Titanium alloy surface treatment method

A surface treatment, titanium alloy technology, applied in the field of material science, can solve problems such as difficult to accurately control the thickness of the deformed layer, inability to process, multi-work hardening and residual stress, so as to avoid unreasonable treatment process and improve surface wear resistance , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

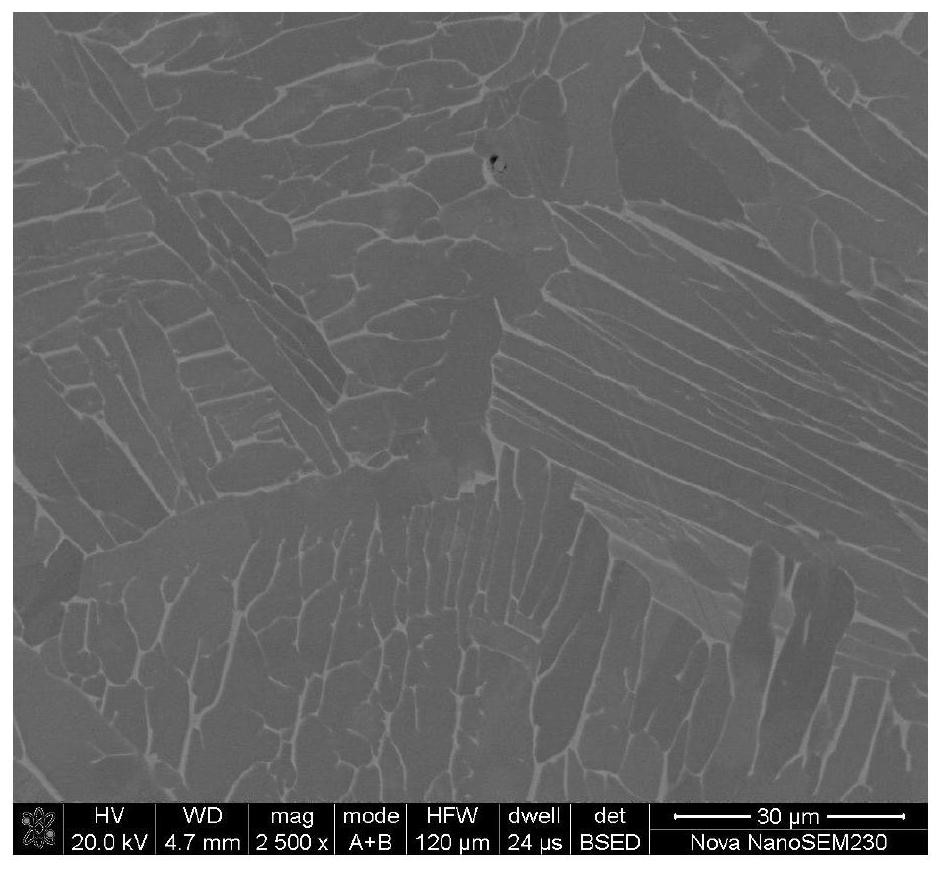

[0043] This embodiment provides a method for surface treatment of titanium alloys. Take a TC4 titanium alloy workpiece, and use a WC / Co hemispherical tool to carry out surface mechanical grinding treatment (SMGT treatment) on the workpiece. The grinding speed is 0.2m / s, and each pass presses The reduction is 30 μm, the grinding passes are 8 times, the total reduction is 240 μm, and the total depth of the deformed layer is about 60 μm. The metallographic structure after treatment is shown in Figure 1(a) and Figure 1(b). Among them, Figure 1(a) is the matrix structure of TC4 titanium alloy, and Figure 1(b) is the structure treated with SMGT.

[0044]It can be seen from Fig. 1(a) and Fig. 1(b) that the area of the above TC4 titanium alloy after SMGT treatment presents nanometer-sized grain layer, submicron-sized grain layer, deformed grain layer and initial grain layer in sequence along the pressing direction. The gradient structure of the granular tissue layer. The thickness...

Embodiment 2

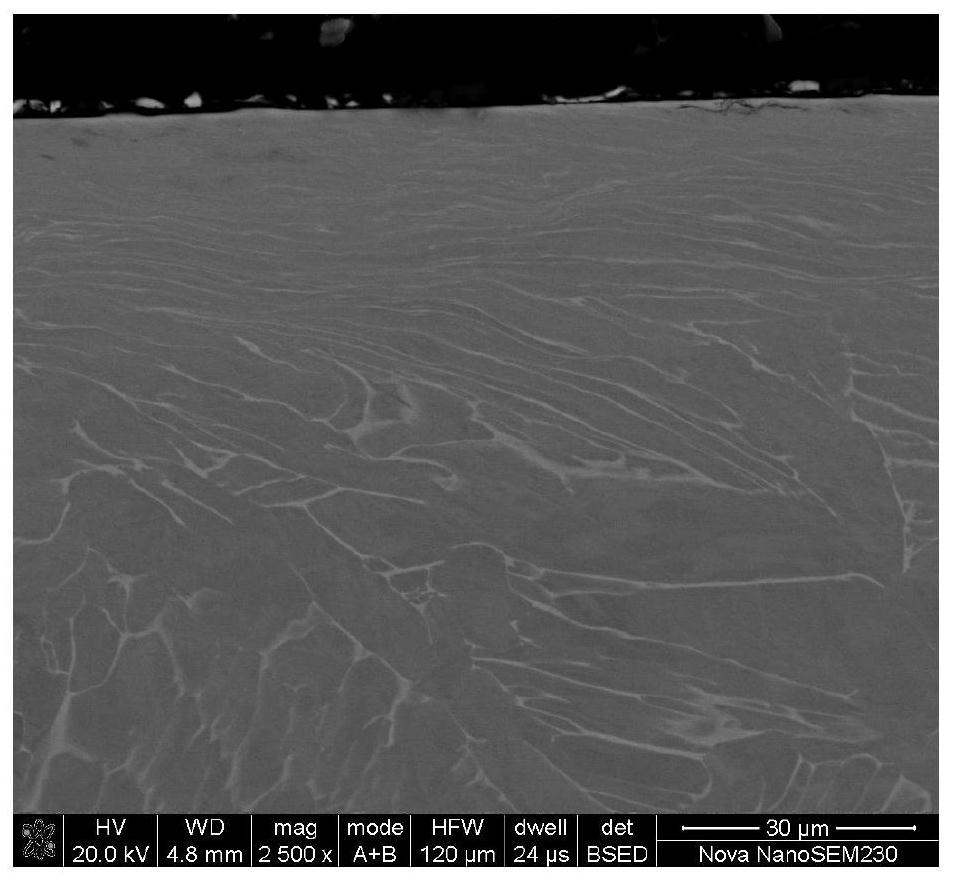

[0046] The difference between this embodiment and Embodiment 1 is that the grinding passes are 10 times, the total reduction is 300 μm, and the total depth of the deformed layer is about 90 μm. according to figure 2 As shown, the area of the above TC4 titanium alloy after SMGT treatment presents a gradient structure of nanometer-sized grain layer, submicron-sized grain layer, deformed grain layer and initial grain structure layer along the pressing direction. The thickness of the nano-sized grain layer is about 20 μm, the thickness of the sub-micron-sized grain layer is about 30 μm, and the thickness of the deformed grain layer is about 40 μm. The thickness of the grinding layer in this embodiment is large and uniform.

Embodiment 3

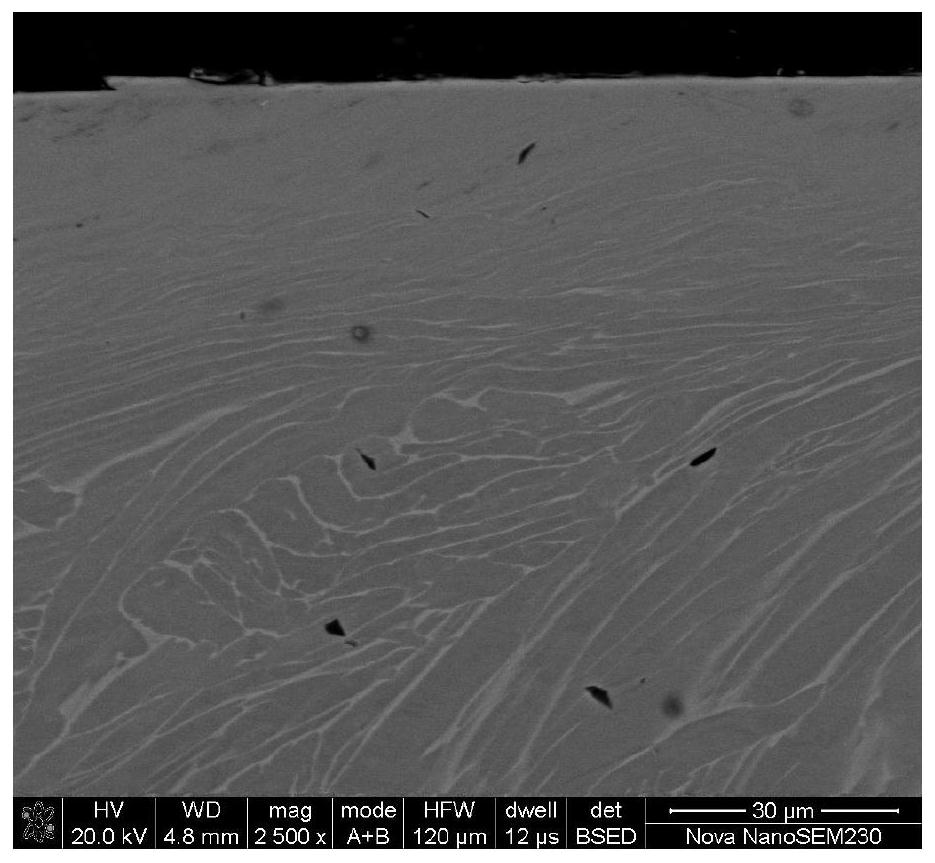

[0048] The difference between this embodiment and Embodiment 1 is that the grinding passes are 12 times, and the total reduction is 360 μm. according to image 3 As shown, when the total reduction is too large, the surface of TC4 titanium alloy is damaged and peeled off, and the deformation layer and grain refinement layer cannot be observed, and the titanium alloy matrix is underneath the peeled off layer.

[0049] It can be seen from the above examples 1 to 3 that when the grinding speed and the reduction of each pass are constant, the thickness of the total deformed layer increases continuously with the increase of the total reduction. However, when the total reduction is too large, the surface of TC4 titanium alloy may be damaged during the grinding process ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com