High-strength steel wire rod with good low-temperature impact toughness and production method thereof

A technology of low temperature impact toughness and production method, applied in the field of steel wire rods, can solve problems such as cost increase, and achieve the effects of low use cost, fine grain size, high material strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

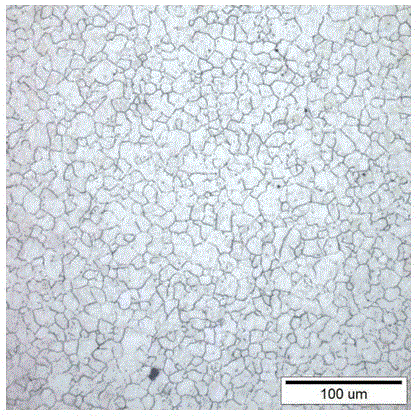

Embodiment 1

[0024] Embodiment 1: The high-strength steel wire rod with good low-temperature impact toughness adopts the following production method.

[0025] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into steel slabs, its composition by weight percentage is: C 0.35%, Si 0.19%, Mn 0.83%, P 0.020%, S 0.020%, Cr 0.94%, Mo 0.19 %, and the rest is iron.

[0026] (2) Heating process: heating the steel billet to 1000°C, holding time for 120min.

[0027] (3) Rolling process and silk spinning process: the dephosphorized steel billet is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of advance and finish rolling is 875°C. Sizing; after finishing rolling, the spinning temperature is controlled at 850°C.

[0028] (4) Cooling process: enter the Stelmore cooling line, adjust the number of openings of the air-cooling line insulation cover and the opening of the f...

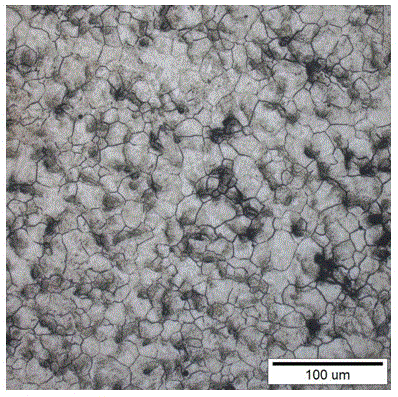

Embodiment 2

[0029] Embodiment 2: The high-strength steel wire rod with good low-temperature impact toughness adopts the following production method.

[0030] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into steel slabs, its composition by weight percentage is: C 0.38%, Si 0.20%, Mn 0.85%, P 0.018%, S 0.020%, Cr 0.95%, Mo 0.20 %, and the rest is iron.

[0031] (2) Heating process: heating the steel billet to 1050°C, holding time for 115min.

[0032] (3) Rolling process and silk spinning process: the dephosphorized steel billet is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of advance and finish rolling is 873°C. After sizing and finishing rolling, the spinning temperature is controlled at 840°C.

[0033] (4) Cooling process: enter the Stelmore cooling line, adjust the number of openings of the air-cooling line insulation cover and the opening of th...

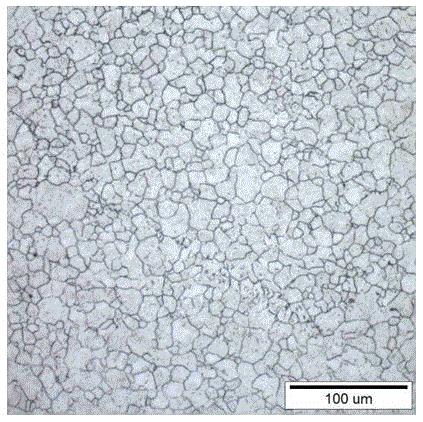

Embodiment 3

[0034] Embodiment 3: The high-strength steel wire rod with good low-temperature impact toughness adopts the following production method.

[0035] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into billets, the composition of which is by weight percentage: C 0.42%, Si 0.19%, Mn 0.84%, P 0.020%, S 0.018%, Cr 0.93%, Mo 0.19 %, and the rest is iron.

[0036] (2) Heating process: heating the billet to 1100°C, holding time for 110min.

[0037] (3) Rolling process and silk spinning process: the dephosphorized steel billet is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of advance and finish rolling is 880°C. After sizing and finishing rolling, the spinning temperature is controlled at 845°C.

[0038] (4) Cooling process: enter the Stelmore cooling line, adjust the number of openings of the air-cooling line insulation cover and the opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com