A kind of in-situ preparation method of surface self-lubricating cemented carbide

A cemented carbide, in-situ preparation technology, applied in the direction of metal material coating process, solid diffusion coating, coating, etc., can solve the problems of long carburizing time, grain growth, low efficiency, etc., to improve carburizing Effects of carbon efficiency, small particle size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

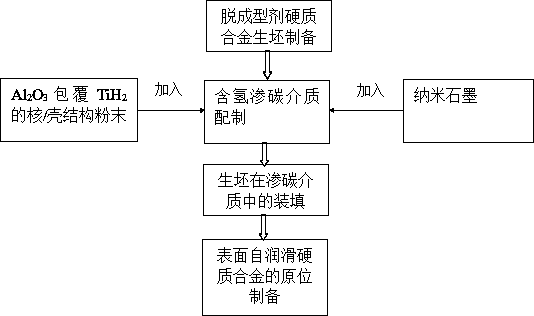

Method used

Image

Examples

example 1

[0018] Example 1: Prepare surface self-lubricating carbide in situ according to the following steps:

[0019] (1) Preparation of green body of cemented carbide with release agent: Weigh various raw material powder ingredients according to weight percentage, among which Co accounts for 20wt%, and WC is the balance; mix the weighed powder and pass through 48h ball milling, 400 mesh screen Filtrate, dry at 86°C, mix 90% of the weight of cemented carbide powder with Buna-Na rubber molding agent, press and form under a pressure of 340MPa to obtain a cemented carbide green body; keep the cemented carbide green body at 570°C for 3 hours in a vacuum sintering furnace , the heating rate is 2°C / min, the vacuum degree is 21Pa, and the cemented carbide green body with a porosity of 27% and the removal of the forming agent is formed;

[0020] (2) Preparation of hydrogen-containing carburizing medium: first weigh TiH with a particle size of 0.6 μm 2 The powder is added to absolute ethanol ...

example 2

[0023] Example 2: Prepare surface self-lubricating carbide in situ according to the following steps:

[0024] (1) Preparation of the release agent cemented carbide green body: Weigh various raw material powder ingredients by weight percentage, of which Co accounts for 8wt%, TiC accounts for 5wt%, TaC accounts for 1wt%, and WC is the balance; the weighed powder Mixed and ball milled for 60 hours, filtered with a 400-mesh screen, dried at 92°C, mixed with butadiene rubber molding agent according to 95% of the weight of the cemented carbide powder, and pressed under a pressure of 310MPa to obtain a cemented carbide green body; cemented carbide raw The blank is kept in a vacuum sintering furnace at 640°C for 3 hours, the heating rate is 5°C / min, and the vacuum degree is 20Pa, forming a cemented carbide green body with a porosity of 35% and the removal of forming agents;

[0025] (2) Preparation of hydrogen-containing carburizing medium: first weigh TiH with a particle size of 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com