Lithium ion battery self-supporting silicon-based anode material with multilayered film and preparation method of anode material

A silicon-based anode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low area specific capacity and complex preparation process, achieve high area specific capacity, improve mass specific capacity, Mitigate the effect of capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

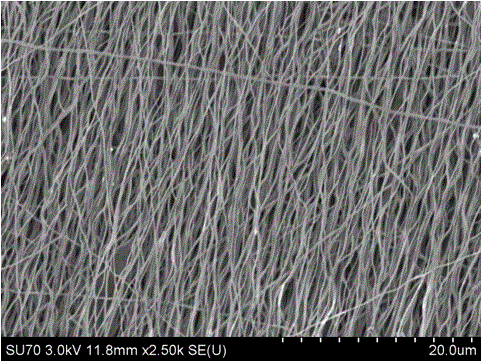

Image

Examples

preparation example Construction

[0024] The preparation method of the lithium-ion battery self-supporting silicon-based negative electrode material of multilayer thin film comprises the following steps:

[0025] 1) Disperse the high molecular polymer in an organic solvent, magnetically stir for 18 to 48 hours and then ultrasonically treat it for 30 to 60 minutes to obtain a 5 to 15wt% high molecular polymer solution;

[0026] 2) Disperse the high molecular polymer and nano-silica powder with a mass ratio of 1:1~12:1 in the same organic solvent, magnetically stir for 18~48 hours, and ultrasonically treat for 30~60 minutes to obtain the high molecular polymer and Nano silicon powder dispersion;

[0027] 3) Electrospinning is carried out using a coaxial spinning device. The inner tube is a dispersion of high molecular polymer and nano-silica powder, and the outer tube is a high molecular polymer solution. First, inject the high molecular polymer solution for 40 minutes. Stop the injection, start injecting the h...

Embodiment 1

[0031] 1) Dissolve 1.5g of polyacrylonitrile in dimethyl diamide, stir it magnetically for 24 hours and then sonicate it for 30 minutes to obtain an 8wt% polymer solution;

[0032] 2) Disperse nano-silica powder and polyacrylonitrile in the same organic solvent, magnetically stir for 24 hours and then ultrasonically treat for 30 minutes to obtain a dispersion of high molecular polymer and nano-silica powder;

[0033] 3) Prepare multi-layer films by spinning with an electrospinning machine: adjust and set appropriate positive high voltage 18Kv, negative high voltage -2kV, ambient temperature 30 oC, the humidity is 40%, and the high-speed directional attachment is selected as the receiving device. Using a coaxial spinning device, the inner tube is a high molecular polymer and nano silicon powder dispersion, and the outer tube is a high molecular polymer solution. The distance from the nozzle of the coaxial spinning device to the receiving device is 15 cm. First inject the high...

Embodiment 2

[0038] 1) Dissolve 1.5g of polyvinylpyrrolidone in dimethyl diamide, stir it magnetically for 24 hours and then sonicate it for 30 minutes to obtain a 5wt% polymer solution;

[0039] 2) Disperse nano-silica powder and polyvinylpyrrolidone in the same organic solvent, magnetically stir for 24 hours, and then ultrasonically treat for 30 minutes to obtain a dispersion of high molecular polymer and nano-silica powder;

[0040] 3) Prepare multi-layer films by spinning with an electrospinning machine: adjust and set appropriate positive high voltage 15Kv, negative high voltage -2kV, ambient temperature 40 o C, the humidity is 40%, and the high-speed directional attachment is selected as the receiving device. Using a coaxial spinning device, the inner tube is a high molecular polymer and nano silicon powder dispersion, and the outer tube is a high molecular polymer solution. The distance from the nozzle of the coaxial spinning device to the receiving device is 10 cm. First inject t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com