Downhole oil-water interface detector

A technology of oil-water interface and detector, which is applied in the direction of liquid level indicator for physical variable measurement, which can solve the problems of poor detection effect of downhole detection sensors and achieve high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

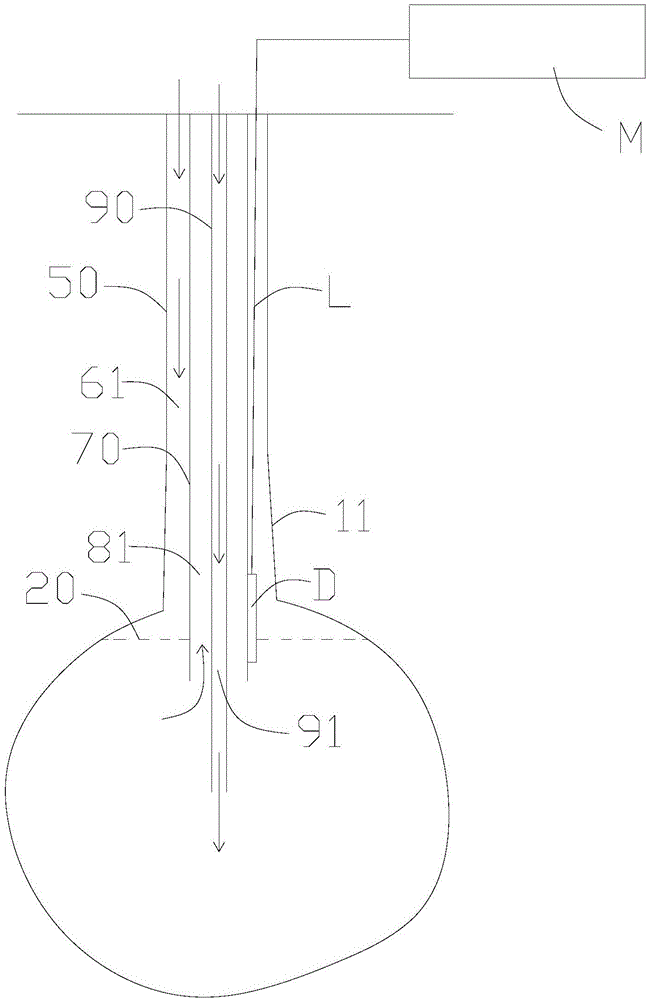

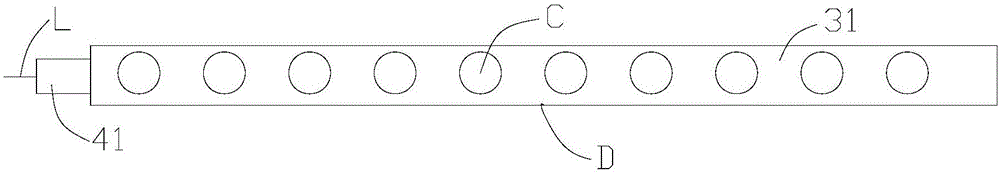

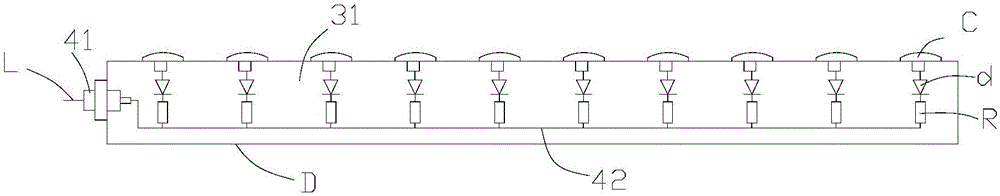

[0034] Such as Figures 1 to 5 As shown, in the process of cavitation, water is injected through the cavitation inner tube 90 , the cavitation inner tube 90 is covered with the cavitation outer tube 70 , and the cavitation outer tube 70 is covered with the casing 50 . The inner cavity 91 of the cavity-making inner tube 90 is a water injection channel, the inner annular channel 81 between the cavity-making outer tube 70 and the cavity-making inner tube 90 is a channel for discharging brine, and the outer tube between the casing 50 and the cavity-making outer tube 70 The annular passage 61 is a passage for injecting diesel oil. Below the casing 50 is the open hole section 11 .

[0035] During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com