Method for realizing nitriding or carburizing by thermal airflow jetting heating and shot blasting

A technology of hot gas flow and nitriding, applied in the direction of solid-state diffusion coating, coating, metal material coating process, etc., can solve the problem that the carburizing process has no contribution, the carburizing process is irrelevant, and damages the precision of parts and other issues, to achieve the effect of reducing energy consumption, improving utilization rate, and improving the accuracy of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

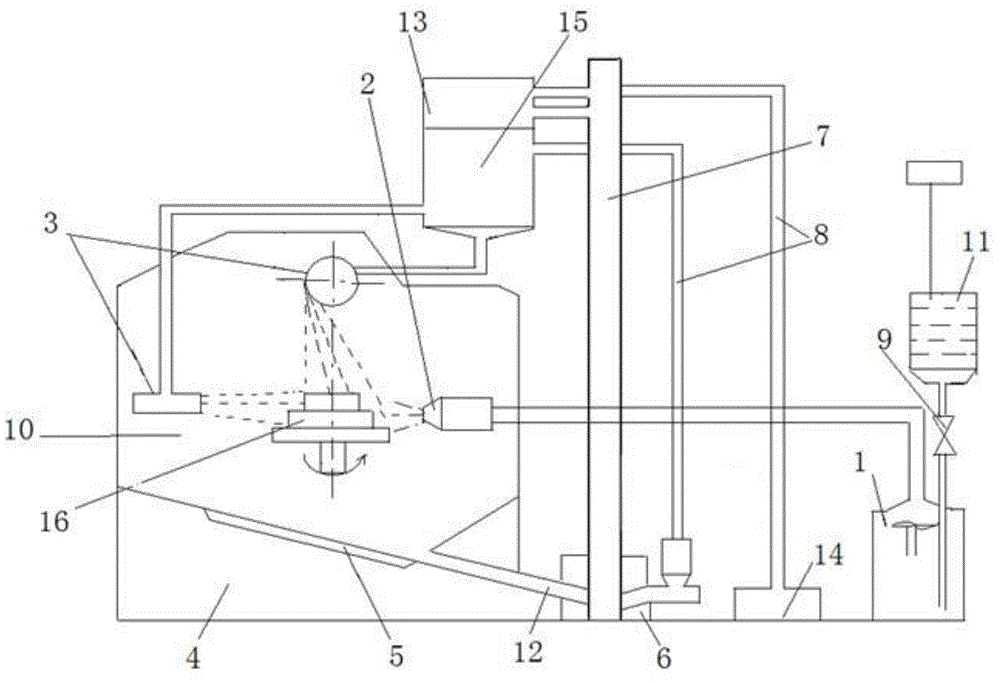

Image

Examples

Embodiment 1

[0047] A method for hot air jet heating and shot peening to realize nitriding, comprising the following steps:

[0048] (1) Clean the dirt on the surface of the parts with gasoline, alcohol or acetone, install the cleaned parts into the chemical heat treatment furnace, leave a distance of 15mm between the surfaces of the parts that need to be nitrided, and the surface that does not need to be nitrided Close to each other to save space;

[0049] (2) Nitriding treatment: Spray nitriding atmosphere on the surface of the part to remove the air around the part; heat the ammonia gas to 300°C through the hot air flow generator, and spray it to the surface of the part through the hot air flow nozzle to heat the surface of the part at high speed. At the same time, Use the shot blasting machine to spray the round steel wire cut shot onto the surface of the part to create crystal defects on the metal surface; the diameter of the steel cut shot is 0.51mm, and at the same time, the hot air...

Embodiment 2

[0052] A method for hot air jet heating and shot peening to realize nitriding, comprising the following steps:

[0053] (1) Clean the dirt on the surface of the parts with gasoline, alcohol or acetone, install the cleaned parts in the chemical heat treatment furnace, leave a distance of 25mm between the surfaces of the parts that need to be nitrided, and the surface that does not need to be nitrided Close to each other to save space;

[0054] (2) Nitriding treatment: Nitriding atmosphere is sprayed on the surface of the parts in the furnace to remove the air around the parts; the ammonia gas is heated to 500°C through the hot air flow generator, and sprayed to the surface of the parts through the hot air flow nozzle to heat the surface of the parts at high speed. At the same time, use the shot blasting machine to spray the round steel wire cut shot onto the surface of the part to create crystal defects on the metal surface; the diameter of the steel cut shot is 2.0mm, and at t...

Embodiment 3

[0057] A method for hot air jet heating and shot peening to realize nitriding, comprising the following steps:

[0058] (1) Clean the dirt on the surface of the parts with gasoline, alcohol or acetone, install the cleaned parts in the chemical heat treatment furnace, leave a distance of 40mm between the surfaces of the parts that need to be nitrided, and the surface that does not need to be nitrided Close to each other to save space;

[0059] (2) Nitriding treatment: spray nitriding atmosphere to the parts in the furnace to remove the air around the parts; heat the ammonia gas to 400°C through the hot air flow generator, and spray it to the surface of the parts through the hot air flow nozzle to heat the surface of the parts at high speed, and at the same time , using a shot blasting machine to spray round steel wire cut shot onto the surface of the part to create crystal defects on the metal surface; the diameter of the steel cut shot is 1.0mm, and at the same time, the hot a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com