Hot working method of high-performance small-distortion carburized outer ring

A high-performance, thermal processing technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of complex outer ring manufacturing process, unsatisfactory fatigue strength, and decreased fatigue performance of outer ring parts, so as to reduce the grain length. Large time, avoiding large temperature differences, and improving the effect of carburizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

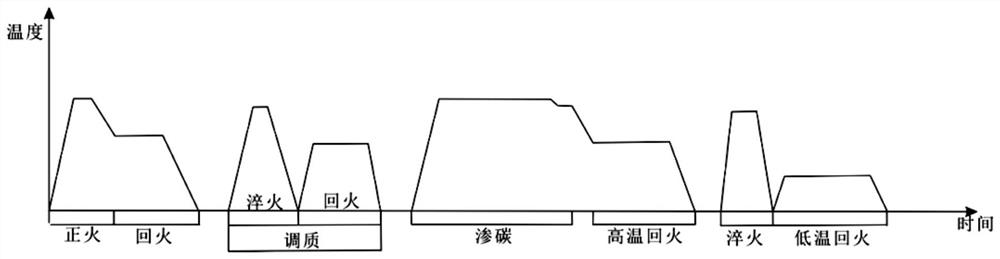

[0048] like image 3 The heat treatment process shown in the outer ring is shown in the thermal processing method of high performance minority alpha-carbon outer ring, which includes the following steps:

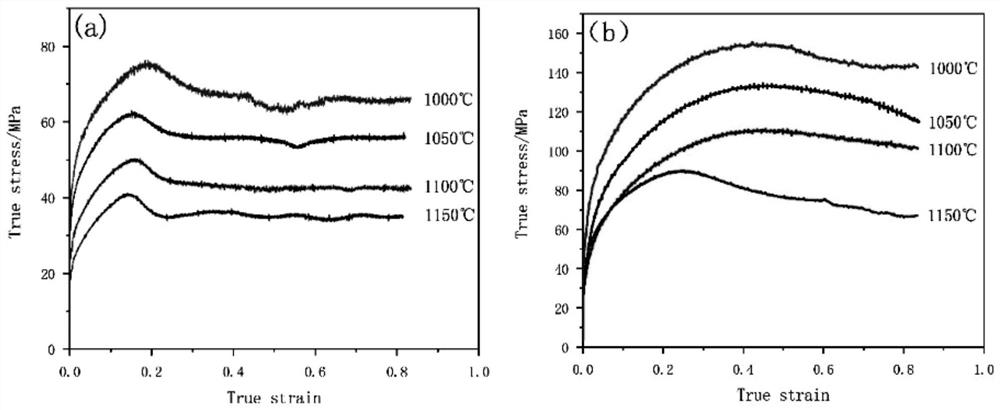

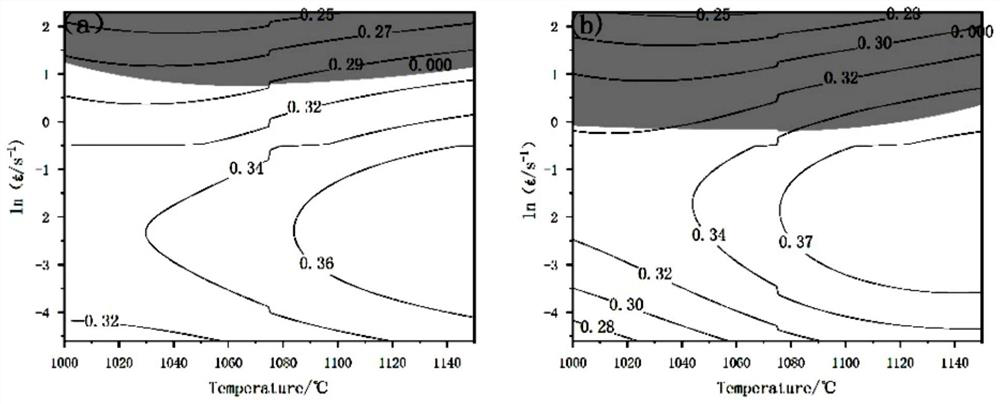

[0049] Step 1, use 17Cr2Ni2Movnb steel, a round rod of φ90mm in diameter, to obtain a ring blank, then normal fire + high temperature tempering, roughing, regulation, semi-finishing, carbon + high temperature temper, quench + low temperature Fire; forging is free forged, forged than about 4, starting temperature 1150 ° C, terminal temperature 1050 ° C, strain rate is 0.01s -1 ~ 0.75s -1 After the forging is finished; normal fire parameters: 930 ° C × 90min, dispersed air cooling, high temperature temper parameters: 650 ° C × 150 min, air cooling; rough car; massage parameter 880 ° C × 60 min, oil cold, 550 ° C × 150min, water-cooled, purpose to uniform tissue, fine grain, eliminate the machine to stress; then semi-essential vehicle processing, coarse processing teeth and splines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com