Preparation method of rare earth carburized wear-resistant Fe-W alloy

An alloy and rare earth technology, which is applied in the field of preparation of wear-resistant Fe-W alloy on the surface of rare earth infiltration, can solve the problems of long carburizing time and large hardness gradient of carburized layer, so as to reduce the hardness gradient and increase the depth of carburized layer , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

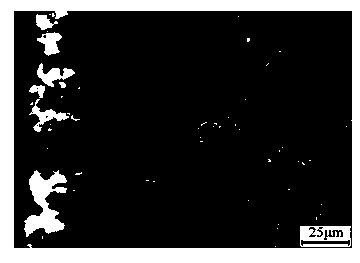

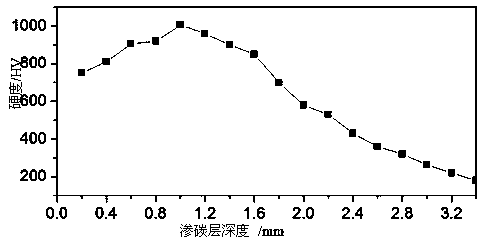

[0020] The mass percentage of Fe-W alloy composition is: W5.5%, Fe94.5%. The mass percentage of the carburizing agent is: charcoal 75%, silicon carbide 10, CeO 2 5%, barium carbonate 10%. The Fe-W alloy sample was made into a 20×20×50mm sample with a wire cutting machine, polished with 240#, 800# and 1200# water sandpaper in turn, cleaned with ultrasonic waves in distilled water, and then dried. Spread a 20mm thick carburizing agent on the bottom of the corundum crucible, put in the prepared sample, and make the sample distance from the corundum crucible wall greater than 20mm, then fill the remaining space in the crucible with carburizing agent and compact it, and cover the crucible After the crucible is closed, a high-temperature sealant is used to ensure that the inner space of the crucible is filled with compacted carburizing agent during the process. Heat the temperature of the high-temperature furnace to 850°C and keep it warm, put it into a sealed crucible, raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com