A shaft coupling for a rolling mill

A technology for couplings and rolling mills, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc. Problems such as cracking of the cross shaft of the coupling and shortening the service life of the universal coupling have been achieved to overcome the effects of being susceptible to corrosion, enhancing the balance of the transmission, and having a large amount of axial adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

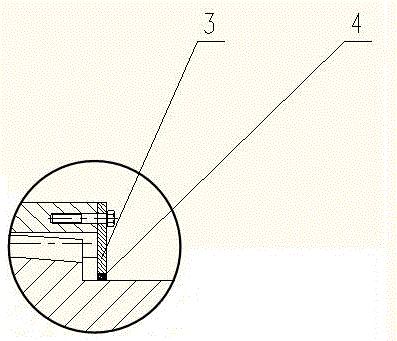

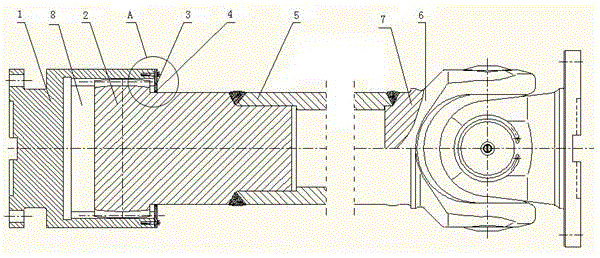

[0026] For ease of description, the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, a coupling for a rolling mill of the present invention includes a sleeve inner tooth flange 1, a sleeve drum-shaped outer tooth adapter 2 and a single-section cross cardan shaft 6 with a fork 7, and the sleeve inner teeth The inner teeth of the flange 1 are meshed with the sleeve drum-shaped outer gear handle 2, and the end of the sleeve drum-shaped outer gear handle 2 away from the sleeve inner gear flange 1 is fixed with a connecting pipe for adjusting the length of the coupling 5, and the end of the connecting pipe 5 away from the sleeve drum-shaped external gear handle 2 is fixedly connected to the fork 7 of the single-section cross cardan shaft 6 .

[0028] Wherein, in the above-mentioned embodiment, the connecting pipe 5 is welded to the fork 7 of the single-section cross cardan shaft 6 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com