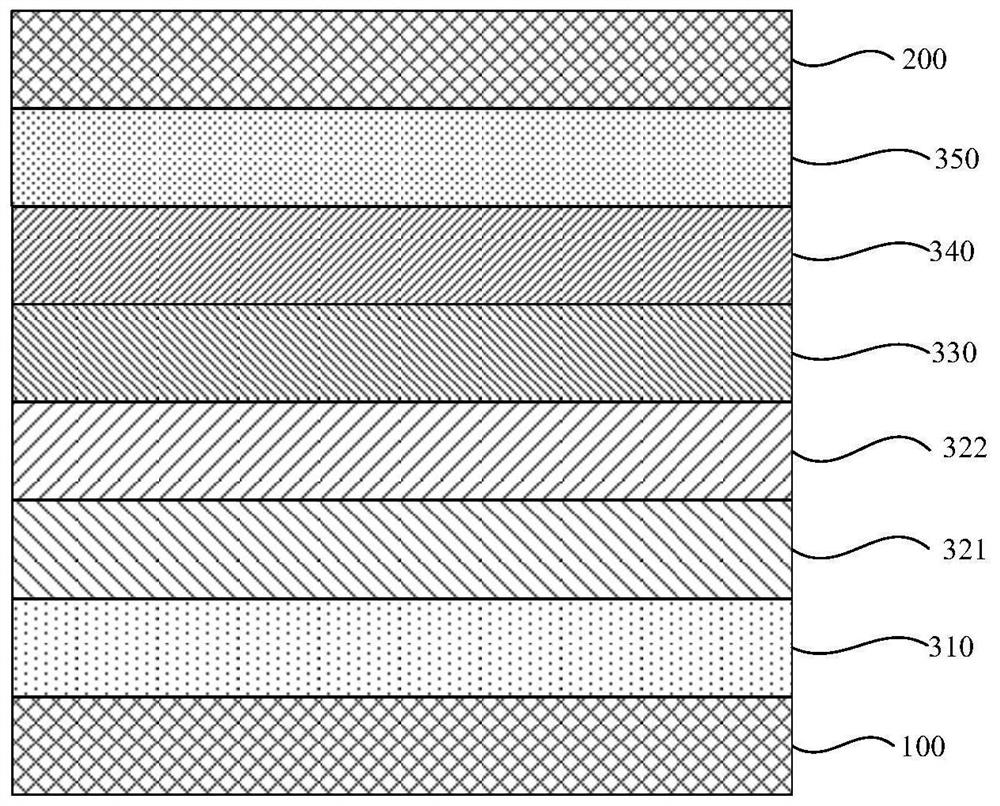

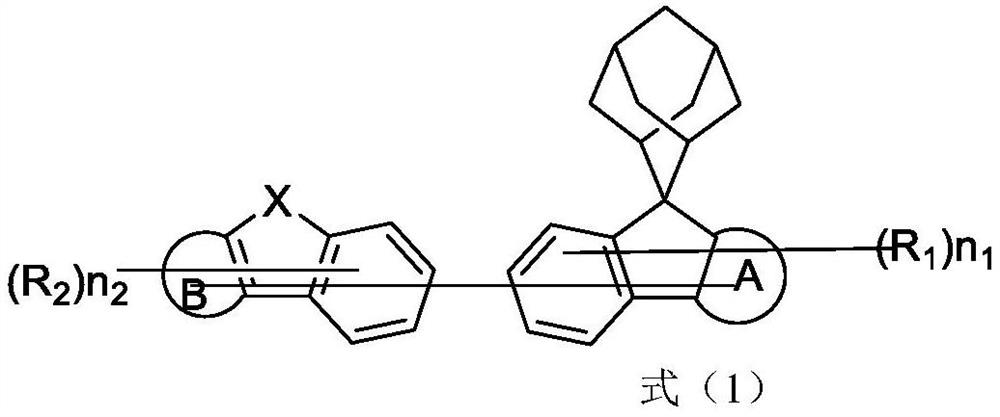

Compound, organic electroluminescent device and electronic device

A compound and chemical formula technology, applied in the field of organic electroluminescent materials, can solve the problems of short luminous life and low luminous efficiency, and achieve the effects of increasing recombination rate, improving efficiency performance, and reducing π-π stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0236]In the synthesis examples described below, all temperatures are in degrees Celsius unless otherwise stated. Some reagents were purchased from commercial suppliers such as Aldrich Chemical Company, Arco Chemical Company and Alfa Chemical Company, and some intermediates that could not be directly purchased were prepared from commercially available raw materials through simple reactions. Unless otherwise stated, they were used without further purification. The rest of the conventional reagents are from Shantou Xilong Chemical Factory, Guangdong Guanghua Chemical Reagent Factory, Guangzhou Chemical Reagent Factory, Tianjin Haoyuyu Chemical Co., Ltd., Tianjin Fuchen Chemical Reagent Factory, Wuhan Xinhuayuan Technology Development Co., Ltd., Qingdao Tenglong It can be purchased from Chemical Reagent Co., Ltd. and Qingdao Ocean Chemical Factory. Anhydrous tetrahydrofuran, dioxane, toluene, ether and other anhydrous solvents are obtained by reflux drying of metal sodium. The r...

preparation example 1-13

[0243] 1. Synthesis of intermediate a-1

[0244]

[0245] 2-Bromo-4-chloro-1-iodobenzene (80.0 g; 252.1 mmol), phenylboronic acid (33.8 g; 277.3 mmol), tetrakis(triphenylphosphine)palladium (5.8 g; 5.0 mmol), potassium carbonate ( 76.5g; 554.6mmol), tetrabutylammonium bromide (16.2g; 50.4mmol) were added in the flask, and a mixed solvent of toluene (640mL), ethanol (320mL) and water (160mL) was added, under nitrogen protection, the temperature was raised to 80°C, keep the temperature and stir for 8 hours; cool to room temperature, stop stirring, wash the reaction solution with water, separate the organic phase, dry with anhydrous magnesium sulfate, remove the solvent under reduced pressure, and obtain the crude product; use n-heptane as the mobile phase crude product for silica gel column After chromatographic purification, intermediate a-1 (40.5 g; yield 60%) was obtained as a light gray solid product.

[0246] Using a method similar to the synthesis of intermediate a-1, ...

preparation example 2-14

[0297] Table 9: Preparation Examples 2-14

[0298]

[0299]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com