Low-alloy high-strength large-diameter thick-walled seamless steel pipe and manufacturing method thereof

A low-alloy high-strength, seamless steel pipe technology, applied in the field of metallurgy, can solve the problems of complex heat treatment process and high rejection rate, and achieve the effects of reducing production costs, preventing grain growth, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

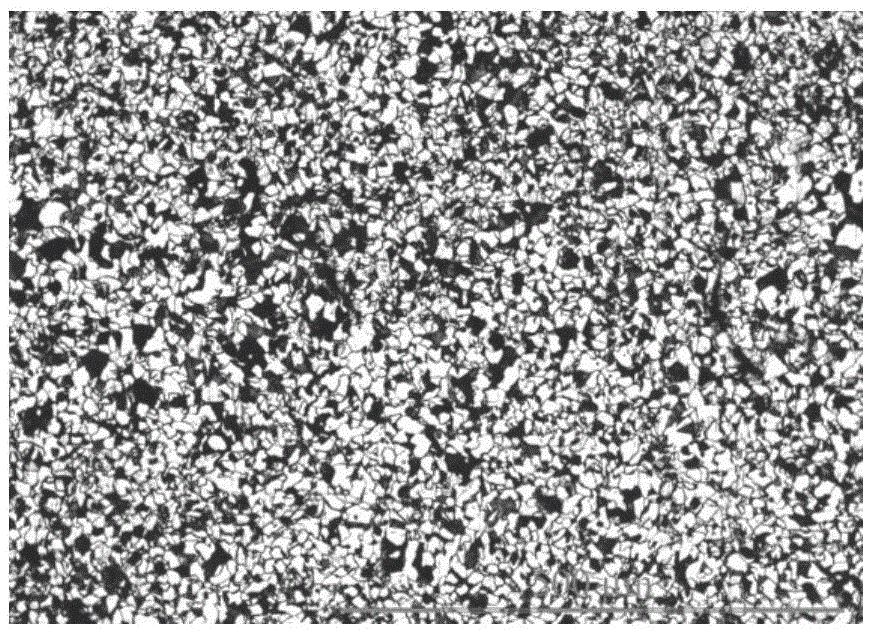

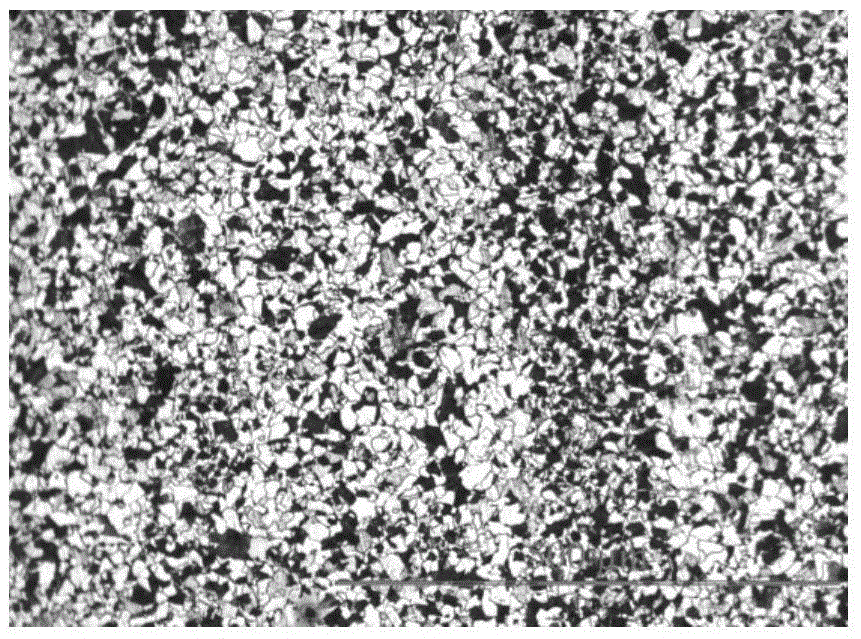

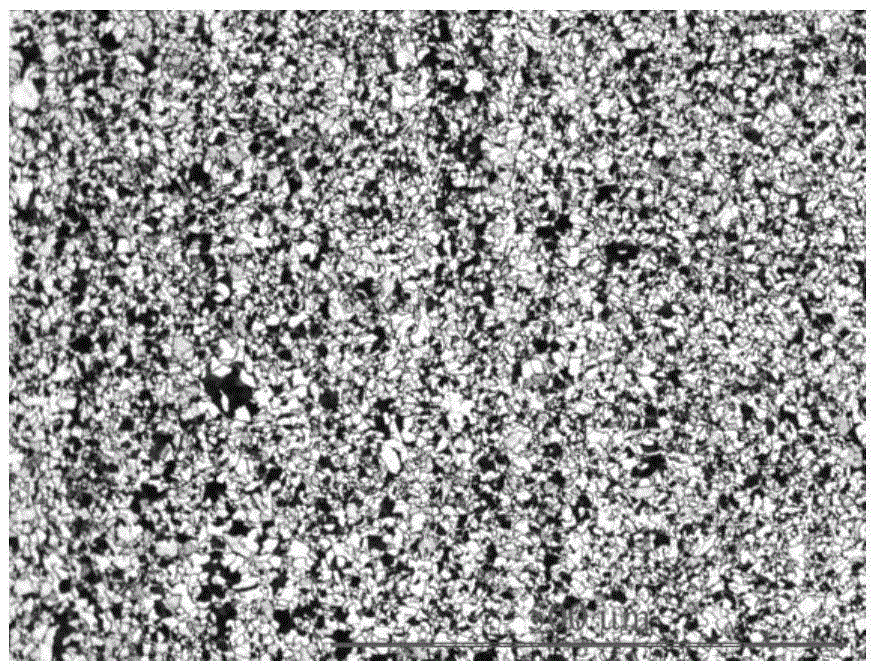

Image

Examples

Embodiment 1

[0038] Embodiment 1 is used to produce a steel pipe with a specification of Φ298.5×70 mm and a steel grade of S355J2H.

[0039] The production process is: electric furnace smelting→LF furnace refining→VD vacuum treatment→ingot casting→forging tube billet→annealing→ring furnace heating→piercing→pipe rolling unit rolling→inspection→normalizing (air cooling + fog cooling)→ Straightening→super detection→inspection→packing.

[0040] The above-mentioned production process will be described in detail below.

[0041] First, the target molten steel is obtained through electric furnace smelting, LF furnace refining, and VD vacuum treatment, and the target molten steel is cast into an ingot to obtain a die-casting steel ingot. The chemical composition of the target molten steel is shown in Table 1. In Table 1, the target molten steel has a carbon equivalent of 0.47% to 0.51%. +Spray cooling" or "air cooling" enhanced cooling to produce large-diameter thick-walled pipes can avoid the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com