Simple preparation method for explosive solvate

A technology for solvates and explosives, applied in the direction of organic chemistry, etc., can solve the problems such as the bonding of explosive powder particles into blocks, affecting the assembly effect of solvates, and being prone to desolvation, etc., so as to avoid dissolution or agglomeration. Good experimental reproducibility, beneficial to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

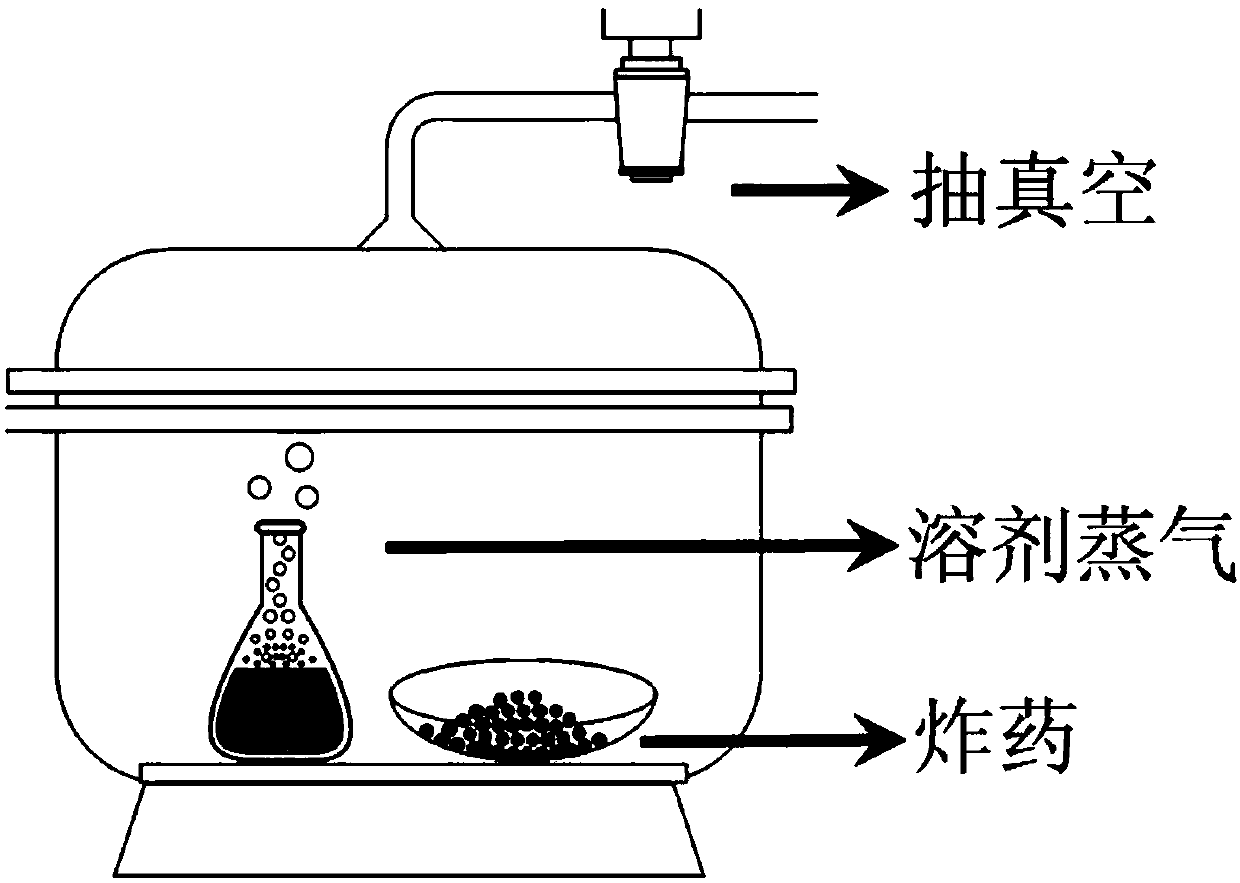

[0033] (1) Spread 10g of Oktogen (HMX) explosives on a surface dish with a diameter of 120mm, and measure 40g of N,N-dimethylformamide (DMF) solvent in a 150ml conical flask , and then put the watch glass and Erlenmeyer flask together in a glass desiccator with a volume of 2 L.

[0034] (2) Use a vacuum pump to vacuumize the desiccator. After the vacuum reaches 0.5 bar, stop vacuuming and close the valve.

[0035] (3) At room temperature, DMF solvent vapor and HMX explosives undergo gas-solid reaction in a desiccator for 8 hours, then open the vacuum valve to restore the desiccator to normal pressure, and then take out the solid sample, which is the obtained HMX / DMF explosive solvent compounds.

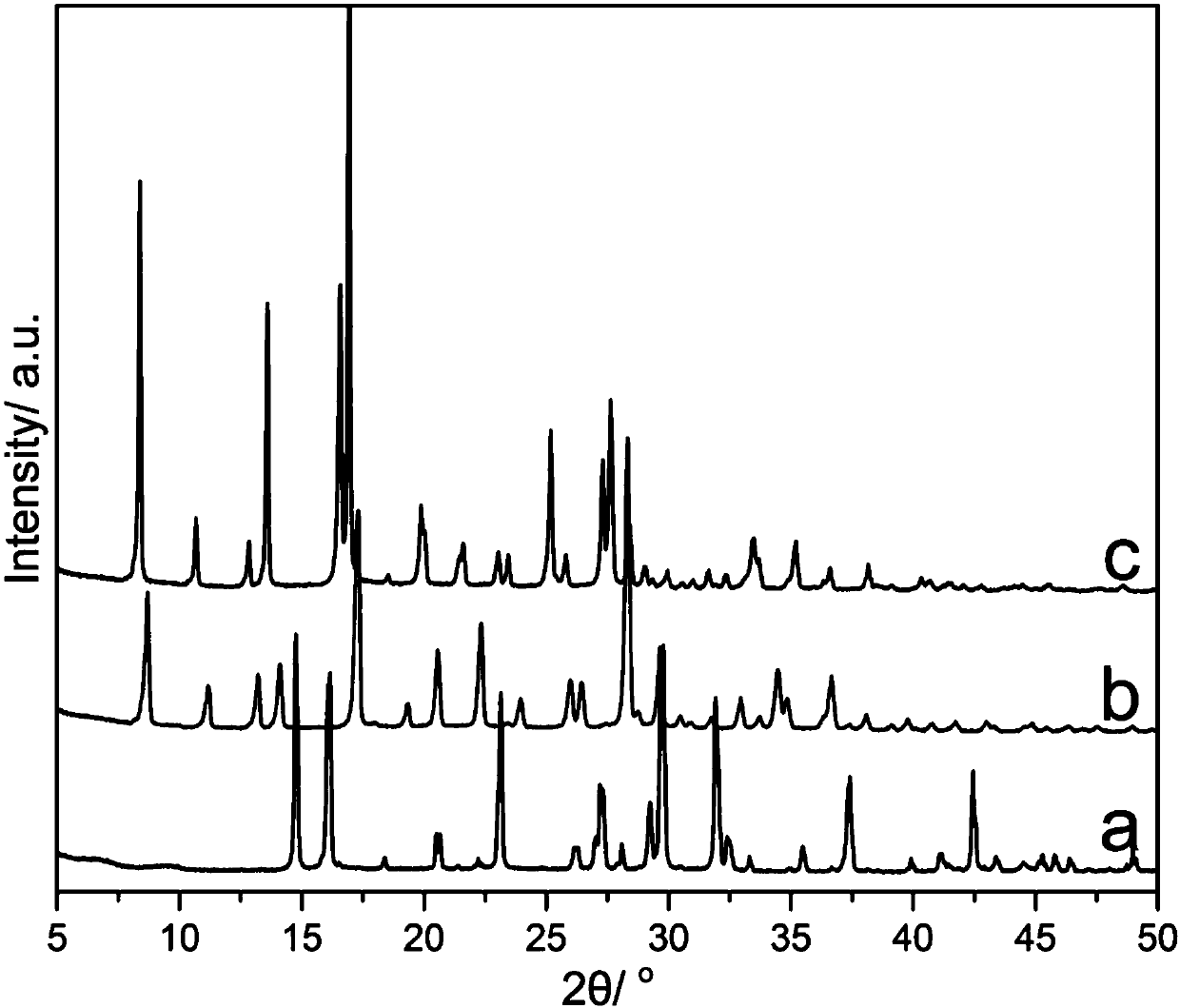

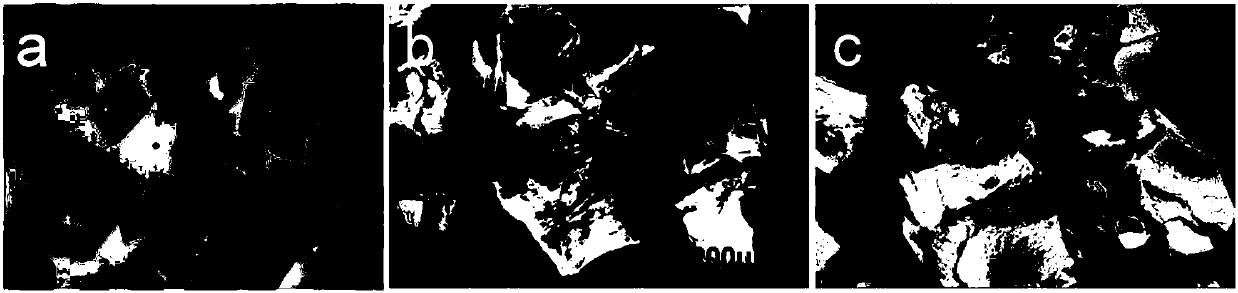

[0036] as attached figure 2 , 3 shown, with figure 2 Shown in a and b are the X-ray powder diffraction spectrograms of the HMX raw material and the solvate, and it can be seen that the raw material HMX has all been converted into the solvate at this time. attached image 3A an...

Embodiment 2

[0038] (1) Spread 10g of Octojin (HMX) explosives on a surface dish with a diameter of 120mm, measure 60g of N-methylpyrrolidone (NMP) solvent in a 150ml conical flask, and then surface The dish and Erlenmeyer flask were placed together in a glass desiccator with a volume of 2 L.

[0039] (2) Use a vacuum pump to vacuumize the desiccator. After the vacuum degree reaches 0.01 bar, stop vacuuming and close the valve.

[0040] (3) At room temperature, NMP solvent vapor and HMX explosives undergo gas-solid reaction in a desiccator for 1 day, then open the vacuum valve to restore the desiccator to normal pressure, and then take out the solid sample, which is the obtained HMX / NMP explosive solvent compounds. as attached figure 2 Shown in c is the X-ray powder diffraction spectrogram of this solvate, shows that raw material HMX has all been converted into solvate at this moment. attached image 3 Where c is the topography of the solvate, it can be seen that the solvate crystal p...

Embodiment 3

[0042] (1) Spread 10 g of hexanitrohexaazaisowurtzitane (CL-20) explosives on a surface dish with a diameter of 120 mm, and measure 100 g of hexamethylphosphoryl trisulfite in a 150 ml conical flask Amine (HMPT) solvent, and then put the watch glass and Erlenmeyer flask together in a glass desiccator with a volume of 2L.

[0043] (2) Use a vacuum pump to vacuumize the desiccator. After the vacuum degree reaches 0.001 bar, stop vacuuming and close the valve.

[0044] (3) At room temperature, after the gas-solid reaction between HMPT solvent vapor and CL-20 explosive in the desiccator for 1 day, open the vacuum valve to restore the desiccator to normal pressure, and then take out the solid sample, which is the obtained CL-20 / HMPT explosive solvate. attached Figure 4 Shown in a and b are the X-ray powder diffraction spectra of the CL-20 raw material and the solvate. It can be seen that the raw material CL-20 has been completely converted into a solvate at this time. attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com