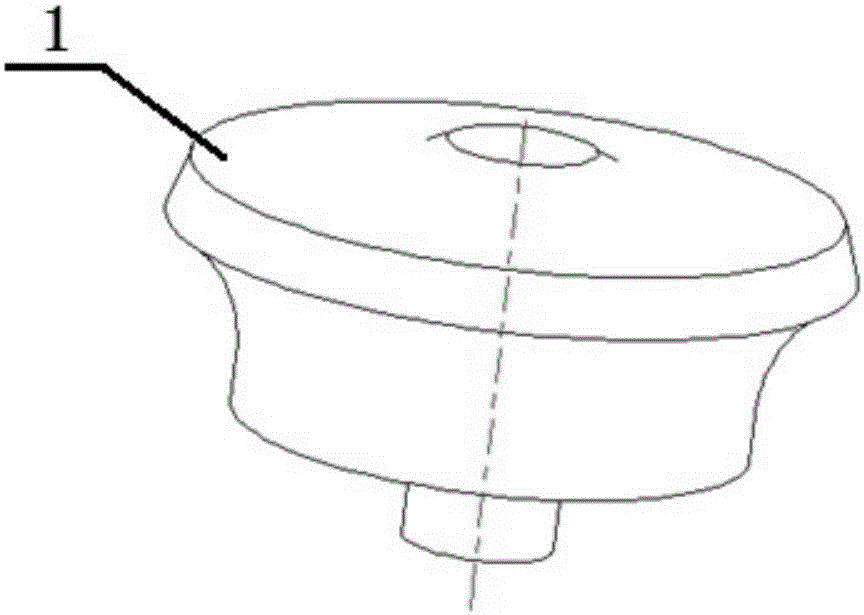

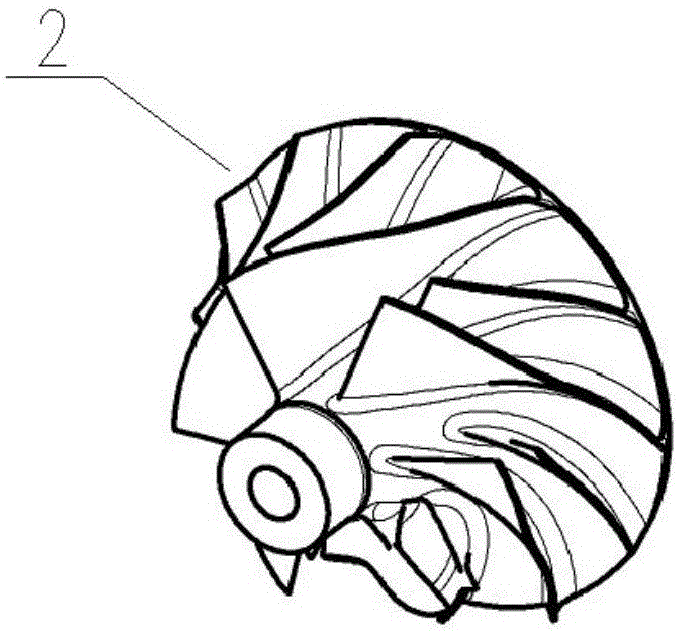

Forging method for 2618A aluminum alloy impeller forging

A technology for aluminum alloy impellers and forgings, which is applied in the forging field of 2618A aluminum alloy impeller forgings, and can solve problems such as size deformation of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

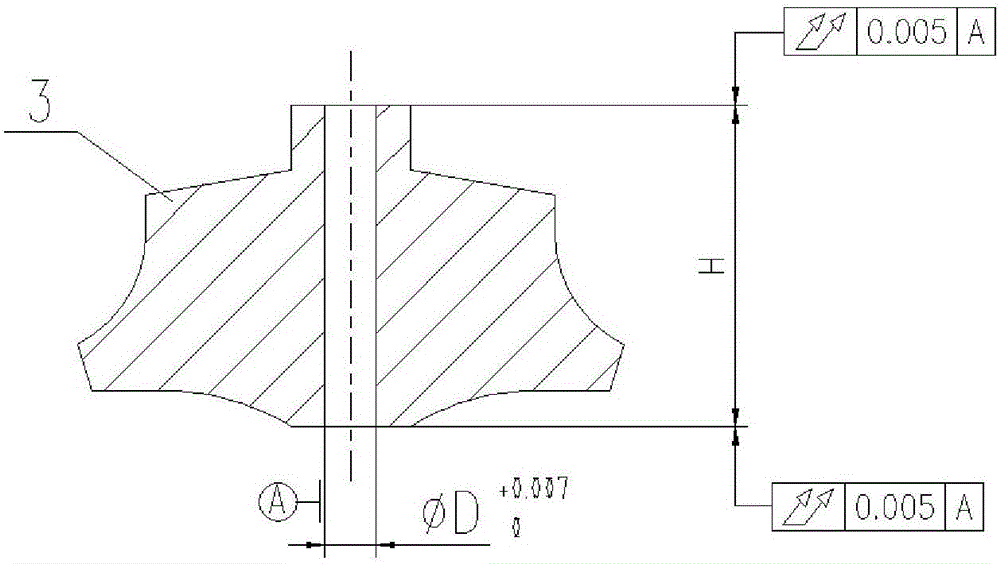

Image

Examples

Embodiment 1

[0024] The applicant provides a forging method of a 2618A aluminum alloy impeller forging, the specific steps are as follows:

[0025] (1) Cutting, heating, and one-time forging: the heating temperature of the billet is controlled at 440°C, and the deformation of the forging is controlled at 36%;

[0026] (2) Edge trimming and water cooling: Water cooling is used after trimming, and the water temperature is controlled at 30°C. The water temperature in the continuous production process should not exceed 35°C. The water cooling time is at least 5 minutes, and the secondary forging is completed within 2 hours;

[0027] (3) Secondary forging: carry out secondary forging after water cooling, the temperature of the forging is normal temperature, and the deformation of the forging is controlled at 5%;

[0028] (4) Solid solution: heat preservation at 530°C for 60 minutes, then heat up to 540°C with the furnace for 10 minutes, then water cooling, the water cooling temperature is 50°C,...

Embodiment 2

[0031] The applicant provides a forging method of a 2618A aluminum alloy impeller forging, the specific steps are as follows:

[0032] (1) Cutting, heating, and one-time forging: the heating temperature of the billet is controlled at 430°C, and the deformation of the forging is controlled at 26%;

[0033] (2) Edge trimming and water cooling: Water cooling is used after edge trimming, the water temperature is controlled at 20°C, the water temperature in the continuous production process should not exceed 35°C, the water cooling time is at least 5 minutes, and the secondary forging is completed within 2 hours;

[0034] (3) Secondary forging: carry out secondary forging after water cooling, the temperature of the forging is normal temperature, and the deformation of the forging is controlled at 2%;

[0035] (4) Solid solution: heat preservation at 530°C for 60 minutes, then heat up to 540°C with the furnace for 10 minutes, then water cooling, the water cooling temperature is 40°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com