Machining method for reducing gear noise of electric scooter

An electric scooter and processing method technology, applied in the direction of components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of multiplying production costs, reduce interference parts, reduce noise, The effect of improving the transmission balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

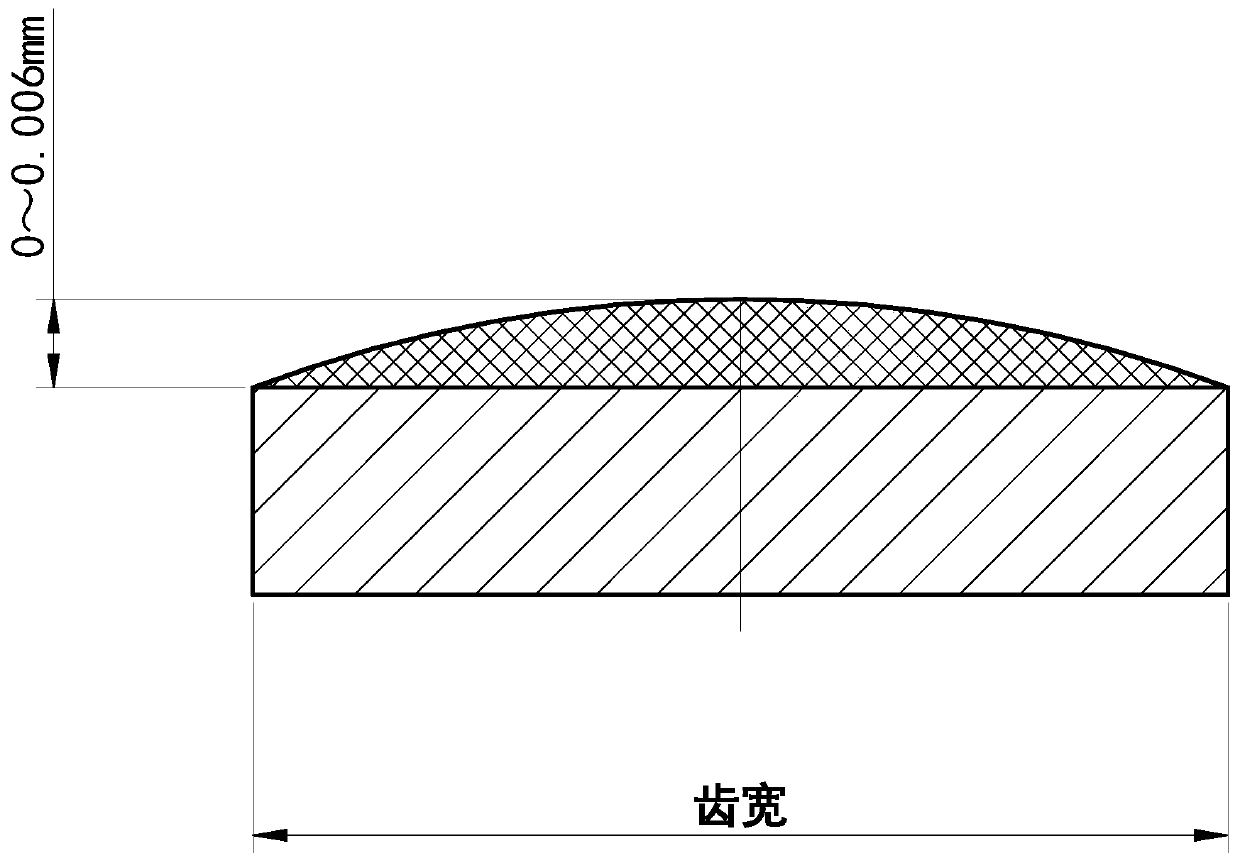

[0021] In this example, the teeth of the large and small gears of the electric scooter are modified to reduce the noise of the gear pair. The modification of the pinion is mainly to modify the helix of the tooth part. The modification scheme is as follows: figure 1 Shown: In the direction of the helical line of the tooth surface, outside the control of the total helical line error, the amount of drumming is gradually gentle in the middle of the helix line to 0-0.006mm,

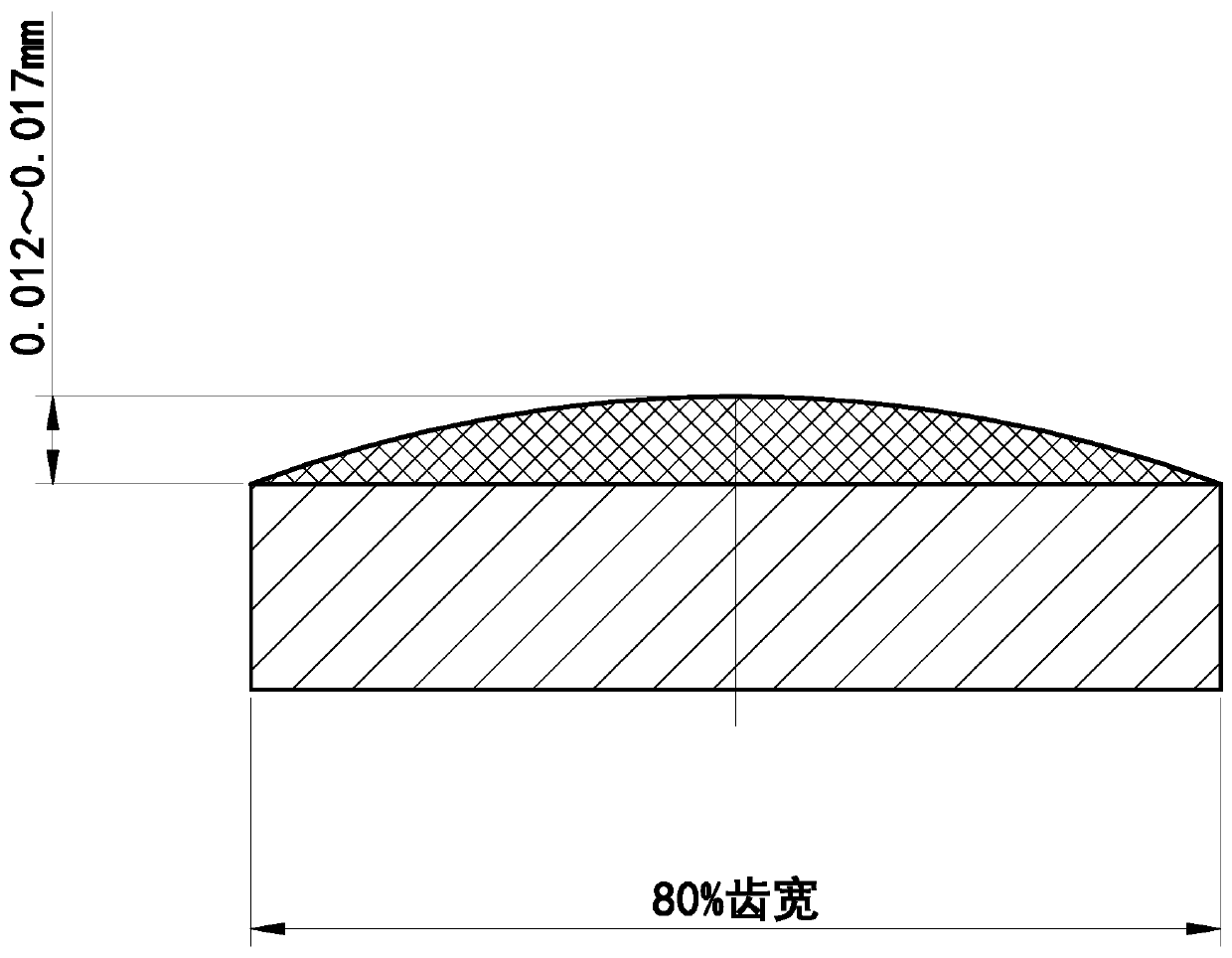

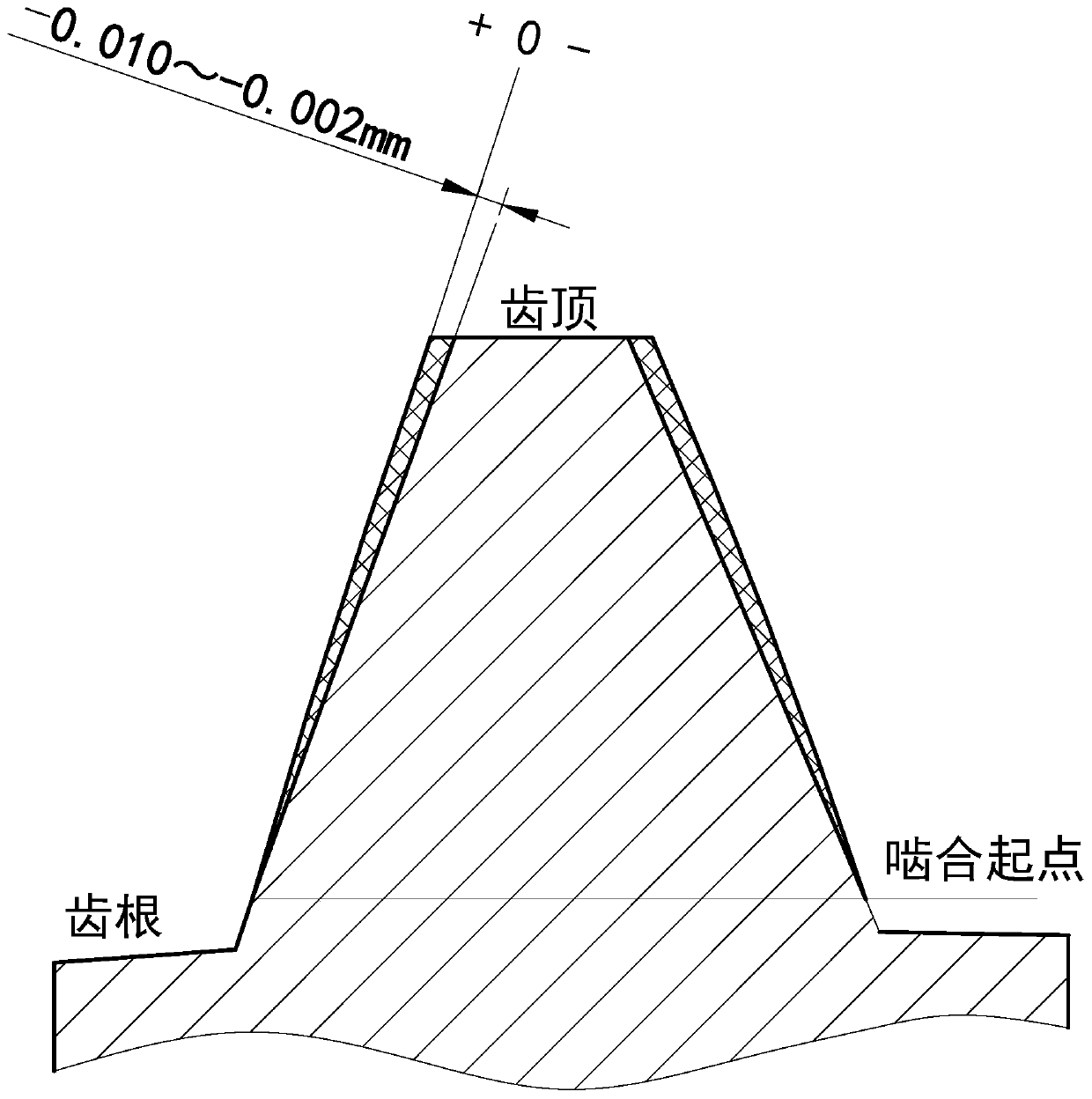

[0022] The modification of the large gear is mainly to modify the helix and tooth profile of the tooth. Helical line modification scheme such as figure 2 Shown: In the direction of the helical line of the tooth surface, except for the control of the total helical line error, the 80% area in the middle of the helix line is gradually gentle and the drum shape repairing amount is 0.012-0.018mm; the tooth profile modification scheme is as follows image 3 Shown: It is on the tooth profile surface, from the mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com