Patents

Literature

35results about How to "Promotes transmission balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

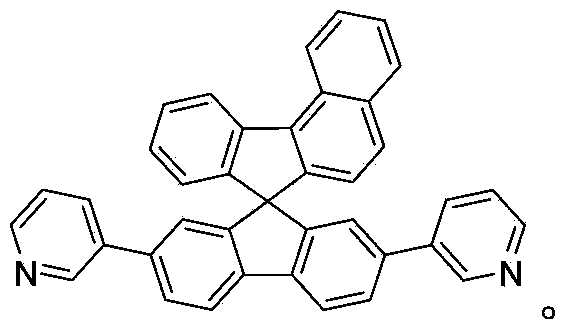

Organic compound, electronic element comprising same, and electronic device

ActiveCN111018797AIncrease space volumeHigh glass transition temperatureOrganic chemistrySolid-state devicesArylSimple Organic Compounds

The invention relates to the technical field of organic photoelectric materials, and in particular, relates to an organic compound, an electronic element containing the same and an electronic device.The compound has a structure represented by a chemical formula 1', wherein one of R1, R2, R3 and R4 is a group defined in the specification, and the other three are selected from substituents such asalkyl, halogen and cyano; one of R5, R6, R7 and R8 is a group defined in the specification, the other three are selected from substituents such as alkyl, halogen and cyano, Y and Y1 are respectively and independently a group defined in the specification, and L and L1 are single bonds, aryl, heteroaryl and the like. By using the organic compound in an electronic component, the driving voltage, luminous efficiency, and life of the electronic component are improved.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

Automobile gearbox gear carburizing and quenching heat treatment method

ActiveCN103710714AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

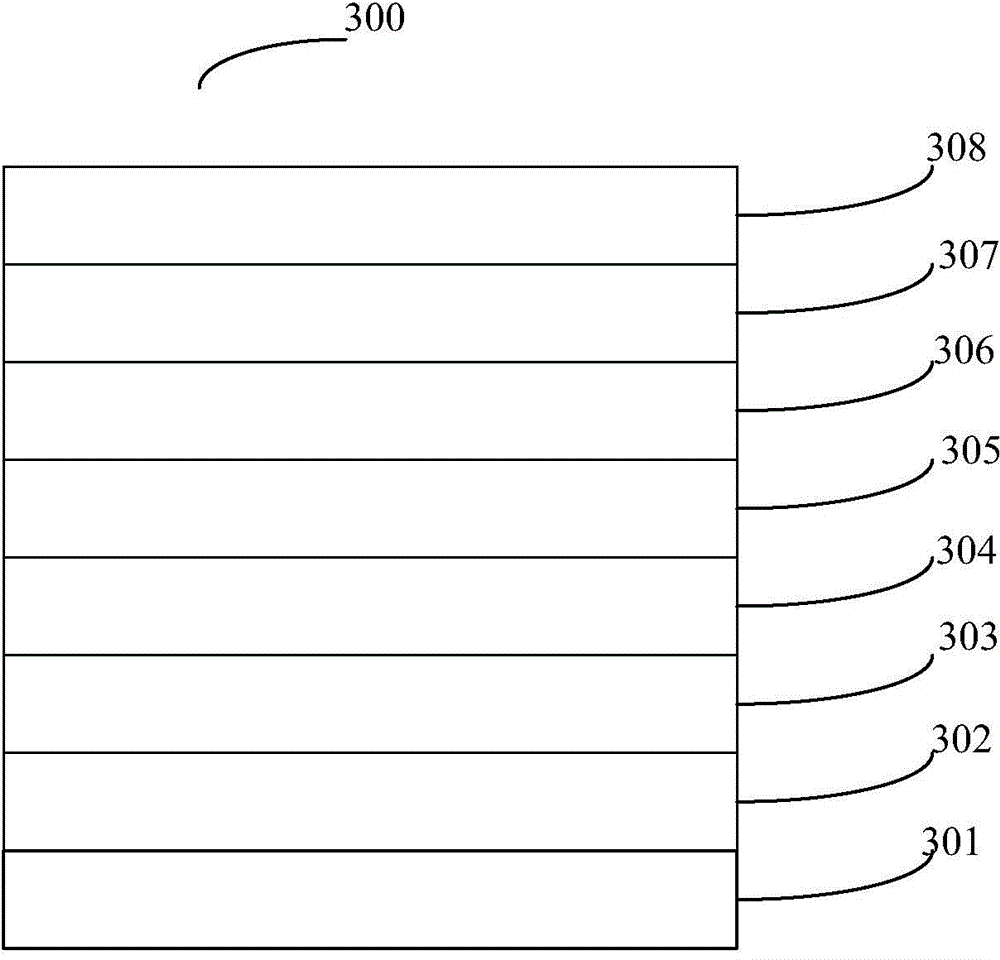

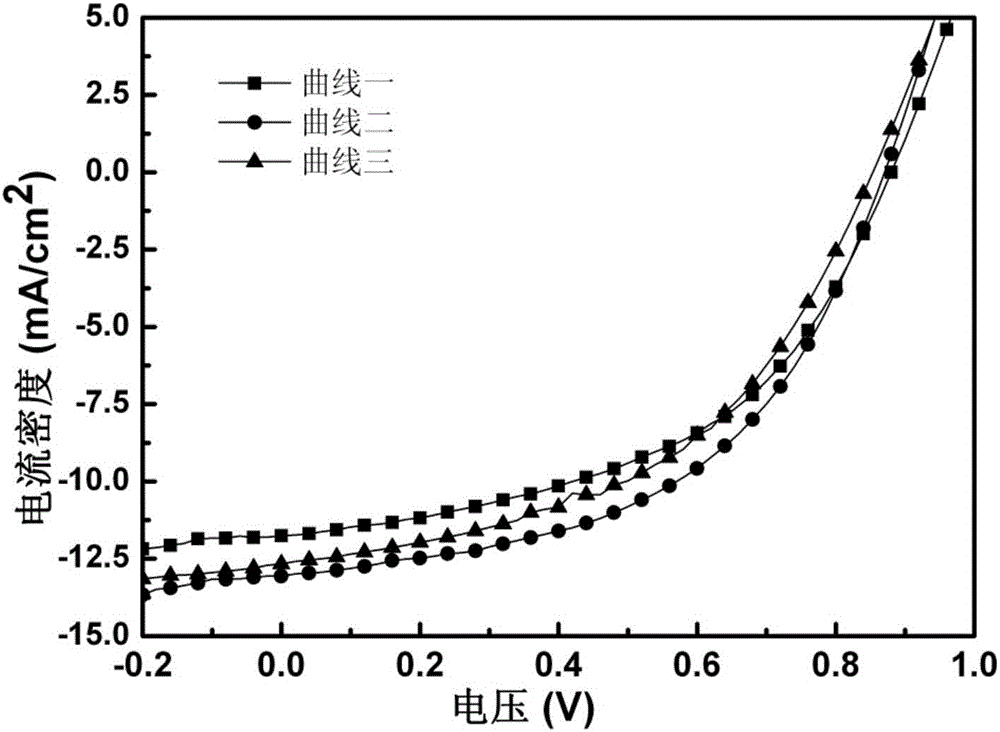

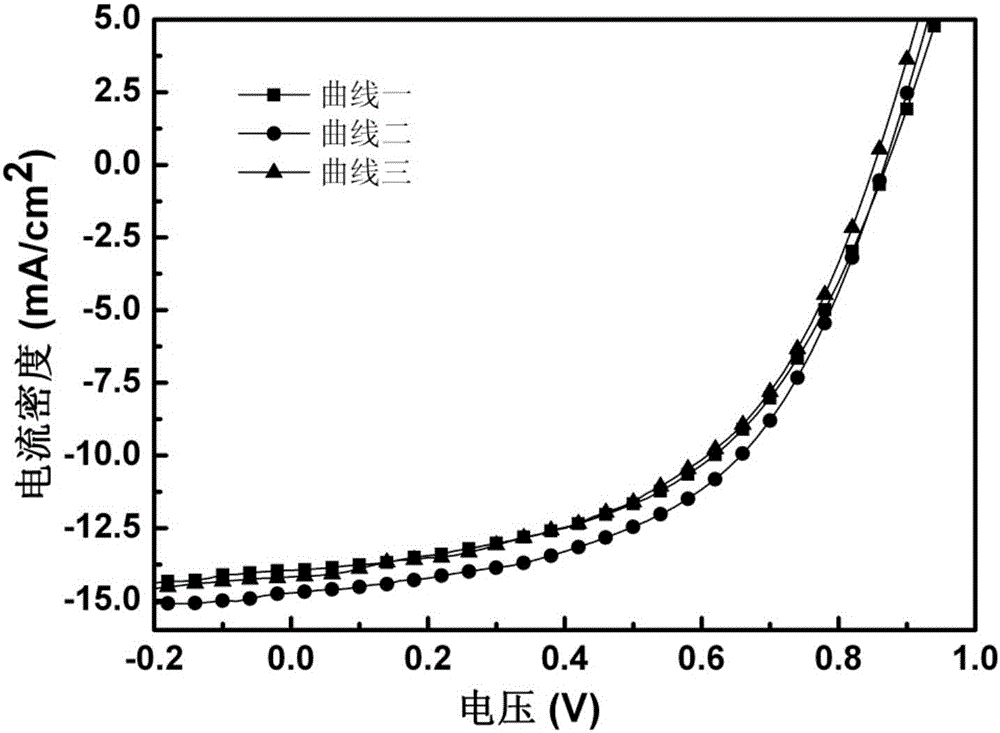

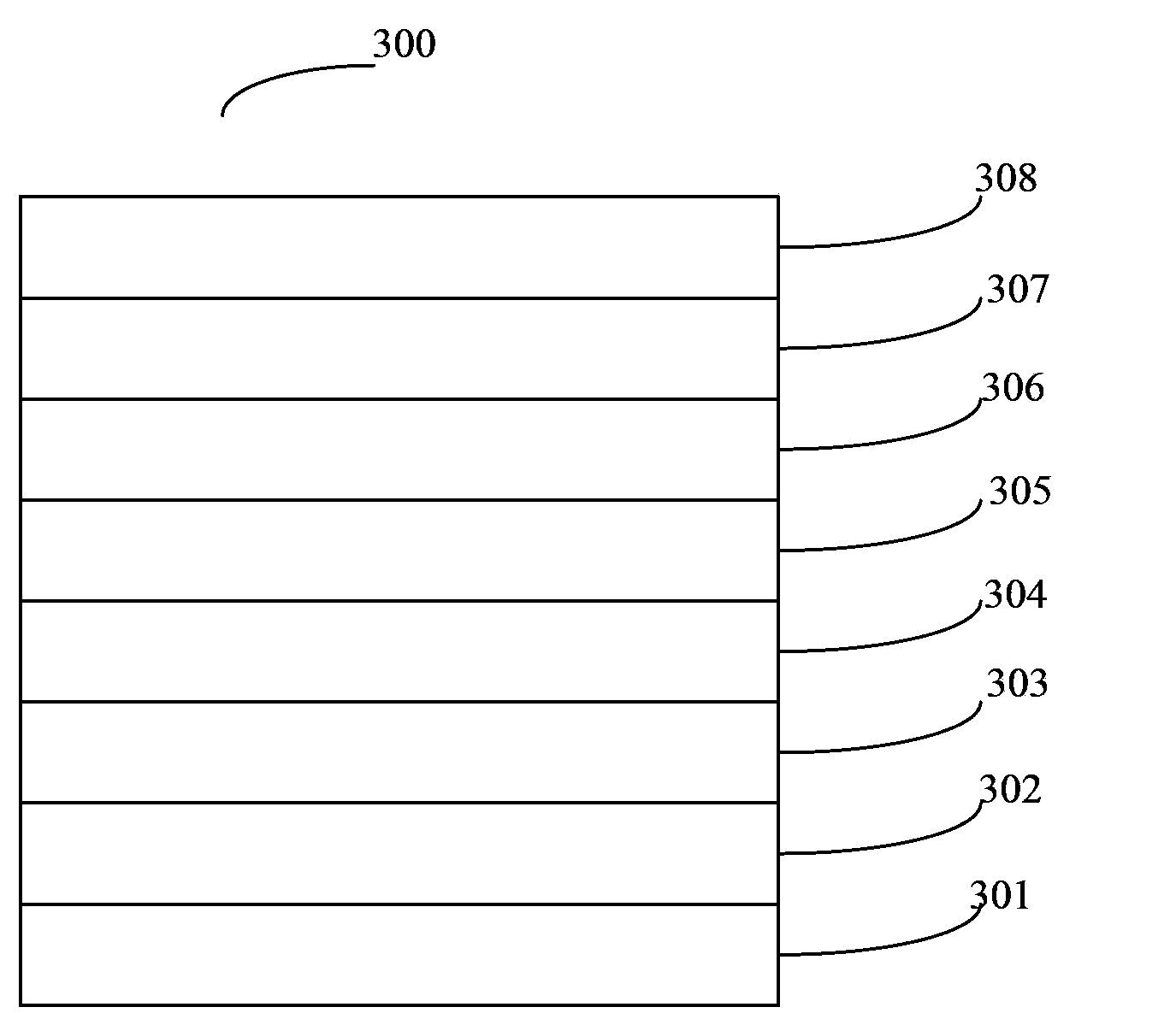

Inverse type polymer solar cell based on modification of active layer and transmission layer and preparation method of solar cell

InactiveCN105047821AGood surface plasmon resonance effectEasy transferSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerMolybdenum trioxide

The invention relates to an inverse type polymer solar cell based on modification of an active layer and a transmission layer, and belongs to the technical field of polymer solar cells. The polymer solar cell is of a typical inverse structure. UV processing and hydroxylation are carried out on a titanium dioxide electron transmission layer, and polyethylene imine modification is then carried out; an active layer is doped with inorganic quantum dots to further adjust the energy level among acceptors and enhance transmission of carriers; and a hole transmission layer employs water-soluble molybdenum trioxide, and doped with gold nano-particles. Spin coating of aqueous solution saves more energy compared with vapor deposition; surface plasmon resonance caused by doping of the gold nano-particles can reflect light back to an active layer, further to utilize light and help transmission of charges in a transmission layer; and carrier transmission is smoother, and a more balanced electro-hole transfer speed can be achieved.

Owner:JILIN UNIV

Processing technology for gearbox gear

InactiveCN104762629AProlong carburizing timeReduce energy consumptionSolid state diffusion coatingGear transmissionCarburizing

The invention relates to a processing method for a gear, especially to a processing technology for a gearbox gear. The processing technology comprises the following steps: step 1, blanking and forging so as to obtain a cylindrical blank; step 2, homogenization treatment of components of the forged blank and drilling of a center hole through lathing; step 3, gear hobbing out of the cylindrical blank via a hobbing machine; step 4, carbonization of a workpiece; step 5, cooling and quenching after carbonization; and step 6, machining of the workpiece so as to form the gear. The processing technology provided by the invention has the following beneficial effects: a, carburizing temperature and quenching temperature are reduced, carburizing time is not prolonged, and energy consumption is reduced; b, generation of a black structure is prevented, a uniform carburizing layer is obtained, the microstructure of the carburizing layer having undergone carbonization and quenching is improved, an optimal metallographic structure is obtained, and thus, surface hardness, wear resistance and fatigue resistance of the gear are obviously improved; and c, deformation is reduced, gear processing and assembling dimension precision of the gear is improved, gear transmission balance is enhanced, noise is reduced, and the service life of the gear is prolonged.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Thermal treatment method for carburizing and quenching of gearbox gears

InactiveCN105586599AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a thermal treatment method for carburizing and quenching of gearbox gears. The thermal treatment method includes the steps of A, carburizing, B, quenching and C tempering. In the step of A, carburizing, the gears are placed in a heating furnace, the temperature of the heating furnace is increased from the room temperature to the temperature of 850-900 DEG C for carburizing, and carburizing time is 2-5 h; the carburizing process includes a beginning stage, a strong carburizing stage and a diffusion stage; the carbon potential (CP) of the beginning stage is 0.9-1 C%, the CP of the strong carburizing stage is 1-1.1 C%, and the CP of the diffusion stage is 0.8-0.9 C%; the time of the beginning stage is 12-15 min, the time of the strong carburizing stage is 200-220 min, and the time of the diffusion stage is 20-40 min. In the step of B, quenching, the carburized gears are cooled to 810-850 DEG C, then temperature equilibrium is carried out for 20-40 min, and then the gears are quenched in quenching oil with the temperature being 85-95 DEG C. In the step C, tempering, the quenched gears are subjected to tempering at the temperature of 155-170 DEG C for 1-2 h.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

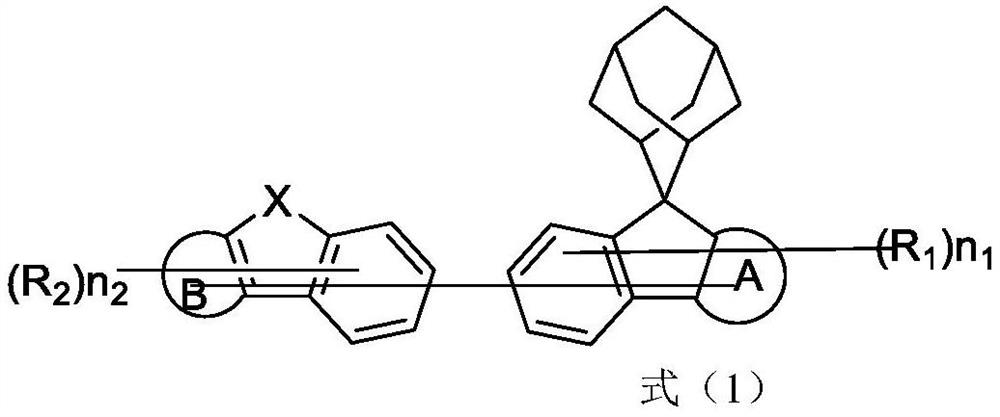

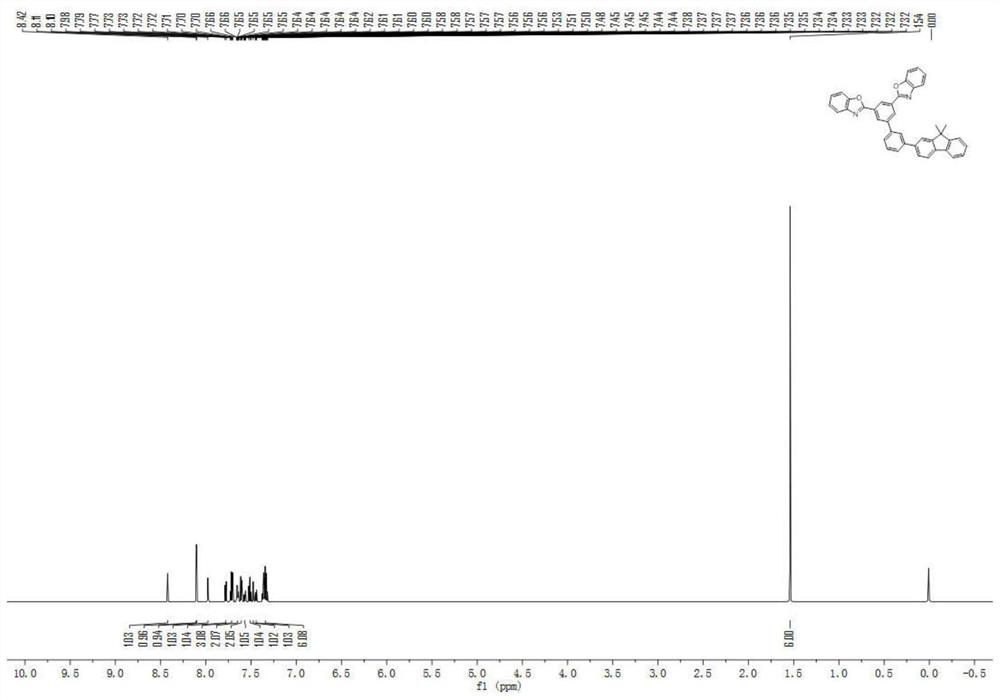

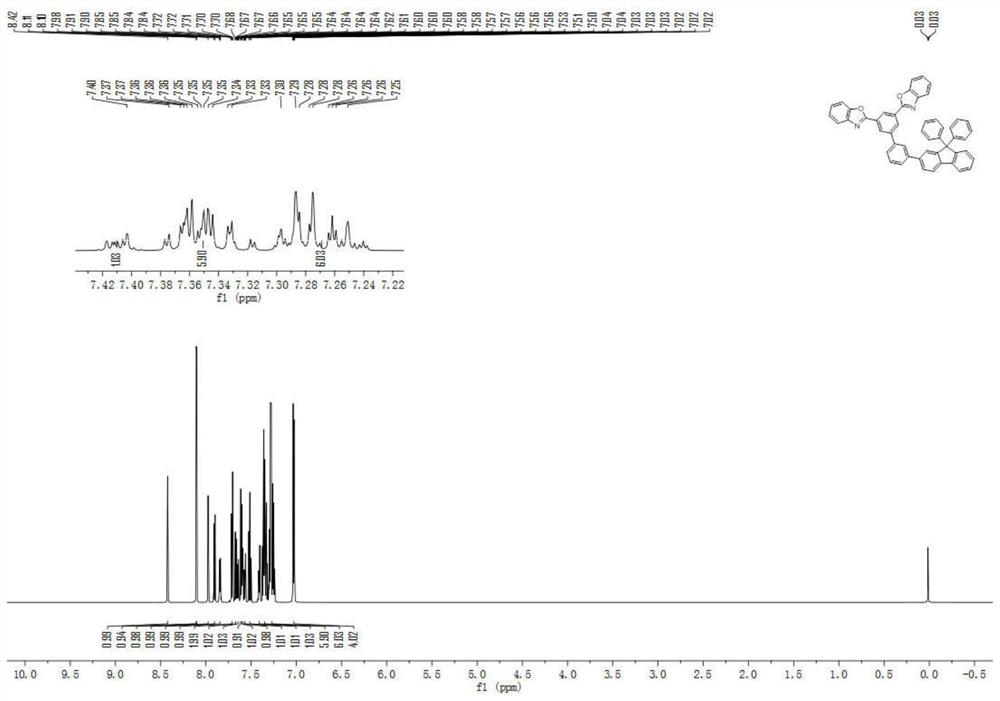

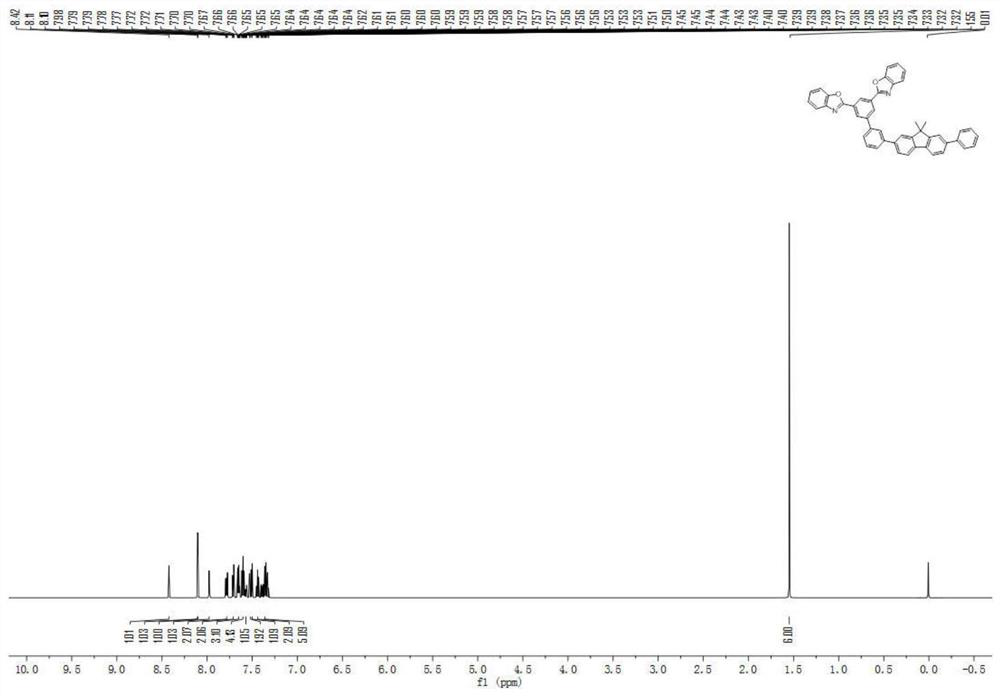

Compound, organic electroluminescent device and electronic device

ActiveCN111961038AMacromolecular structure has strong rigidityImprove rigiditySilicon organic compoundsOrganic chemistry methodsSimple Organic CompoundsOrganic electroluminescence

The invention provides an organic compound, an organic electroluminescent device and an electronic device. The chemical structure of the organic compound comprises an adamantane spirofluorene ring anda dibenzo five-membered ring, and the organic compound has an excellent energy transfer function, can be used as a luminescent layer material in an electroluminescent device, improves the efficiencyof the organic electroluminescent device and prolongs the service life of the organic electroluminescent device.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

Heat processing method for carburizing and quenching

InactiveCN105986220AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a heat processing method for carburizing and quenching. The method comprises the following steps: A) a carburizing step, placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 850-900 DEG C for carburizing for 2-5 h, wherein the carbon potential CP in a strong carburizing stage is 1.02-1.1C%, and the carbon potential CP in a diffusion stage is 0.8-0.9C%; B) a quenching step: cooling the obtained carburized gear to 810-850 DEG C, equalizing the temperature for 20-40min, and quenching in 85-95 DEG C quenching oil; and C) a tempering step: tempering the obtained quenched gear at 155-170 DEG C for 1-2 h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:重庆文力机械有限公司

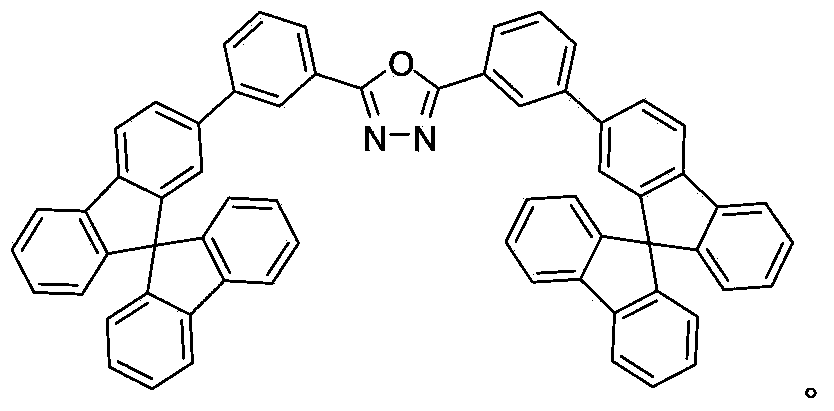

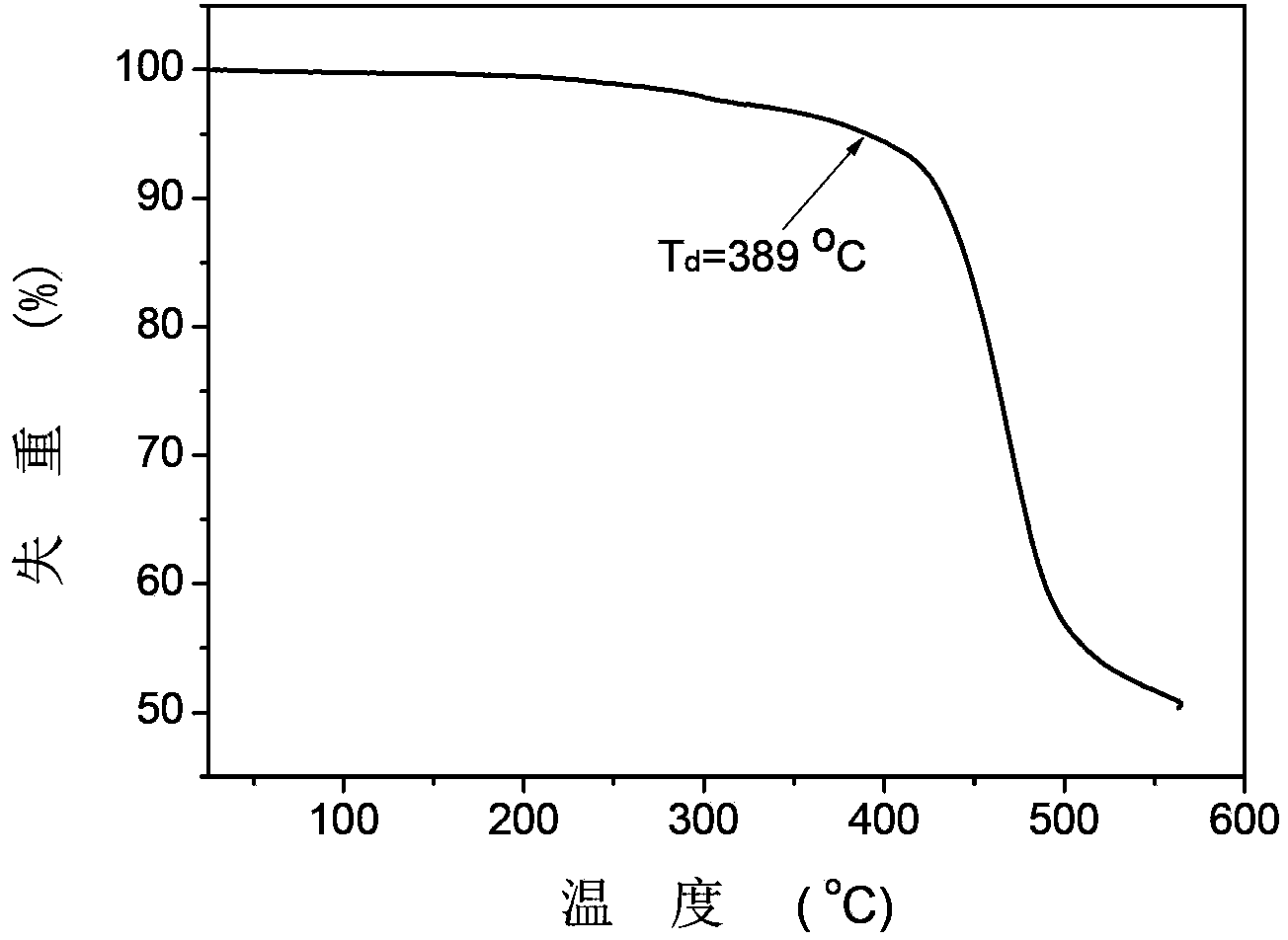

Heterocyclic compound and organic electroluminescent device comprising same

ActiveCN112661714AImprove film formationImprove thermal stabilityOrganic chemistrySolid-state devicesElectron holeElectron transporting layer

The invention provides a heterocyclic compound and an organic electroluminescent device containing the heterocyclic compound, and relates to the technical field of organic electroluminescence. The heterocyclic compound disclosed by the invention has good film-forming property and thermal stability and relatively high glass-transition temperature, and the service life of the device can be prolonged when the heterocyclic compound is applied to an organic layer of the organic electroluminescent device; meanwhile, the structure has a deep HOMO energy level, so that holes can be effectively prevented from diffusing from the light-emitting layer to the electron transport layer and the recombination probability of the holes and electrons in the light-emitting layer can be effectively improved; and when the heterocyclic compound provided by the invention is applied to the electron transport or hole blocking layer, the light-emitting efficiency of a device can be effectively improved.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

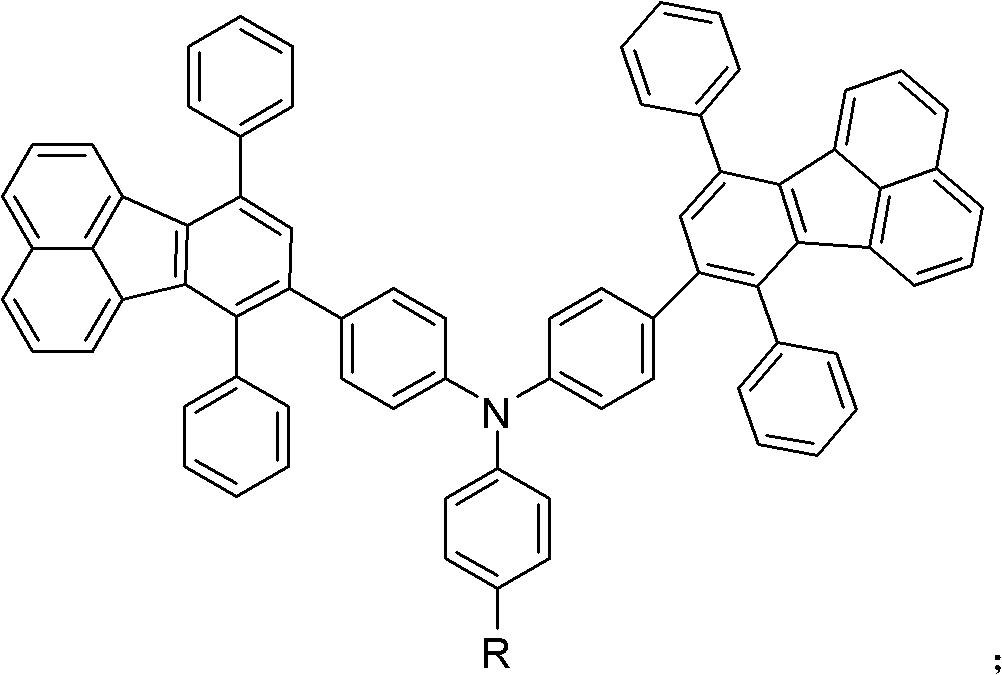

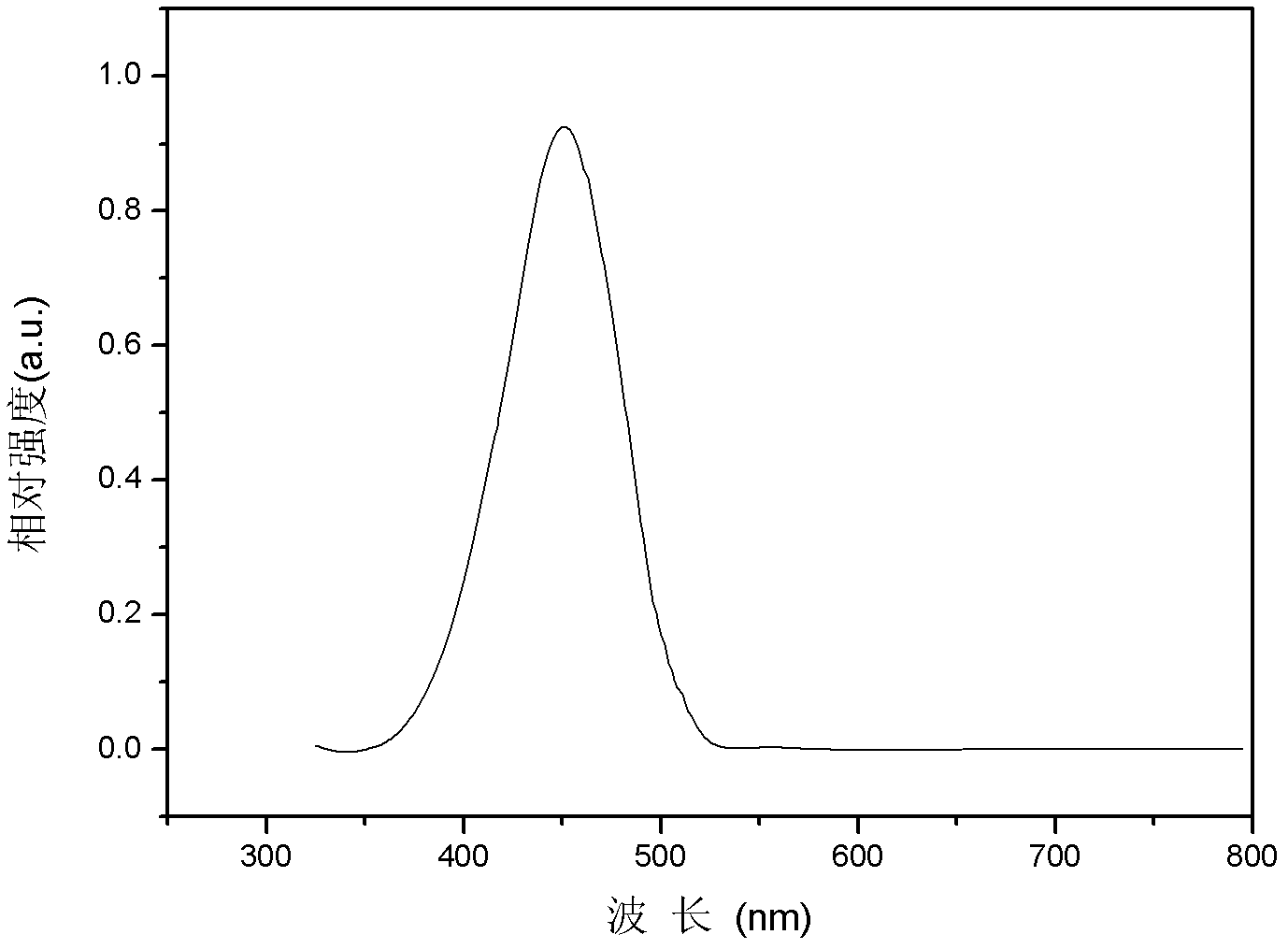

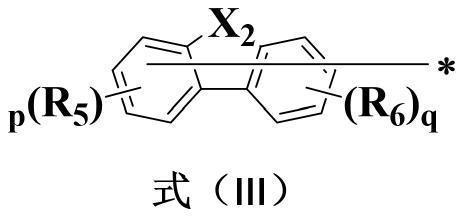

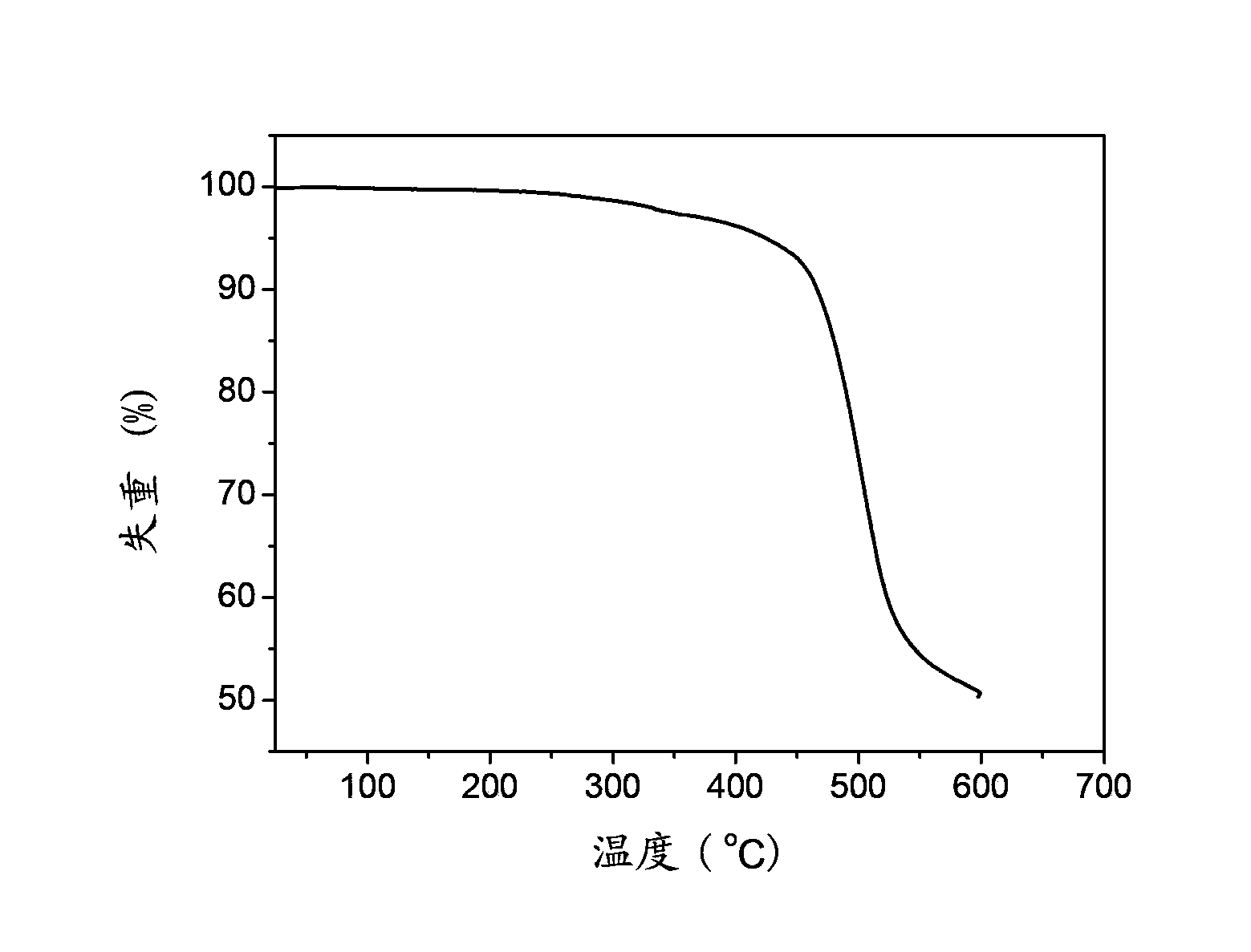

Double-fluoranthene organic semiconductor material as well as preparation method and application thereof

ActiveCN103012206AImprove solubilityImprove film formationAmino preparation from aminesCarboxylic acid nitrile preparationSolubilitySemiconductor materials

The invention relates to a double-fluoranthene organic semiconductor material. The double-fluoranthene organic semiconductor material can be shown as a structural formula described in the specification, wherein -R is -CN, -NO2, -CF3, -F or -CHO. The double-fluoranthene organic semiconductor material emits pure blue lights, the double-fluoranthene organic semiconductor material can be easily dissolved in common organic solvents such as tetrahydrofuran, dichloromethane, methylbenzene and chloroform as an electron withdrawing group is introduced into the structure, and solubility and film-forming property of the double-fluoranthene organic semiconductor material are improved; meanwhile, a fluoranthene group is a rigid substituent group, so that the double-fluoranthene organic semiconductor material also has excellent thermal stability; the fluoranthene group can cause the double-fluoranthene organic semiconductor material to have higher hole mobility; and electro transport performance of the double-fluoranthene organic semiconductor material is improved as the electron withdrawing group is introduced, so that carrier transport balance is facilitated. The invention also provides a preparation method of the double-fluoranthene organic semiconductor material and an application of the double-fluoranthene organic semiconductor material in an organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

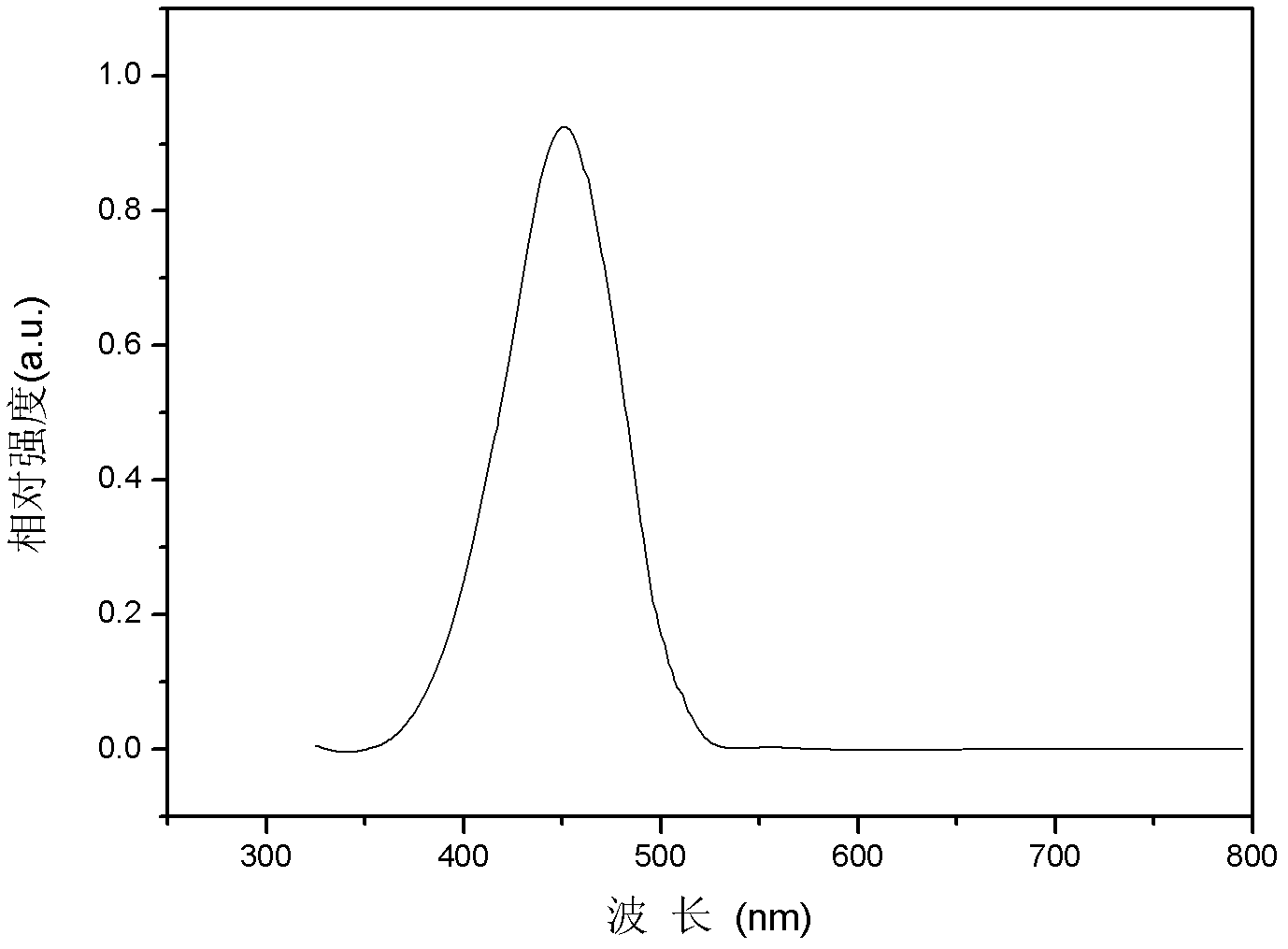

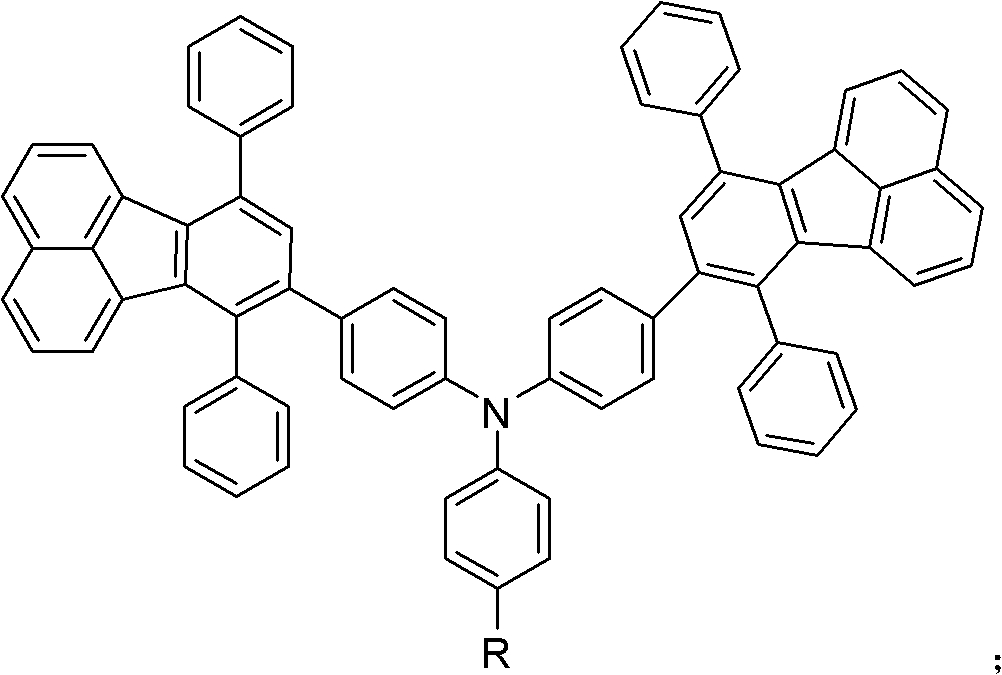

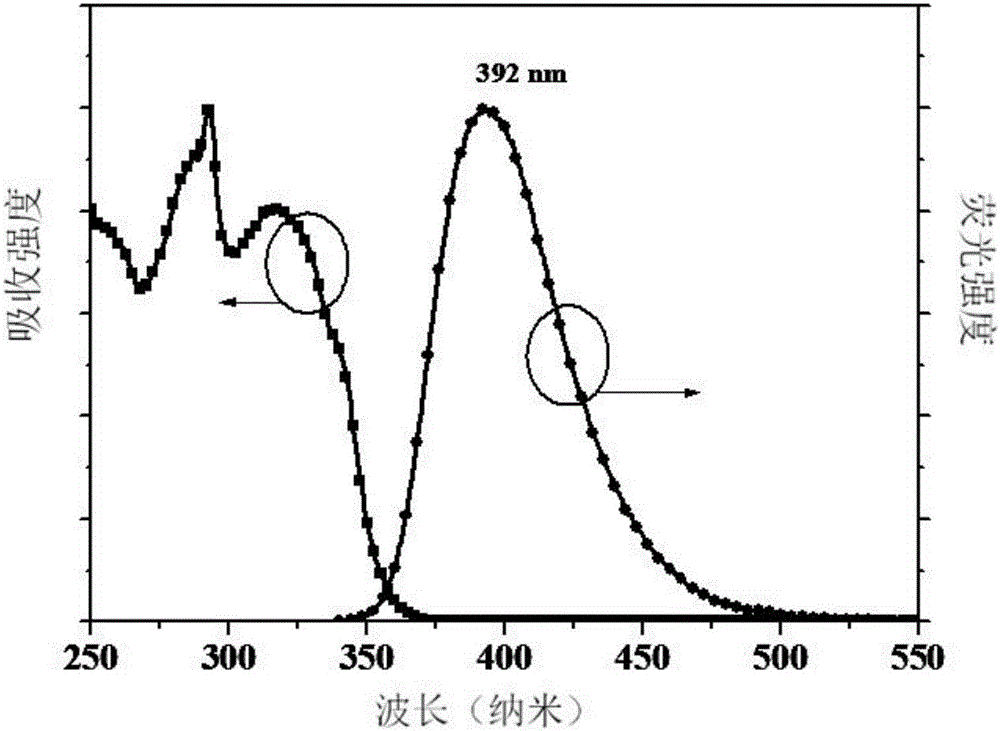

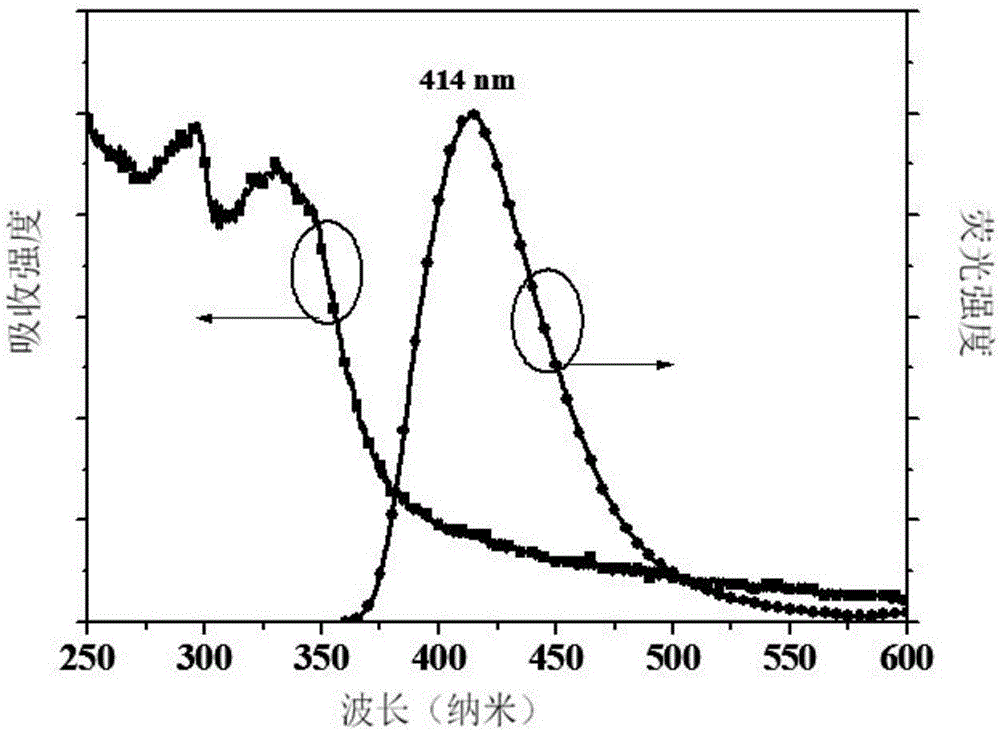

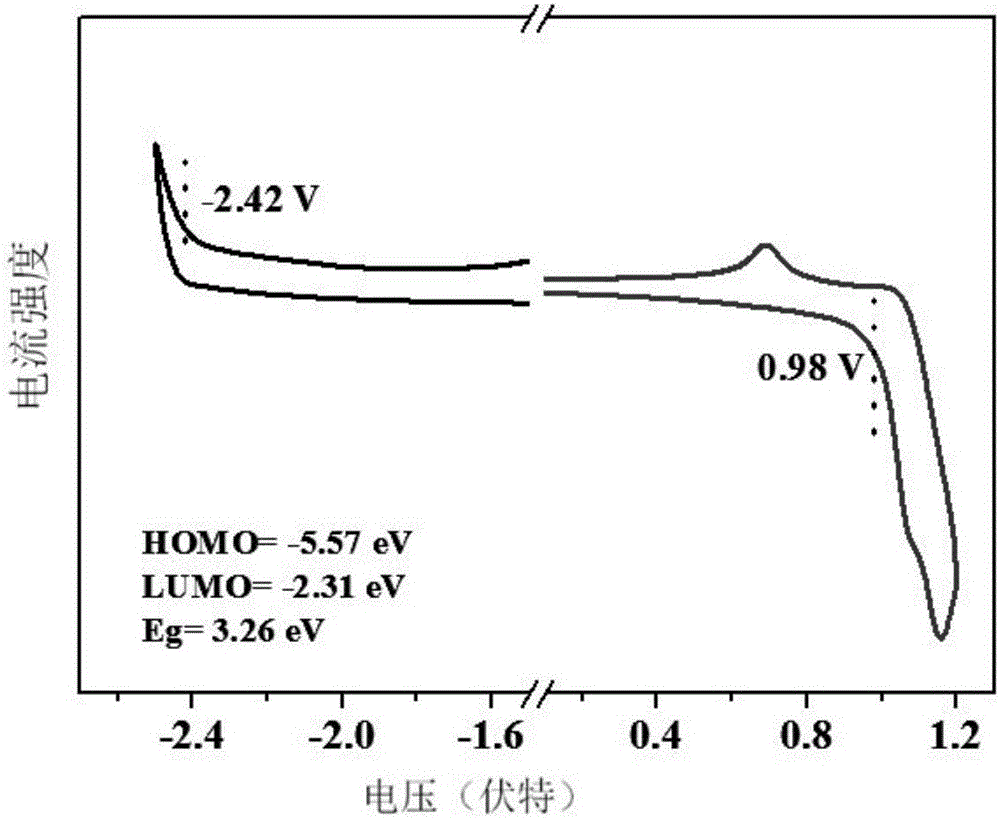

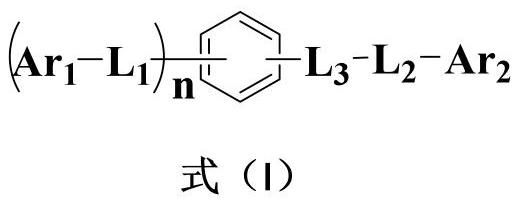

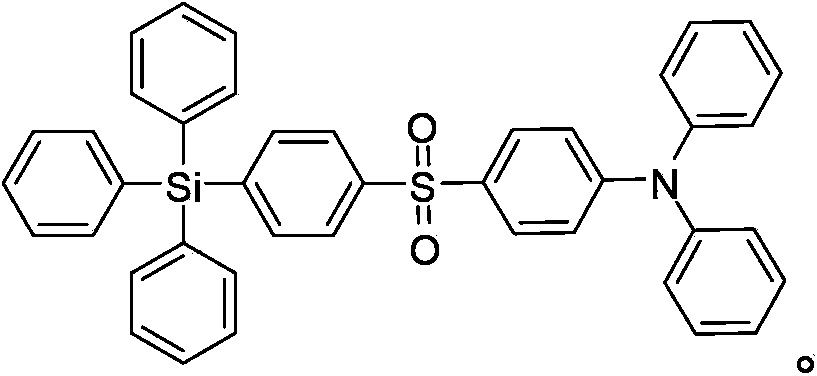

Blue electroluminescent compounds and application thereof in organic electroluminescent devices

ActiveCN106632269AEasy to makeEasy to operateOrganic chemistrySolid-state devicesElectron donorFluorescence

The invention belongs to the field of organic electroluminescence and particularly relates to luminescent molecules containing electron donor-acceptor (D-A) groups, and their application in blue organic electroluminescent device. The compounds are prepared via classical aromatic coupling reaction and used for luminescent layers of electroluminescent devices. The compounds have a structure shown in formula I shown in the description, wherein aryl Ar is any one of benzene, naphthalene, anthracene, fluorene or spirofluorene, and Ar variation is effective in adjusting luminescent color and the like. The compounds synthesized herein are simple to prepare and high in yield, and present deep blue to pure blue, and even near-ultraviolet fluorescence-emission; by using the compounds with Ar as phenyl to act as a luminescent layer, it is possible to acquire a near-ultraviolet electroluminescent device with starting voltage of 3.2 V, maximum external quantum efficiency of 6.57% and luminescent intensity of 408 nanometers.

Owner:QINGDAO UNIV OF SCI & TECH

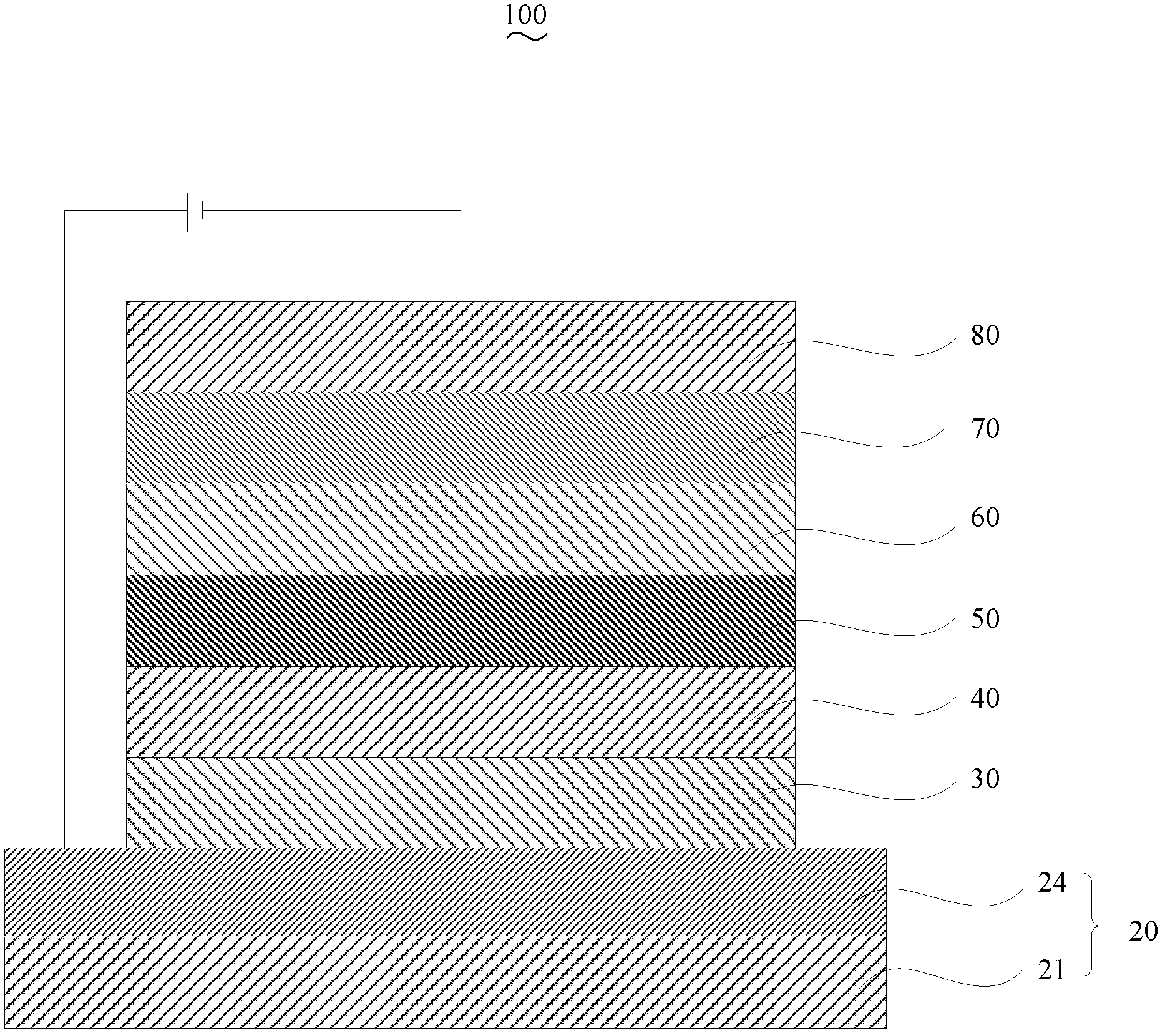

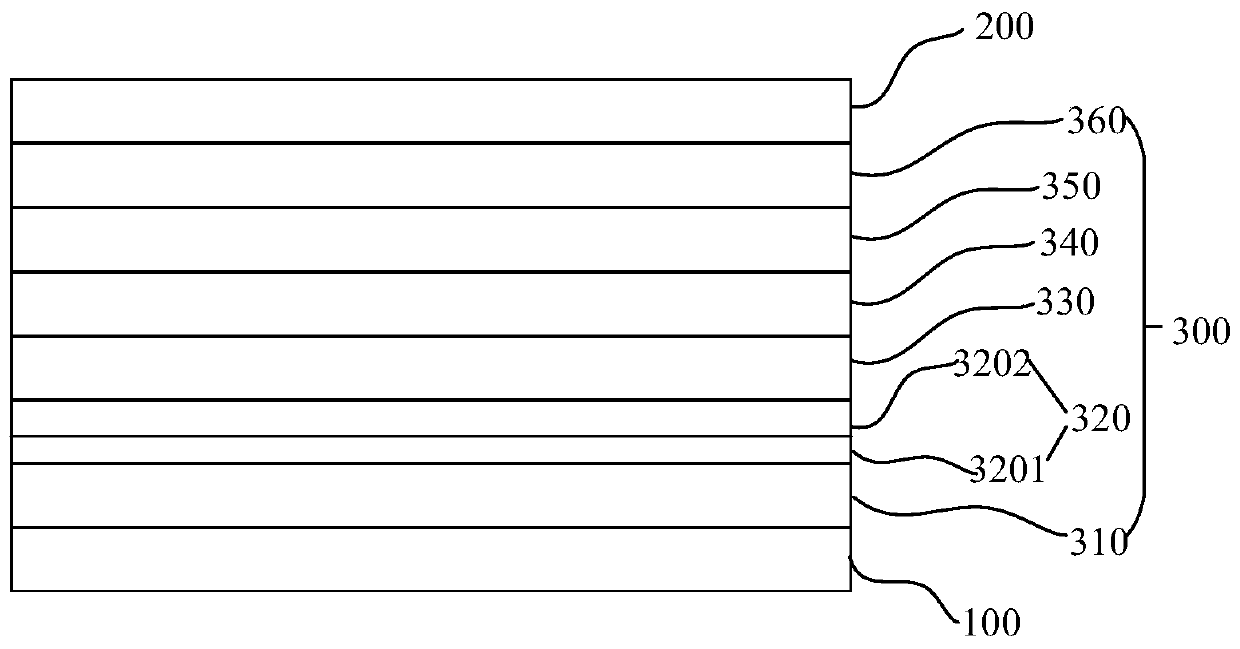

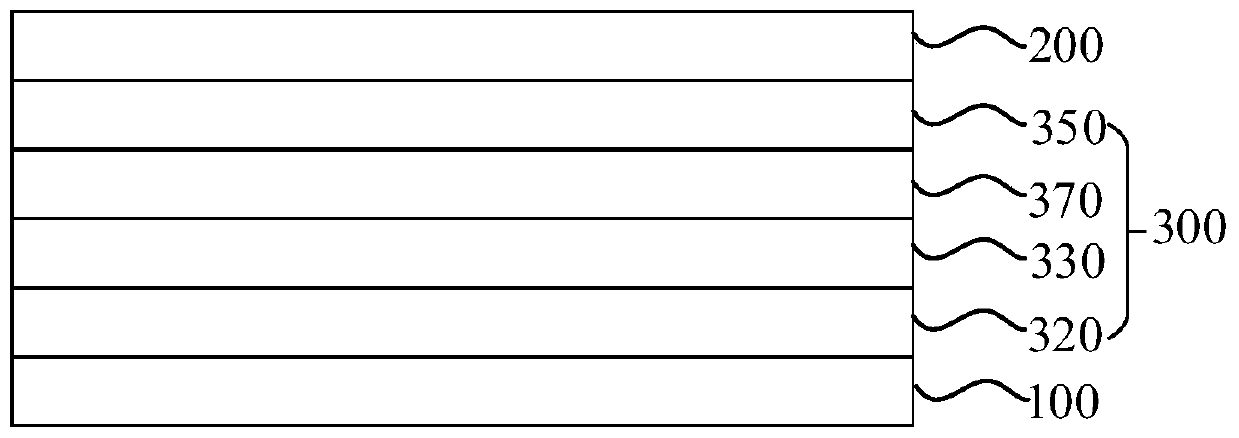

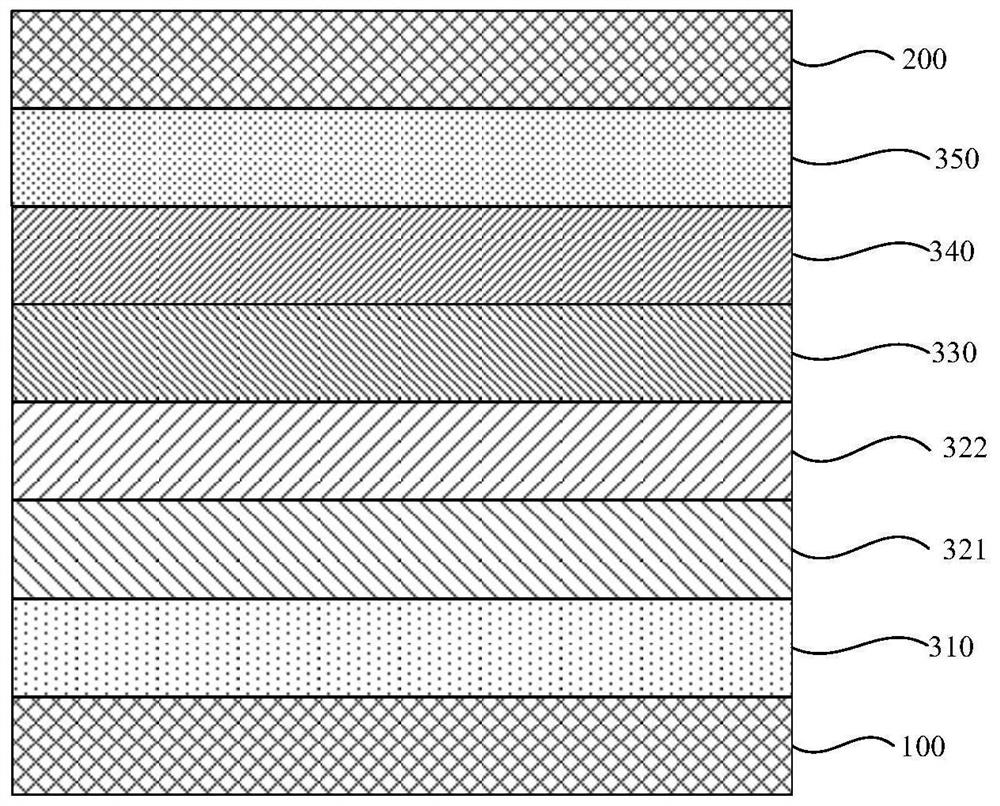

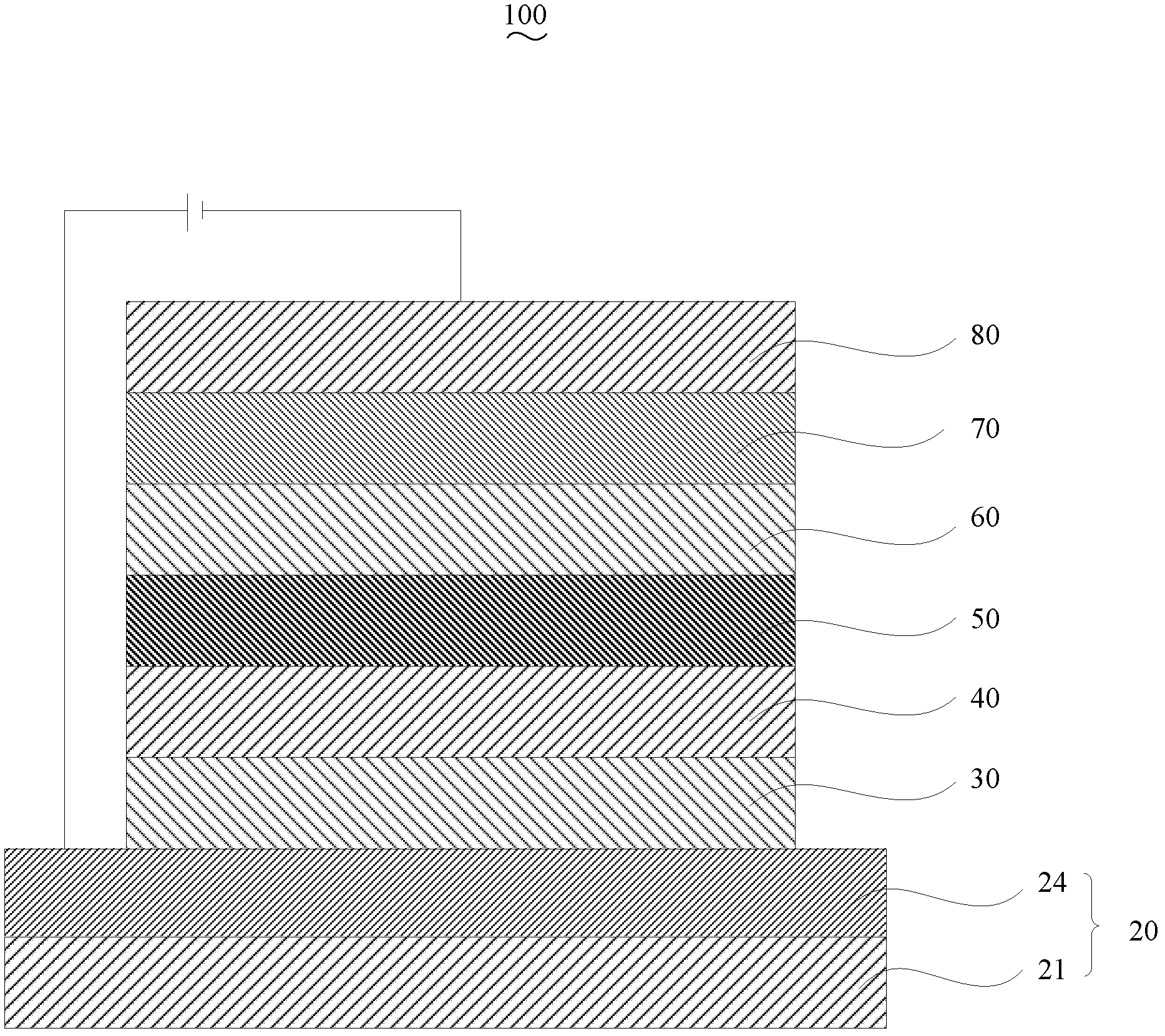

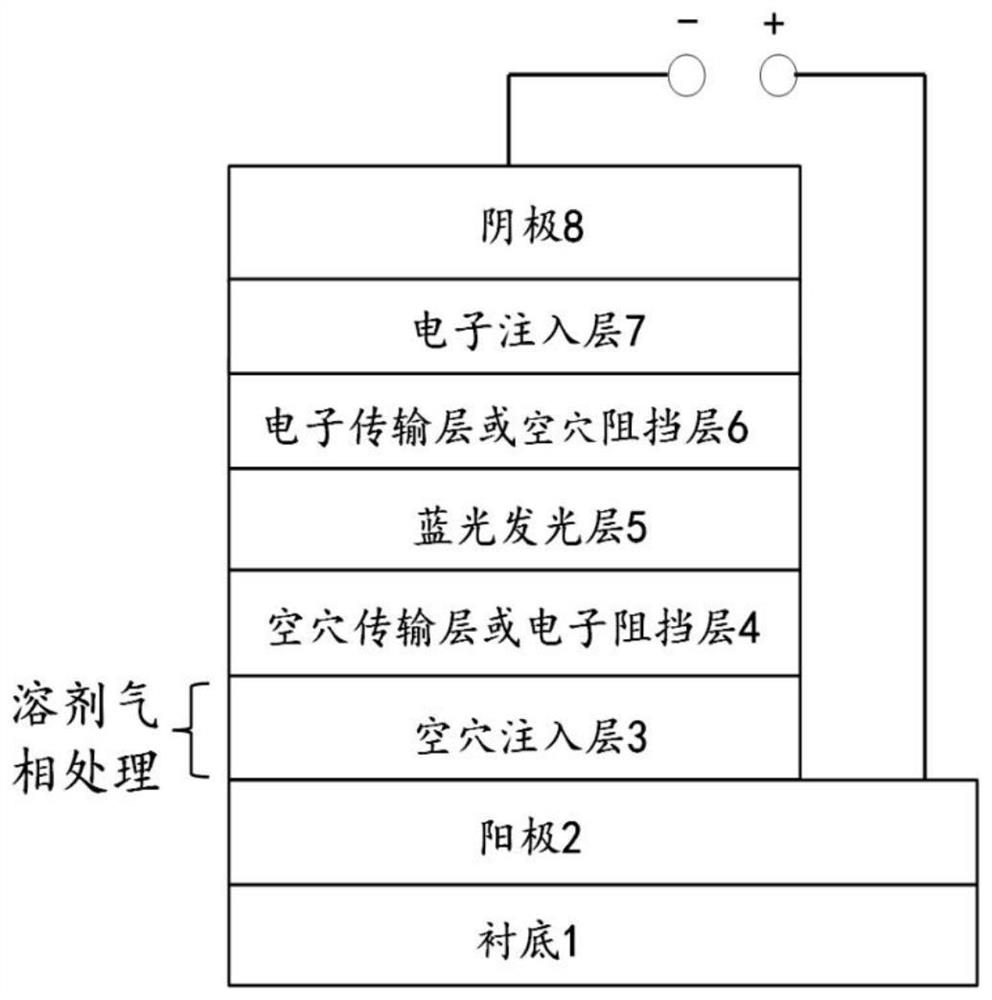

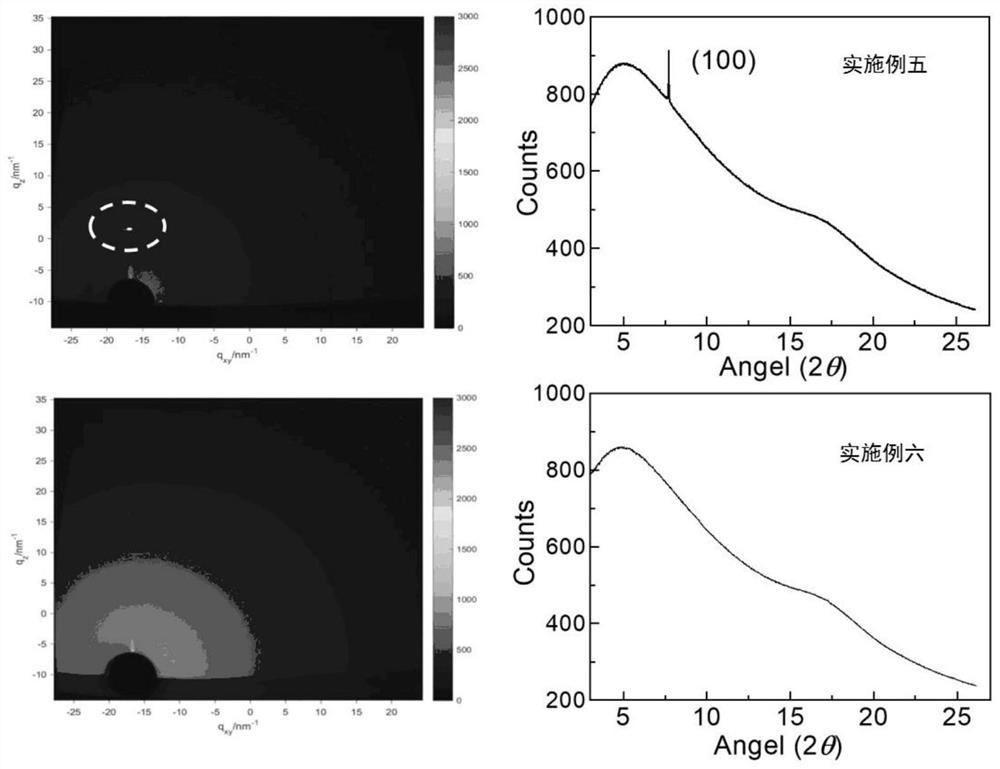

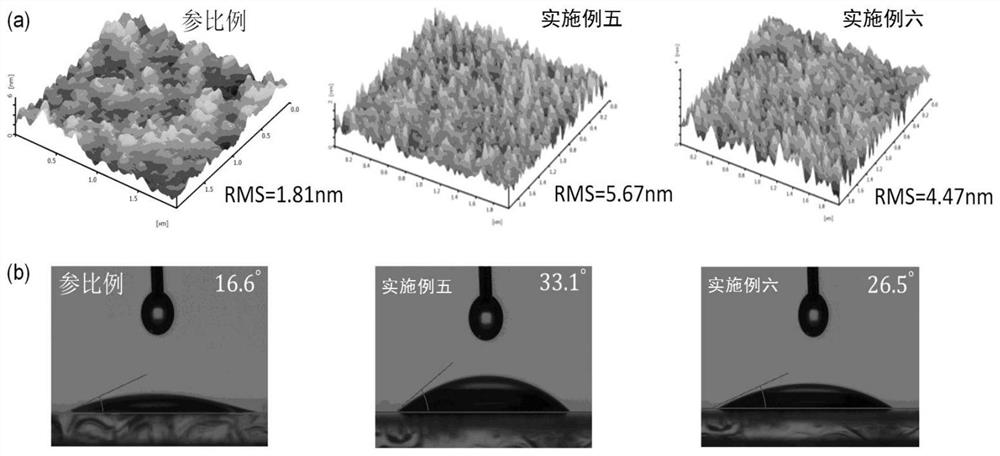

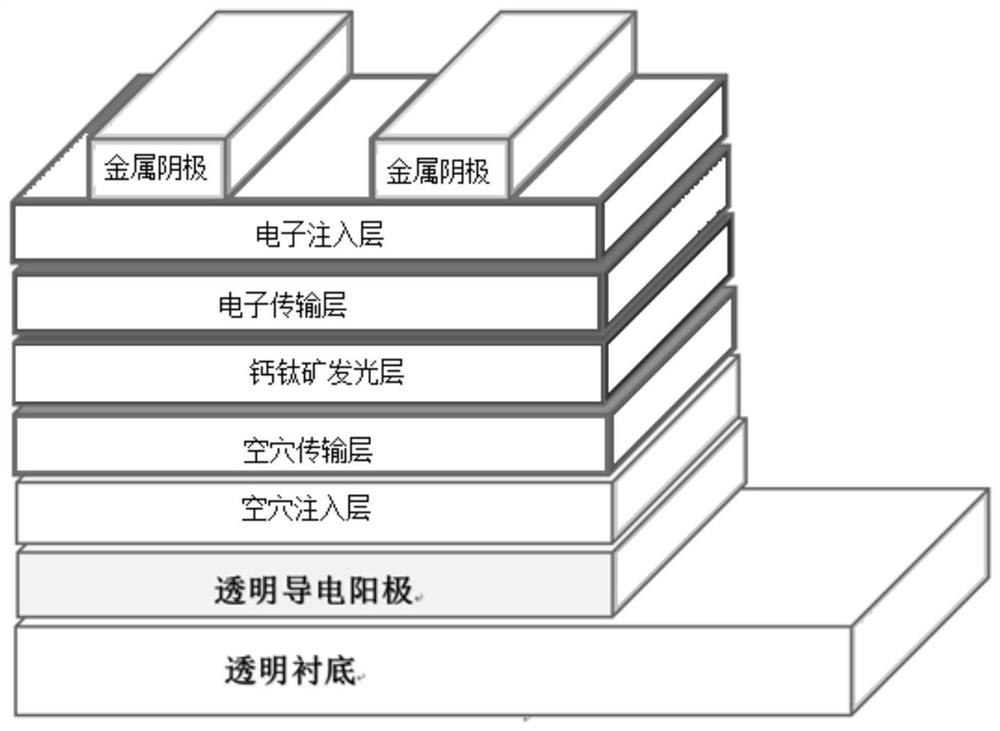

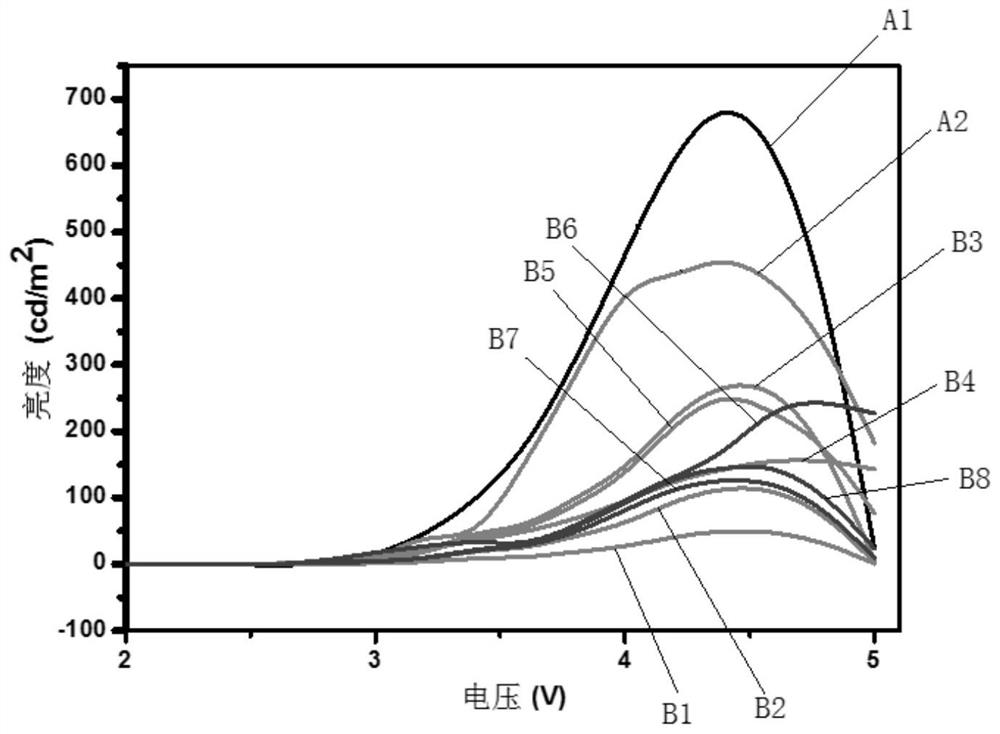

Blue light OLED based on solvent vapor phase processing hole injection layer and preparation method thereof

PendingCN112510164AOvercoming the defect of serious leakage currentPromotes transmission balanceSolid-state devicesSemiconductor/solid-state device manufacturingHigh concentrationEtching

The invention discloses a blue light OLED based on a solvent vapor phase processing hole injection layer and a preparation method thereof, and the method comprises the steps: carrying out spin coating, printing, spraying or evaporation of a polymer, small molecule or oxide hole injection layer film with a proper thickness on an anode by employing a solvent vapor phase processing method; placing the film in a high-concentration organic solvent or acid vapor atmosphere, and standing for a certain period of time; and taking out the film, annealing and drying, and sequentially laminating a spin-coating or evaporation hole transport layer or electron blocking layer, a blue light emitting layer, an electron transport layer or hole blocking layer, an electron injection layer and a cathode to obtain a complete blue light OLED device. According to the method provided by the invention, the defect of serious current leakage caused by solvent doping or soaking etching of a hole injection layer isovercome. A scattering structure and phase separation which are beneficial to light emission are formed on the surface of a thin film by utilizing the relatively mild micro-etching effect of gas molecules, so that the optical coupling and external quantum efficiency of the blue-light OLED are remarkably improved.

Owner:SHANGHAI UNIV

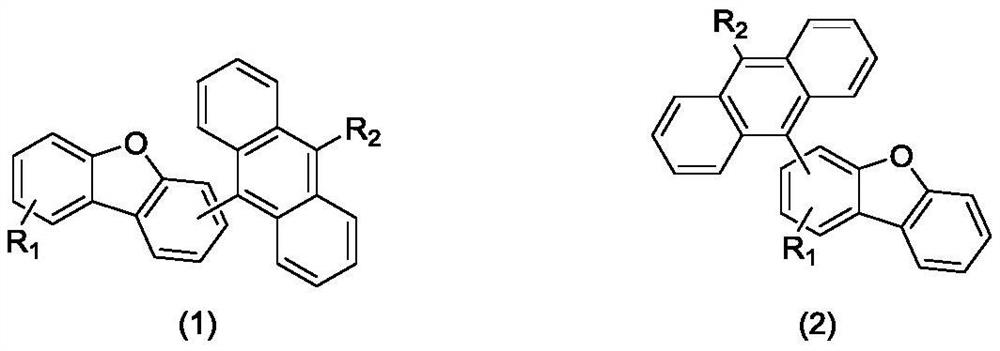

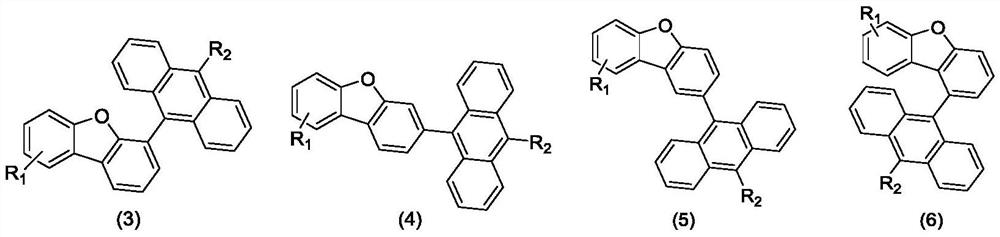

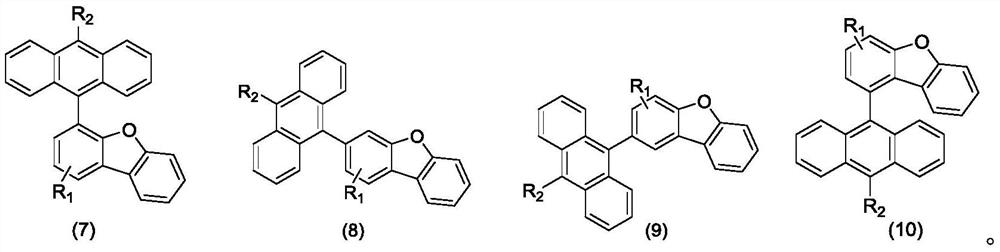

Organic electroluminescent material with a dibenzofuran anthracene core structure, and preparation method and device thereof

ActiveCN112500397AHigh Quantum Fluorescence EfficiencyHigh electron mobilityOrganic chemistrySolid-state devicesPhysicsOrganic electroluminescence

The invention relates to the technical field of photoelectric material application, and discloses an organic electroluminescent material with a dibenzofuran anthracene core structure, and a preparation method and a device thereof. According to the organic electroluminescent material with the dibenzofuran anthracene-connected core structure, the dibenzofuran anthracene-connected core structure is subjected to specific substitution and fine regulation and control through specific functional groups, and a luminescent host material with excellent comprehensive performance is provided; the problemsof relatively strong intramolecular charge transfer and luminescence red shift caused by pi conjugation of an existing blue-light fluorescent material are effectively solved, the technical effect ofconsidering both efficiency and saturated blue light color is achieved, and the blue-light fluorescent material has a remarkable application value in blue-light devices as a luminescent main body material.

Owner:WUHAN SUNSHINE OPTOELECTRONICS TECH CO LTD

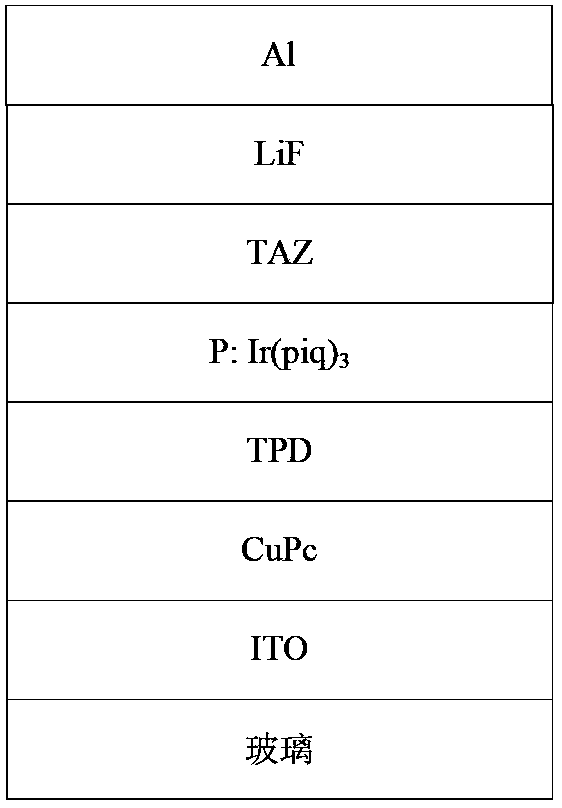

Electronic input type red phosphorescent compound, preparation method thereof and organic electroluminescent device

InactiveCN103804246ACapable of transporting electronsHigh triplet energy levelOrganic chemistryOrganic compound preparationElectronic transmissionOrganic semiconductor

The invention belongs to the field of organic semiconductor materials, and discloses an electronic input type red phosphorescent compound, a preparation method thereof and an organic electroluminescent device. The compound has a structural formula shown in the specification. The electronic input type red phosphorescent compound has an electronic transmission capacity, so it is benefit for realizing the carrier transfer balance, thereby the luminous efficiency of the compound is substantially improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

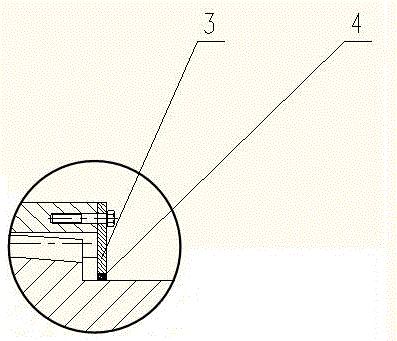

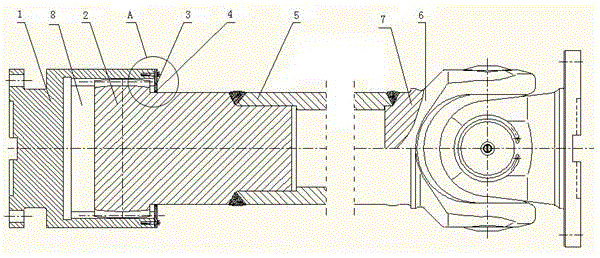

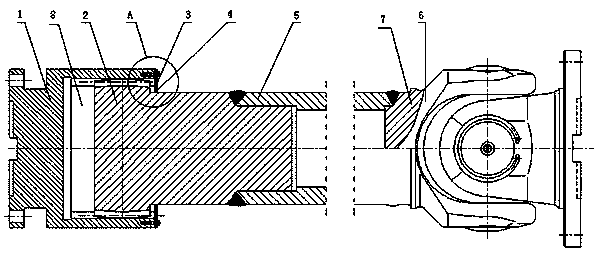

Coupler for rolling mill

InactiveCN103410879AExtended service lifeImprove contact conditionsYielding couplingCouplingEngineering

The invention provides a coupler for a rolling mill. The coupler comprises an internal-tooth flange, an external-tooth connector and a single-section crossed universal shaft with a fork head, wherein the internal teeth of the internal-tooth flange are meshed with the external teeth of the external-tooth connector; one end, which is away from the internal-tooth flange, of the external-tooth connector is connected with a connection pipe; one end, which is away from the external-tooth connector, of the connection pipe is fixedly connected with the fork head; lubricating oil is filled in a cavity formed between the internal-tooth flange and the external-tooth connector; a sealing end cover is arranged on the end part of the meshed end of the external-tooth connector and the internal-tooth flange and seals the external-tooth connector through a sealing ring. The coupler disclosed by the invention has large transmission torque and is high in transmission balance; the shortcomings of a rolling mill in a severe environment with a small space and a lot of water vapour are overcome; the coupler has an automatic lubricating function, can realize buffering and shock absorption and protect a transmission system, is convenient to mount and dismount and long in service life.

Owner:JIGANG GRP

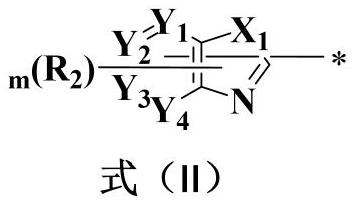

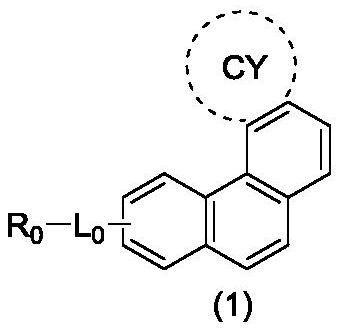

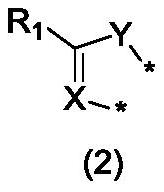

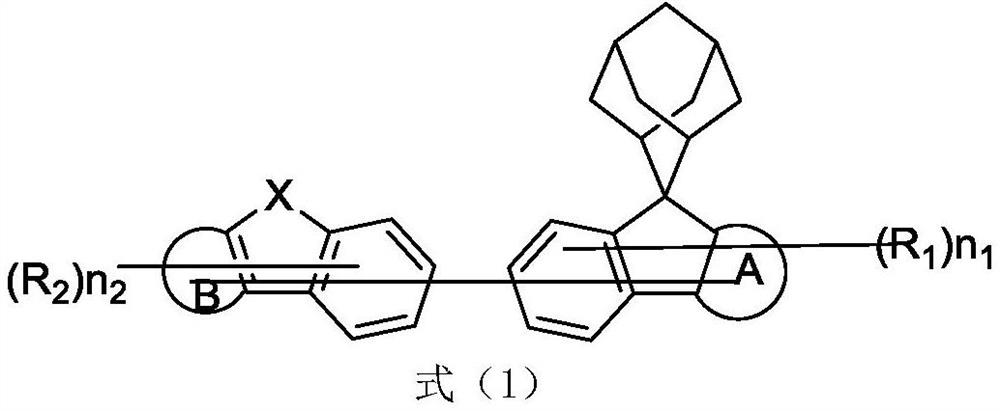

Benzo five-membered heterocyclic derivative and organic electroluminescent device thereof

PendingCN113735780AHigh electron mobilityDeep HOMO levelOrganic chemistrySolid-state devicesElectron holeOrganic electroluminescence

The invention provides a benzo five-membered heterocyclic derivative and an organic electroluminescent device thereof, and relates to the technical field of organic photoelectric materials. The benzo five-membered heterocyclic derivative provided by the invention has relatively good electron mobility, can effectively promote transmission balance of holes and electrons, and meanwhile, the benzo five-membered heterocyclic derivative has relatively good hole blocking capability, can effectively block the holes in a light-emitting layer, and increases the recombination probability of the holes and the electrons. When the compound is applied to a hole blocking layer or an electron transport layer of an organic electroluminescent device, the luminous efficiency and the service life of the device can be effectively improved; besides, when the benzo five-membered heterocyclic derivative is applied to the organic electroluminescent device as a light extraction material, the total emission of an interface between an electrode film and a glass substrate and an interface between the glass substrate and air can be effectively solved, and the light extraction efficiency is improved, so that the luminous efficiency of the organic electroluminescent device is improved, and the service life of the organic electroluminescent device is prolonged.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

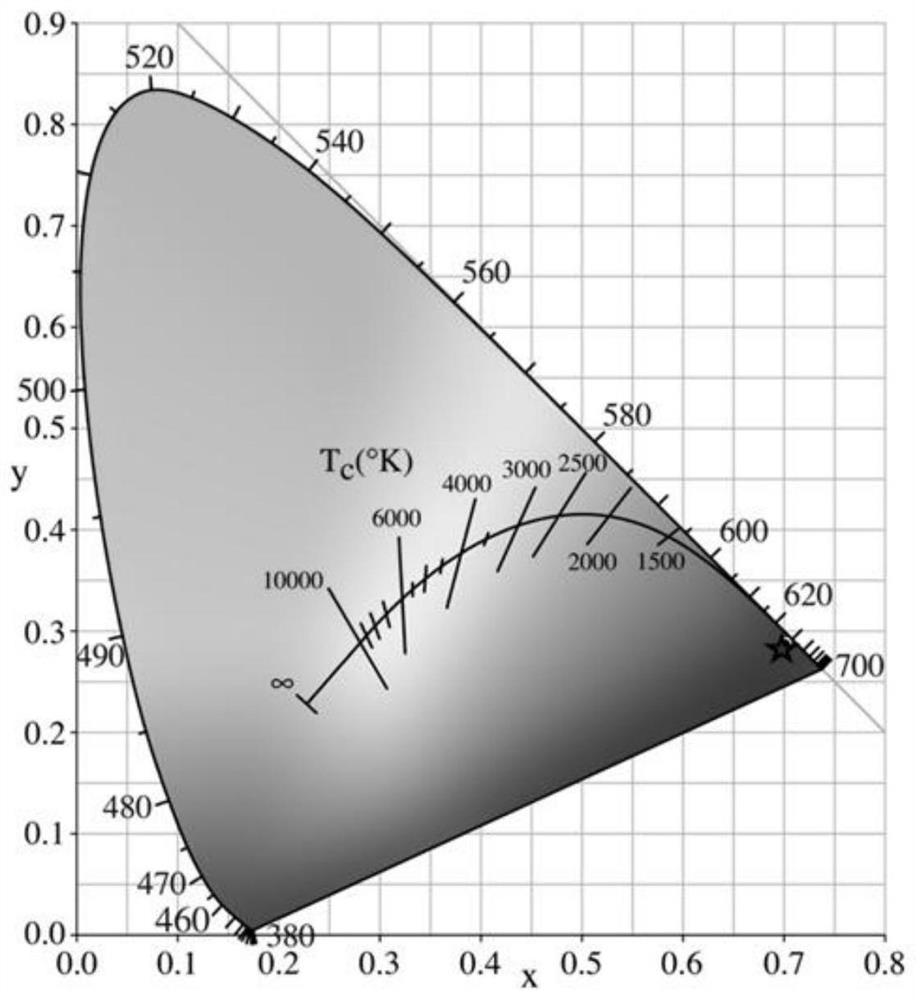

Red light quasi-two-dimensional perovskite light-emitting diode with dication structure

ActiveCN112038495AGood temperature and humidity stabilityHigh PLQYSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsPerovskite (structure)

Owner:JILIN UNIV

Organic semiconductor material, preparation method thereof and electroluminescent device

InactiveCN104119290APromotes transmission balancePrevent postbackOrganic chemistrySolid-state devicesTriplet stateComputational chemistry

The invention provides an organic semiconductor material, which has a chemical formula shown as below. The organic semiconductor material is a red phosphorescence host material with electron-transporting capacity, so that the electron-transporting capacity is enhanced to facilitate carrier transporting balance; and the organic semiconductor material also has high triplet state energy level and excellent thermal stability, and effectively prevents back passing of energy to the host material in the luminescence process, thus greatly improving the luminous efficiency. The invention also provides a preparation method of the organic semiconductor material, and an electroluminescent device containing the organic semiconductor material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Bipolar red phosphorescent compound, and preparation method and application thereof

InactiveCN103804406AHigh triplet energy levelImprove luminous efficiencyGroup 4/14 element organic compoundsSolid-state devicesHost materialOrganic semiconductor

The invention belongs to the field of organic semiconductor materials, and discloses a bipolar red phosphorescent compound, and a preparation method and an application thereof. The compound has a structural formula shown in the specification. The bipolar red phosphorescent compound has a high triplet energy level, so the return of energy to a host material in the luminescence process can be effectively prevented, the carrier transfer balance is benefited, and the luminous efficiency is substantially improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

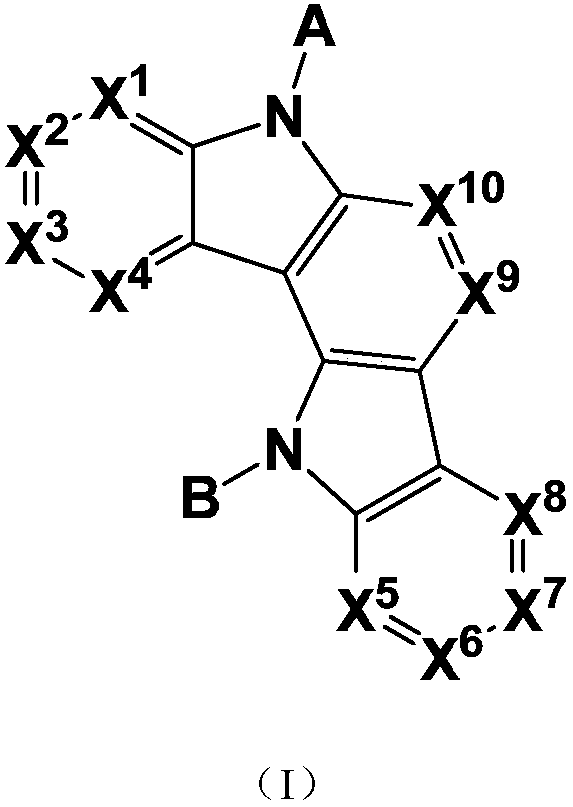

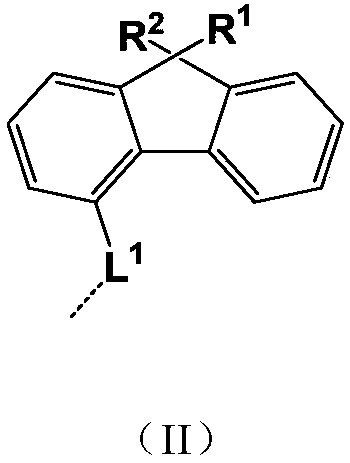

General formula compound and application thereof

InactiveCN110272422AImprove hole injection efficiencyImprove transmission efficiencyOrganic chemistrySolid-state devicesHydrogenDevice Properties

The invention discloses a general formula compound of formula (I) shown in the description. In the formula (I), X<1> to X<10> are respectively independently selected from CR<3> or N, at least one of A and B is selected from a structure represented by formula (II) shown in the description, and the remaining one is an arylene group or a fused arylene group, a heterocyclic arylene group or a fused heterocyclic arylene group; and in the formula (II), L<1> is selected from an arylene group and a heterocyclic arylene group, and R<1>, R<2> and R<3> are respectively independently selected from hydrogen, an alkyl group, an aryl or fused aryl group and a heteroaryl or fused heteroaryl group. The compound of the present invention has excellent device properties and stability when used as a host material in the light-emitting layer of an OLED. The present invention also discloses an organic light-emitting device adopting the general formula compound.

Owner:BEIJING ETERNAL MATERIAL TECH +1

Organic electroluminescent material containing phenanthrene structure and device thereof

PendingCN113816909AHigh blue fluorescence quantum efficiencyBlue fluorescence short quantum efficiencyGroup 5/15 element organic compoundsSolid-state devicesPhenanthreneOrganic electroluminescence

The invention relates to the technical field of photoelectric material application, and discloses an organic electroluminescent material containing a phenanthrene structure and a device thereof. According to the organic electroluminescent material, an alkyl group and a specific functional group are introduced into a specific site of a phenanthrene-containing core structure to finely regulate and control the core structure, so that the luminescent main body material with excellent comprehensive performance is provided, and the problems of intramolecular charge transfer, luminescent red shift and the like of the existing luminescent main body material are effectively improved; and the organic electroluminescent device made of the material has remarkable progress in the aspects of driving voltage, current efficiency, service life and the like.

Owner:WUHAN SUNSHINE OPTOELECTRONICS TECH CO LTD

Heat treatment method for carburizing and quenching of automobile gearbox gears

ActiveCN103710714BHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

Compound, organic electroluminescent device and electronic device

ActiveCN111961038BMacromolecular structure has strong rigidityImprove rigiditySilicon organic compoundsOrganic chemistry methodsSimple Organic CompoundsOrganic electroluminescence

The application provides an organic compound, an organic electroluminescent device and an electronic device. The chemical structure of the organic compound of the present invention includes an adamantane spirofluorene ring and a dibenzo five-membered ring. The organic compound has an excellent energy transfer function and can It is used as a light-emitting layer material in electroluminescent devices, improving the efficiency of organic electroluminescent devices and increasing the life of organic electroluminescent devices.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

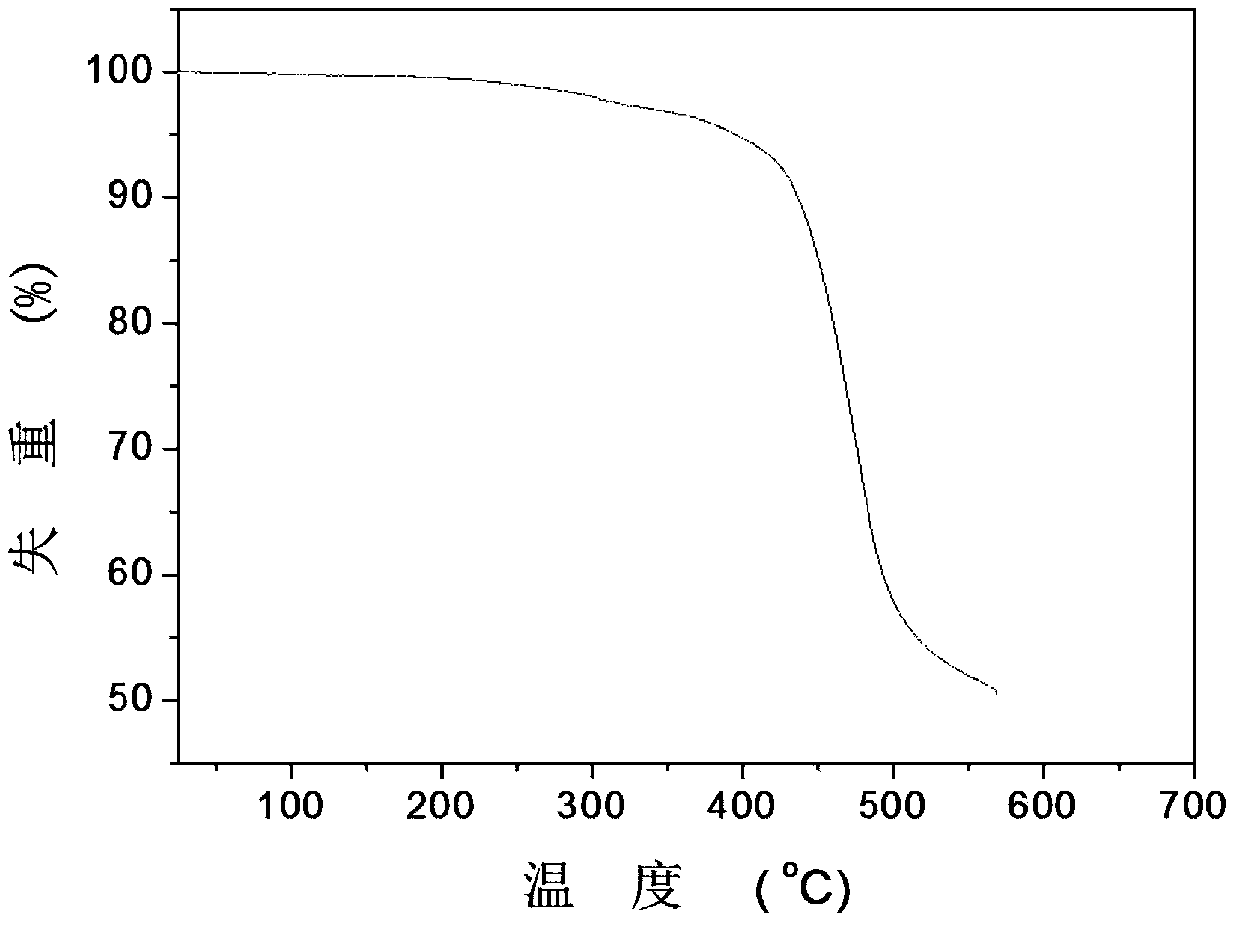

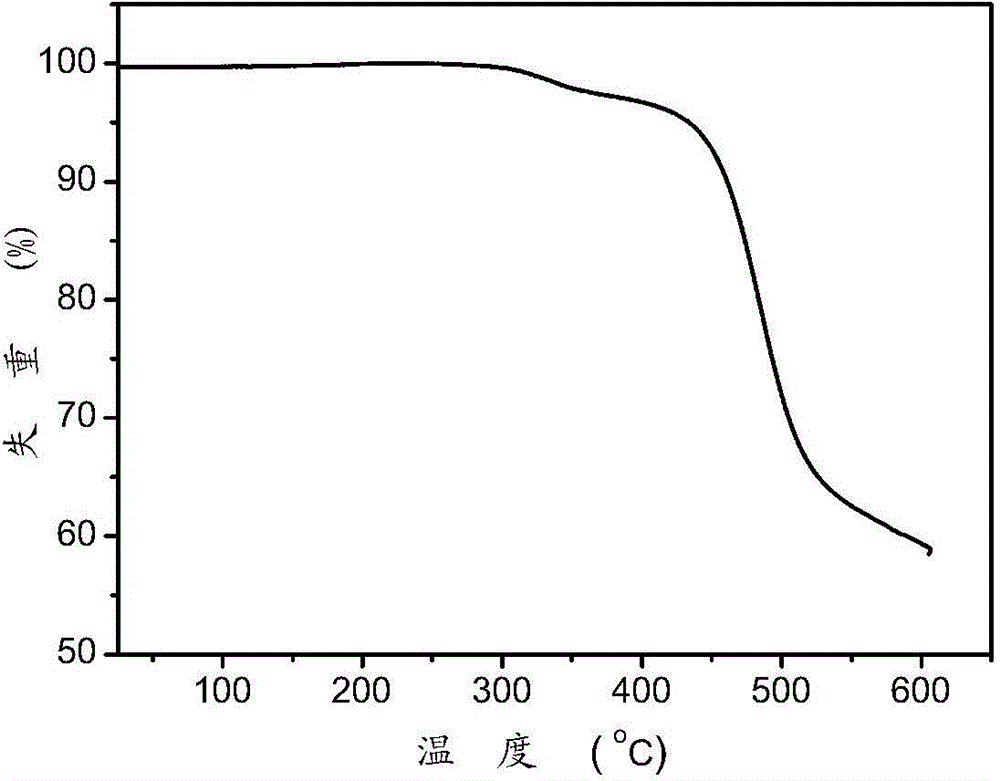

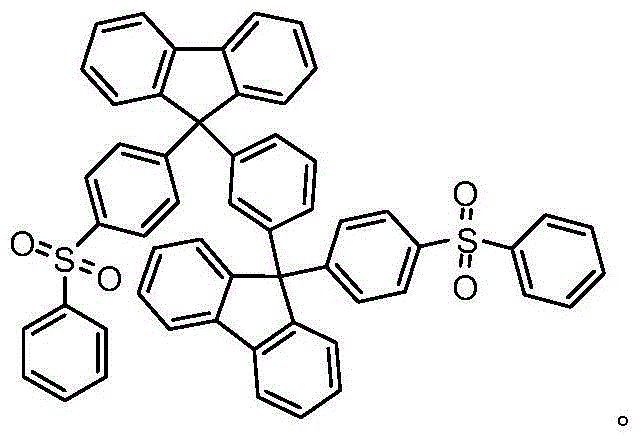

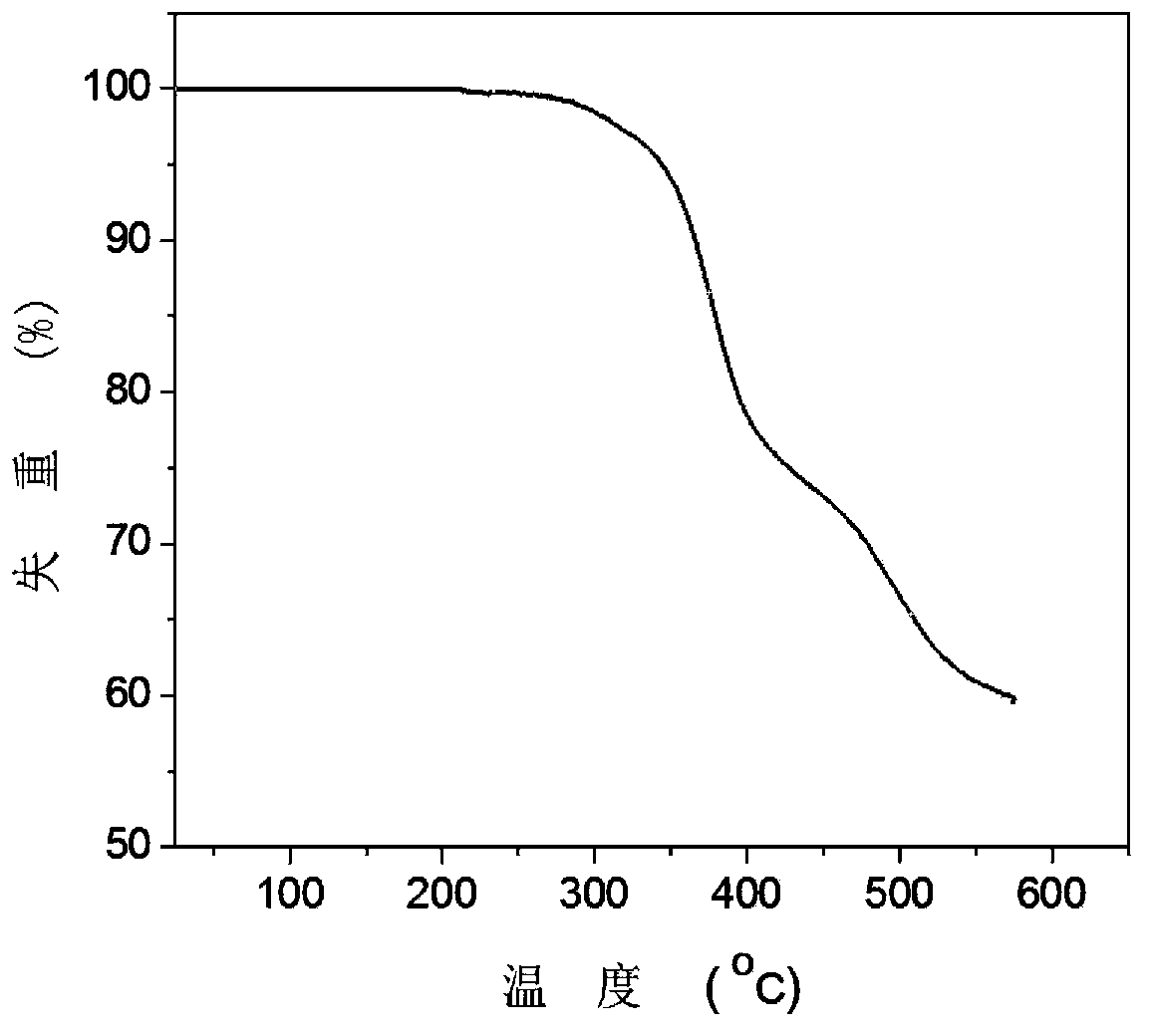

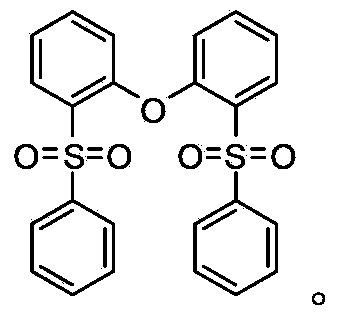

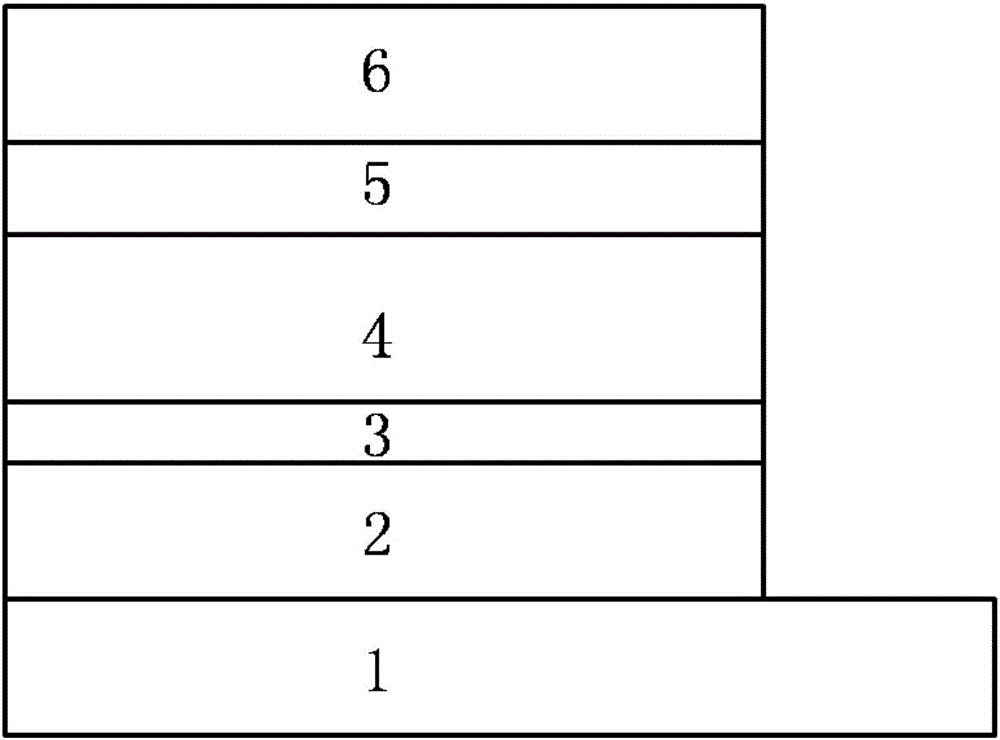

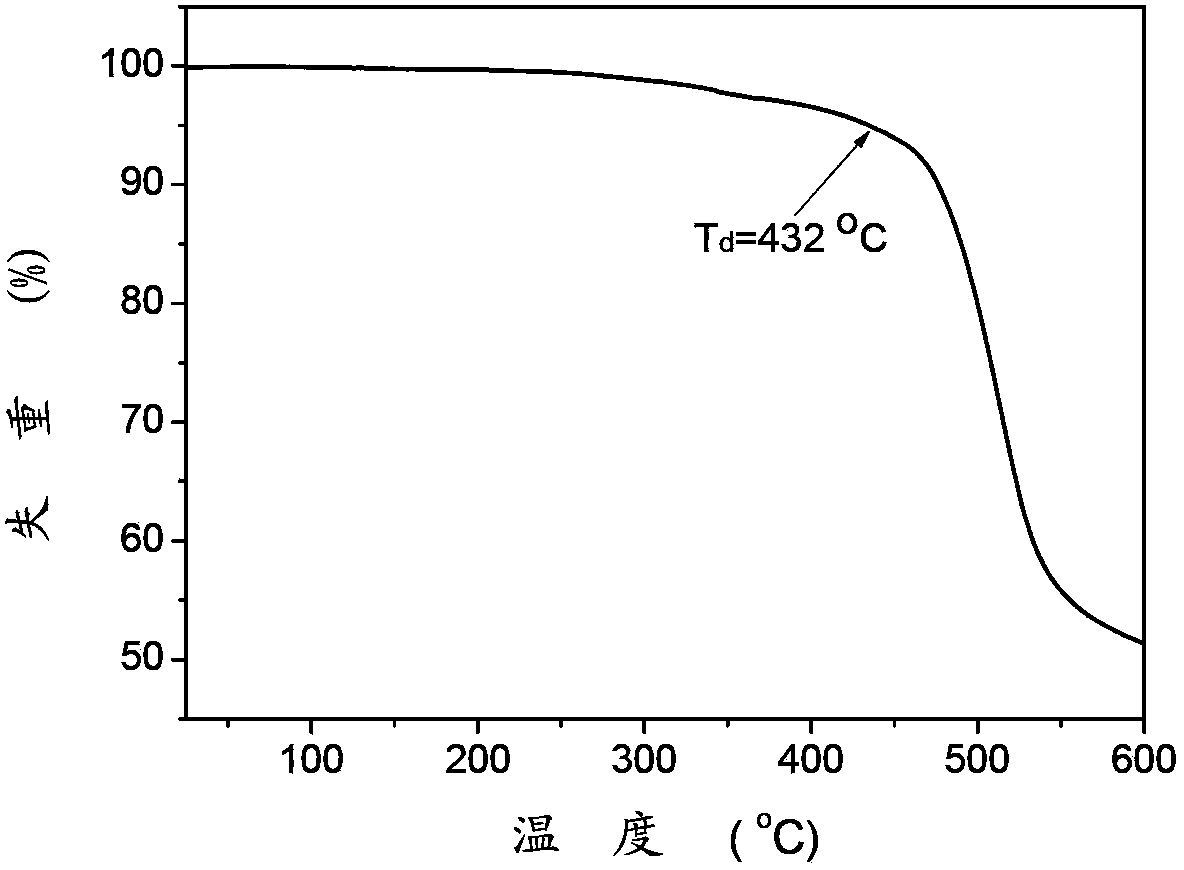

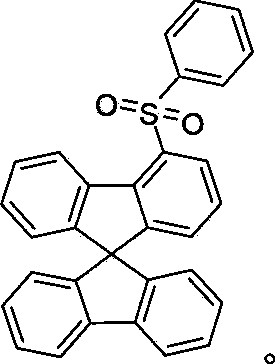

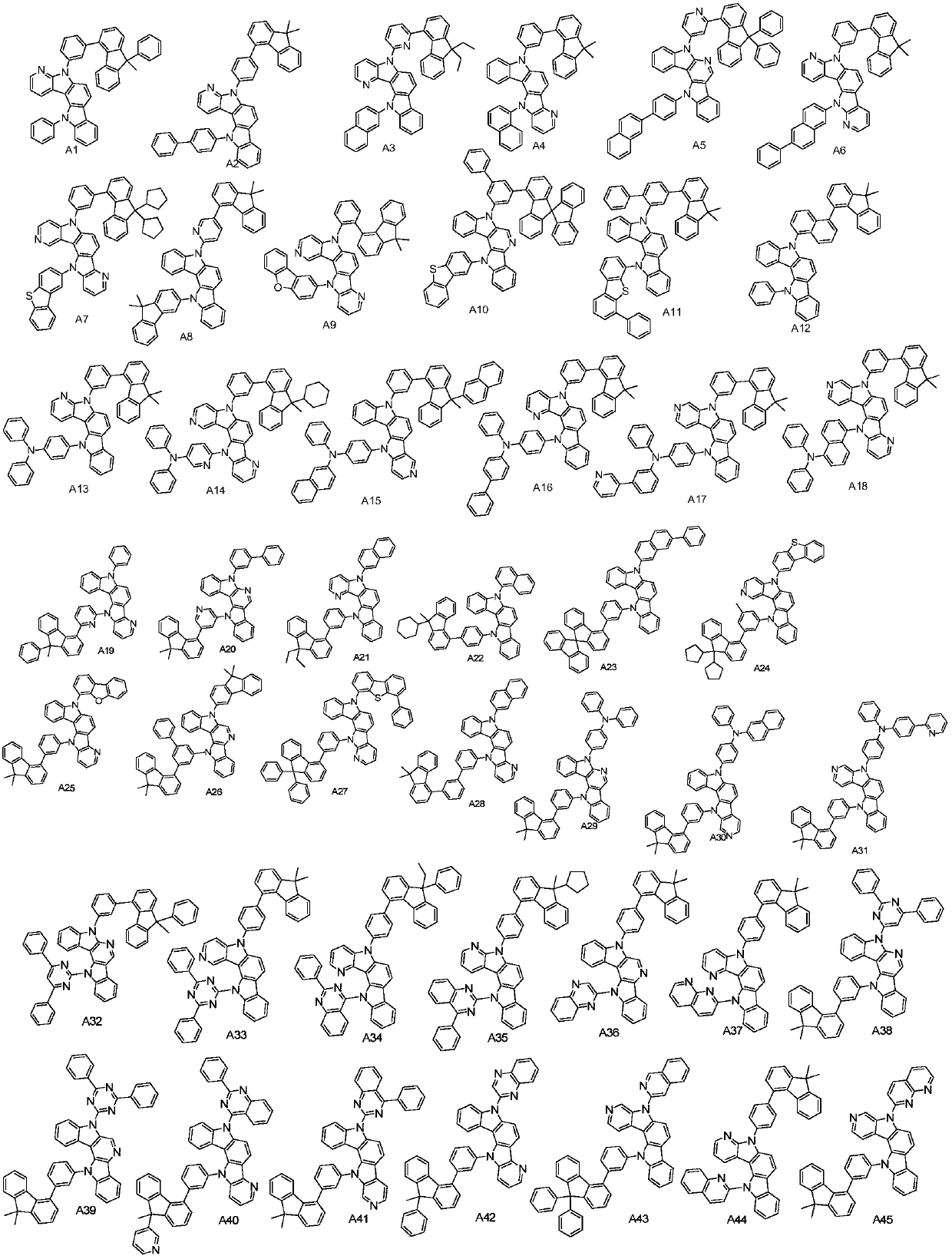

Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof

InactiveCN104629733AHigh triplet energy levelPromotes transmission balanceGroup 5/15 element organic compoundsSolid-state devicesDevice materialTriplet state

The invention belongs to the field of organic electroluminescent device material, and discloses a spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, a preparation method and an application thereof. A structural formula of the material is shown as follows, in the formula, R is C1-C20 alkyl group. In the spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, a diphenyl phosphine sulfur group with a tetrahedral structure has electron-withdrawing P=S, has high triplet state energy level and good electron transmission performance, the electron transmission capability can be enhanced, the main material is in favor of carrier transmission balance, the main material has high triplet state energy level, energy return on the main material during a luminescence process can be effectively prevented, and luminescence efficiency is greatly increased.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Bifluoranthene organic semiconductor material and its preparation method and application

ActiveCN103012206BImprove solubilityImprove film formationCarboxylic acid nitrile preparationAmino preparation from aminesSolubilityOrganic solvent

The invention relates to a double-fluoranthene organic semiconductor material. The double-fluoranthene organic semiconductor material can be shown as a structural formula described in the specification, wherein -R is -CN, -NO2, -CF3, -F or -CHO. The double-fluoranthene organic semiconductor material emits pure blue lights, the double-fluoranthene organic semiconductor material can be easily dissolved in common organic solvents such as tetrahydrofuran, dichloromethane, methylbenzene and chloroform as an electron withdrawing group is introduced into the structure, and solubility and film-forming property of the double-fluoranthene organic semiconductor material are improved; meanwhile, a fluoranthene group is a rigid substituent group, so that the double-fluoranthene organic semiconductor material also has excellent thermal stability; the fluoranthene group can cause the double-fluoranthene organic semiconductor material to have higher hole mobility; and electro transport performance of the double-fluoranthene organic semiconductor material is improved as the electron withdrawing group is introduced, so that carrier transport balance is facilitated. The invention also provides a preparation method of the double-fluoranthene organic semiconductor material and an application of the double-fluoranthene organic semiconductor material in an organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

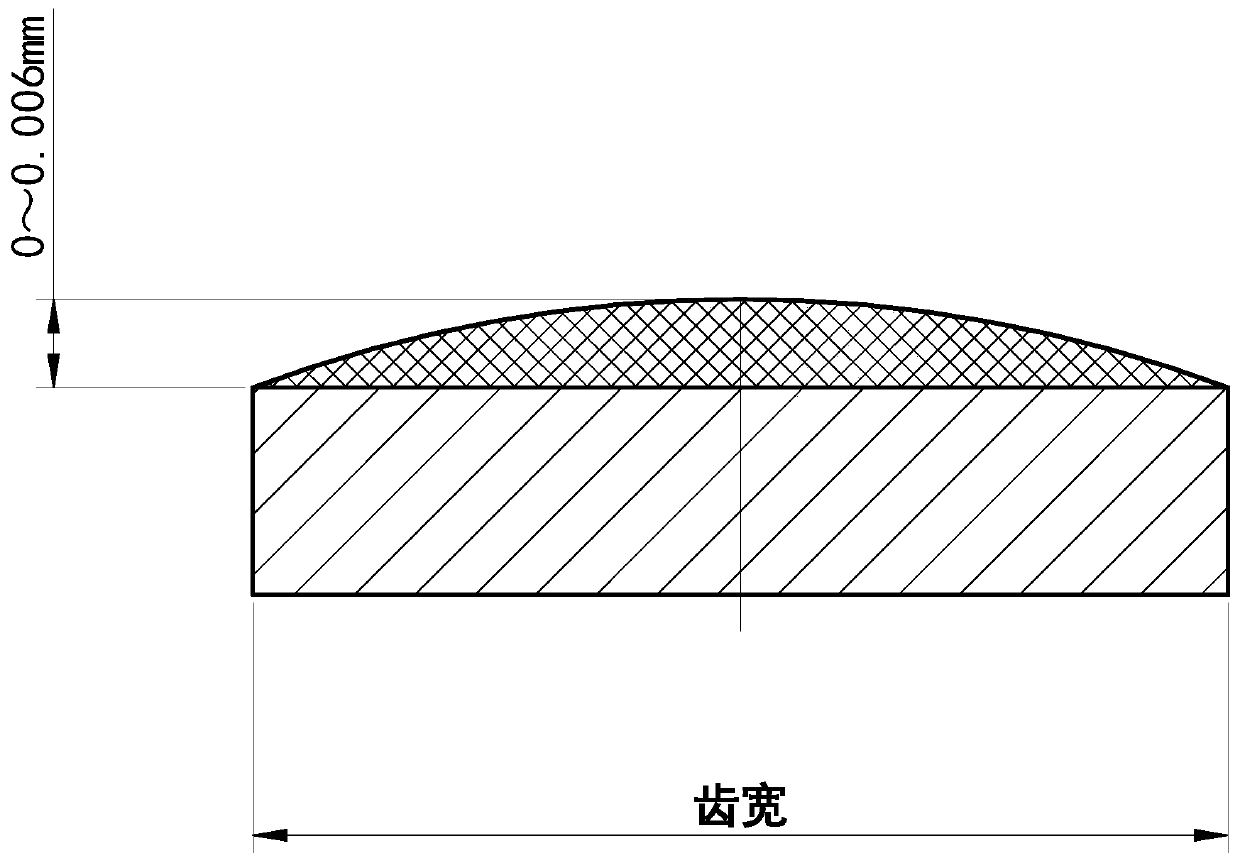

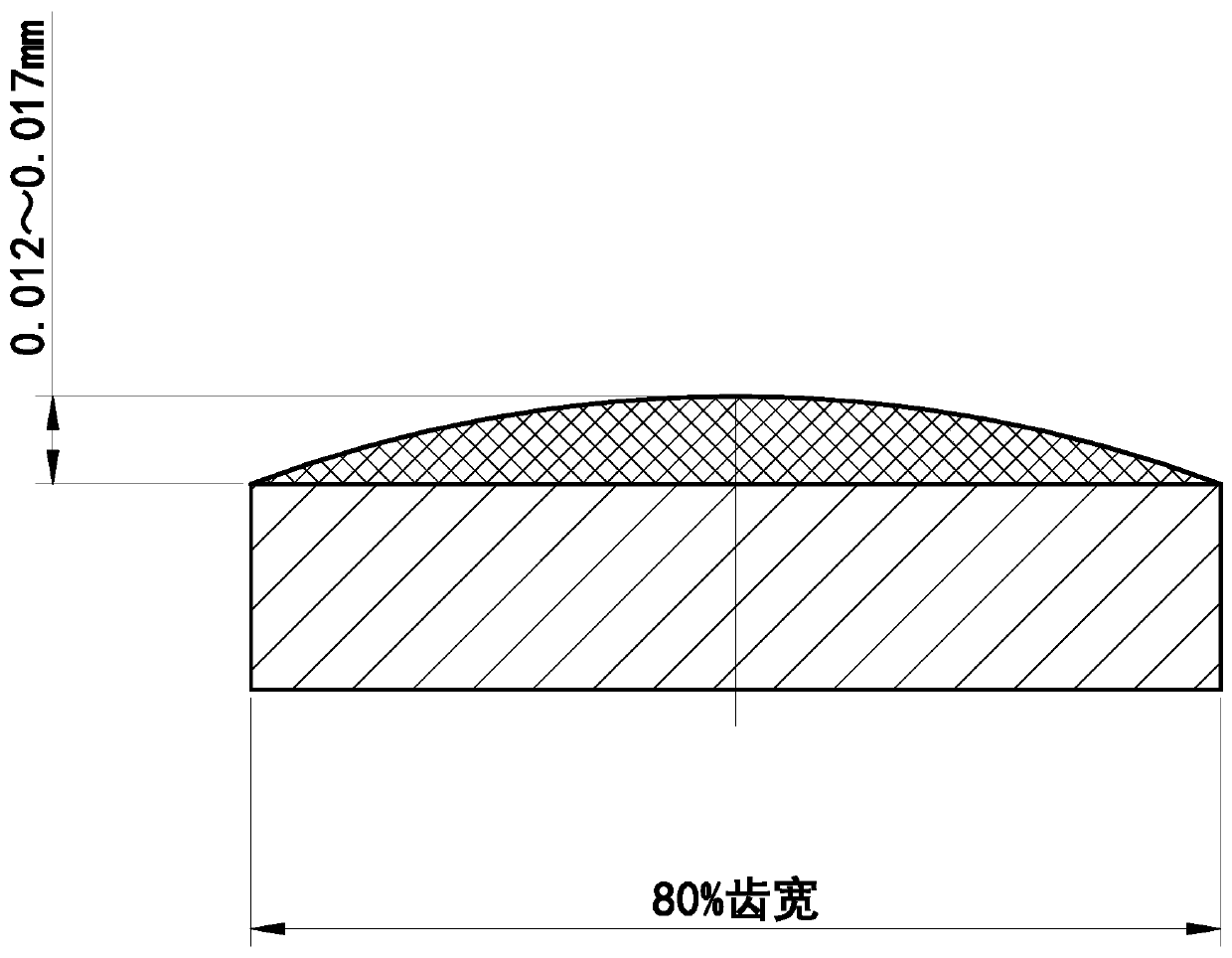

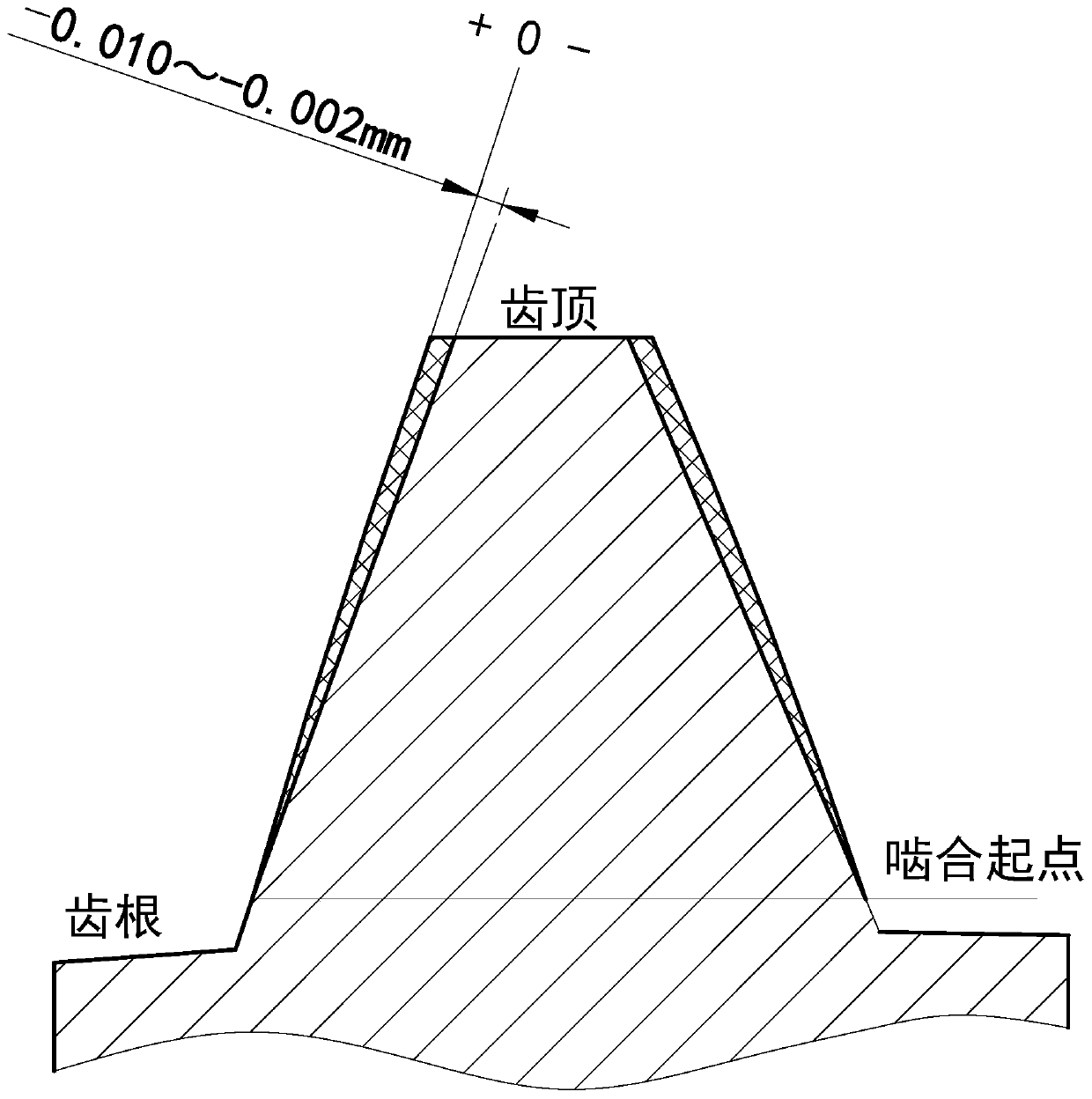

Machining method for reducing gear noise of electric scooter

InactiveCN110671483AImprove comfortReduce contact frictionPortable liftingGearing elementsGear driveGear wheel

The invention discloses a machining method for reducing gear noise of an electric scooter. The method comprises the following steps that a main gear and a pinion of the electric scooter are shaped toachieve the purpose of reducing the noise of a gear pair, a spiral line of a toothed part is shaped during pinion shaping, and a spiral line and tooth profile of the toothed part are shaped during main gear shaping. According to the method, the main gear and the pinion of the electric scooter can be shaped, the contact friction surface of the tooth surfaces of the gear pair during moving is reduced on the premise that the manufacturing cost is not increased, parts producing interference are reduced, the transmission balance is improved, and the purpose of reducing the noise of the gear pair isachieved. The method is especially suitable for low-cost products, but in the case of aged electric scooters with severe requirements on gear transmission noise, the noise of the aged electric scooters can be reduced, and the comfort of the aged electric scooters is improved.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

Red light phosphorescent host material, preparation method and organic electroluminescent device thereof

InactiveCN104177287AHas electron transport propertiesImprove thermal stabilityOrganic chemistrySolid-state devicesHost materialTriplet state

Belonging to the field of organic semiconductor materials, the invention discloses a red light phosphorescent host material, a preparation method and an organic electroluminescent device thereof. The host material has a structural formula shown as the specification. The red light phosphorescent host material provided by the invention has electron transport performance, strengthened electron transport capacity, is conducive to carrier transport balance, has a high triplet state energy level, and can effectively prevent back transmission of energy to the host material in a luminescence process, thus greatly improving the luminescence efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

A shaft coupling for a rolling mill

InactiveCN103410879BExtended service lifeImprove contact conditionsYielding couplingCouplingEngineering

Owner:JIGANG GRP

Organic semiconductor material, preparation method thereof and electroluminescent device

InactiveCN104449666AEnhanced electron transport capabilitiesGood for carrier transport balanceOrganic chemistryOrganic compound preparationElectron transmissionChemistry

The invention provides an organic semiconductor material. The organic semiconductor material has the chemical formula represented by a formula shown in specifications. The organic semiconductor material provided by the invention has a relatively high triplet energy level, so that energy is effectively prevented from being transferred back to a main body material during luminescence; due to the phosphorescent main body material with electron transmission capability, the electron transmission capability is enhanced, the balance of current carrier transmission is facilitated, the luminescence efficiency is greatly increased, and the thermal stability is relatively high. The invention further provides a preparation method of the organic semiconductor material and an electroluminescent device containing the organic semiconductor material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Electron transport type red light phosphorescent material, preparation method and organic electroluminescent device thereof

InactiveCN104178122AElectron-transport red phosphorescent material with enhanced electron-transport propertiesHigh triplet energy levelOrganic chemistryOrganic compound preparationHost materialTriplet state

The invention belongs to the field of organic semiconductor materials, and discloses an electron transport type red light phosphorescent material, a preparation method and an organic electroluminescent device thereof. The structural formula of the material is shown as the specification. The electron transport type red light phosphorescent material provided by the invention has strong electron transport capability and good carrier transport balance. Also the material has a high triplet state energy level, and can effectively prevent back transmission of energy to a host material in a luminescence process. Thus, the luminescence efficiency is high.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

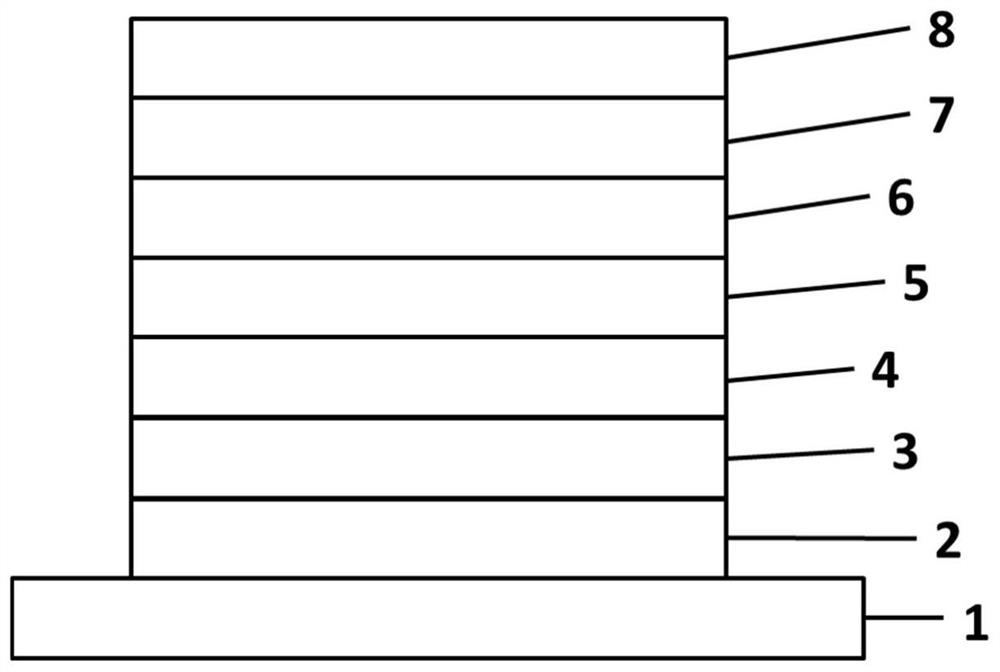

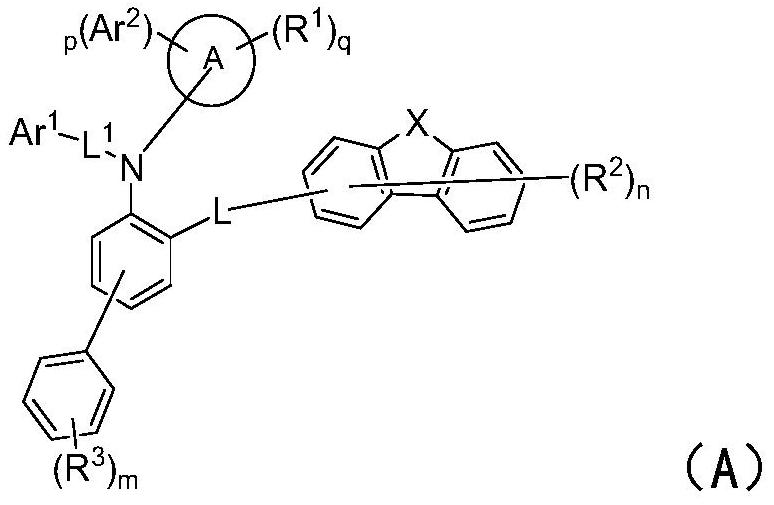

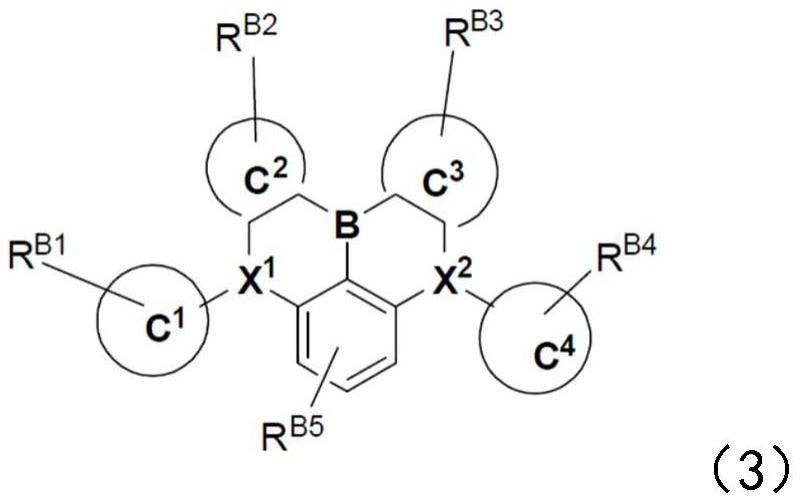

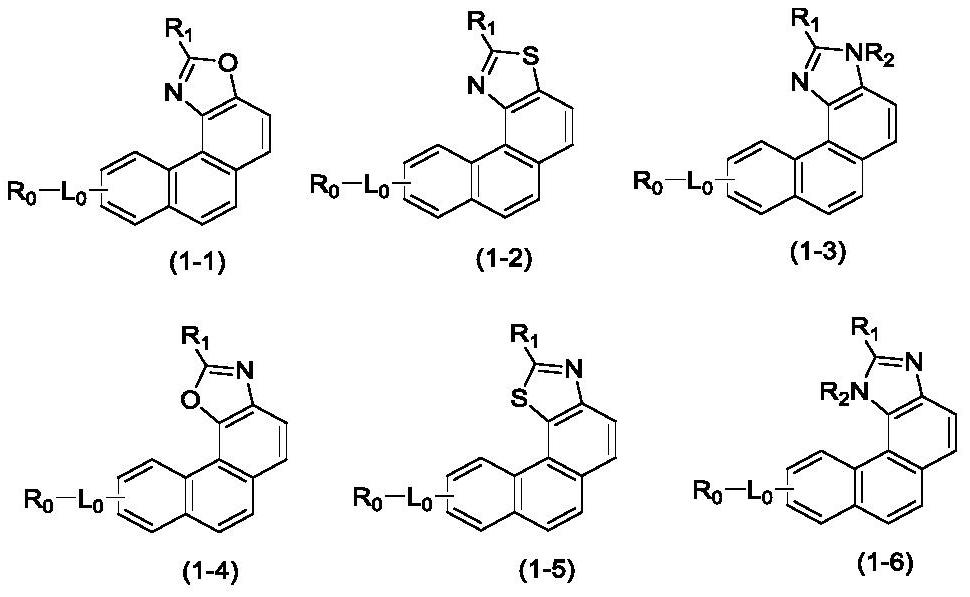

Organic light emitting device

PendingCN114512618ALow excitation voltageImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectron blocking layer

The invention relates to an organic light-emitting device which comprises a first electrode, a second electrode and an organic layer located between the first electrode and the second electrode, and the organic layer comprises an electron blocking layer and a light-emitting layer; the electron blocking layer comprises a compound with a structure shown in a general formula (A), the light-emitting layer comprises a compound shown in a general formula (3) as a guest material, and the performance and the stability of the device can be improved by using specific matching of the electron blocking layer material with the structure shown in the general formula (A) and the guest material shown in the general formula (3) in the light-emitting device.

Owner:BEIJING ETERNAL MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/32fce2eb-d379-401a-9d4b-8e45c0d94951/HDA0000410490790000011.PNG)

![Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/32fce2eb-d379-401a-9d4b-8e45c0d94951/HDA0000410490790000012.PNG)

![Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof Spiro[fluorine-xanthene]phosphine sulfur red light phosphorescence main material, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/32fce2eb-d379-401a-9d4b-8e45c0d94951/BDA0000410490780000022.PNG)