X65 pipe line steel and production method thereof

A production method and technology for pipeline steel, applied in the direction of temperature control, etc., to achieve the effects of improving strength and toughness, optimizing product structure, and preventing mixed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

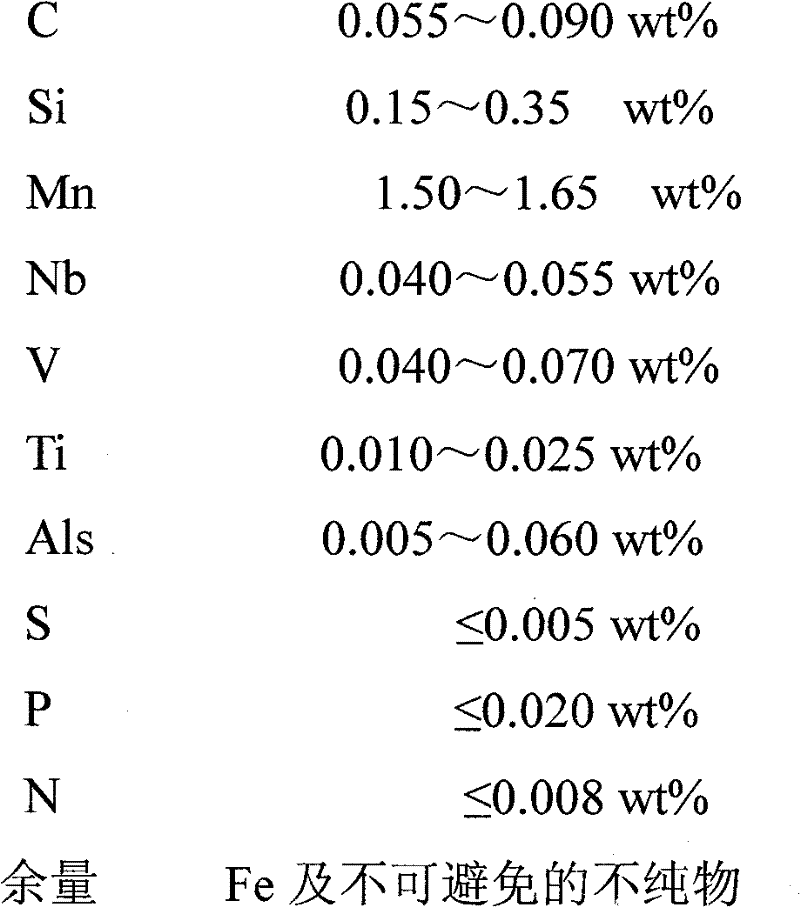

Embodiment 1

[0049] A. The slab with the following chemical composition: C 0.06wt%, Si 0.20wt%, Mn 1.58wt%, S 0.004wt%, P 0.018wt%, Nb 0.045wt%, V 0.050wt%, Ti 0.1wt%, N 0.007wt%, Als 0.030wt%, and the rest are Fe and unavoidable impurities, which are sent to a heating furnace with a temperature of 1230°C in the soaking section and heated for 250 minutes, wherein the heating of the slab in the soaking section The time is 60 minutes to ensure that the micro-alloying elements such as Nb and V precipitated in the slab are fully re-dissolved, the austenite grains are refined and the controlled cooling precipitation after rolling is prepared, the internal structure of the slab is uniform, and the furnace is released;

[0050] B. Use high-pressure water with a pressure of 18MPa to spray water on the front and back sides of the slab to descale for 12 seconds;

[0051] C. Send the descaled slab to the furnace coil rolling mill for rolling, and control the rolling start temperature to 1100°C, carry...

Embodiment 2

[0056]A. The slab with the following chemical composition: C 0.09wt%, Si 0.35wt%, Mn 1.65wt%, S 0.003wt%, P 0.015wt%, Nb 0.055wt%, V 0.07wt%, Ti 0.01wt%, N 0.005wt%, Als 0.005wt%, the rest is Fe and unavoidable impurities; it is sent to a heating furnace with a furnace temperature of 1270°C in the soaking section, and heated for 150 minutes, of which, the time for the slab in the soaking section 40 minutes to ensure that the microalloy elements such as Nb and V precipitated in the slab are fully re-dissolved, refine the austenite grains and prepare for the controlled cooling precipitation after rolling, uniform the internal structure of the slab, and release from the furnace;

[0057] B. Use high-pressure water with a pressure of 20MPa to spray water on the front and back sides of the slab to descale for 10 seconds;

[0058] C. Send the descaled slab to the furnace coil rolling mill for rolling, and control the rolling start temperature to 1200°C, conduct 4 passes of continuou...

Embodiment 3

[0063] A. The slab with the following chemical composition: C 0.055wt%, Si 0.15wt%, Mn 1.5wt%, S 0.003wt%, P 0.015wt%, Nb 0.04wt%, V 0.04wt%, Ti 0.25wt%, N 0.005wt%, Als 0.06wt%, the rest is Fe and unavoidable impurities; it is sent to a heating furnace with a temperature of 1250°C in the soaking section, and heated for 200 minutes, of which, the time for the slab in the soaking section 50 minutes to ensure that the microalloy elements such as Nb and V precipitated in the slab are fully re-dissolved, refine the austenite grains and prepare for the controlled cooling precipitation after rolling, uniform the internal structure of the slab, and release from the furnace;

[0064] B. Use high-pressure water with a pressure of 15MPa to spray water on the front and back sides of the slab to descale for 15 seconds;

[0065] C. Send the descaled slab to the furnace coil rolling mill for rolling, and control the rolling start temperature to 1150°C, conduct continuous rough rolling for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com