Step-by-step type arc-shaped nail bin

A step-by-step, staple cartridge technology, applied in the field of medical devices, can solve problems such as poor suture effect, reduced degree of cavity curvature, difficulty in forming a circular channel, etc., and achieve the effect of improving suture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

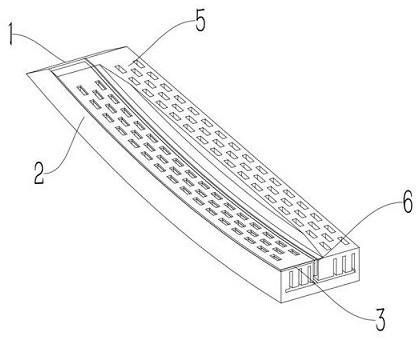

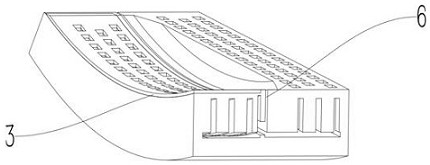

[0031] Embodiment one: see Figure 1-3 as shown,

[0032]The step-by-step arc-shaped nail cartridge provided in this embodiment includes a staple cartridge body 1, and the staple cartridge body 1 includes a first closing portion 2, and the first closing portion 2 is used to communicate with the stopper extending into the cavity. The plate fits and sutures the cavity under pressure, and makes the cross-sectional shape of the portion of the cavity that cooperates with the first closing part 2 be arc-shaped during sewing. The step-by-step arc-shaped staple cartridge includes a staple cartridge body 1, and the staple cartridge body 1 includes a first closing portion 2. When the staple cartridge is used to suture the cavity, the portion of the cavity that needs to be formed is placed in the first closing portion. On the closing part 2, a baffle that matches the first closing part 2 is inserted into the patient's cavity, so that the first closing part 2 and the baffle interact to a...

Embodiment 2

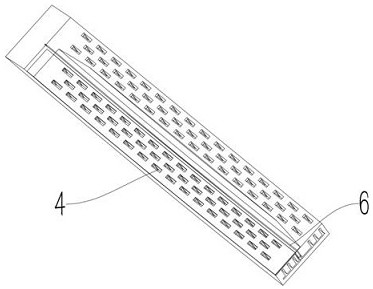

[0035] Embodiment two: see Figure 1-3 as shown,

[0036] The difference between this embodiment and Embodiment 1 is that: the first closure part 2 is provided with several first placement holes 4, the first placement holes 4 are used to place staples, and the first placement holes 4 are Multiple rows are arranged, and each row includes several first placement holes 4 , gaps are formed between the first placement holes 4 in the same row, and the gaps in adjacent rows are staggered. Several first placement holes 4 are provided on the first closure part 2, and the staples are placed in the first placement holes 4. When the cavity is sutured, the staples in the first placement holes 4 are pushed out of the first closure. part 2, and the first placement holes 4 are provided in multiple rows, so that when the staples in two adjacent first placement holes 4 on the same row are used to suture the cavity tissue, there is a gap between the two staples so that The tissue at this place...

Embodiment 3

[0038] Embodiment three: see Figure 1-3 as shown,

[0039] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: the staple cartridge body 1 further includes a second closing portion 5, and the second closing portion 5 is used for applying pressure to suture the lumen. The staple cartridge body 1 also includes a second closing portion 5, which can pressurize and sew the cavity. Suture, and make the first closing part 2 suture the cavity that needs to form the channel, and the second closing part 5 closes and sutures another part of the cavity, and the cavity tissue of the closed suture is convenient to take out from the cavity forming the channel At the same time, the blood loss at the incision of the cavity tissue is effectively reduced.

[0040] As a preferred embodiment, on the basis of the above method, further, the surface of the second closing part 5 for matching with the cavity is a plane. In the operation of suturing the cavity and takin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com