Steel for hard tinplate bottle caps and production method thereof

A technology of tin-plated substrate and production method, which is applied in the direction of temperature control, etc., can solve the problems of high porosity in acid rolling, unstable rolling, poor surface quality, etc., and achieve improved surface quality, avoid mixed crystals, and good performance uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

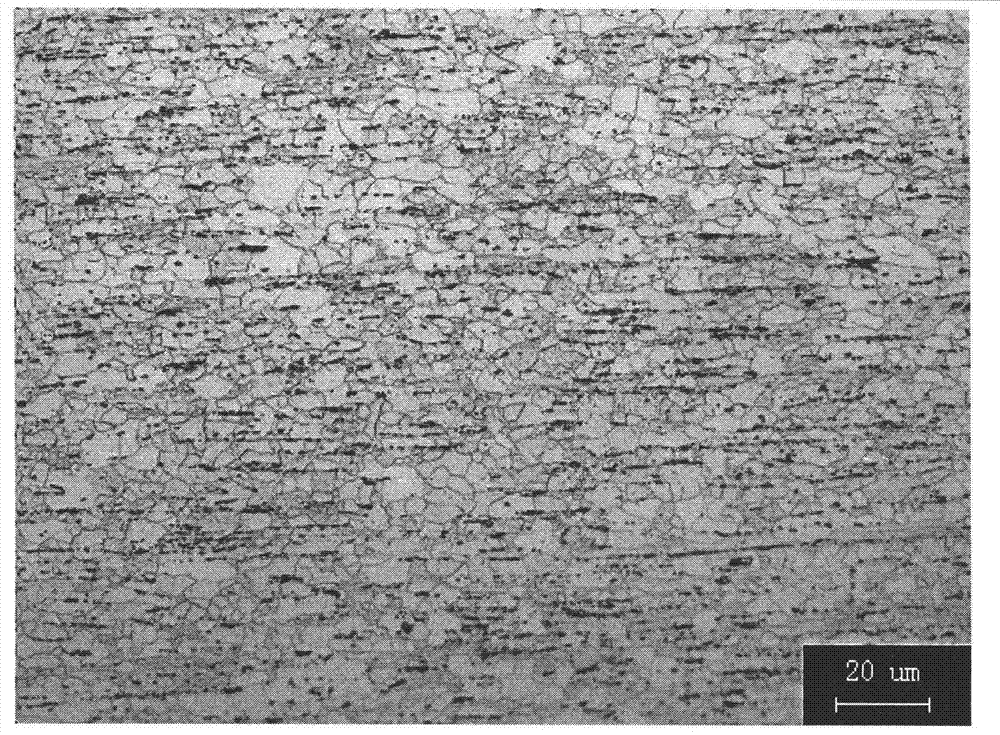

Image

Examples

Embodiment 1-3

[0015] (1) Steelmaking process: Steelmaking organizes conventional production according to the composition design requirements. The production process is as follows: after smelting in the mixed iron furnace, it enters the can dumping station for desulfurization, slag removal, converter, argon blowing station, continuous casting, and hot delivery. The actual performance values of the chemical composition of the two heats of steel are shown in Table 1.

[0016] Table 1 Chemical Composition Performance of Steelmaking Test

[0017] Sample identification

C%

Si%

Mn%

P%

S%

Alt%

N%

1#

0.0608

0.0173

0.328

0.0134

0.0121

0.0325

0.0022

2#

0.0713

0.0237

0.3593

0.0114

0.0105

0.0399

0.0031

3#

0.0528

0.0187

0.4593

0.0121

0.0123

0.0365

0.0038

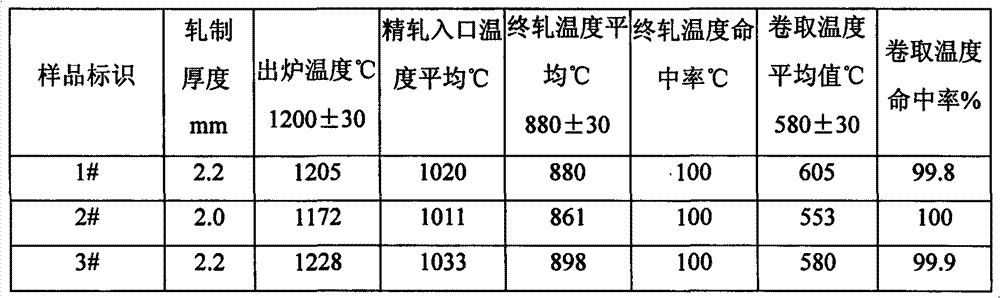

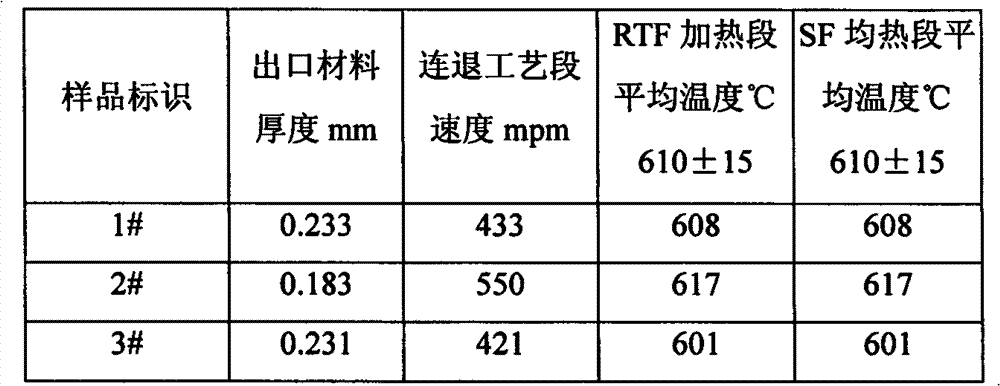

[0018] (2) Hot rolling process: The hot rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com