Deformation high-temperature alloy blade forged piece and precision forging method thereof

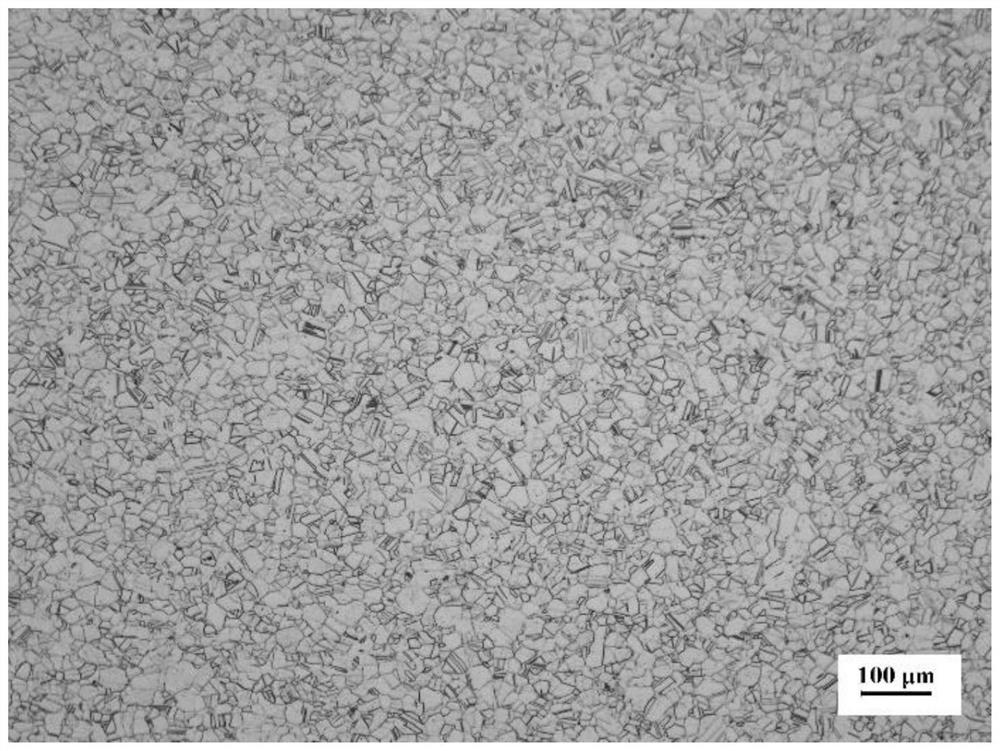

A technology for deforming superalloys and blades, used in metal extrusion, metal processing equipment, metal extrusion control equipment, etc., can solve problems such as the inability to meet the requirements of blade temperature bearing capacity, and achieve improved material utilization and uniform structure. state, the effect of optimizing the forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A precision forging method for a deformed superalloy blade forging, comprising the following steps:

[0064] S1. Extrusion: Select qualified nickel-based superalloy GH4169D alloy bars, and carry out surface treatment on the GH4169D alloy bars. Specifically, use 120-mesh steel sand medium for shot blasting, and the shot blasting time is 15 minutes. For GH4169D alloy Bar surface cleaning;

[0065] Then put the GH4169D alloy bar into the oven, the heating temperature is 120°C, and the heating time is 60min, and then take out the bar from the oven and spray the glass lubricant to obtain a glass lubricant-coated bar with a coating thickness of 0.09±0.01mm material;

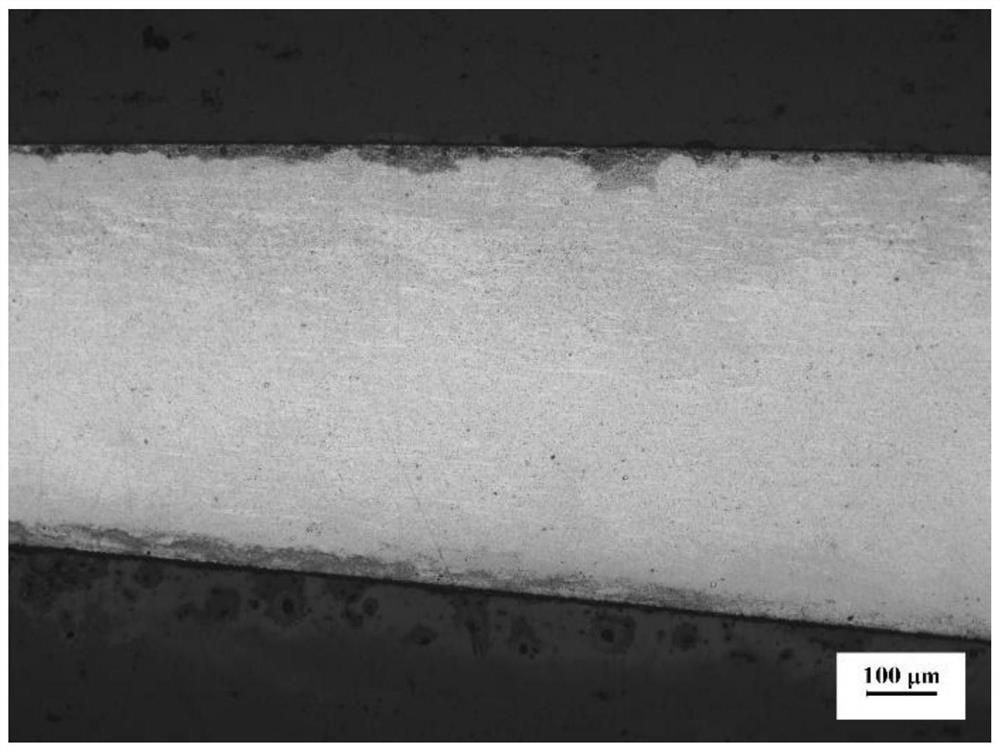

[0066] Then the alloy bar is heated in a heating furnace at a heating temperature of 1060°C and kept for 15 minutes, and then within 17 seconds, the alloy bar in the heating furnace is taken out from the heating furnace and transferred to a screw press for extrusion molding to obtain Extrusion, cooling, extrus...

Embodiment 2

[0079] A precision forging method for a deformed superalloy blade forging, carried out according to the method in Example 1, the difference is that:

[0080] S1. Extrusion: heat the bar in a heating furnace at a temperature of 950°C, keep it warm for 60 minutes, then take the alloy bar in the heating furnace out of the heating furnace and transfer it to a screw press within 17 seconds for extrusion Forming, the extrusion ratio is 2;

[0081] S2. Upsetting head: return the extruded part to the furnace to heat, the heating temperature is 910°C, and the heating time is 60 minutes, then quickly take out the extruded part from the heating furnace within 17 seconds to the screw press to hit the upsetting head to obtain the upsetting part, and cool it down;

[0082] S3. Pre-forging: return the heading piece to the furnace for heating, the heating temperature is 910°C, and the heating time is 60 minutes. Then take out the heading piece from the heating furnace and transfer it to the s...

Embodiment 3

[0085] A deformed superalloy blade forging and its precision forging method are carried out according to the method in Example 1, the difference is that:

[0086] S1. Extrusion: heat the bar in a heating furnace at a temperature of 1150°C, keep it warm for 8 minutes, then take out the alloy bar in the heating furnace from the heating furnace and transfer it to a screw press within 17 seconds for extrusion Forming, the extrusion ratio is 12;

[0087] S2. Upsetting head: return the extruded part to the furnace to heat, the heating temperature is 1060 ° C, and the heating time is 8 minutes, then quickly take out the extruded part from the heating furnace within 17 seconds to the screw press to hit the upsetting head to obtain the upsetting part, and cool down;

[0088] S3. Pre-forging: return the heading piece to the furnace for heating, the heating temperature is 1060°C, and the heating time is 6 minutes. Then take out the heading piece from the heating furnace and transfer it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com