Patents

Literature

57results about How to "Prevent mixed crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel for hard tinplate bottle caps and production method thereof

InactiveCN102766800AImprove surface qualityGood performance uniformityTemperature control deviceTinningChemical composition

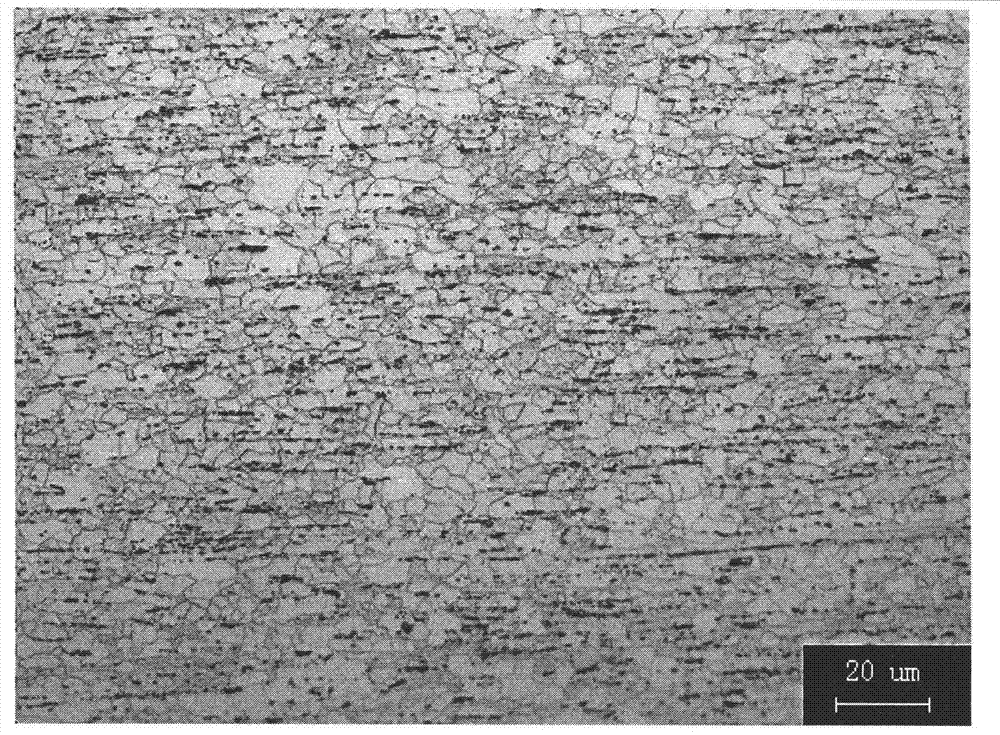

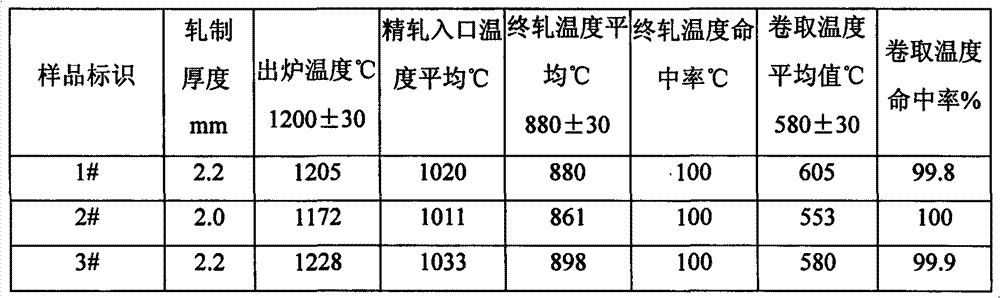

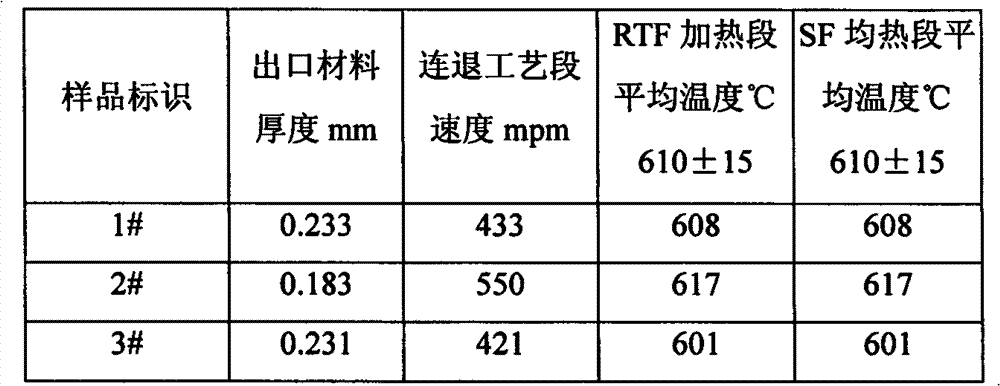

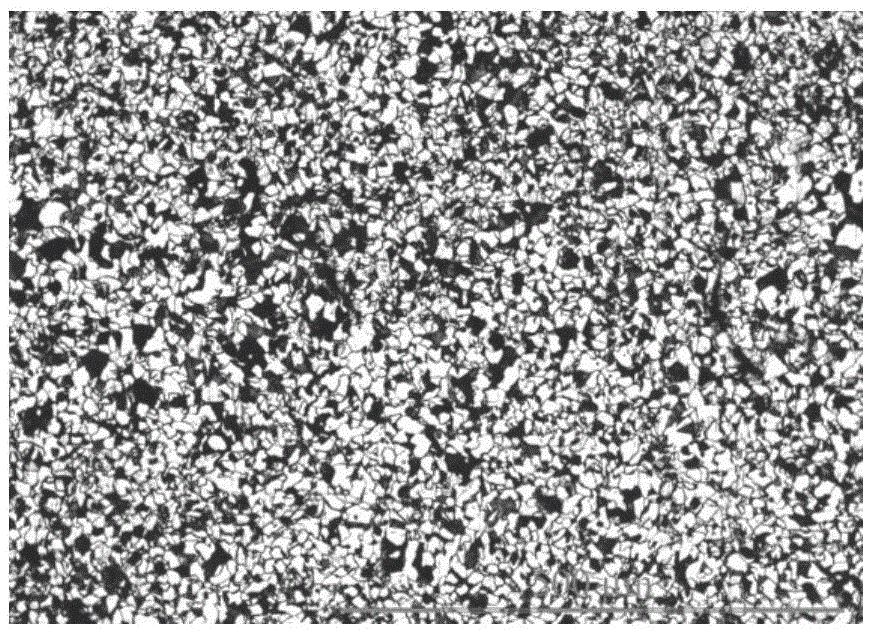

The invention relates to steel for bottle caps and a preparation method thereof, especially to steel for hard tinplate bottle caps and a production method thereof. The invention mainly solves the technical problems of unstable rolling, high hole ratio for pickling-rolling and poor surface quality of each process during pickling-rolling production of present steel for bottle caps. The technical scheme provided by the invention is as follows: the steel for hard tinplate bottle caps comprises the following chemical components of: by weight, 0.045-0.088% of C, Si being less than or equal to 0.1%, 0.30-0.50% of Mn, P being less than or equal to 0.020%, S being less than or equal to 0.020%, 0.010-0.060% of Alt, N being less than or equal to 0.0060%, and the balance Fe and some unavoidable impurity elements. The production method comprises four steps of steeling-making, hot rolling, pickling-rolling and continuous annealing, and is characterized in that hot rolling is controlled in the way: tapping temperature is 1200+ / -30 DEG C, finishing temperature is 880+ / -30 DEG C and coiling temperature is 580+ / -30 DEG C; cooling mode is forepart cooling; pickling-rolling and continuous annealing are controlled in the way: RTF section temperature is 610+ / -15 DEG C and SF section temperature is 610+ / -15 DEG C. Hardness of the obtained tinplate finished product is HR30T63+ / -3. The production method provided by the invention is mainly used for production of steel for bottle caps.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

X52 pipeline steel and production method thereof

ActiveCN101928884AIncrease varietySimple structureTemperature control deviceChemical compositionAdditional values

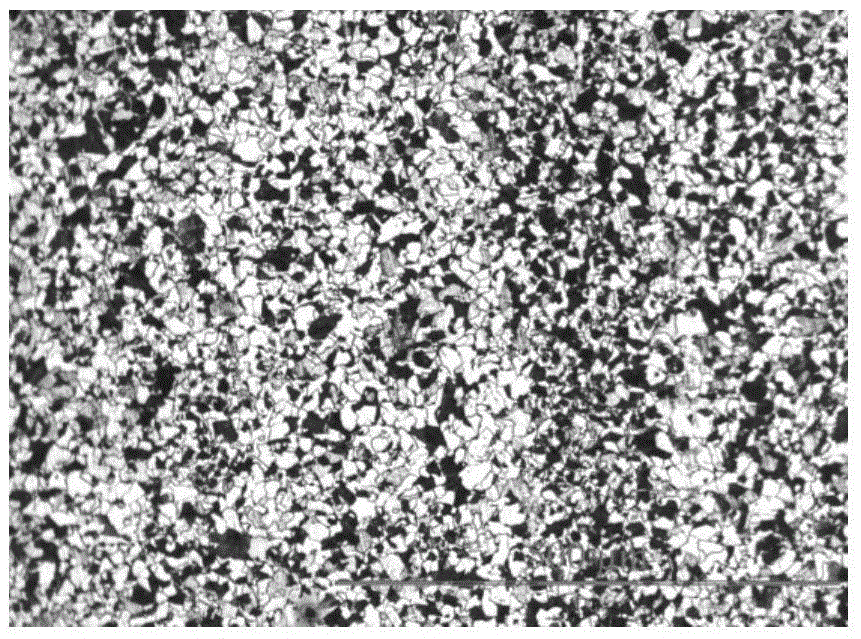

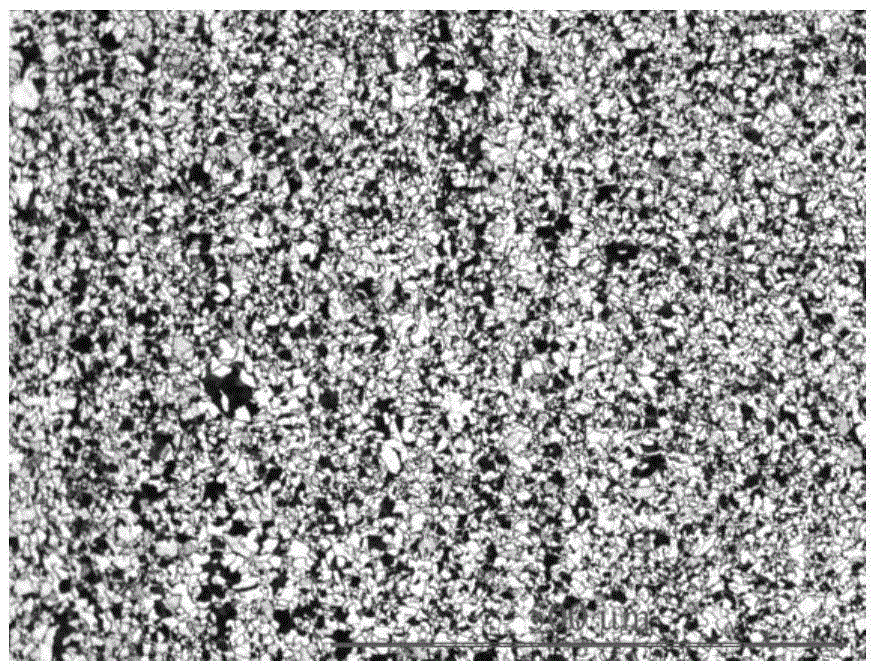

The invention provides an X52 pipeline steel and a production method thereof. The X52 pipeline steel comprises the following chemical components: 0.070-0.090wt% of C, 0.15-0.30wt% of Si, 1.10-1.30wt% of Mn, 0.006wt% or more of S, 0.020wt% or more of P, 0.020-0.040wt% of Nb, 0.010-0.020wt% of Ti, 0.008wt% or more of N, 0.010-0.040wt% of Als, the rest of Fe and unavoidable impurities. After heating and descaling, rough rolling and finish rolling are performed on the same dual-frame compact Steckel mill continuously; through delayed rolling control in rolling process, the enhancement function of microalloy elements such as Nb and V added to the steel are given a full play, thereby obtaining superfine and uniform tissue, effectively preventing the occurrence of mixed crystal, and greatly improving the strength and toughness of the X52 pipeline steel. The X52 pipeline steel produced with the method belongs to high-technology product with high additional value, thus the economical benefit is significant.

Owner:WUKUN STEEL

X60 pipe line steel and production method thereof

ActiveCN101928882AOptimize product structurePrevent mixed crystalsTemperature control deviceChemical compositionMixed crystal

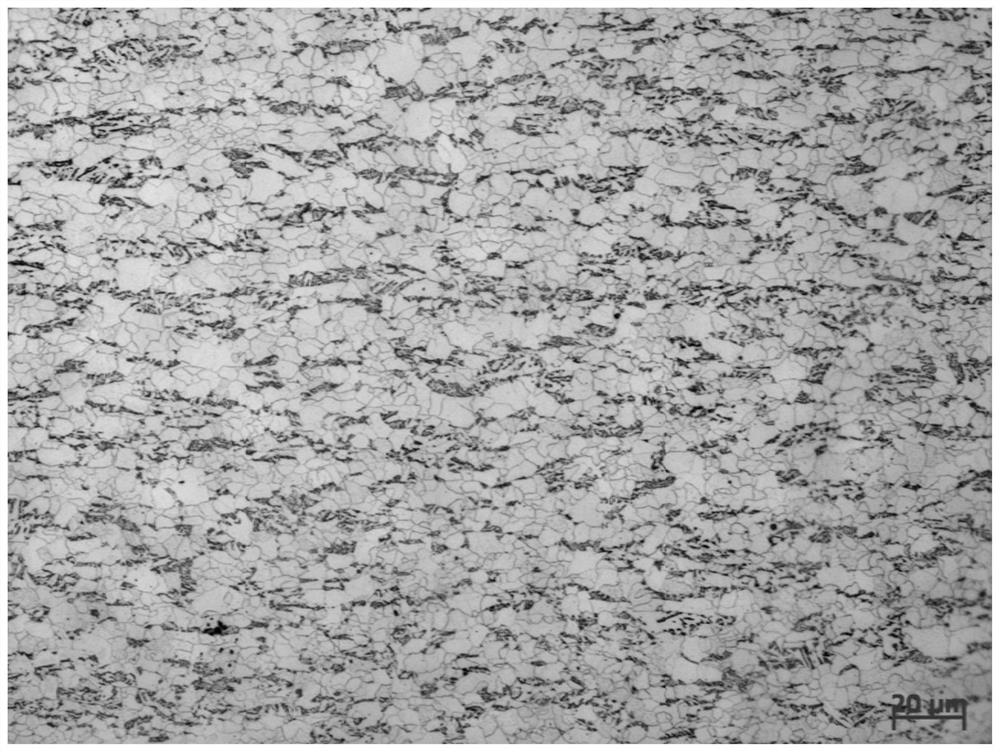

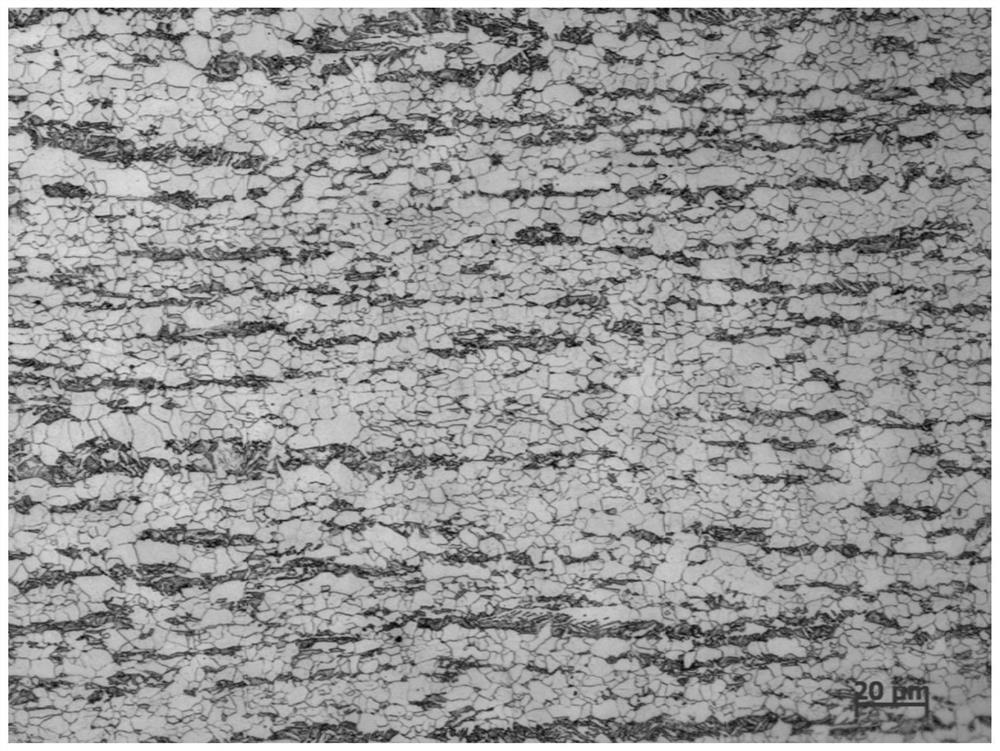

The invention provides X60 pipe line steel and a preparation method thereof. The X60 pipe line steel comprises the following chemical components in percentage by weight: 0.060 to 0.080 percent of C, 0.15 to 0.30 percent of Si, 1.35 to 1.55 percent of Mn, less than or equal to 0.006 percent of S, less than or equal to 0.020 percent of P, 0.035 to 0.055 percent of Nb, 0.035 to 0.055 percent of V, 0.010 to 0.025 percent of Ti, less than or equal to 0.008 percent of N, 0.010 to 0.040 percent of Als, and the balance of Fe and inevitable impurities. After heating and descaling, rough rolling and finish rolling are continuously completed on the same steckel mill, the reinforcing effect of Nb, V and other microalloyed elements added in the steel can be sufficiently played by delay controlled rolling in the rolling process, micro-uniform tissues can be obtained, occurrence of mixed crystal can be effectively prevented, and the strength and toughness of the X60 pipe line steel can be greatly improved. The produced X60 pipe line steel belongs to the product with high technology content and high additional value, and has remarkable economic benefit.

Owner:WUKUN STEEL

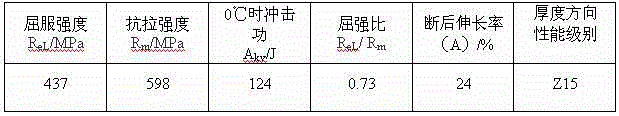

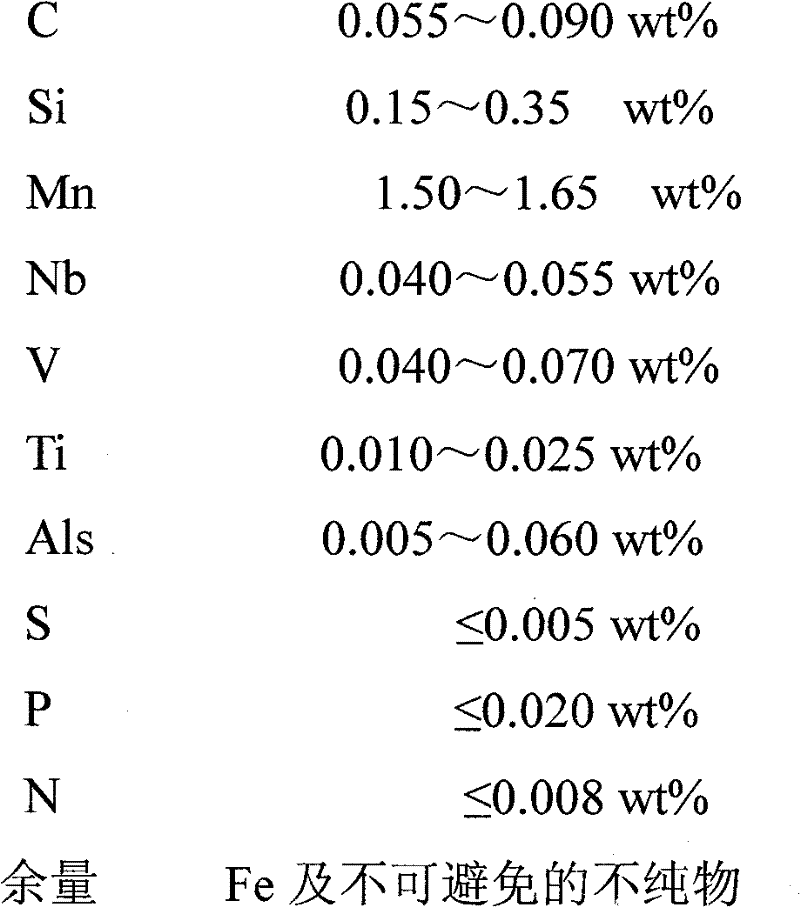

X65 pipe line steel and production method thereof

ActiveCN101928883AIncrease varietySimple structureTemperature control deviceChemical compositionEconomic benefits

The invention provides X65 pipe line steel and a production method thereof. The X65 pipe line steel comprises the following chemical components in percentage by weight: 0.055 to 0.090 percent of C, 0.15 to 0.35 percent of Si, 1.50 to 1.65 percent of Mn, less than or equal to 0.005 percent of S, less than or equal to 0.020 percent of P, 0.040 to 0.055 percent of Nb, 0.040 to 0.070 percent of V, 0.010 to 0.025 percent of Ti, less than or equal to 0.008 percent of N, 0.005 to 0.060 percent of Als, and the balance Fe and inevitable impurities. After heating and descaling, rough rolling and finish rolling are continuously completed on the same double-rack compact steckel mill, the reinforcing effect of Nb, V and other microalloyed elements added in the steel can be sufficiently played by delay controlled rolling in the rolling process, a micro-uniform tissue can be obtained, the occurrence of mixed crystals can be effectively prevented, and the strength and toughness of the X65 pipe line steel can be greatly improved. The produced X65 pipe line steel belongs to the product with high technology content and high additional value, and has remarkable economic benefit.

Owner:WUKUN STEEL

X56 pipeline steel and production method thereof

The invention provides X56 pipeline steel and a production method thereof. The X56 pipeline steel comprises the following chemical components: 0.060-0.090wt% of C, 0.20-0.30wt% of Si, 1.30-1.50wt% of Mn, not more than 0.008wt% of S, not more than 0.020wt% of P, 0.035-0.055wt% of Nb, 0.020-0.040wt% of V, 0.010-0.022wt% of Ti, not more than 0.008wt% of N, 0.010-0.040wt% of Als and the balance Fe and inevitable impurities. The production method is characterized by continuously finishing rough rolling and finish rolling on the same double-stand compact steckel mill after heating and descaling. The X56 pipeline steel has the following advantages: the strengthening effects of the microalloying elements added to the steel, such as Nb, V and the like are brought into full play through delay rolling control in the rolling process and the superfine and uniform structure is obtained, thus effectively preventing mixed crystals and greatly improving the strength and toughness of the X56 pipeline steel; and the X56 pipeline steel produced by the method has high-tech content, high added value and obvious economic benefits.

Owner:WUKUN STEEL

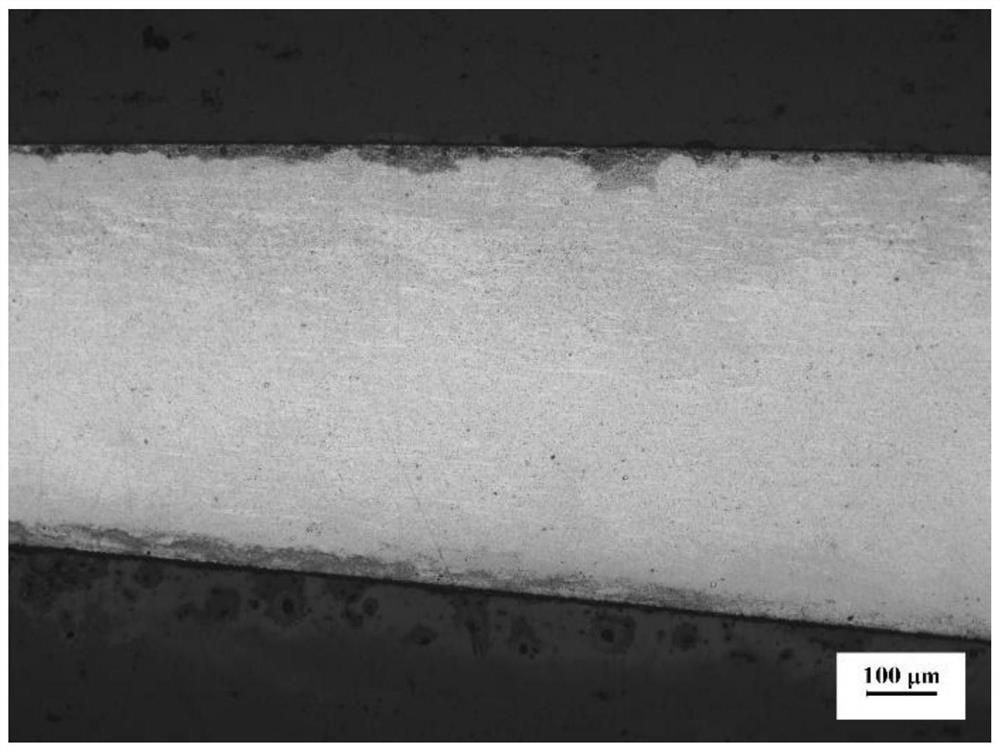

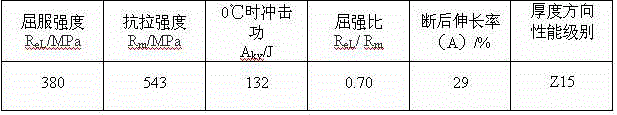

Low-alloy high-strength large-diameter thick-walled seamless steel pipe and manufacturing method thereof

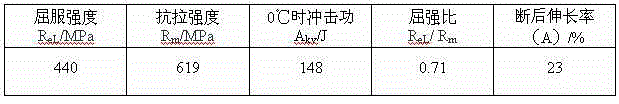

ActiveCN105586532AGuaranteed mechanical performance indexEnough deformationSteelmakingRefining (metallurgy)

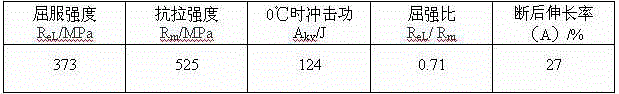

The invention relates to the technical field of metallurgy, and provides a low-alloy high-strength large-diameter thick-walled seamless steel pipe and a manufacturing method thereof. The method comprises the steps of steelmaking, wherein smelting and refining are performed to obtain target molten steel, and ingot casting is performed on the target molten steel to obtain static ingots; pipe billet forging, wherein forging and annealing are performed on the static ingots to obtain pipe billets; pipe rolling, wherein the pipe billets are heated inside an annular furnace at the temperature of 1230-1270 DEG C, holes are formed after heating is performed, and rolling forming is performed through a pipe mill; normalizing heat treatment, wherein normalizing heat treatment is performed on rolled and formed steel pipes, the normalizing furnace discharge pipe temperature is 920-940 DEG C in the normalizing heat treatment process, and the cooling mode is the air-cooling or air-cooling and mist spraying mode. The steel pipe produced through the manufacturing method is uniform in texture, good in performance and capable of achieving high-strength and excellent subzero 20 DEG C low-temperature toughness, in addition, by adopting the simplified production technology, the production efficiency can be improved, the production cost can be lowered, and meanwhile the steel pipe has the good using safety due to the low yield ratio.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Low-yield-ratio high-toughness TMCP type bridge steel plate and production method thereof

ActiveCN112322995AImprove performanceLow yield ratioTemperature control deviceToughnessMaterials science

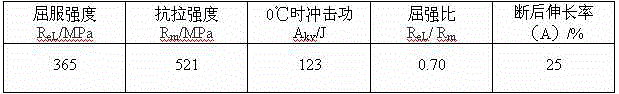

The invention discloses a low-yield-ratio high-toughness TMCP type bridge steel plate and a production method thereof. The steel comprises the following chemical components in percentage by weight of0.07 to 0.12% of C, 0.11 to 0.18% of Si, 1.42 to 1.52% of Mn, 0.008 to 0.015% of P, 0.002 to 0.010% of S, 0.08 to 0.16% of Cr, 0.012 to 0.018% of Nb, 0.008 to 0.016% of Ti, 0.020 to 0.050% of Alt, 0.002 to 0.005% of N, the balance iron and impurities and 0.350 to 0.369% of carbon equivalent. According to the production method, a continuous casting billet is subjected to heating, controlled rollingincluding recrystallization zone rolling, temperature waiting and non-recrystallization zone rolling and controlled cooling including ferrite zone cooling, temperature waiting and bainite zone cooling, and the bridge steel plate is manufactured. The obtained bridge steel plate is low in yield ratio, high in toughness and excellent in welding performance.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

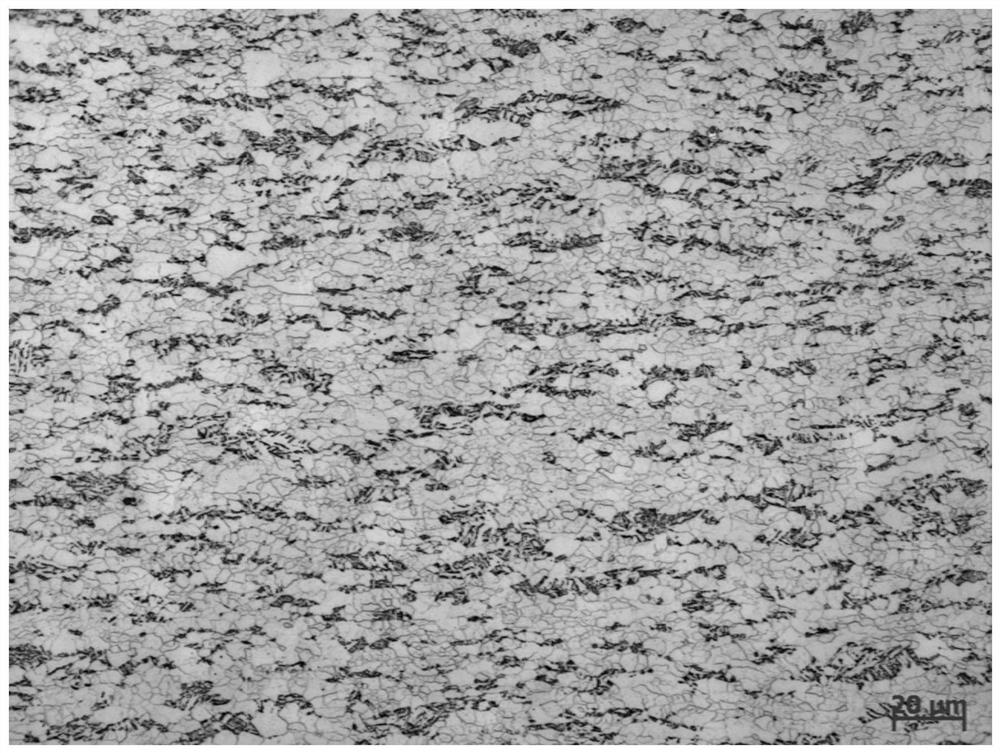

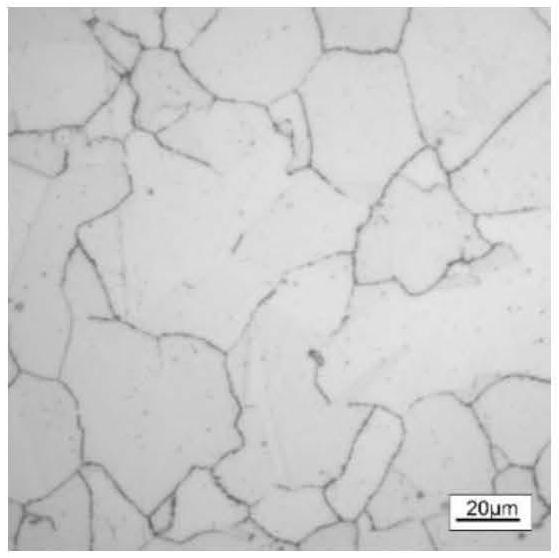

Method for producing ageing steel of martensite without cobalt in high tensile and high toughness

InactiveCN1626686AUniform deformationIncrease temperatureSolution treatmentHigh volume manufacturing

A machining technology for the aged 18(Ni)-series non-Co martensite steel with high strength and toughness includes hot working, cold working by direct cold rolling or machining without solution treatment, ageing at 400-600 deg.C for 0.5-3 hrs, and air or water cooling. Its advantages are short period and simplified heat treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Hot working process of GH4738 nickel-based superalloy

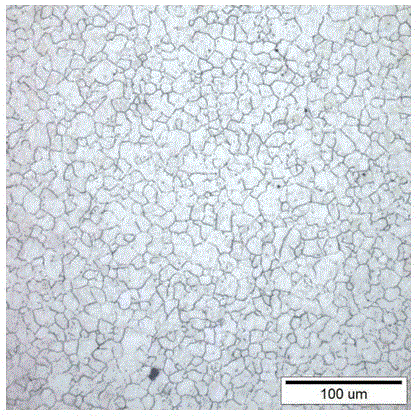

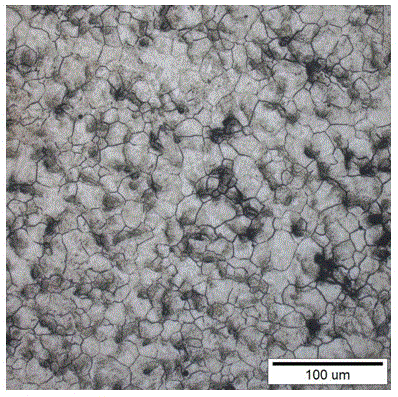

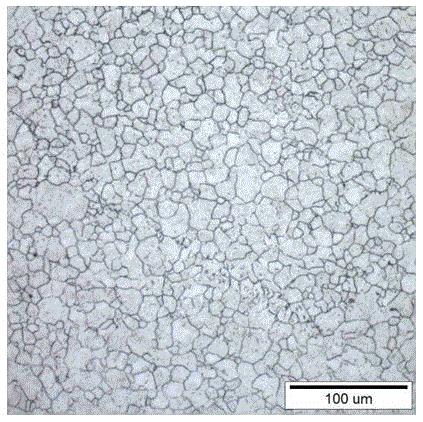

PendingCN113560481AAvoid specimen crackingUniform tissueMetal-working apparatusWheelsVacuum induction meltingCrystallite

The invention discloses a hot working process of a GH4738 nickel-based superalloy. The process comprises the following steps that A, the GH4738 nickel-based superalloy is taken as a raw material, and is smelted by adopting a vacuum induction melting (VIM) process and a vacuum consumable remelting (VAR) process in sequence to obtain a vacuum consumable ingot; B, the vacuum consumable ingot is subjected to homogenization treatment and cogging forging treatment, and a GH4738 alloy bar blank is obtained; C, the GH4738 alloy bar blank is put into a gas furnace to be heated along with the furnace, flat anvil upsetting is conducted through a forging hammer after heat preservation, and a GH4738 alloy disc forge piece is obtained; and D, the GH4738 alloy disc forge piece is sequentially subjected to solution treatment, stabilizing treatment and secondary aging treatment, and the GH4738 nickel-based high-temperature alloy uniform in grain size and excellent in high-temperature erosion performance is obtained. According to the hot working process, the phenomena of mixed crystals, coarse crystals and the like in a GH4738 high-temperature alloy deformation structure can be avoided, the overall hardness and high-temperature erosion performance of a final forge piece are improved, and meanwhile the yield of the forge piece is increased.

Owner:INNER MONGOLIA UNIV OF TECH

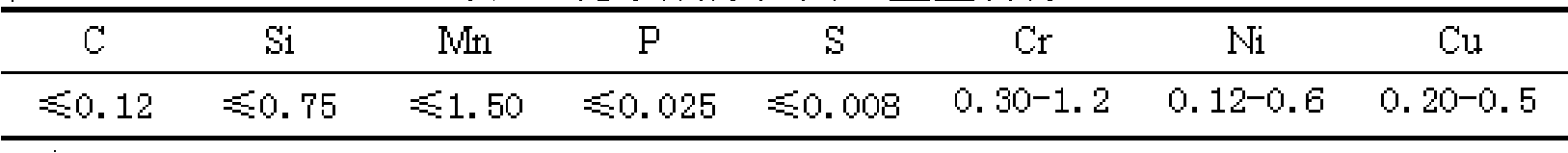

High strength weathering steel and producing method thereof

The invention relates to a high-intensity anti-atmosphere corrosion steel and a production method thereof and belongs to the field of metallurgy. The technical problem needed to be solved by the invention is to provide a V-Ti-N-Nb micro-alloy high-intensity anti-atmosphere corrosion steel which has an easily-controlled hot rolling technique and has an obvious yield point. The weight percentages of the chemical components of the high-intensity anti-atmosphere corrosion steel of the invention are: equal to or less than 0.12 percent of C, equal to or less than 0.75 percent of Si, equal to or less than 1.50 percent of Mn, equal to or less than 0.025 percent of P, equal to or less than 0.008 percent of S, 0.30 to 1.25 percent of Cr, 0.12 to 0.65 percent of Ni, 0.20 to 0.55 percent of Cu, 0.006 to 0.02 percent of Ti, 0.04 to 0.09 percent of V, 0.01 to 0.02 percent of N, 0.015 to 0.03 percent of Nb and the rest is Fe and unavoidable impurities. The high-intensity anti-atmosphere corrosion steel of the invention can be used for producing the mechanical devices and parts that need to be exposed in the air.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

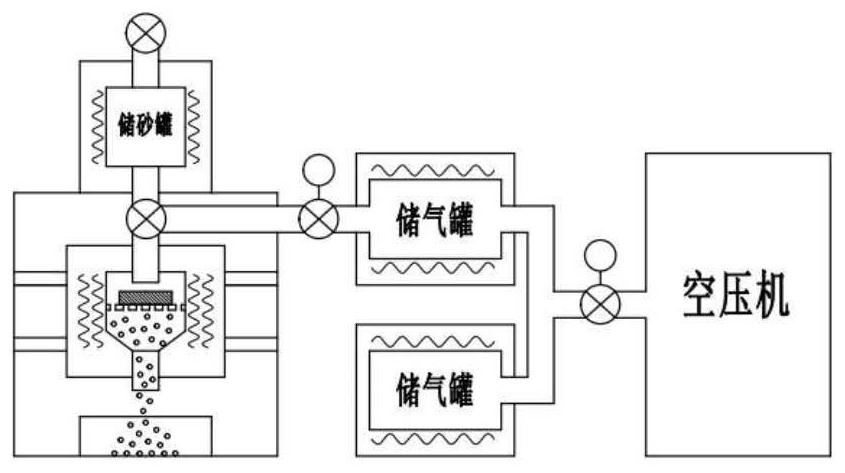

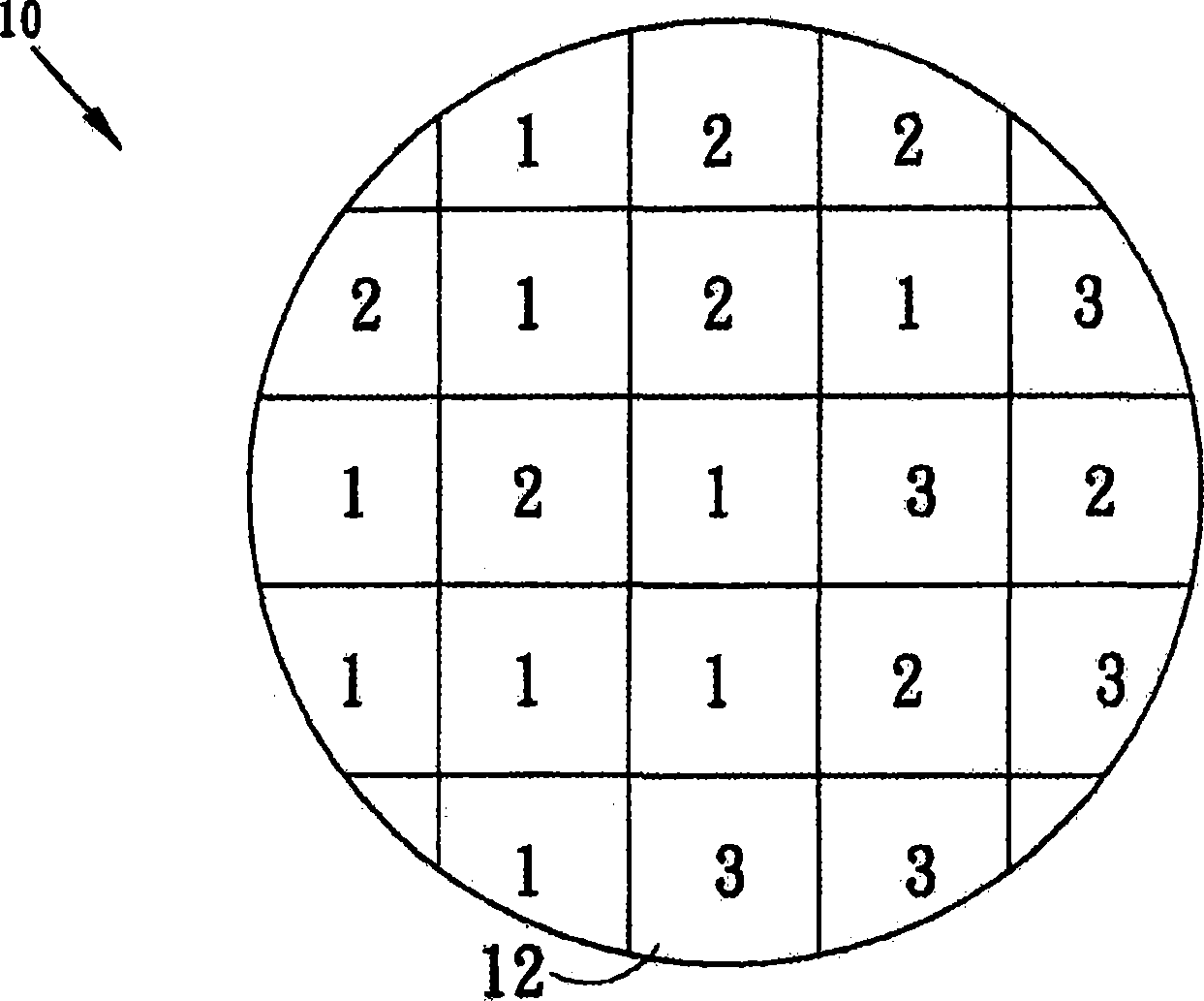

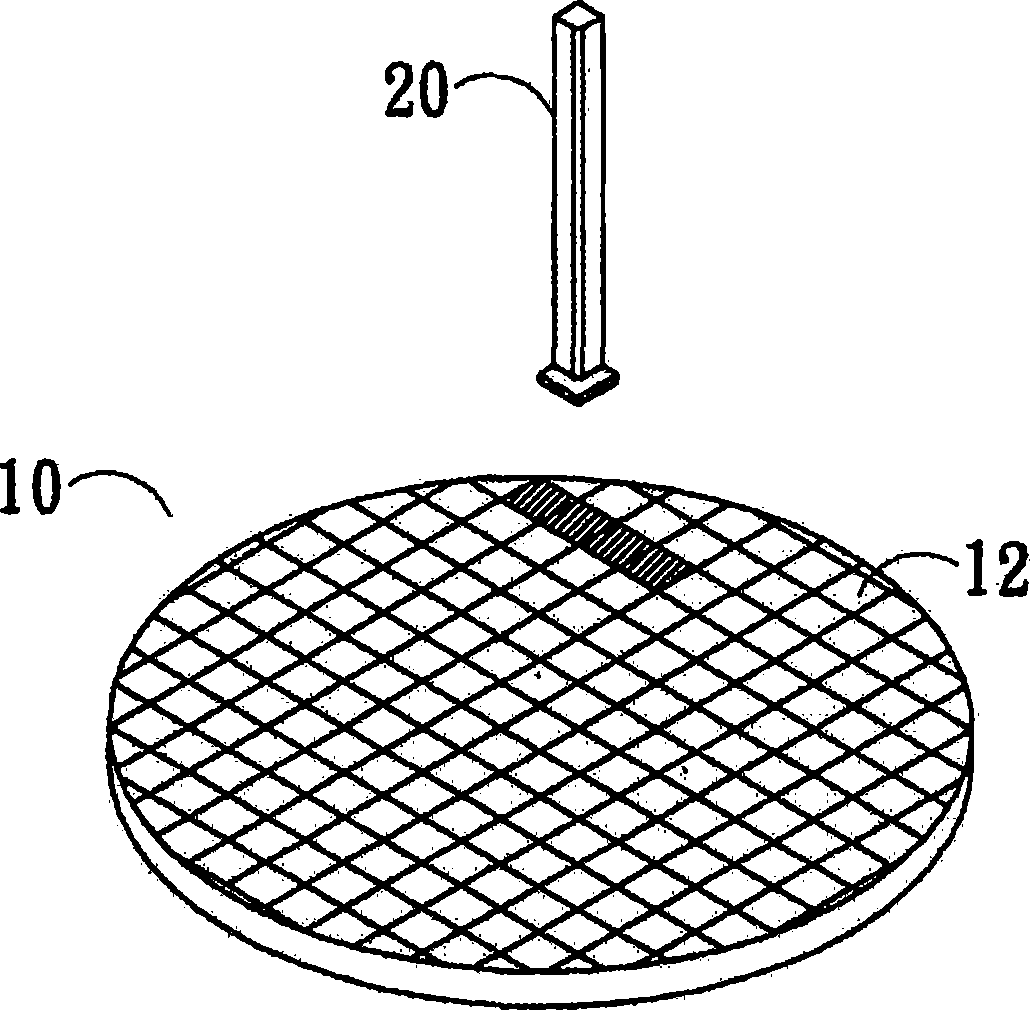

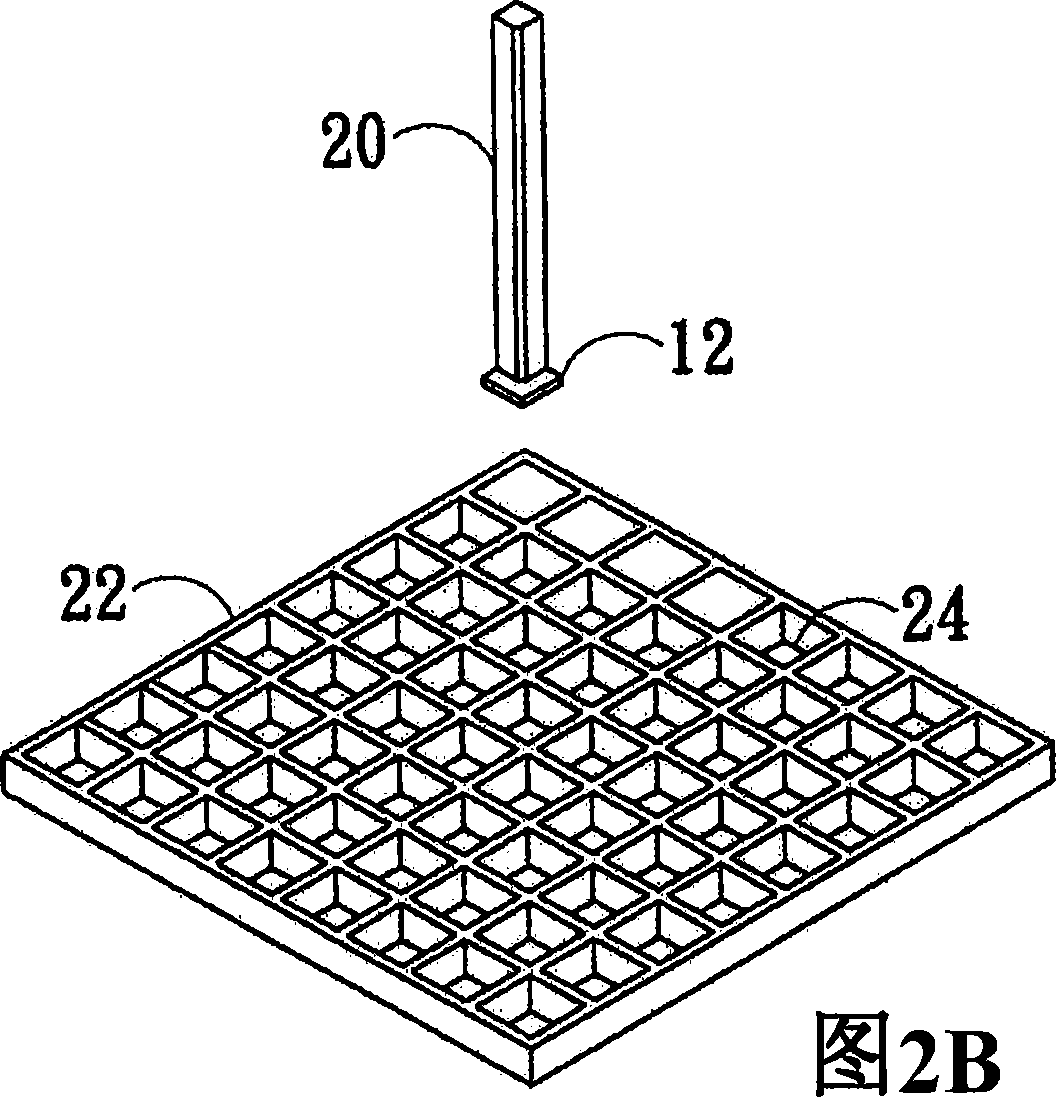

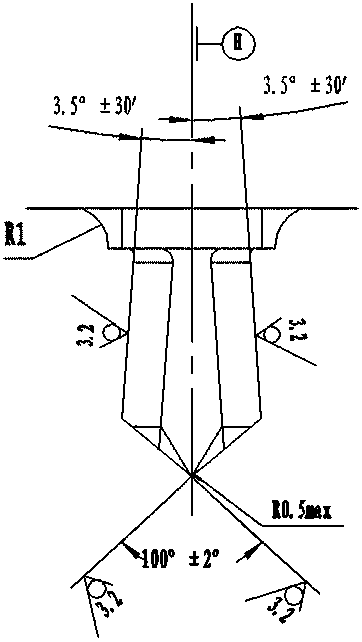

Device for picking up and sorting crystal grains

ActiveCN1873940AIncrease the efficiency of picking and sortingPrevent mixed crystalsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingContinuous/uninterruptedEngineering

Sorter of picking up crystal grains includes multiple collection racks with basins. Each collection rack is corresponding to different sorts of qualities of crystal grains. Adsorption header picks up crystal grains in same sort of quality to a basin. When crystal grains are full in a basin, a basin transportation module carries the basin to a collection rack. Thus, crystal grains are picked up according to different qualities to relevant collection rack continuously till all crystal grains are picked up. The invention increases picking up and sorting efficiency, and preventing issue of mixed up crystal grains.

Owner:KING YUAN ELECTRONICS

Production method for second gears of automatic automotive transmissions

InactiveCN103753159AMass productionStable productionGearing elementsAutomatic transmissionAutomotive transmission

The invention provides a production method for second gears of automatic automotive transmissions. According to the production method, pre-forging blanks are subjected to cold extrusion after being produced by isothermal forging. The production method is characterized in that the inclination of the inner walls of modified grooves of the pre-forging blanks is 2-4 degrees larger than that of finish-forging blanks. Products produced by the production method are high in accuracy and low oxidizing, good internal structure of metal is realized, crystal grains are fine, and poor textures such as coarse crystals and mixed crystals are avoided; equipment as needed is low in tonnage and small in forming fore, filling of tooth profile is easy, unit pressure borne by molds is remarkably reduced, and service life of the molds are quite long; product hardness reaches HB130-150, and metal structure reaches the second level; the tooth profile is fully filled and does not deform during heat treatment after cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

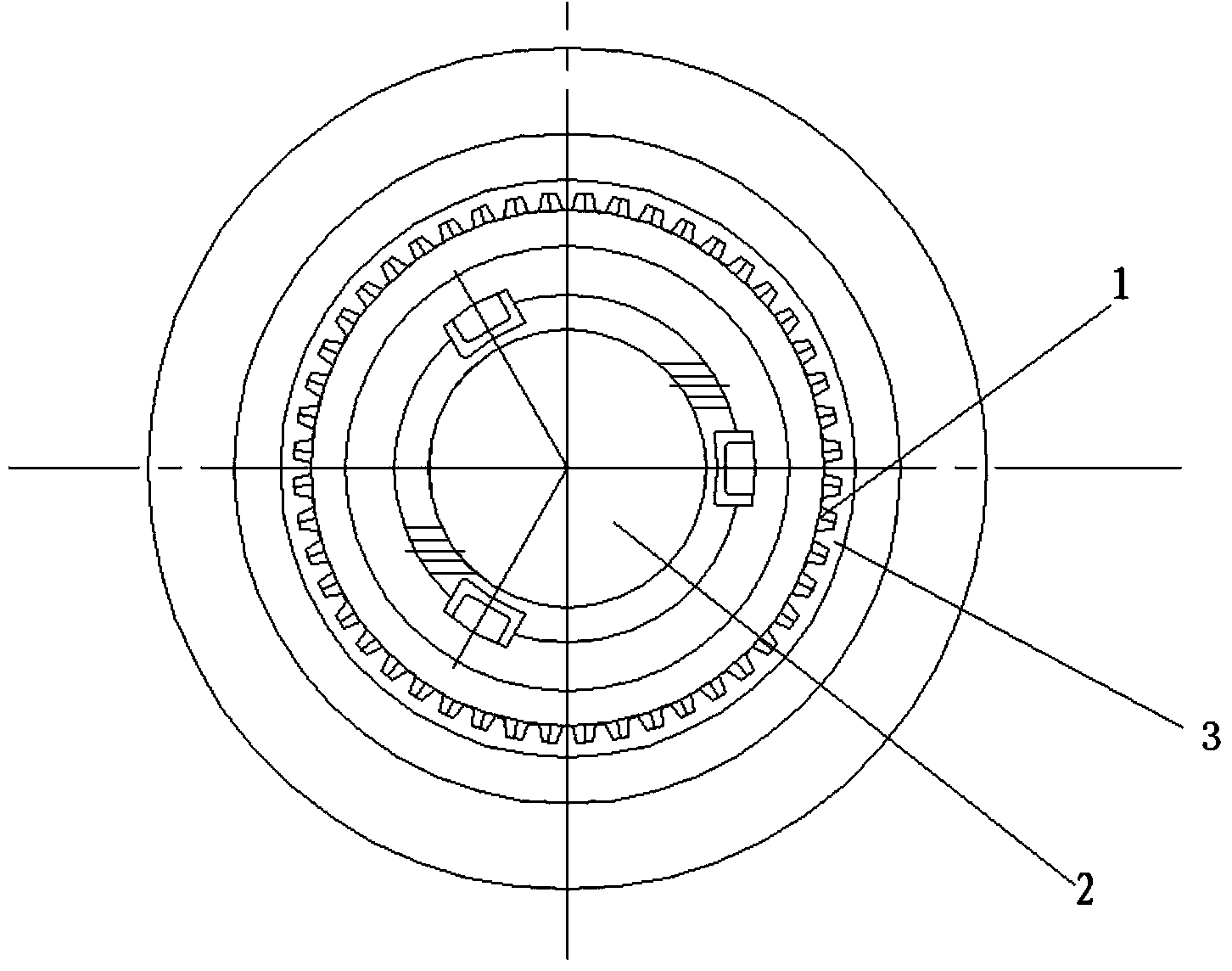

Hardenablity-retaining gear steel and preparation method thereof

The invention discloses hardenablity-retaining gear steel and a preparation method thereof. The hardenablity-retaining gear steel mainly comprises the following components in percentage by mass: 0.18-0.21% of C, 0.20-0.28% of Si, 0.75-1.05% of Mn, 0.95-1.25% of Cr, 0.035-0.055% of Ti, 0.020-0.035% of Al, 0.0008-0.0030% of B, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 20 ppm of T[O], less than or equal to 80 ppm of T[N], less than or equal to 0.10% of Ni, less than or equal to 0.20% of Cu, less than or equal to 0.10% of Mo, and the balance of Fe. The gear steel with a narrow hardenability band and an excellent fatigue life is prepared by controlling primary melting and strengthening refining, large ladle submerged nozzle argon blowing, catalyzer slag protection, plasma tundish heating and constant-temperature constant-pull-speed casting, and compound electromagnetic stirring through converter, dual-refining and continuous casting processes.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Q420-grade anti-seismic steel and method for producing Q420-grade anti-seismic steel by virtue of steckel mill

InactiveCN104561780AHigh strengthImprove plasticityWork treatment devicesMetal rolling arrangementsSheet steelRoom temperature

The invention relates to Q420-grade anti-seismic steel and a method for producing the Q420-grade anti-seismic steel by virtue of a steckel mill, and belongs to the technical field of metal material processing and forming. The Q420-grade anti-seismic steel consists of the following components: C, Si, Mn, S, P, Nb, V, Ti, N, Als and the balance of Fe and inevitable impurities. A Q420-grade anti-seismic steel sheet which is high in strength and low in yield ratio can be prepared by heating a slab, spraying water and removing phosphorous, continuously completing rough rolling and finish rolling on a same dual-stand compact steckel mill, cooling a steel sheet obtained from finish rolling by virtue of a coiling machine and naturally air-cooling to room temperature. By adding such micro-alloying elements as Nb and V to the Q420-grade anti-seismic steel, the strength and the tenacity of the Q420-grade anti-seismic steel sheet are effectively improved; in the process of producing the Q420-grade anti-seismic steel sheet, the method disclosed by the invention fully explores the potential of the dual-stand compact steckel mill of kunming Iron and Steel; the variety of plate and strip products is expanded and product structure is optimized.

Owner:KUNMING UNIV OF SCI & TECH +1

X65 pipe line steel and production method thereof

ActiveCN101928883BIncrease varietySimple structureTemperature control deviceChemical compositionEconomic benefits

The invention provides X65 pipe line steel and a production method thereof. The X65 pipe line steel comprises the following chemical components in percentage by weight: 0.055 to 0.090 percent of C, 0.15 to 0.35 percent of Si, 1.50 to 1.65 percent of Mn, less than or equal to 0.005 percent of S, less than or equal to 0.020 percent of P, 0.040 to 0.055 percent of Nb, 0.040 to 0.070 percent of V, 0.010 to 0.025 percent of Ti, less than or equal to 0.008 percent of N, 0.005 to 0.060 percent of Als, and the balance Fe and inevitable impurities. After heating and descaling, rough rolling and finishrolling are continuously completed on the same double-rack compact steckel mill, the reinforcing effect of Nb, V and other microalloyed elements added in the steel can be sufficiently played by delaycontrolled rolling in the rolling process, a micro-uniform tissue can be obtained, the occurrence of mixed crystals can be effectively prevented, and the strength and toughness of the X65 pipe line steel can be greatly improved. The produced X65 pipe line steel belongs to the product with high technology content and high additional value, and has remarkable economic benefit.

Owner:WUKUN STEEL

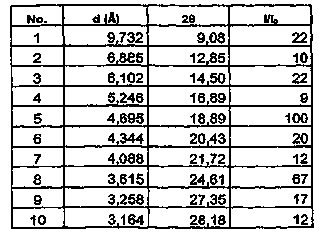

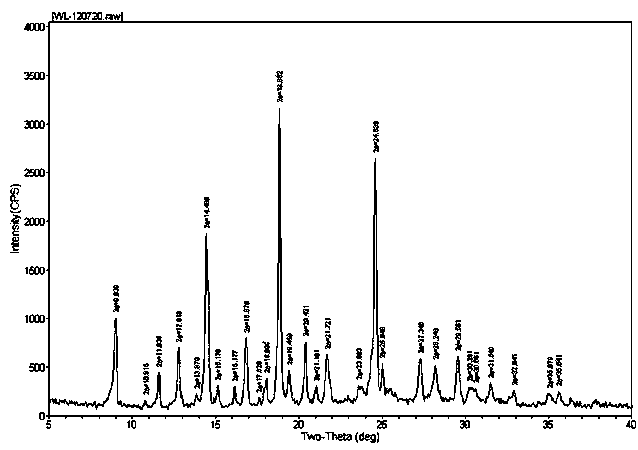

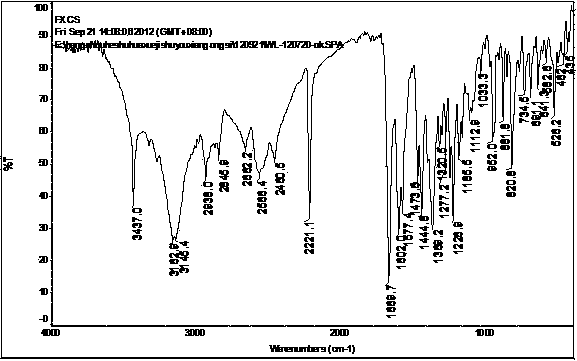

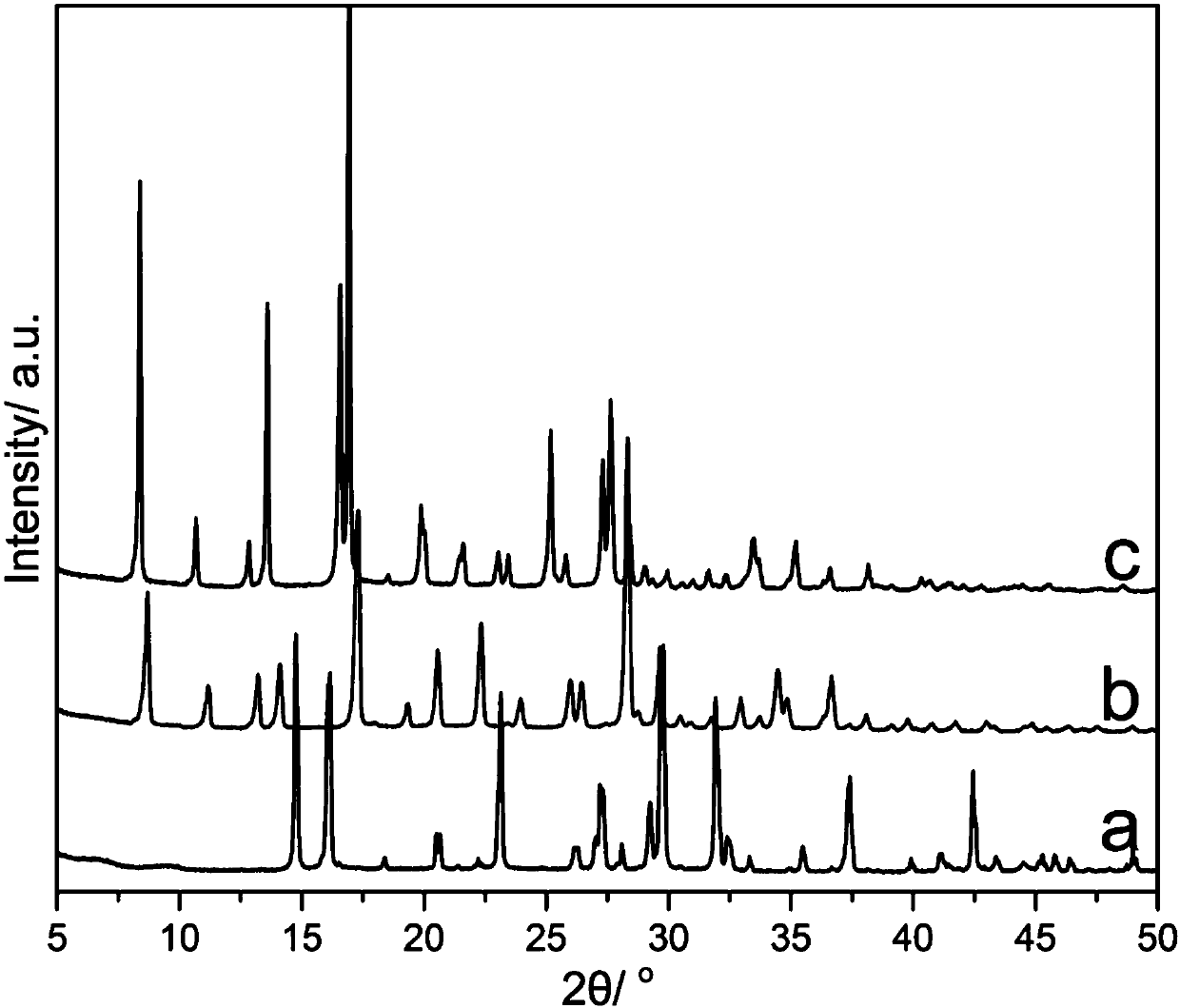

Preparation method and application of vilazodone hydrochloride IV crystal

ActiveCN103772368AEliminate the trouble of preparing hydrochloric acidSimple processOrganic chemistryRefluxOrganic solvent

The invention discloses a preparation method and application of a 5-(4-(4-(5-cyano-3-indolyl)butyl)-1-piperazinyl)benzofuran-2-formamide hydrochloride IV crystal. The method comprises the steps of: 1) under certain temperature, dissolving 5-(4-(4-(5-cyano-3-indolyl)butyl)-1-piperazinyl)benzofuran-2-formamide in an organic solvent to obtain a solution; 2) heating the solution obtained in step 1) to a reflux temperature of 40DEG C; 3) slowly adding concentrated hydrochloric acid dropwise; 4) subjecting the system obtained in step 3) to heat preservation reaction for 0.5-12 hours; 5) conducting filtering to obtain an IV crystal form wet product; and 6) conducting vacuum drying to the wet product obtained in step 5) at 80-140DEG C to a constant weight, thus obtaining the IV crystal. By adopting the technical scheme, the process is simplified, a complex preparation process of the existing IV crystal is overcome, and a mixed crystal can be avoided. The method provided by the invention can achieve high crystal purity, stable volume production and high yield, and is easy to realize industrialized production.

Owner:HANGZHOU HEZE PHARMA TECH

Temperature control method for rolled strip steel in ferrite area

PendingCN113828643AGuaranteed rolling capacityReduce the amount of cooling waterTemperature control deviceMetal rolling arrangementsTemperature controlWater flow

The invention relates to a temperature control method for rolled strip steel in a ferrite area. The temperature control method comprises the following steps: arranging a first intermediate billet cooling device at an outlet of a roughing mill, and arranging a second intermediate billet cooling device at an outlet of a hot coil box or a heat preservation cover; controlling the heating temperature of a steel billet to be 1050-1200 DEG C, controlling the temperature of an intermediate billet after rough rolling to be within the austenite temperature range of steel and to be 10-40 DEG C higher than the final temperature of austenite, and detecting the temperature of the intermediate billet in front of an inlet of a finishing mill group in real time; and fully opening a first cooling device, and making the second intermediate billet cooling device adjust the opening and closing combination and the cooling water flow of each pair of coolers in real time according to the temperature, so that the intermediate billet in front of the inlet of the finishing mill group is cooled to be 0 to 30 DEG C higher than the ferrite phase transformation final temperature. According to the temperature control method, the problems that in the prior art, before finish rolling, the temperature of the intermediate billet is not accurately controlled, the temperature of a strip billet is not uniform, and the cooling swing time between rough rolling and finish rolling is too long are solved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Forging method for 2618A aluminum alloy impeller forging

ActiveCN106086734AImprove performanceReduce residual stressMetal-working apparatusImpellerRoom temperature

The invention provides a forging method for a 2618A aluminum alloy impeller forging. The forging method comprises the following steps: (1) blanking, heating and preliminary forging: controlling the blank heating temperature at 430 to 440 DEG C, and controlling the deformation of a forging below 40 percent; (2) edge cutting and water cooling: performing water cooling after edge cutting is completed at the water temperature of 20 to 30 DEG C; (3) secondary forging: performing secondary forging after the water cooling is completed until the forging temperature is at normal temperature, and controlling the deformation of the forging at 2 to 5 percent; (4) solid dissolving: preserving the heat at the temperature of 530 DEG C for 60 minutes, heating the forging in a furnace to the temperature of 540 DEG C, preserving the heat for 10 minutes, and then performing water cooling at the water cooling temperature of 40 to 50 DEG C, wherein the water temperature increase rate in a quenching process is less than or equal to 10 DEG C; and (5) aging: after the solid dissolving is completed, stewing at room temperature for at least 4 hours, but not exceeding 20 hours, preserving the heat at the temperature of 193 DEG C for 22 hours, and performing air cooling to room temperature. According to the method, the residual stress of the 2618A aluminum alloy impeller forging can be effectively reduced, so that the problem of size deformation of a finished product can be solved.

Owner:JIANGSU ASIA PACIFIC ANSINDAR ALUMINUM

Deformation high-temperature alloy blade forged piece and precision forging method thereof

ActiveCN112108597AHomogeneous tissue stateGood mechanical propertiesExtrusion control devicesPretreated surfacesSuperalloyAero engine

The invention discloses a deformation high-temperature alloy blade forged piece and a precision forging method thereof. The precision forging method comprises the following steps that S1, a high-temperature alloy bar material is subjected to heat preservation for 8-60 min at the temperature of 950-1150 DEG C, and extrusion is conducted; S2, heating is conducted for 8-60 min at the temperature of 910-1060 DEG C, and head upsetting is conducted; S3, heating is conducted for 6-60 min at the temperature of 910-1060 DEG C, and pre-forging is conducted; and S4, heating is conducted for 4-60 min at the temperature of 910-1060 DEG C, finish forging is conducted, and a finish forged piece is obtained. The invention further discloses the deformation high-temperature alloy blade forged piece obtainedthrough the precision forging method. The precision forging method and the deformation high-temperature alloy blade forged piece have the beneficial effects that precision forging forming of the blade forged piece based on a novel nickel-based high-temperature alloy GH4169D material is achieved, an obtained GH4169D alloy blade can meet the requirements for the shape and size of an aero-engine blade and for the performance at the high temperature of 650 DEG C to 750 DEG C, and the requirement for the temperature bearing capacity of a blade material due to the fact that the performance and theuse requirement of an aero-engine are continuously improved is met.

Owner:BEIJING CISRI GAONA TECH +1

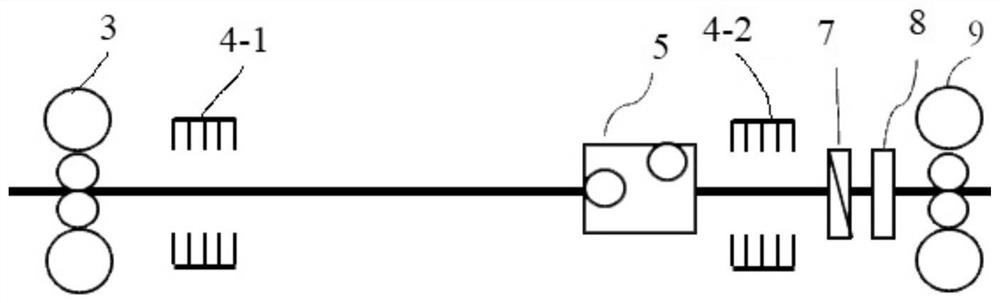

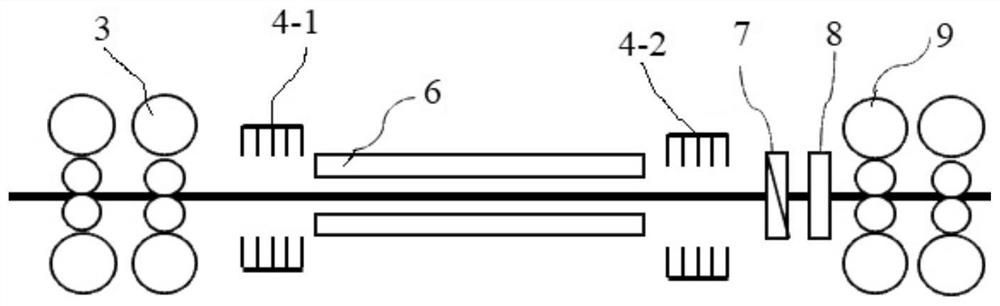

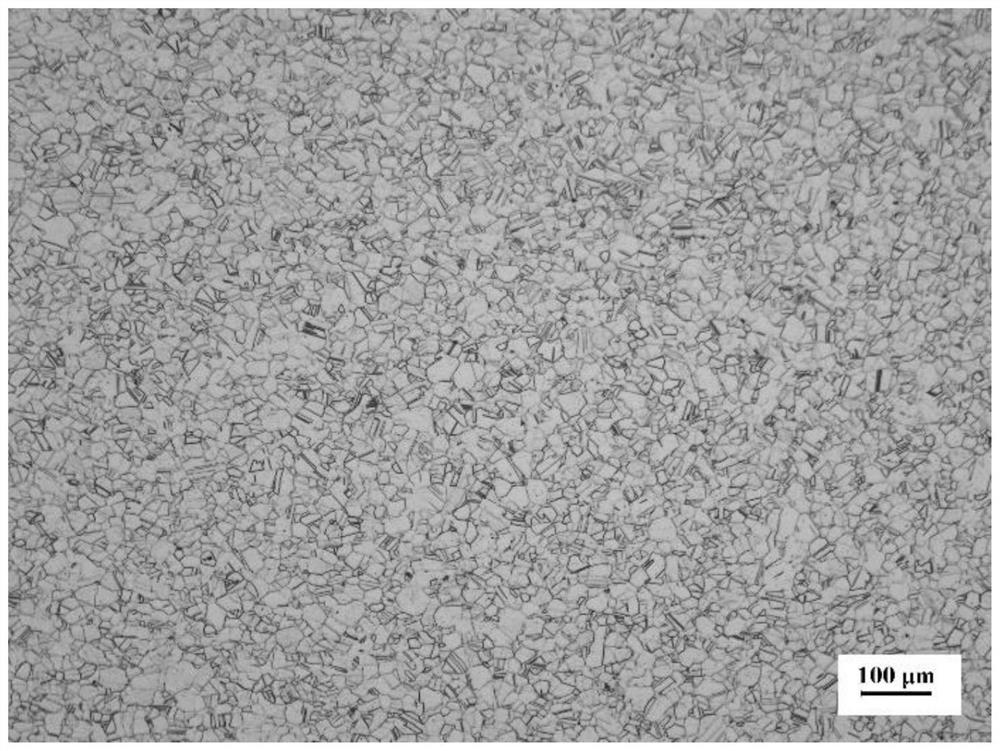

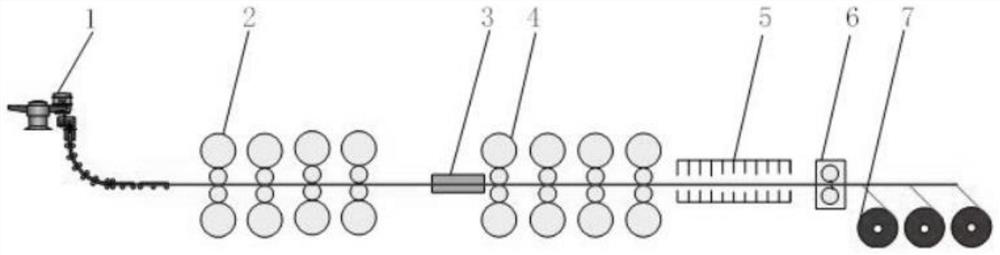

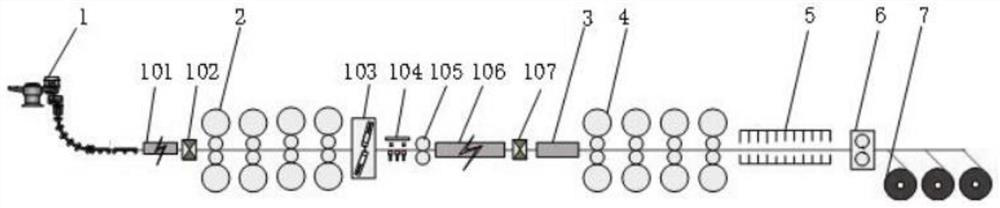

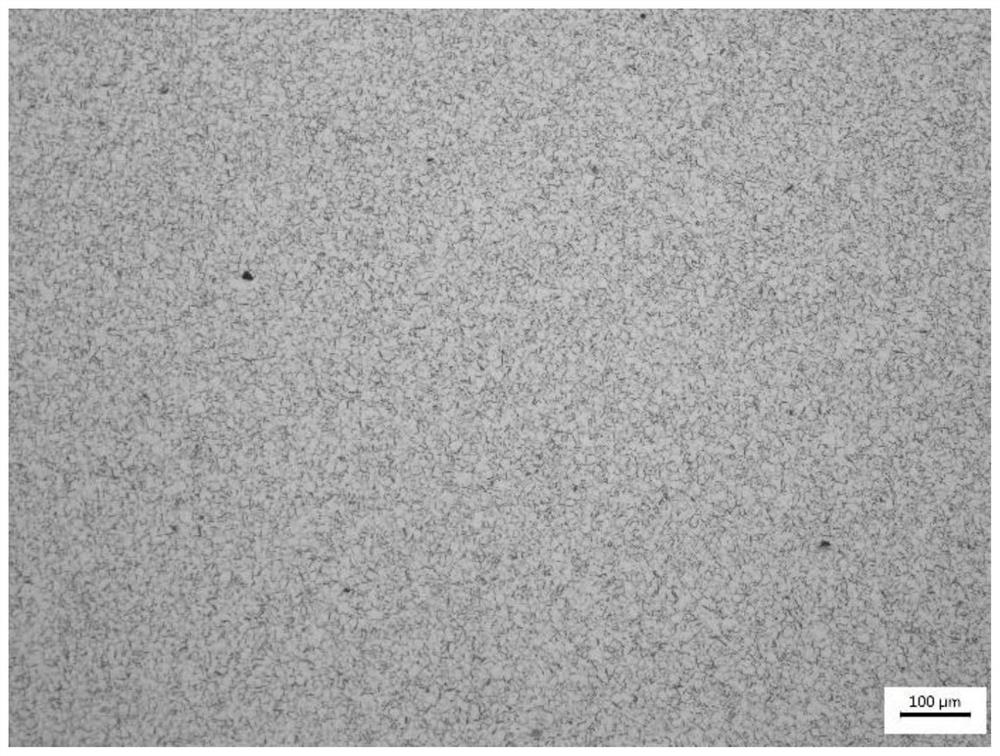

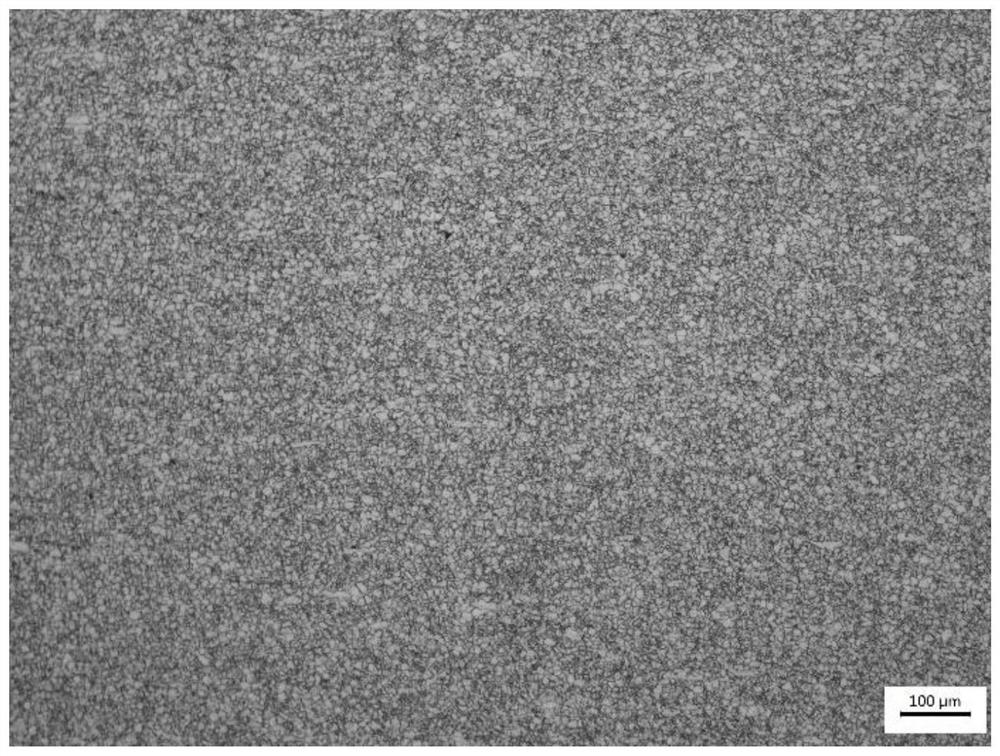

Continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystal and production method

PendingCN114273425AProlong the transition timeExtension of timeTemperature control deviceWork treatment devicesProduction lineSlow cooling

The invention belongs to the technical field of metallurgical processes and equipment, and relates to a continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystals and a control method. The invention discloses a continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystals. The continuous casting and rolling production line comprises a continuous casting machine, a roughing rolling unit, an intermediate billet heat preservation device, a finishing rolling unit, an after-rolling cooling device, a high-speed flying shear and a coiling unit which are sequentially arranged along a rolling line. A rolled piece heating device, a descaling device, an accident handling device, an intermediate billet cooling device and the like can be arranged on the production line according to needs. The intermediate billet heat preservation device is arranged in front of a finishing mill group, the temperature of the intermediate billet when reaching an inlet of the intermediate billet heat preservation device is controlled to be below the ferrite phase change temperature, the heating temperature of the intermediate billet heat preservation device is controlled, the intermediate billet is subjected to heat preservation or slow cooling in the device, the austenite-ferrite phase change time is prolonged, and the production efficiency is improved. And phase change is fully carried out, mixed crystals caused by double-phase rolling are avoided, and the structure property uniformity of a ferrite rolled product is improved.

Owner:CISDI ENG CO LTD +1

Heat treatment process for refining 10Cr9MoW2VNbBn crystal grains

The invention provides a heat treatment process for refining 10Cr9MoW2VNbBn crystal grains. The equilibrium tissue of pearlite and ferrite is obtained, tissue heredity is destroyed, the alloy elementcan be more uniformly distributed, and the heat treatment process can play a good role in solving the problem of crystal mixing. According to the heat treatment process, a 10Cr9MoW2VNbBn steel forgedpiece is sequentially subjected to heat treatment of high-temperature isothermal annealing and conventional isothermal annealing, and then steel forged piece is subjected to line quenching and tempering after being subjected to village processing, wherein the rising temperature of the austenitizing in the high-temperature isothermal annealing and the conventional isothermal annealing after heat preservation is rapidly increasing through high-power heating, so that the heating speed of the steel forging piece is increased, and the nucleation rate of austenite is increased.

Owner:WUXI HONGDA HEAVY IND

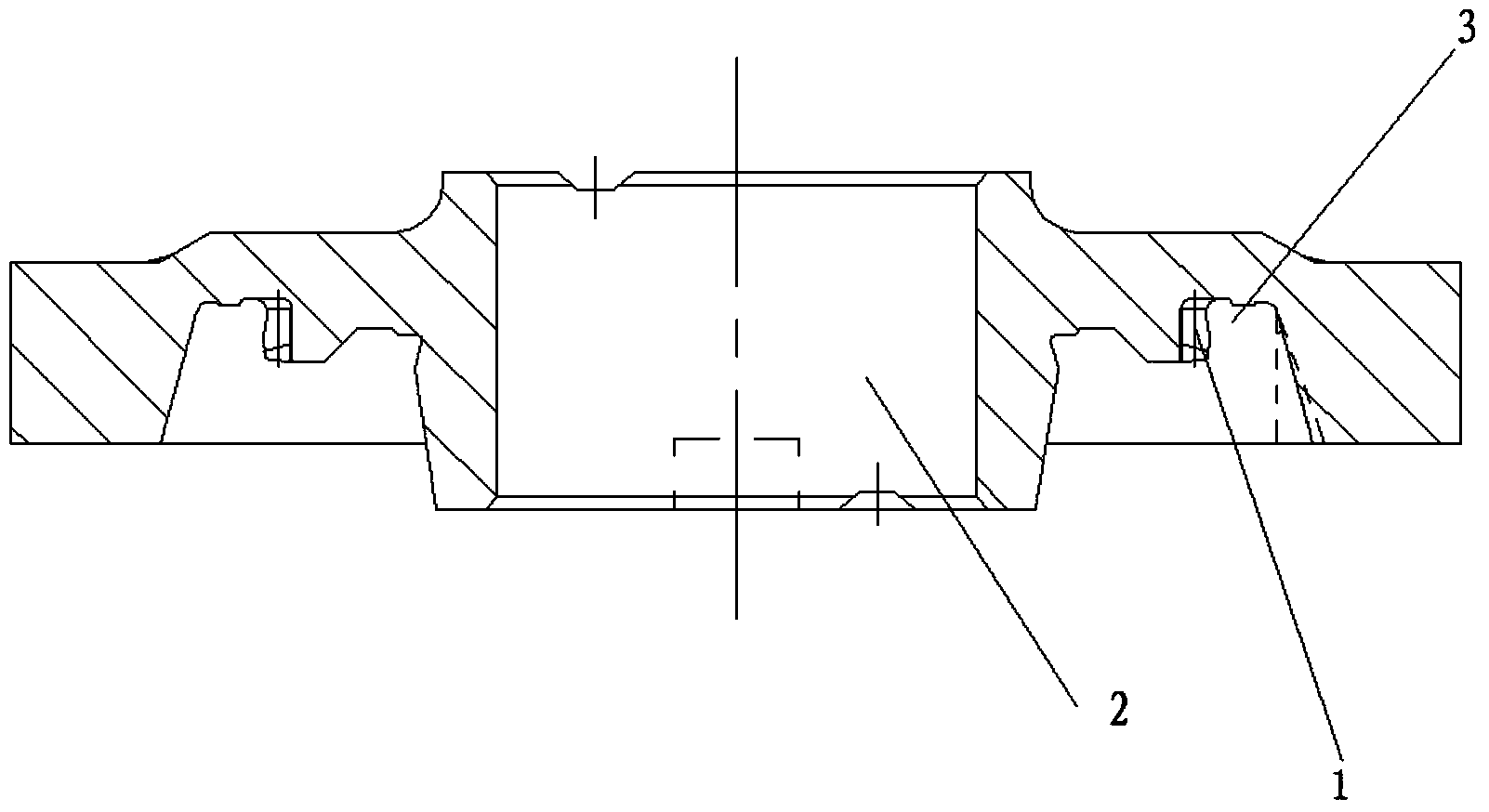

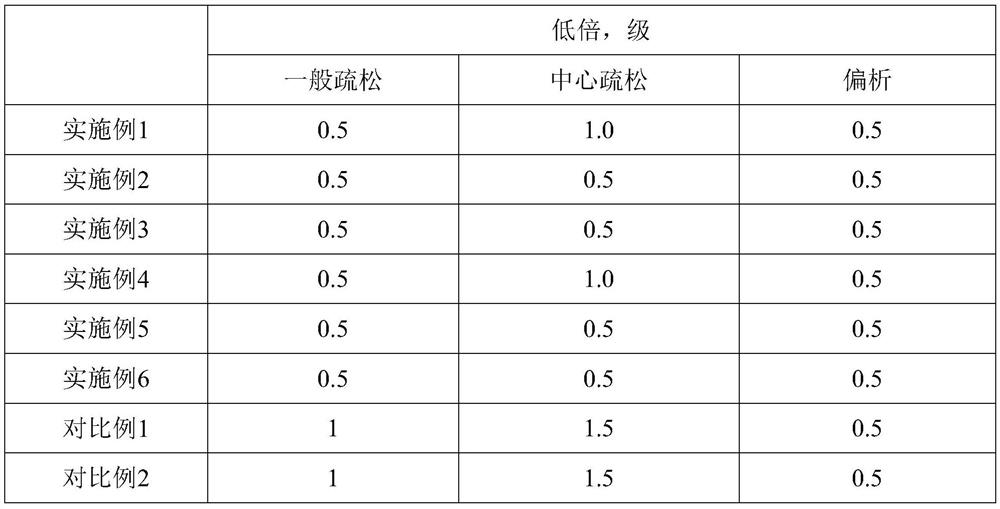

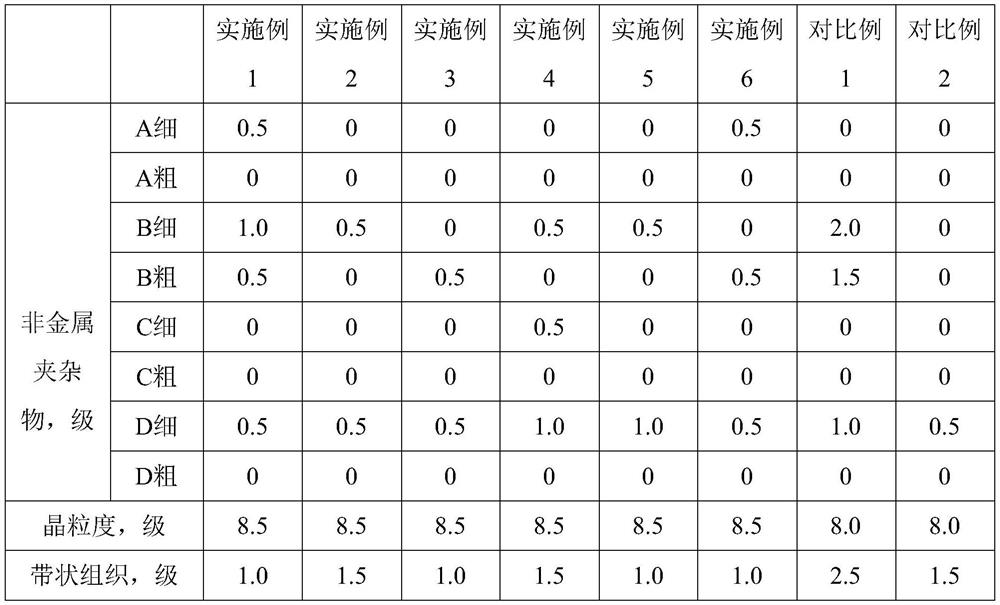

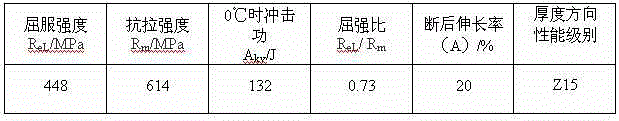

Hot working method of high-performance small-distortion carburized outer ring

PendingCN113862445AFully brokenReduce growth timeSolid state diffusion coatingFurnace typesTemperingHot working

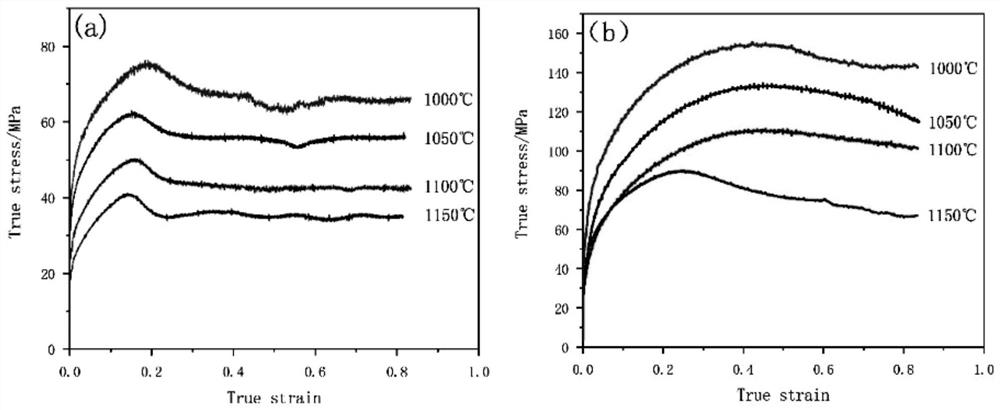

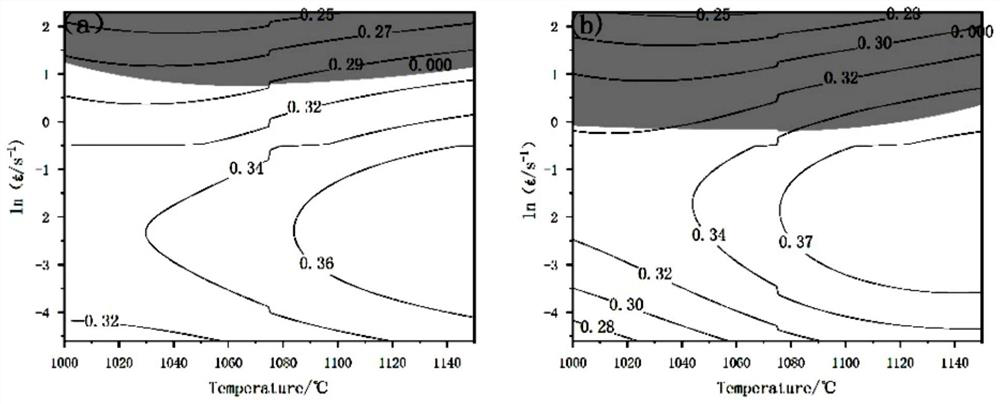

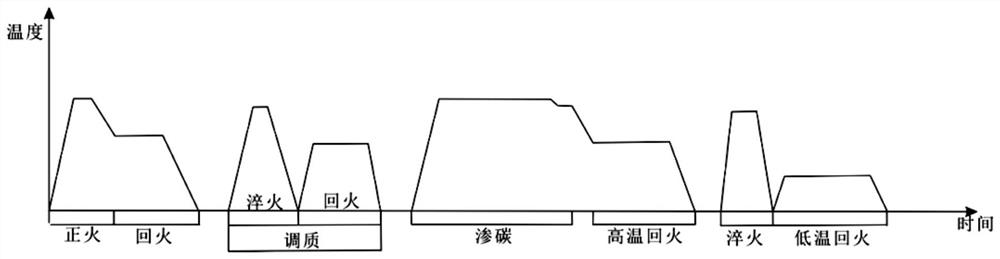

The invention discloses a hot working method of a high-performance small-distortion carburized outer ring, relates to the technical field of hot working methods, and solves the technical problems of complex manufacturing process, non-uniform carburized layer depth and poor quality consistency of the existing outer ring, and is suitable for forging and heat treatment of the outer ring made of 17Cr2Ni2MoVNb steel, the diameter of the outer ring is 150-200 mm, and the wall thickness of the outer ring is 8-10 mm. The hot working method comprises the following steps of constructing a true stress-strain curve and a hot working diagram, forging, normalizing and tempering at a high temperature, roughly machining, thermal refining, roughly machining a tooth shape and the like, performing gas / liquid composite carburizing and tempering at a high temperature, quenching and tempering at a low temperature. According to the hot working method, the ovality of the carburized and quenched outer ring is controlled to be less than or equal to 0.15 mm, the grain size is greater than or equal to 8.5 grades, and the rotating bending fatigue strength of a furnace sample is greater than or equal to 1000 MPa; and the part has high performance, meanwhile, only small heat treatment deformation exists, and good industrial application value is achieved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

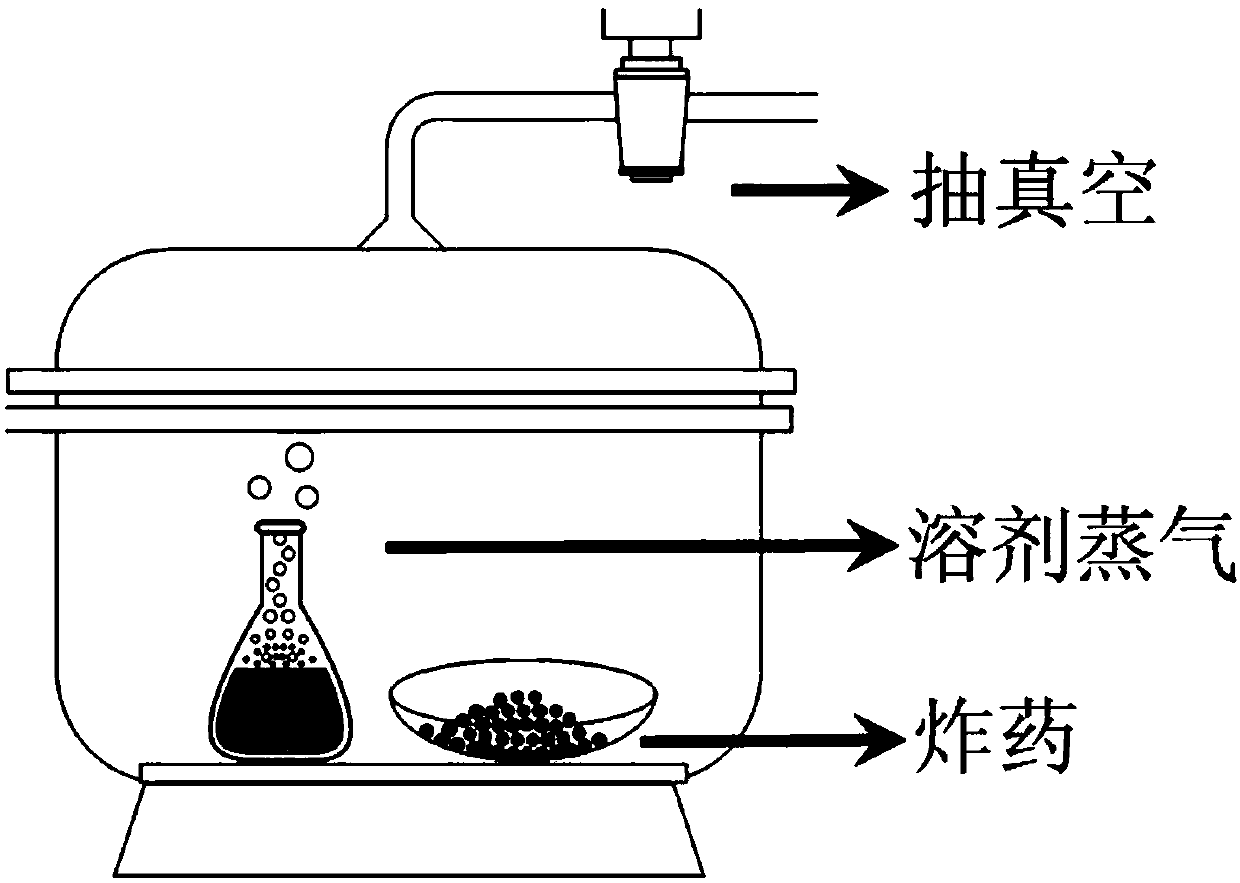

Simple preparation method for explosive solvate

ActiveCN107827835ASimple preparation processNo pollution in the processOrganic chemistryMicro structureSolvent

The invention discloses a simple preparation method for explosive solvate. The simple preparation method comprises the following key steps: under a normal temperature condition, placing explosive rawmaterials and a solvent in a sealed environment separately, slowly volatilizing the solvent through vacuuming, generating solvent steam of low pressure and low concentration, enabling the solvent steam to freely diffuse to the surface of explosive crystal, and inducing a gas-solid reaction, thereby obtaining the explosive solvate. The explosive solvate prepared by using the method is of a micro crystal cluster structure and has relatively low temperature, and a primary template can be provided for later explosive micro structure regulation and control. The method has the characteristics of being simple in process procedure, gentle in experiment condition, rapid and efficient in preparation, free of pollution, low in cost, and the like, and is particularly applicable to on-scale preparation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Low-silicon microalloyed high-temperature carburized gear steel and manufacturing method thereof

InactiveCN112593036AImprove fatigue lifeReduced enrichmentSolid state diffusion coatingManufacturing convertersAustenite grainSlag

The invention discloses low-silicon microalloyed high-temperature carburized gear steel and a manufacturing method thereof. The manufacturing method includes the steps that about 20% of scrap steel isadded into a converter, then molten iron is added for smelting, final steel tapping control targets are that C is larger than or equal to 0.08% and P is smaller than or equal to 0.015%, sliding plateslag stopping operation is conducted in the steel tapping process, and discharged slag is reduced; and alloying is started about 90 seconds after tapping is started, and ferro-aluminum, carbon powder, an alloy and lime are added in sequence. According to the low-silicon microalloyed high-temperature carburized gear steel and the manufacturing method thereof, enrichment of inclusions at the innerside of a gate is greatly reduced, steady-state control over a stopper curve in the casting process is achieved, involving of large-size inclusions due to the fact that the stopper curve suddenly fluctuates is avoided, continuous casting production of at least six furnaces can be achieved, and meanwhile the service fatigue life of a gear is remarkably prolonged; and abnormal growth of austenite grains is hindered, and the austenite grain coarsening temperature of the gear steel is increased, so that the effects of preventing mixed grains and coarse grains of the austenite grains of the gear steel after high carburizing temperature are achieved.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Forging method of Cr18Mn18N steel forge piece and forge piece

The invention provides a forging method of a Cr18Mn18N steel forge piece and the forge piece and relates to the manufacturing field. The forging method of the Cr18Mn18N steel forge piece comprise the following steps of: heating a Cr18Mn18N steel ingot to a heating moulding temperature of 1190-1210 DEG C; carrying out heat preservation at the heating moulding temperature; carrying out repeated firing forging moulding; and then cooling. In the repeated firing forging moulding step, firing deformation during each firing is 10-20%, and final forging temperature is 850-950 DEG C. The forging method has the advantages that multiple steps coordinate with each other, so that the finally obtained forge piece is free of cracks on the surface, fibrous tissues of the forge piece are consistent with shape of the forge piece, and a metal streamline is complete; and defects are small, demands can be met, and machining dimension can be guaranteed.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Deformation high-temperature alloy blade forged piece and die forging method thereof

ActiveCN112108598APrevent coarse grainPrevent mixed crystalsPretreated surfacesExtrusion control devicesSuperalloyAero engine

The invention discloses a deformation high-temperature alloy blade forged piece and a die forging method thereof. The die forging method comprises the following steps: extrusion heating, specifically,the heating temperature is 950-1100 DEG C, and the heat preservation time is 10-60 min; extrusion forming; finish forging heating, specifically, the heating temperature is 910-1060 DEG C, and the heat preservation time is 5-60 min; and finish forging for obtaining a finish forged piece. The provided method can effectively realize the consistency of the quality of the forged pieces, increases thequalification rate of the finished forge piece and improve the quality of the finished forge piece. The invention further discloses a deformation high-temperature alloy blade forged piece obtained through the die forging method. The deformation high-temperature alloy blade forged piece has the advantages that the surface is free of cracks, and the internal structure meets the design requirement, the requirements for the shape and size of an aero-engine blade and for the performance at the high temperature of 650 DEG C to 750 DEG C can be met, and the requirement for the temperature bearing capacity of a blade material due to the fact that the performance and the use requirement of an aero-engine are continuously improved is met.

Owner:BEIJING CISRI GAONA TECH +1

X60 pipe line steel and production method thereof

ActiveCN101928882BIncrease varietySimple structureTemperature control deviceEconomic benefitsAdditional values

The invention provides X60 pipe line steel and a preparation method thereof. The X60 pipe line steel comprises the following chemical components in percentage by weight: 0.060 to 0.080 percent of C, 0.15 to 0.30 percent of Si, 1.35 to 1.55 percent of Mn, less than or equal to 0.006 percent of S, less than or equal to 0.020 percent of P, 0.035 to 0.055 percent of Nb, 0.035 to 0.055 percent of V, 0.010 to 0.025 percent of Ti, less than or equal to 0.008 percent of N, 0.010 to 0.040 percent of Als, and the balance of Fe and inevitable impurities. After heating and descaling, rough rolling and finish rolling are continuously completed on the same steckel mill, the reinforcing effect of Nb, V and other microalloyed elements added in the steel can be sufficiently played by delay controlled rolling in the rolling process, micro-uniform tissues can be obtained, occurrence of mixed crystal can be effectively prevented, and the strength and toughness of the X60 pipe line steel can be greatly improved. The produced X60 pipe line steel belongs to the product with high technology content and high additional value, and has remarkable economic benefit.

Owner:WUKUN STEEL

High-strength steel wire rod with good low-temperature impact toughness and production method thereof

Owner:XINGTAI IRON & STEEL

A kind of q345 grade anti-seismic steel and the method for producing q345 grade anti-seismic steel with a steel coil mill

The invention relates to Q345-grade anti-seismic steel and a method for producing the Q345-grade anti-seismic steel by virtue of a steckel mill, belonging to the technical fields of machining and forming of metal materials. The Q345-grade anti-seismic steel comprises the following components: C, Si, Mn, S, P, Nb, V, Ti, N, Als and the balance of Fe and impurities. The method comprises the steps of firstly heating a plate blank, spraying water to remove phosphorous, continuously finishing rough milling and precision milling on a double-stander compact steckel mill, feeding the finely milled steel plate to a reeling machine to be reeled, and naturally air cooling to the room temperature, so as to obtain the Q345-grade anti-seismic steel with high strength and low yield ratio. By adding microalloying elements such as Nb and V into the Q345-grade anti-seismic steel, the strength and the toughness of the Q345-grade anti-seismic steel are effectively improved. According to the Q345-grade anti-seismic steel produced by virtue of the method, the potential of the double-stander compact steckel mill manufactured by Kunming iron and steel Co., Ltd. is adequately explored, the variety of plate strip products is expanded, and the product structure is optimized.

Owner:KUNMING UNIV OF SCI & TECH +1

X52 pipeline steel and production method thereof

ActiveCN101928884BIncrease varietySimple structureTemperature control deviceChemical compositionUltimate tensile strength

The invention provides an X52 pipeline steel and a production method thereof. The X52 pipeline steel comprises the following chemical components: 0.070-0.090wt% of C, 0.15-0.30wt% of Si, 1.10-1.30wt% of Mn, 0.006wt% or more of S, 0.020wt% or more of P, 0.020-0.040wt% of Nb, 0.010-0.020wt% of Ti, 0.008wt% or more of N, 0.010-0.040wt% of Als, the rest of Fe and unavoidable impurities. After heating and descaling, rough rolling and finish rolling are performed on the same dual-frame compact Steckel mill continuously; through delayed rolling control in rolling process, the enhancement function of microalloy elements such as Nb and V added to the steel are given a full play, thereby obtaining superfine and uniform tissue, effectively preventing the occurrence of mixed crystal, and greatly improving the strength and toughness of the X52 pipeline steel. The X52 pipeline steel produced with the method belongs to high-technology product with high additional value, thus the economical benefit is significant.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com