Carbide coating based on high-melting-point metal and preparation method thereof

A technology of high melting point metals and carbides, applied in the field of electrochemistry, can solve the problems of hindering carbon infiltration, low carburizing speed, and low carburizing efficiency, so as to improve carburizing efficiency, not easy to crack, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

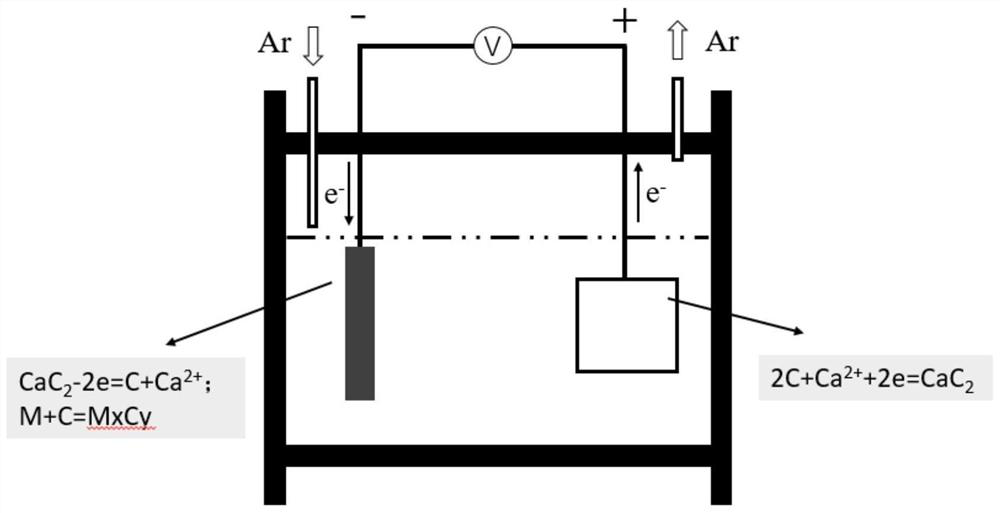

[0045] Embodiments of the present invention provide a method for preparing a carbide coating based on a refractory metal, such as Figure 7 As shown, the method includes:

[0046] Step S1, pretreating the high melting point metal workpiece to obtain the pretreated metal workpiece;

[0047] Step S2, after drying the anhydrous chloride inorganic salt, melt it under an inert atmosphere and add CaC 2 Dissolving to obtain molten salt;

[0048] Step S3, using the graphite electrode as the cathode and the pretreated metal workpiece as the anode, placing it in the molten molten salt, performing electrolysis by means of constant current density or constant voltage electrolysis, and taking out the anode after the electrolysis is completed It is washed and dried to obtain a carbide coating based on a refractory metal.

[0049] Compared with the molten salt electrochemical cathode carburizing technology, the present invention provides a reducing electrolyte environment, which can avoid...

Embodiment 1

[0076] At 850°C, graphite crucible filled with CaCl 2 Molten salt, add 2wt.% CaC 2 , the anode is a mechanically polished Mo sheet, using molten salt electrolysis, with a current density of 5mA / cm 2 The constant current electrolysis method, the electrolysis time is 4 hours, the obtained sample passed the XRD test and the cross-sectional optical photo, and prepared a layer of molybdenum carbide film on the surface of the Mo sheet, such as figure 2 .

Embodiment 2

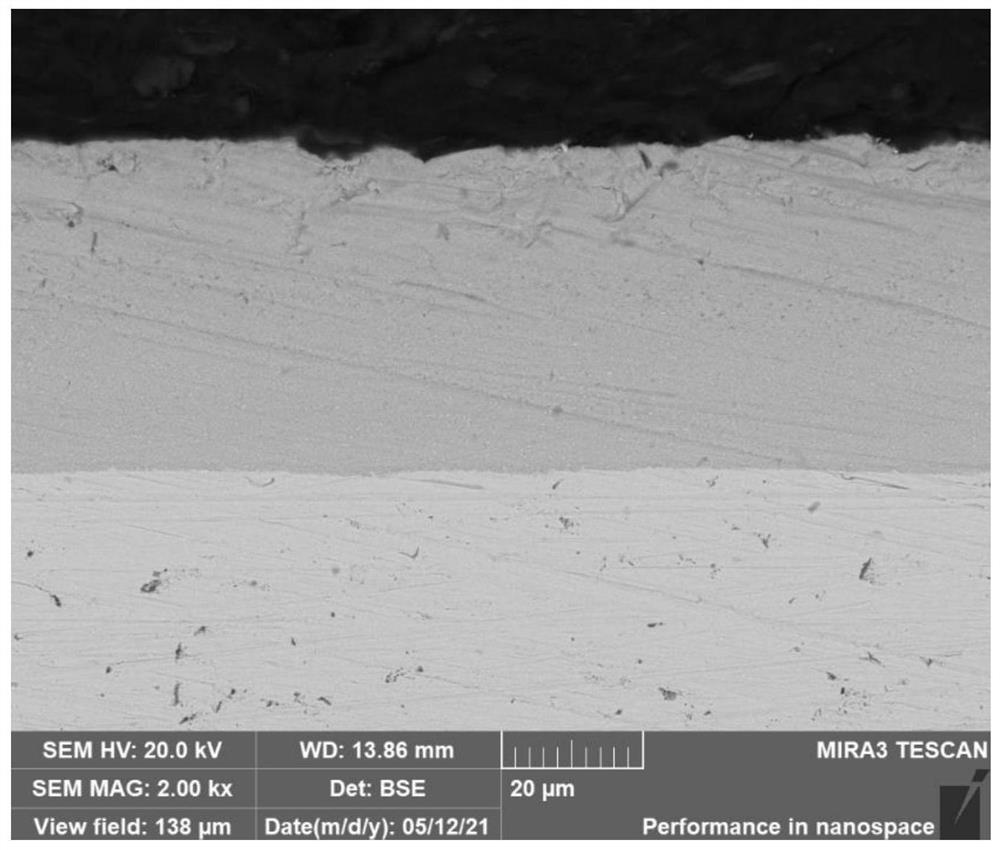

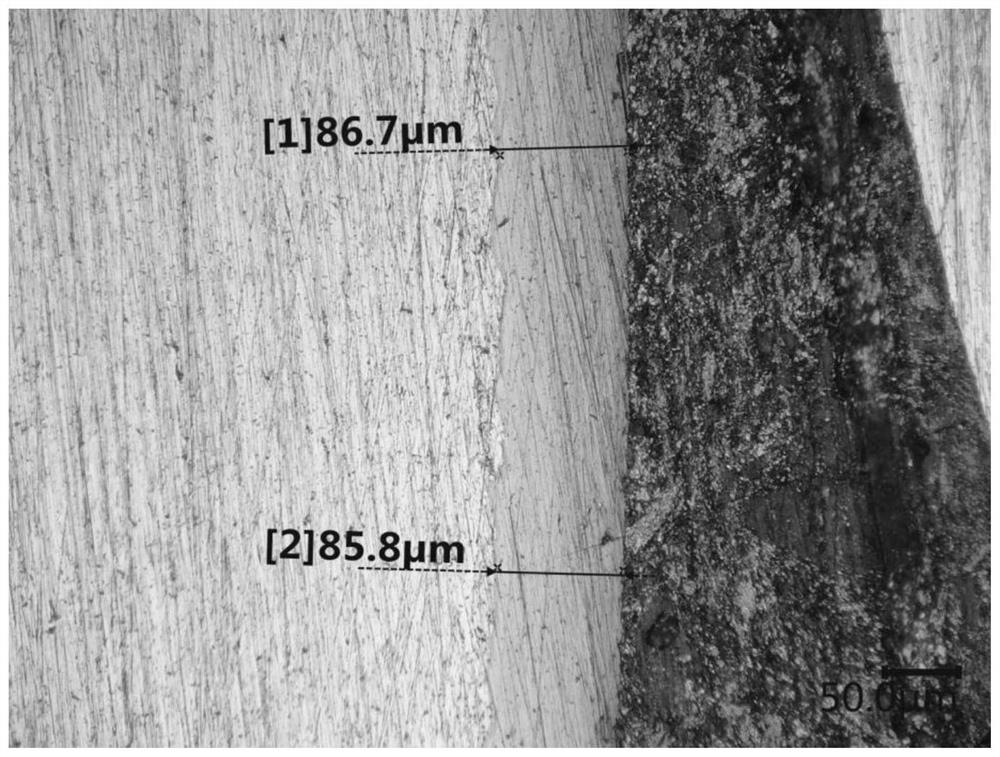

[0078] At 950°C, graphite crucible filled with CaCl 2 Molten salt, add 0.5wt.% CaC 2 , the anode is a mechanically polished W sheet, using molten salt electrolysis, with a current density of 10mA / cm 2 The constant current electrolysis method, the electrolysis time is 8 hours, the obtained sample passed the XRD test and the cross-sectional optical test, and a layer of tungsten carbide film with a thickness of about 80 microns was prepared on the surface of the W sheet, such as image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com