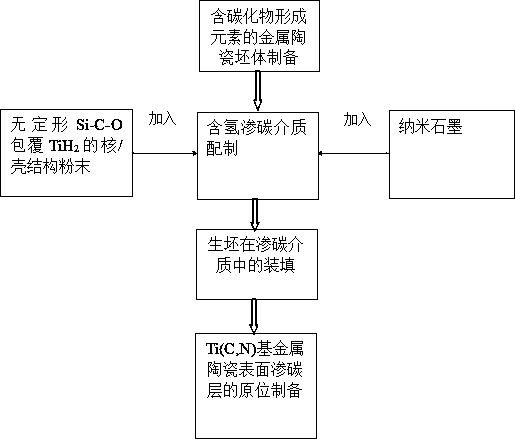

In-situ preparing method for Ti(C,N) base metal ceramic surface carburized layer

ActiveCN106995897ASimple processAvoid running out quicklyTransportation and packagingMetal-working apparatusCrystallitePressure range

The invention discloses an in-situ preparing method for a Ti(C,N) base metal ceramic surface carburized layer. The in-situ preparing method is characterized in that firstly, heat preservation is conducted for 1-2 h at the temperature ranging from 500 DEG C to 700 DEG C, and a metal ceramic blank containing carbide forming elements is formed; then, two kinds of substances including amorphous Si-C-O wrapping TiH2 core / shell structure powder and nano graphite with the granularity ranging from 30 nm to 50 nm are mixed according to the weight percent being 3:2 to prepare a hydrogen-containing carburizing medium; then a raw blank is embedded in the hydrogen-containing carburizing medium and compacted at the pressure ranging from 5 MPa to 15MPa; and finally, liquid-phase sintering is conducted, and the Ti(C,N) base metal ceramic surface carburized layer is formed in an in-situ manner. The method solves the problems that in the existing technology, grains grow seriously, the carburization time is long and efficiency is low; and in-situ preparing of the Ti(C,N) base metal ceramic surface carburized layer in the sintering process is achieved.

Owner:SICHUAN UNIV

A kind of preparation method of gradient cemented carbide with graphite-rich phase on the surface

ActiveCN107058843BIncrease surface areaLarge granularityTransportation and packagingMetal-working apparatusPorosityHydrogen

The invention discloses a preparation method of a gradient cemented carbide with a graphite-rich surface, which is characterized in that it first heats the cemented carbide at 550-750°C for 2-4 hours to form a cemented carbide with a porosity of 25%-40%. Green body; then amorphous Si-C-O-coated TiH2 core / shell structure powder, multi-walled carbon nanotubes with outer diameter less than 8nm, length less than 30μm and specific surface area greater than 350m2 / g, Na2CO3 three kinds of substances by weight The ratio of 1:2:1 is mixed to prepare a hydrogen-containing carburizing medium; then the green body is embedded in the hydrogen-containing carburizing medium and compacted under a pressure of 5~15MPa; finally, liquid phase sintering is carried out to prepare a surface graphite-rich phase gradient cemented carbide. The invention overcomes the problems of severe grain growth, long carburizing time and low efficiency in the prior art, and prepares gradient hard alloy with graphite-rich phase on the surface during the sintering process.

Owner:SICHUAN UNIV

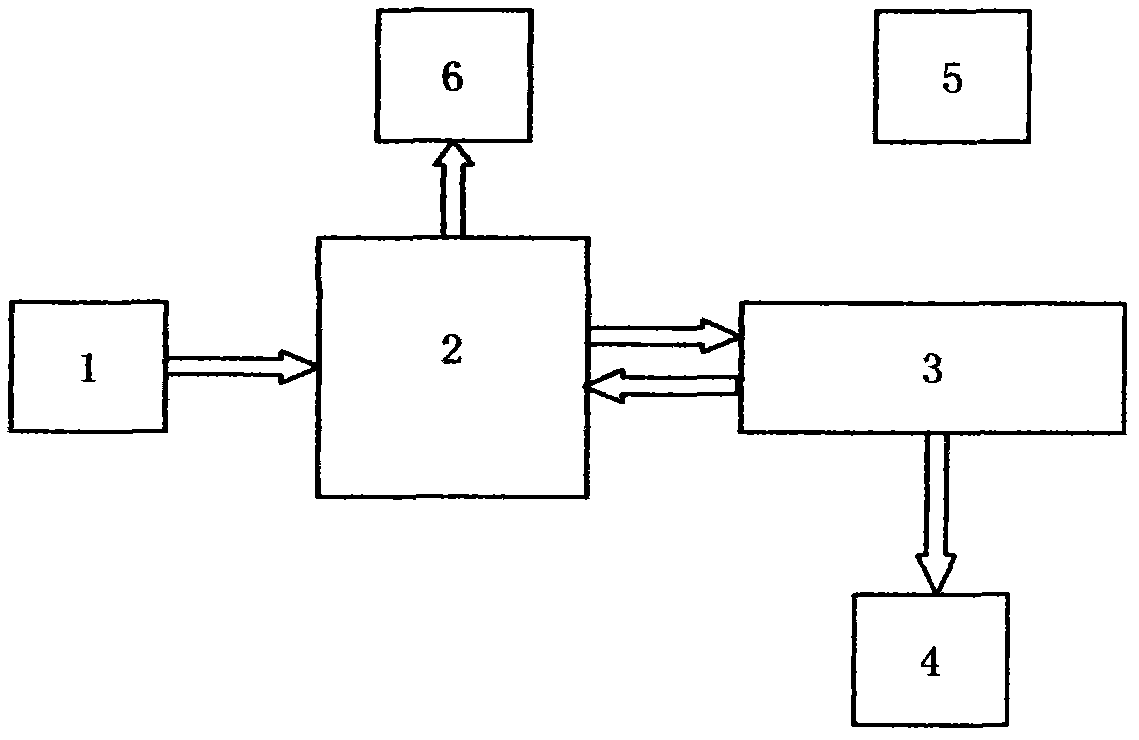

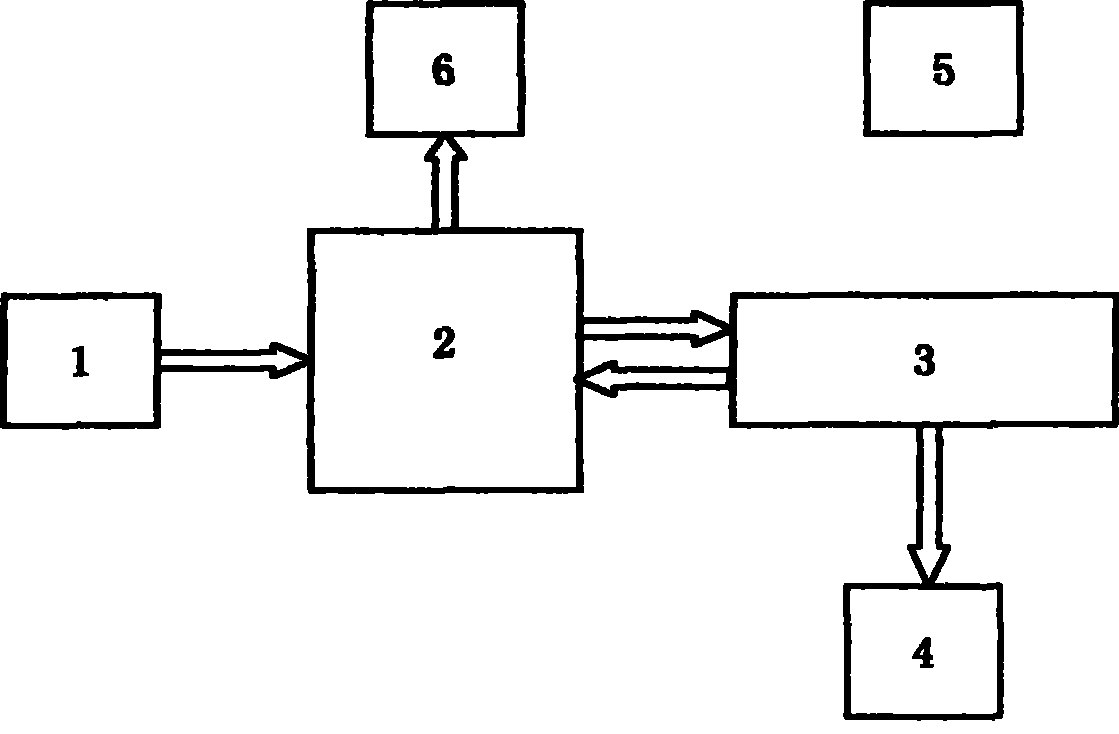

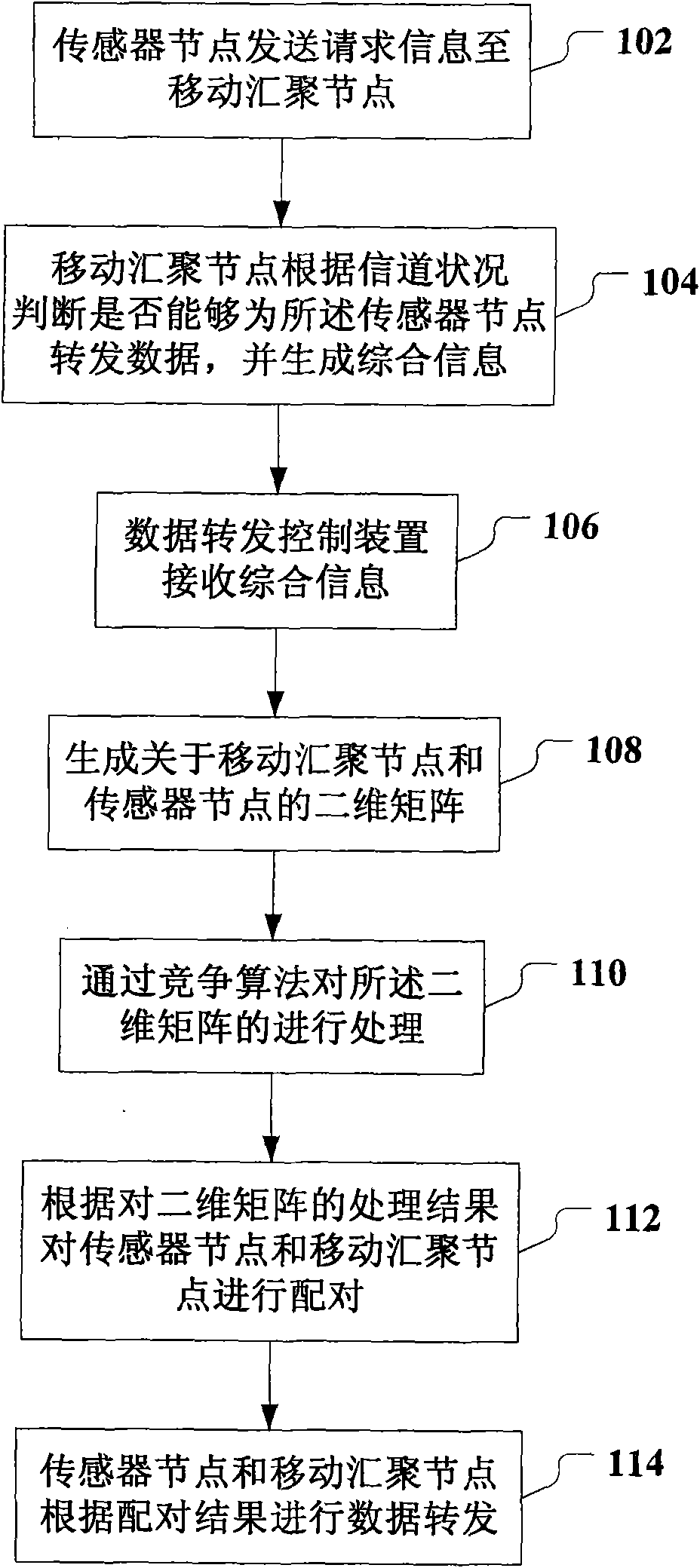

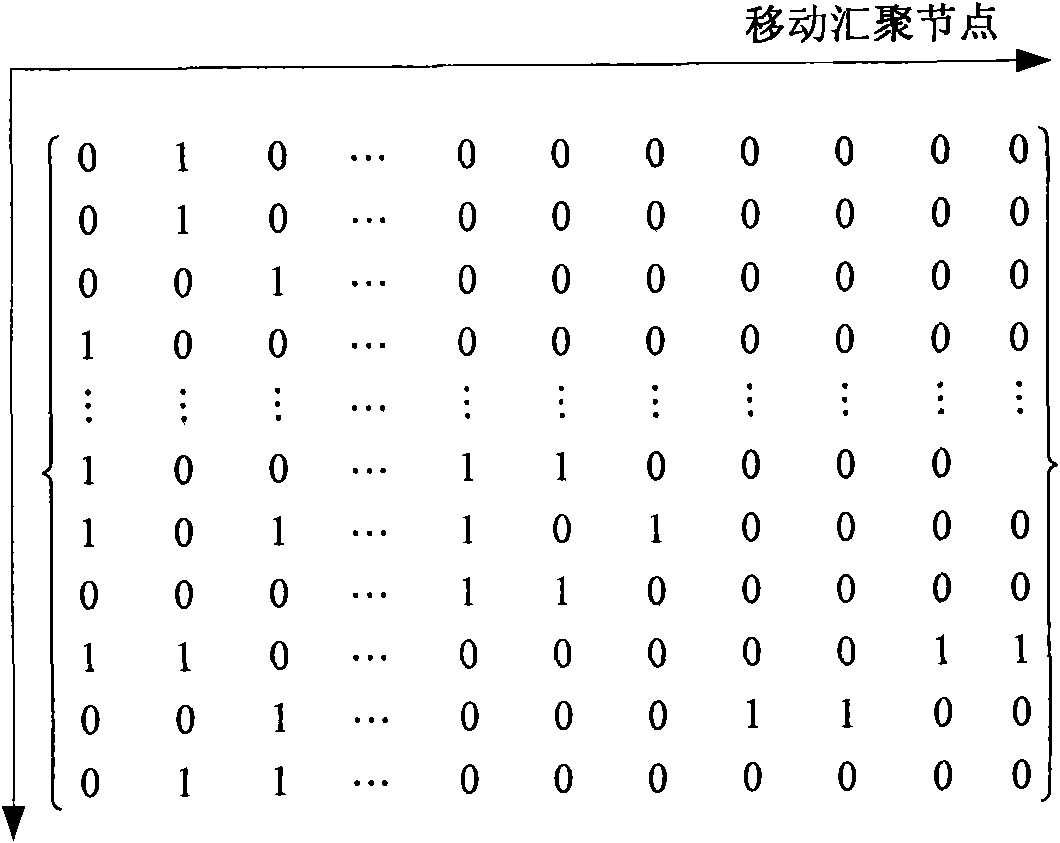

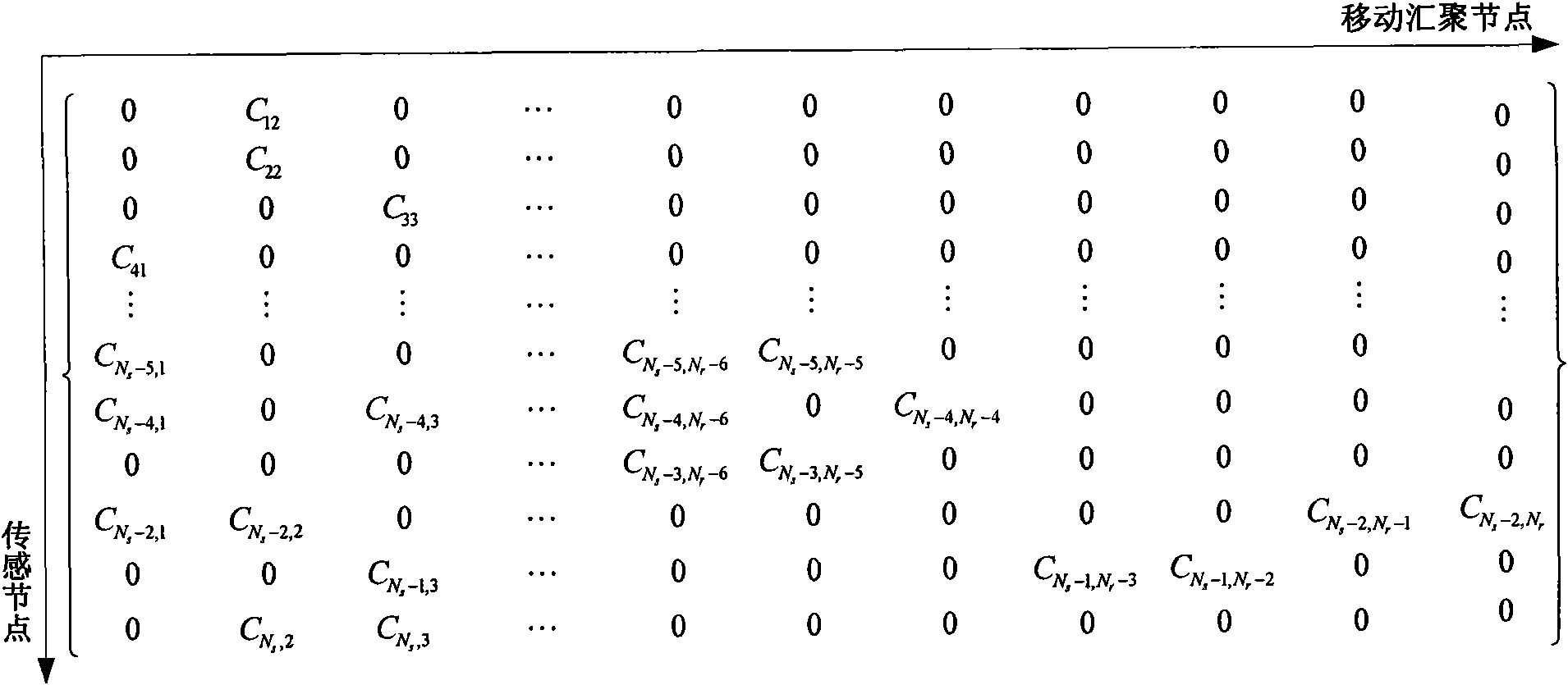

Data forwarding control method, device and system

The invention discloses a data forwarding control method, device and system. The data forwarding control method comprises the following steps: receiving the summarized information of data forwarding capability of each sensor node, wherein, the summarized information is sent by each mobile gathering point; according to the summarized information, generating a two-dimensional matrix about the mobile gathering points and the sensor nodes; processing the two-dimensional matrix by a competitive algorithm, and ensuring that each line in the two-dimensional matrix contains one nonzero value at most,i.e. each sensor node contains one mobile gathering point at most to forward data; and according to the processing result of the two-dimensional matrix, pairing the sensor nodes and the mobile gathering points. The data forwarding control method, device and system are characterized in that the mobile gathering nodes and the sensor nodes requiring data forwarding are subjected to one-to-one data forwarding pairing, so that the mobile gathering node has balanced load, and the phenomena of route blockage of certain mobile gathering node and quick exhaustion of energy can be eliminated.

Owner:CHINA MOBILE GROUP SHAIHAI

Preparation method of cermet wear-resistant material based on carbide-forming elements promoting carbon migration

ActiveCN107099721BFacilitated DiffusionImprove adsorption capacitySolid state diffusion coatingHydrogenWear resistant

The invention discloses a preparation method of metal ceramic wear resistant material based on carbide forming elements promoting carbon migration. The method is characterized by comprising the following steps: firstly performing heat preservation for 1 to 2 h at 500 to 700 DEG C, so as to form a metal ceramic body containing the carbide forming elements; then mixing core / shell structure powder of Al2O3 coated TiH2, graphene with the thickness being smaller than 3 nm, the number of layers being smaller than 3 and the specific surface area being greater than 250 m<2> / g, and Na2CO3 according to a weight percentage of 3:2:1, so as to prepare a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15 MPa; and finally performing liquid-phase sintering, so as to prepare the metal ceramic wear resistant material based on the carbide forming elements promoting carbon migration. The method overcomes the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the metal ceramic wear resistant material during a sintering process.

Owner:SICHUAN UNIV

A kind of in-situ preparation method of surface carburizing cemented carbide

ActiveCN106987751BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusHydrogenCarbon nanotube

Owner:SICHUAN UNIV

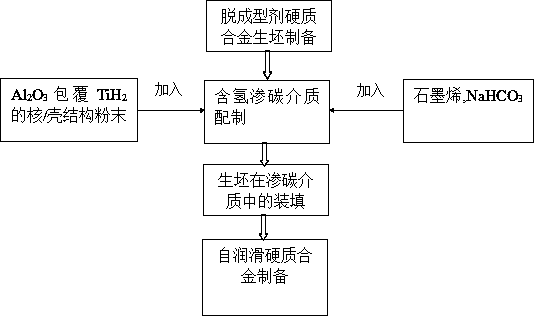

A kind of self-lubricating cemented carbide preparation method

ActiveCN107142409BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityAlloy

The invention discloses a preparation method of a self-lubricating hard alloy. The preparation method of the self-lubricating hard alloy is characterized in that the temperature is kept at 550-750 DEG C for 2-4 hours, so that a forming-agent-free hard alloy green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2, graphene and NaHCO3 are mixed at the weight percentage ratio of 1:2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating hard alloy is achieved in the sintering process. The preparation method of the self-lubricating hard alloy solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating hard alloy is prepared in the sintering process.

Owner:SICHUAN UNIV

Preparation method of surface self-lubricating ti(c,n)-based cermet based on metal hydride

The invention discloses a preparation method of self-lubricating surface Ti (C, N)-based metal ceramic based on a metal hydride. The method is characterized by comprising the following steps: firstly performing heat preservation for 1 to 2 h at 500 to 700 DEG C, so as to form a metal ceramic body containing carbide forming elements; and then mixing core / shell structure powder of Al2O3 coated TiH2, a multiwalled carbon nanotube with the external diameter being smaller than 8 nm, the length being smaller than 30 micrometers and the specific surface area being greater than 350 m<2> / g, and NaHCO3 according to a weight percentage of 3:2:1, so as to prepare a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15 MPa; and finally performing liquid-phase sintering, so as to prepare the self-lubricating surface Ti (C, N)-based metal ceramic. The method overcomes the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the self-lubricating surface Ti (C, N)-based metal ceramic during a sintering process.

Owner:SICHUAN UNIV

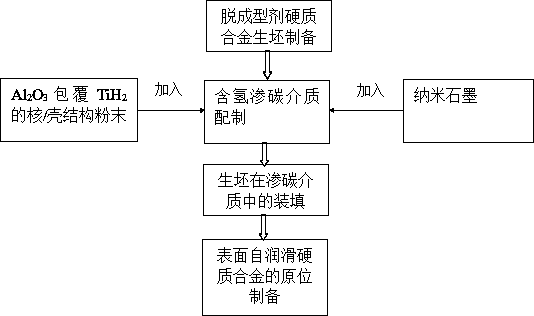

A kind of in-situ preparation method of surface self-lubricating cemented carbide

ActiveCN107043883BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityHydrogen

The invention discloses an in-situ preparation method of a hard alloy achieving surface self-lubrication. The in-situ preparation method of the hard alloy achieving surface self-lubrication is characterized in that forming-agent-free hard alloy green bodies with the porosity being 25%-40% are formed under the condition that the temperature of 550-750 DEG C is kept for 2-4 h; core / shell structure powder with Al2O3 covering TiH2 and nanometer graphite with the thickness granularity being 30-50 nm are mixed at the weight percentage ratio of 1:2 so as to prepare a carburizing medium containing hydrogen; the green bodies are embedded into the carburizing medium containing hydrogen and are compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and in-situ preparation of the hard alloy achieving surface self-lubrication is achieved based on carbon migration. The in-situ preparation method of the hard alloy achieving surface self-lubrication overcomes the problems that in the prior art, grains grow severely, the carburizing time is long and efficiency is low, and in-situ preparation of the hard alloy achieving surface self-lubrication is achieved in the sintering process.

Owner:SICHUAN UNIV

A kind of preparation method of cemented carbide with graphite-rich phase on the surface

ActiveCN107058842BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusGraphiteAlloy

Owner:SICHUAN UNIV

A preparation method of surface self-lubricating ti(c,n) based cermet wear-resistant material

ActiveCN107142407BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityWear resistant

The invention discloses a preparation method of a self-lubricating surface type Ti(C, N)-based cermet wear-proof material. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is characterized in that the temperature is kept at 500-650 DEG C for 2-4 h, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; core / shell structure powder with Al2O3 covering TiH2 and graphene are mixed at the weight percentage ratio of 2:1 to be prepared into a hydrogenous carburizing medium, wherein the thickness of the graphene is smaller than 3 nm, the number of layers of the graphene is smaller than 3, and the specific surface area of the graphene is larger than 250 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and preparation of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is achieved. The preparation method of the self-lubricating surface type Ti(C, N)-based cermet wear-proof material solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the self-lubricating surface type Ti(C, N)-based cermet wear-proof material is prepared in the sintering process.

Owner:SICHUAN UNIV

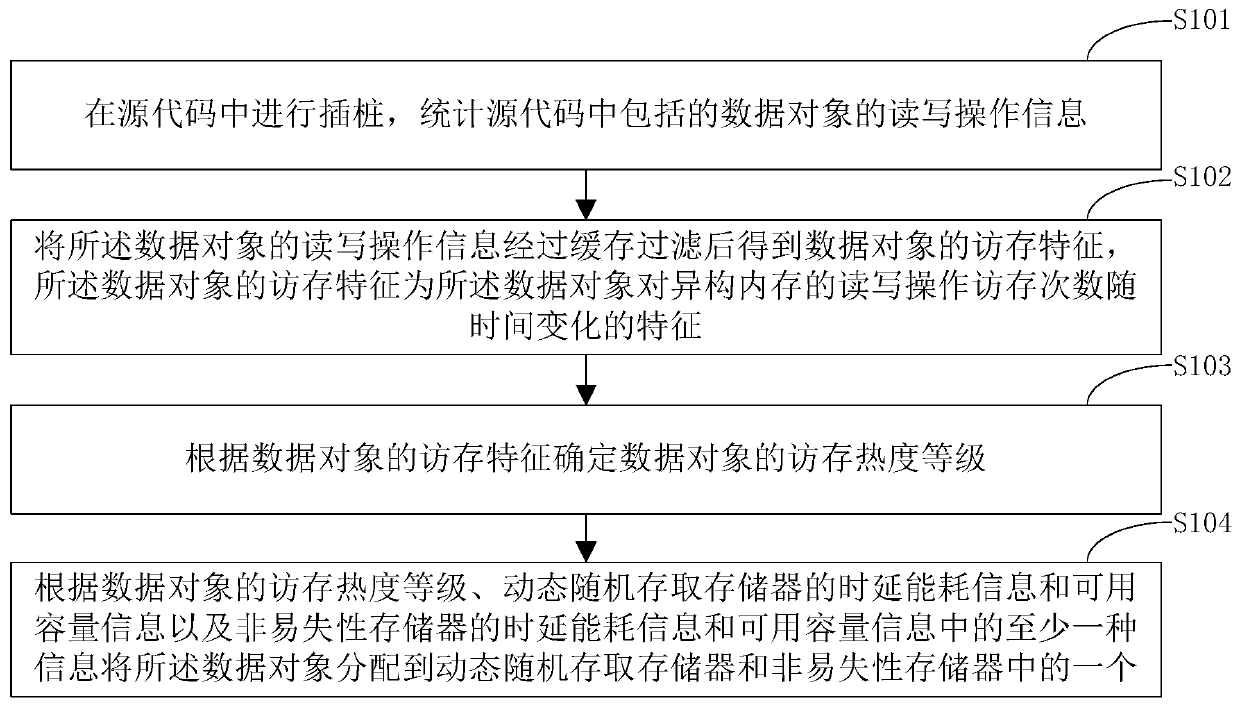

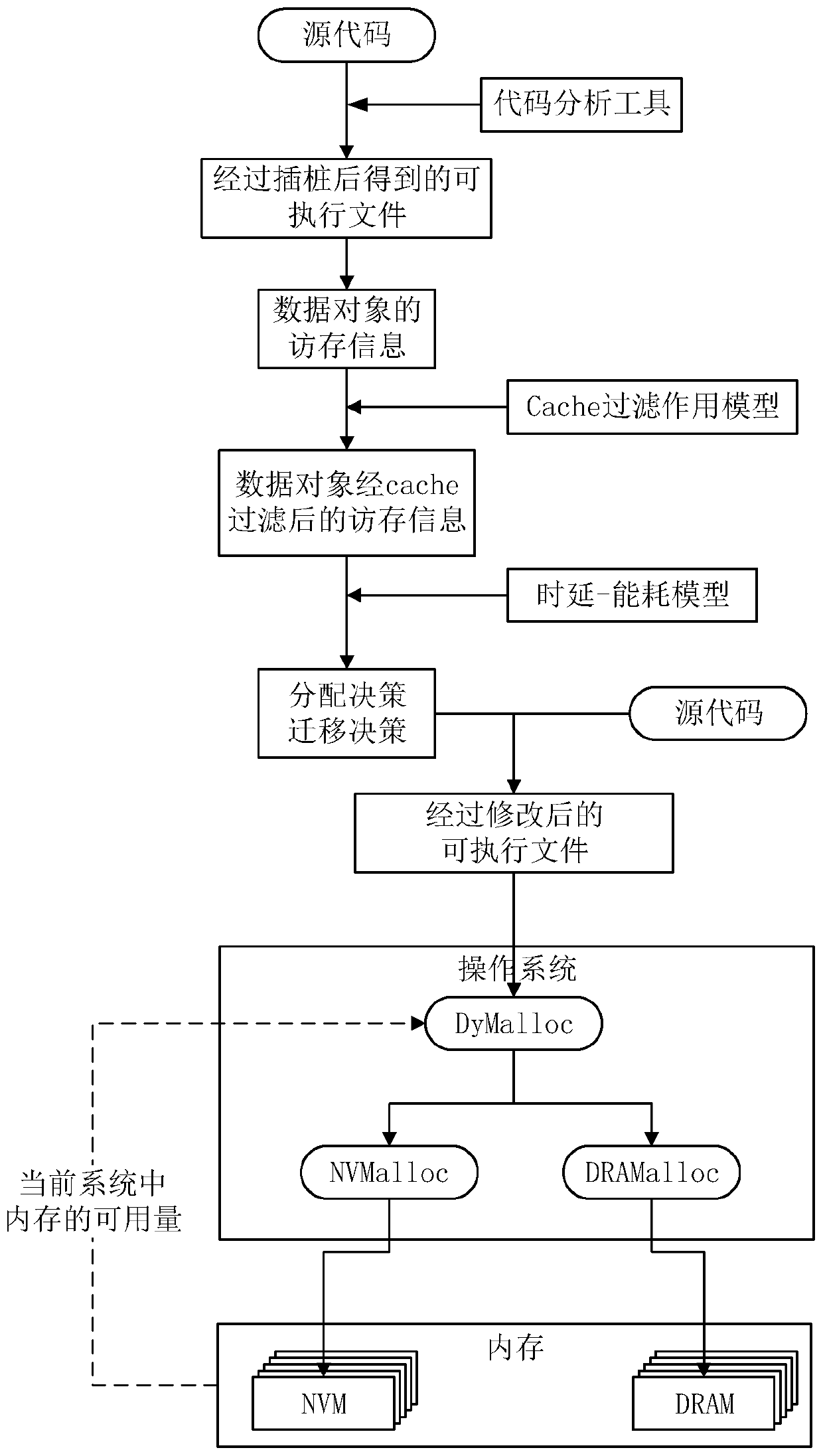

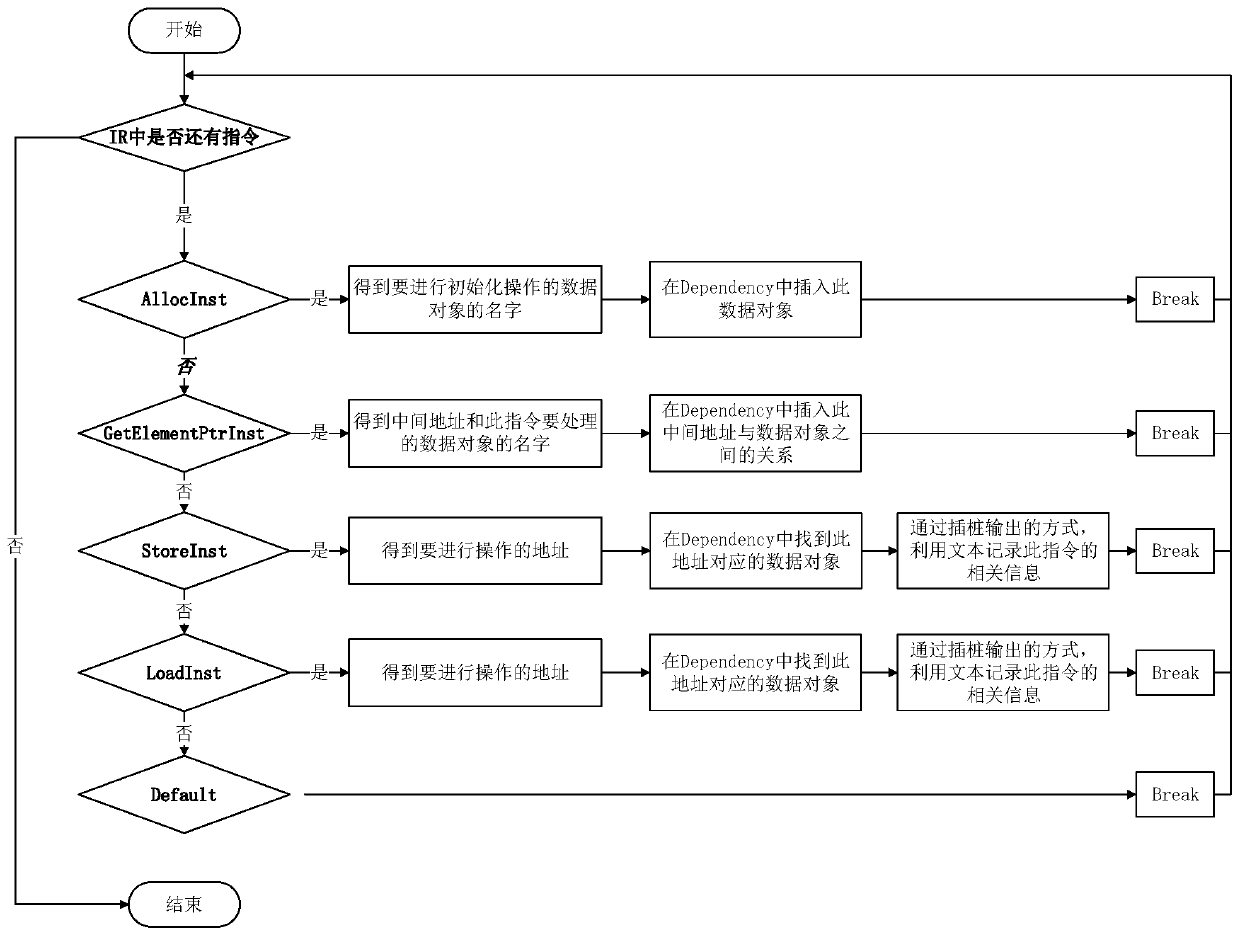

A heterogeneous memory allocation method and system based on data object popularity

ActiveCN107168654BHuge monitoring overheadReduce wasteInput/output to record carriersStatic random-access memoryTime delays

The invention discloses a method and a system for heterogeneous memory allocation based on data object hot degree. The method comprises; performing instrumentation in source codes, counting reading-writing operation information of data objects included in the source codes; through performing cache filtering on the reading-writing operation information of the object, obtaining memory access characteristics of the data object, the memory access characteristics of the data object being characteristic of variation of reading-writing operation memory access frequency of the data object on heterogeneous memory with time; according to the memory access characteristics of the data object, determining memory access hot degree grade of the data object; according to the memory access hot degree grade of the data object, at least a piece of information of time delay energy consumption information and available capacity information of a dynamic random access memory, and time delay energy consumption information and available capacity information of a nonvolatile memory, distributing the data object to one of the dynamic random access memory and the nonvolatile memory. In the method, an object is used as a minimum granularity, resource waste on memory bandwidth can be reduced, and availability of the memory is considered, and performance of the system is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

Downhole Oil-Water Interface Detector

ActiveCN106092256BAccurate measurementHigh measurement accuracyLevel indicators by physical variable measurementElectrical connectionEngineering

The invention provides a downhole oil-water interface detector which comprises a detection sensor D and a ground detector M. A plurality of detection structures are arranged on the detection sensor D, first ends of the multiple detection structures are electrically connected with one another, second ends of the multiple detection structures are connection contact points which are sequentially arranged along the height directions of the detection structures at intervals, and each detection structure comprises a detection resistor R; the ground detector M is connected with the detection sensor D, measurement voltages Vc can be outputted to the detection sensor D by the ground detector M, and measurement currents Ic which flow through the detection sensor D can be detected by the ground detector M, so that the heights of oil-water interfaces can be judged according to the measurement currents Ic. The downhole oil-water interface detector has the advantage that detection effects can be improved by the downhole oil-water interface detector.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

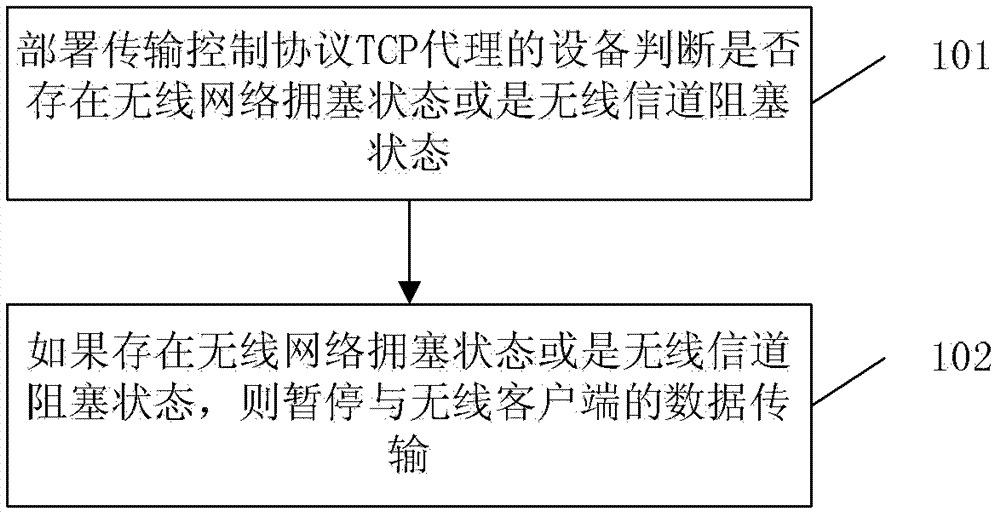

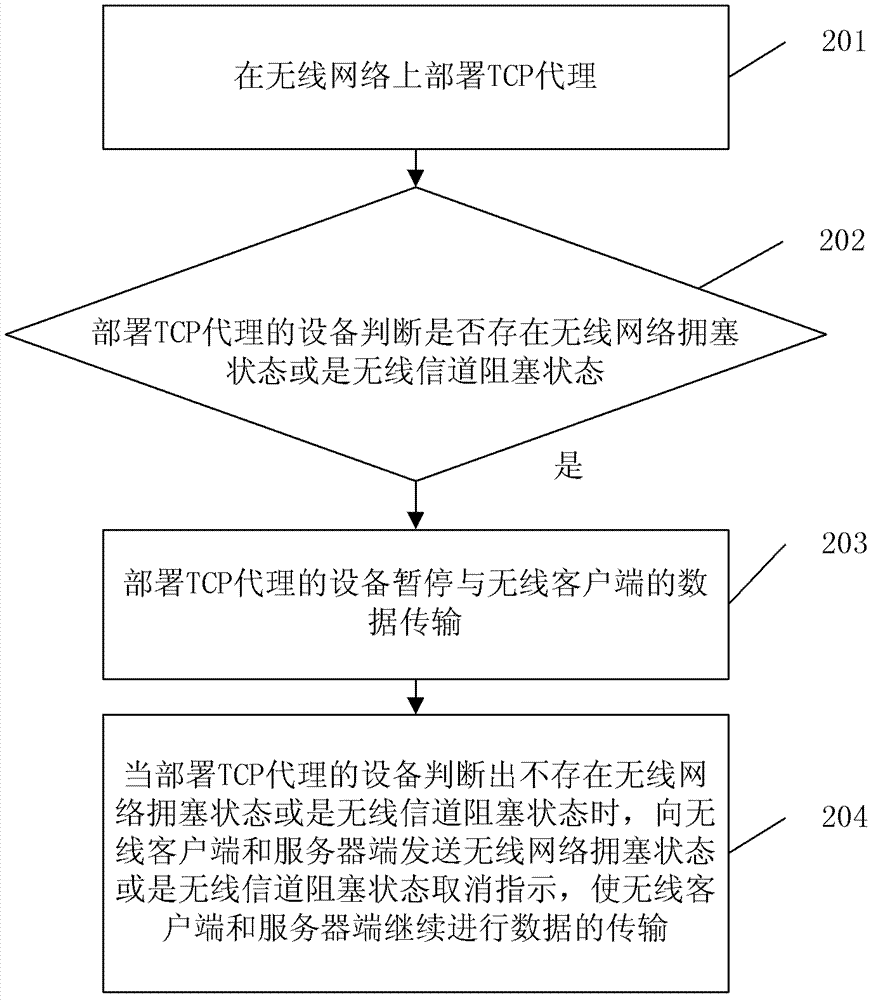

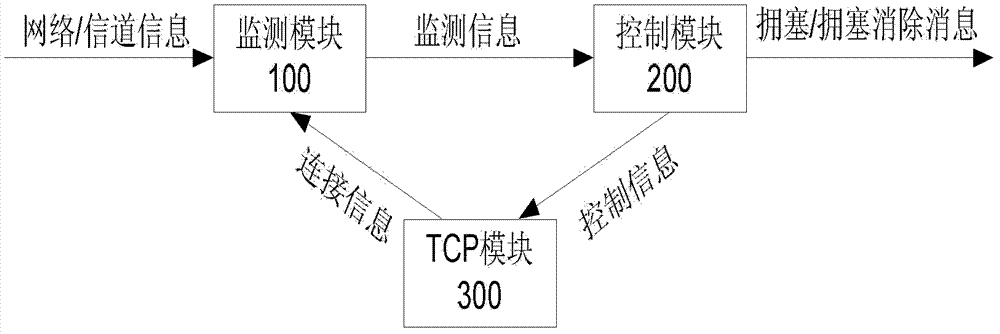

Method, apparatus and system for controlling data transmission

ActiveCN103098510BAvoid running out quicklyAchieve the beneficial effect of saving electricityNetwork traffic/resource managementTransmissionHigh rateClient-side

A method, an apparatus and a system for controlling data transmission are provided in the embodiments of the present invention, which relate to communication technical field. The method comprises: a device deploying a Transmission Control Protocol (TCP) agent determines whether a wireless network congestion state or a wireless channel congestion state is existed; if the wireless network congestion state or the wireless channel congestion state is existed, the data transmission with a wireless client will be suspended. By deploying the TCP agent in the wireless network, with the present invention, the wireless network and the channel information are monitored so that suspending the TCP data transmission with the wireless client can be achieved when the wireless network or channel is congested, the data transmission in a higher rate is transmitted when the wireless network congestion or channel congestion is removed, and thereby the problem that the battery power is consumed rapidly resulted by the online data transmission in a lower rate during a long time is avoided, and the beneficial effect of power saving is achieved.

Owner:HUAWEI TECH CO LTD

Preparation method of surface self-lubricating ti(c,n)-based cermets formed in situ with carbon gradient

ActiveCN107142406BFacilitated DiffusionImprove adsorption capacitySolid state diffusion coatingCarbon nanotubeCarbide

The invention discloses a method for preparing carbon gradient in-situ formed surface self-lubrication type Ti(C, N)-based cermet. The method for preparing carbon gradient in-situ formed surface self-lubrication type Ti(C, N)-based cermet is characterized in that firstly, the temperature is kept at 500-700 DEG C for 1-2 hours, so that a cermet green body containing a carbide forming element is formed; SiO2 core / shell structure powder covered with TiH2, multi-walled carbon nanotubes and BaCO3 are mixed according to the weight percentage ratio of 3:2:1 to be prepared into a hydrogenous carburizing medium, wherein the outer diameter of each multi-walled carbon nanotube is smaller than 8 nm, the length of each multi-walled carbon nanotube is smaller than 30 microns, and the specific surface area of each multi-walled carbon nanotube is larger than 350 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and the self-lubrication surface type Ti(C, N)-based cermet is prepared. The self-lubrication surface type Ti(C, N)-based cermet preparation method adopting carbon gradient in-situ formation solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the surface self-lubrication type Ti(C, N)-based cermet is prepared based on carbon gradient in-situ formation in the sintering process.

Owner:SICHUAN UNIV

In-Situ Preparation Method of Ti(c,n)-Based Cermet Surface Carburized Layer

ActiveCN106995897BFacilitated DiffusionImprove adsorption capacityTransportation and packagingMetal-working apparatusCarbon layerHydrogen

The invention discloses an in-situ preparation method for a carburized layer on the surface of a Ti(C,N)-based cermet, which is characterized in that it is firstly kept at 500-700°C for 1-2 hours to form a cermet green body containing carbide-forming elements ; Then amorphous Si-C-O-coated TiH2 core / shell structure powder, two materials of nano-graphite with a particle size of 30~50nm are mixed by weight percentage 3:2 to prepare a hydrogen-containing carburizing medium; then the green body is buried into the hydrogen-containing carburizing medium and compacted under a pressure of 5-15MPa; finally, liquid-phase sintering is carried out to form a Ti(C,N)-based cermet surface carburized layer in situ. The invention overcomes the problems of serious grain growth, long carburizing time and low efficiency in the existing technology, and realizes in-situ preparation of the carburized layer on the surface of Ti(C,N)-based cermet during the sintering process.

Owner:SICHUAN UNIV

Porcelain formula and production process

InactiveCN112126811AHigh mechanical strengthImprove antifouling performanceAnodisationSolid state diffusion coatingSodium aluminateCerium

The invention provides a porcelain formula and a production process. According to the porcelain formula and the production process, zinc powder, cerium oxide, aluminum oxide, sodium silicate, sodium fluoroaluminate, aniline, nano-graphite, silicon dioxide coated titanium hydride and the like are used as raw materials to prepare a porcelain product which has excellent mechanical strength, an antifouling property and an antibacterial property, wherein the silicon dioxide coated titanium hydride is prepared by a method which comprises the following steps of: firstly, adding titanium hydride intoan ethanol aqueous solution, and ultrasonically dispersing uniformly to obtain prefabricated liquid; and then adding alkylphenol ethoxylates and silicon tetrachloride into p-bromotoluene, slowly dropwise adding the prefabricated liquid while stirring, and carrying out hydrolysis and post-treatment to obtain the silicon dioxide coated titanium hydride.

Owner:长沙而道新能源科技有限公司

In situ preparation method of surface self-lubricating ti(c,n) based cermets based on carbon diffusion

ActiveCN107142405BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityDiffusion

The invention discloses a method for preparing surface self-lubrication type Ti(C, N)-based cermet in situ based on carbon diffusion. The method for preparing the surface self-lubrication type Ti(C, N)-based cermet in situ based on carbon diffusion is characterized in that firstly, the temperature is kept at 500-650 DEG C for 2-4 hours, so that a forming-agent-free cermet green body with the porosity being 25%-40% is formed; Al2O3 core / shell structure powder covered with TiH2, graphene with the particle sizing being 30-50 nm and BaCO3 are mixed according to the weight percentage ratio of 2:1:1 to be prepared into a hydrogenous carburizing medium; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and the self-lubrication surface type Ti(C, N)-based cermet is prepared in situ based on carbon diffusion. The method for preparing the self-lubrication surface type Ti(C, N)-based cermet in situ based on carbon diffusion solves the problems that in the prior art, grains grow severely, the carburizing time is long and efficiency is low, and in-site preparation of the surface self-lubrication type Ti(C, N)-based cermet is achieved in the sintering process.

Owner:SICHUAN UNIV

Method for preparing surface carbon gradient in-situ formed self-lubrication type Ti(C, N)-based cermet

ActiveCN107142406ASimple processAvoid running out quicklySolid state diffusion coatingLubricationCrystallite

The invention discloses a method for preparing carbon gradient in-situ formed surface self-lubrication type Ti(C, N)-based cermet. The method for preparing carbon gradient in-situ formed surface self-lubrication type Ti(C, N)-based cermet is characterized in that firstly, the temperature is kept at 500-700 DEG C for 1-2 hours, so that a cermet green body containing a carbide forming element is formed; SiO2 core / shell structure powder covered with TiH2, multi-walled carbon nanotubes and BaCO3 are mixed according to the weight percentage ratio of 3:2:1 to be prepared into a hydrogenous carburizing medium, wherein the outer diameter of each multi-walled carbon nanotube is smaller than 8 nm, the length of each multi-walled carbon nanotube is smaller than 30 microns, and the specific surface area of each multi-walled carbon nanotube is larger than 350 m<2> / g; the green body is embedded into the hydrogenous carburizing medium and is compacted at the pressure of 5-15 MPa; and finally, liquid-phase sintering is conducted, and the self-lubrication surface type Ti(C, N)-based cermet is prepared. The self-lubrication surface type Ti(C, N)-based cermet preparation method adopting carbon gradient in-situ formation solves the problems that in the prior art, grains grow severely, the carburizing time is long, and efficiency is low, and the surface self-lubrication type Ti(C, N)-based cermet is prepared based on carbon gradient in-situ formation in the sintering process.

Owner:SICHUAN UNIV

Preparation method of surface self-lubricating ti(c,n) based cermet based on carbon migration

ActiveCN107099722BIncrease surface areaImprove adsorption capacitySolid state diffusion coatingPorosityHydrogen

The invention discloses a preparation method of self-lubricating surface Ti (C, N)-based metal ceramic based on carbon migration. The method is characterized by comprising the following steps: firstly performing heat preservation for 2 to 4h at 500 to 700 DEG C, so as to form a metal ceramic body with the porosity being 25 to 40 percent and a shaping agent being removed; then mixing a core / shell structure powder of amorphous Si-C-O coated TiH2, graphene with the thickness being smaller than 3nm, the number of layers being smaller than 3 and the specific surface area being greater than 250m2 / g, and Na2CO3 according to a weight percentage of 2:1:1, so as to a hydrogen-containing carburizing medium; embedding the metal ceramic body into the hydrogen-containing carburizing medium, and performing compaction at 5 to 15MPa; and finally performing liquid-phase sintering, so as to prepare the self-lubricating surface Ti (C, N)-based metal ceramic. The method solves the problems of serious crystal grain growth, long carburizing time and low efficiency in the prior art, and realizes the preparation of the self-lubricating surface Ti (C, N)-based metal ceramic during a sintering process.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com