Device for preparing ultrathin carbon/carbon composite material panel and preparation method of panel

A carbon composite material, ultra-thin technology, applied in ceramic products, applications, household appliances, etc., can solve the problem of ineffective carburization, failure to meet the density requirements of ultra-thin carbon/carbon composite material panels, and affect the uniformity of component density problems such as resistance, to achieve the effect of uniform density and uniform chemical vapor carburizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

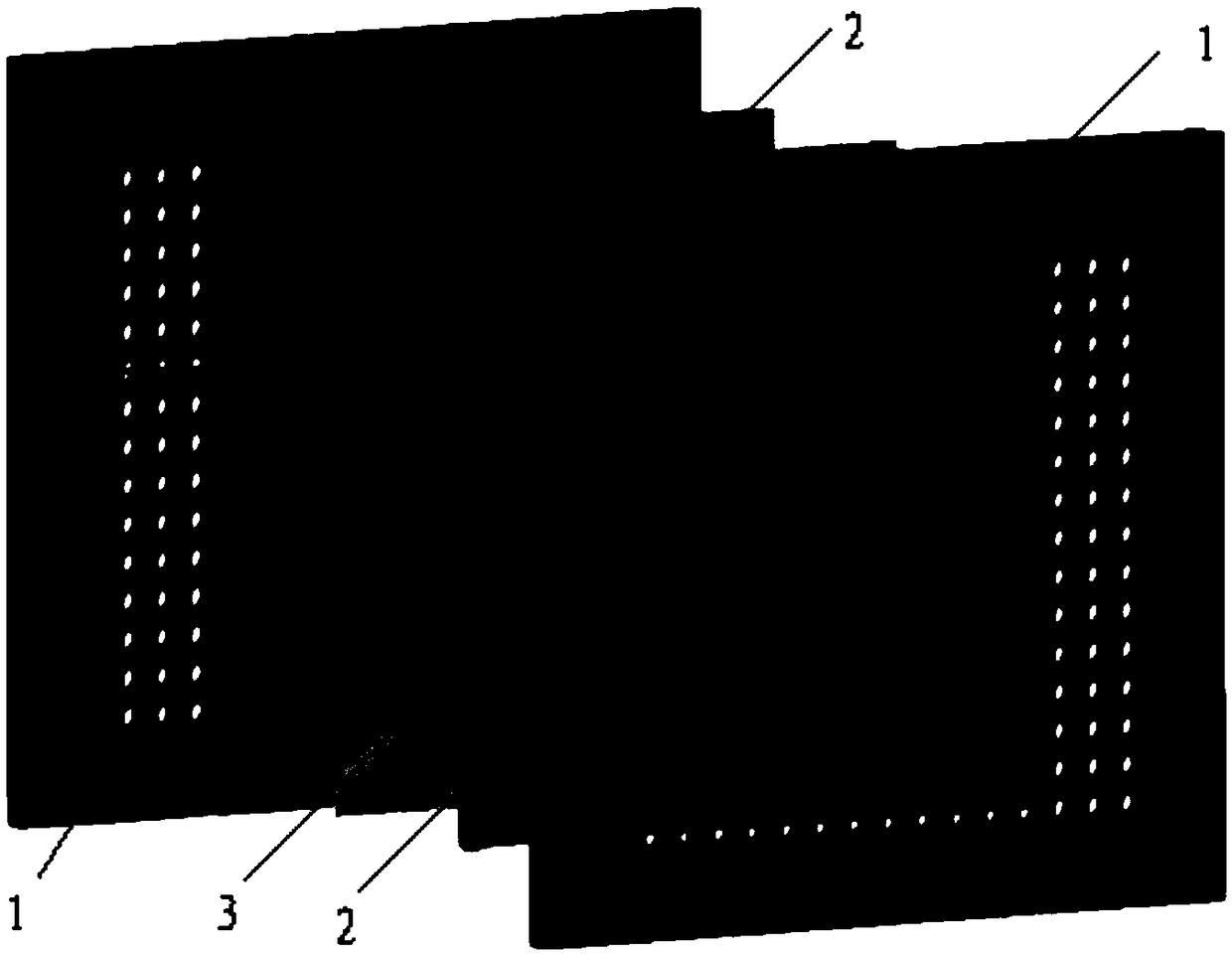

[0033] See attached figure 2 , a device for preparing an ultra-thin carbon / carbon composite panel, the device includes a hollow graphite plate and a microporous air guide plate; the hollow graphite plate and the microporous air guide plate are stacked to form a support plate, and the An ultra-thin carbon / carbon composite material blank is sandwiched between the microporous air guide plates of the plate, and the two support plates are fastened with fasteners to form a device for preparing ultra-thin carbon / carbon composite material panels;

[0034] The thickness of the microporous air guide plate is 5mm, and the density is 1.0g / cm 3 ;

[0035] The thickness of the hollow graphite plate is 30-50mm, and the hollow area accounts for 40-60% of the total area of the graphite plate;

[0036] Use bolts to pass through the bolt holes arranged on the hollow graphite plate, and fasten with nuts.

Embodiment 2

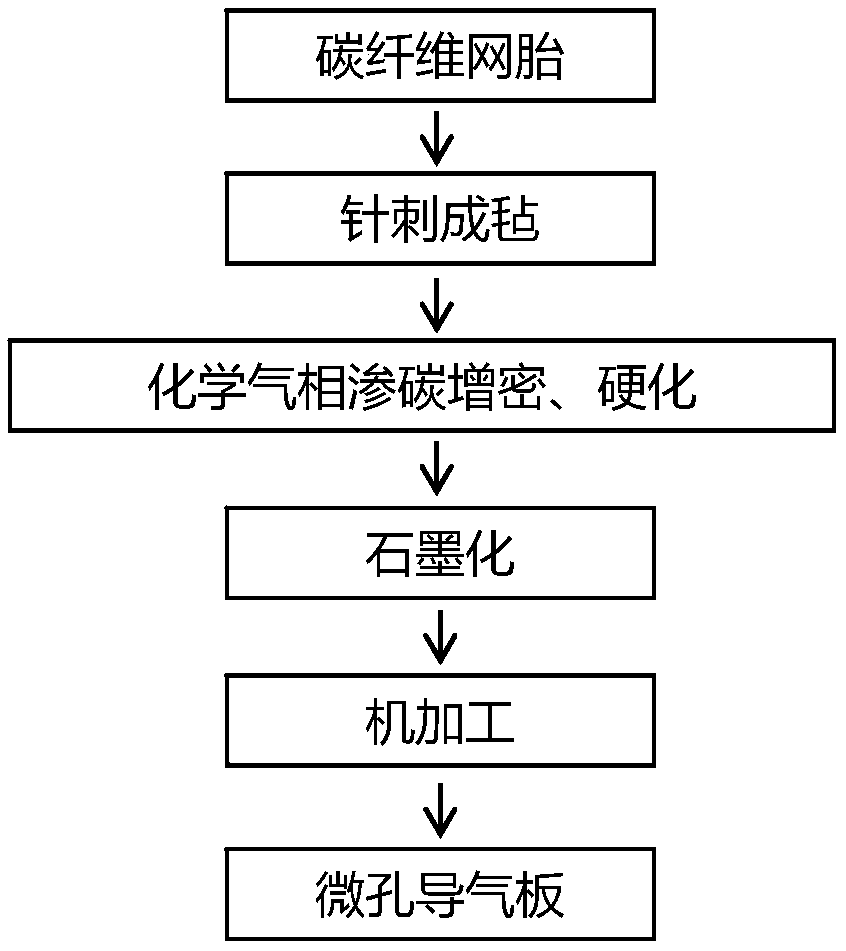

[0038] See attached figure 1 , a microporous air guide plate in a device for preparing ultra-thin carbon / carbon composite panels is prepared by the following scheme:

[0039] The thickness is 1mm, the density is 0.03g / cm 3 T700 carbon fiber mesh tire needle punched to a thickness of 3mm and a density of 0.3g / cm 3 The flat felt is densified to 1.6g / cm by chemical vapor carburizing 3 1. After hardening, carry out graphitization treatment, and machine to obtain a microporous air guide plate with a thickness of 1mm;

[0040] Chemical vapor carburizing densification process parameters are: CH 4 It is carbon source gas, the furnace temperature is controlled at 1000°C, the furnace pressure is 1kPa, and the furnace is released after cumulative chemical vapor carburizing for 50 hours;

[0041]The graphitization treatment system is: control the atmosphere in the furnace to be argon 0.11-0.13MPa, the furnace temperature to be 2000°C, the holding time to be 2h, and cool down with the ...

Embodiment 3

[0046] A microporous air guide plate in a device for preparing ultra-thin carbon / carbon composite panels is prepared by the following scheme:

[0047] The thickness is 3mm, the density is 0.03g / cm 3 T700 carbon fiber mesh tire needle punched to a thickness of 8mm and a density of 0.2g / cm 3 The flat felt is densified to 0.3g / cm by chemical vapor carburizing 3 , After hardening, carry out graphitization treatment, and machine to obtain a 6mm thick microporous air guide plate;

[0048] Chemical vapor carburizing densification process parameters are: CH 4 It is carbon source gas, the furnace temperature is controlled at 1000°C, the furnace pressure is 3kPa, and the furnace is released after cumulative chemical vapor carburizing for 5 hours;

[0049] The graphitization treatment system is as follows: the atmosphere in the furnace is controlled to be argon 0.11-0.13MPa, the furnace temperature is 2300°C, the holding time is 1h, and the furnace is cooled.

[0050] The device for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com