Preform structure of carbon/carbon composite material thick plate and thick plate preparation method

A carbon composite material and preform technology, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc. The sealing effect is aggravated, and the effect of strong adsorption, reduced density difference and high carburizing efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

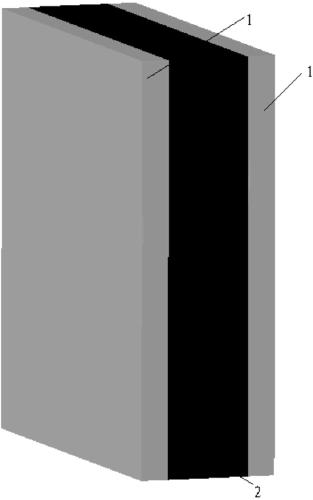

[0022] See attached figure 1 , a prefabricated body structure of a carbon / carbon composite material slab, the prefabricated body structure includes a core layer and a tire mesh layer, the core layer is a carbon fiber felt with a thickness of 20-40mm, and the tire mesh layer is needle-punched Carbon fiber mesh tires on both sides of the core layer;

[0023] The carbon fiber felt of the core layer is a carbon fiber needle-punched integral felt or a carbon fiber three-dimensional weaving felt with a density of 0.4-0.8g / cm 3 ;

[0024] The carbon fiber of the tire net layer is T700, the thickness of the net tire layer is 2-10mm, and the density is 0.1-0.3g / cm 3 .

Embodiment 2

[0026] A method for preparing a thick plate of carbon / carbon composite material. The prefabricated structure of a thick plate of carbon / carbon composite material is placed in a chemical vapor phase carburizing furnace, and after chemical vapor phase carburizing and densification, graphitization treatment, Machining; repeat the above process once, and the obtained carbon / carbon composite material has a density of 1.85g / cm 3 ;

[0027] The technical parameters of chemical vapor carburizing and densification each time are: use propylene or natural gas as the carbon source gas, control the furnace temperature at 900°C, furnace pressure at 1kPa, and chemical vapor carburizing for 50 hours;

[0028] The graphitization treatment system is as follows: the atmosphere in the furnace is controlled to be argon 0.11-0.13MPa, the furnace temperature is 2000°C, the holding time is 1h, and the furnace is cooled;

[0029] Machining is to process the surface of the tire mesh layer on the workp...

Embodiment 3

[0033] A method for preparing a thick plate of carbon / carbon composite material. The prefabricated structure of a thick plate of carbon / carbon composite material is placed in a chemical vapor phase carburizing furnace, and after chemical vapor phase carburizing and densification, graphitization treatment, Machining; repeat the above process 4 times, the obtained carbon / carbon composite material has a density of 1.80g / cm 3 ;

[0034] The technical parameters of chemical vapor carburizing and densification each time are: use propylene as the carbon source gas, control the furnace temperature at 950°C, furnace pressure at 6kPa, and chemical vapor carburizing for 100 hours;

[0035] The graphitization treatment system is as follows: the atmosphere in the furnace is controlled to be argon 0.11-0.13MPa, the furnace temperature is 2300°C, the holding time is 2h, and the furnace is cooled;

[0036] Machining is to process the surface of the tire mesh layer on the workpiece that has b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com