Patents

Literature

141results about How to "Higher quality than capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

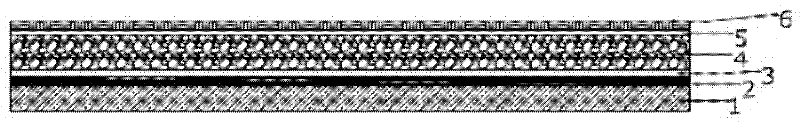

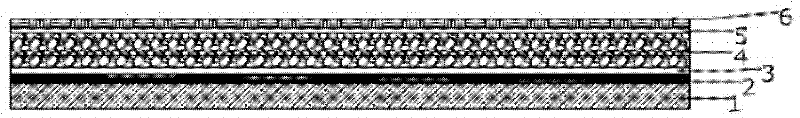

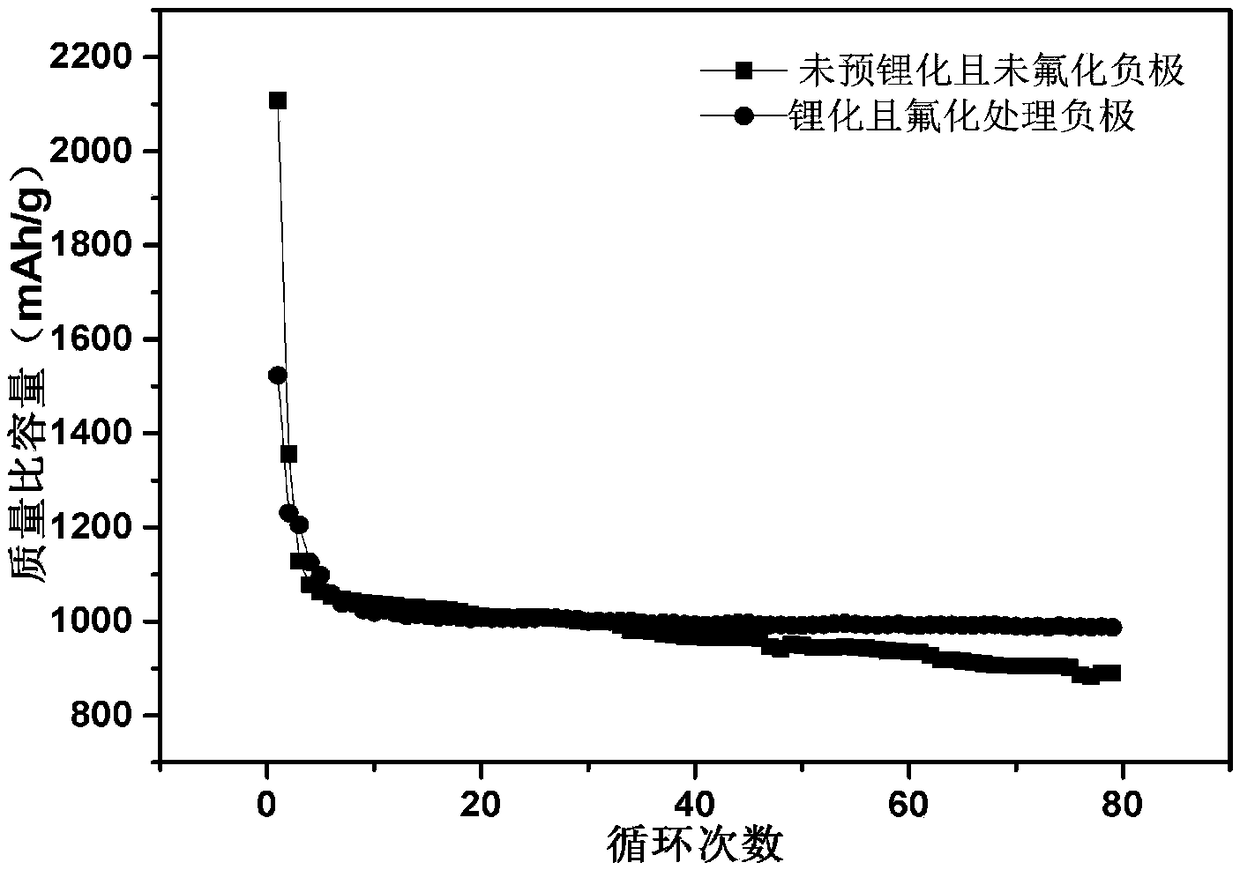

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

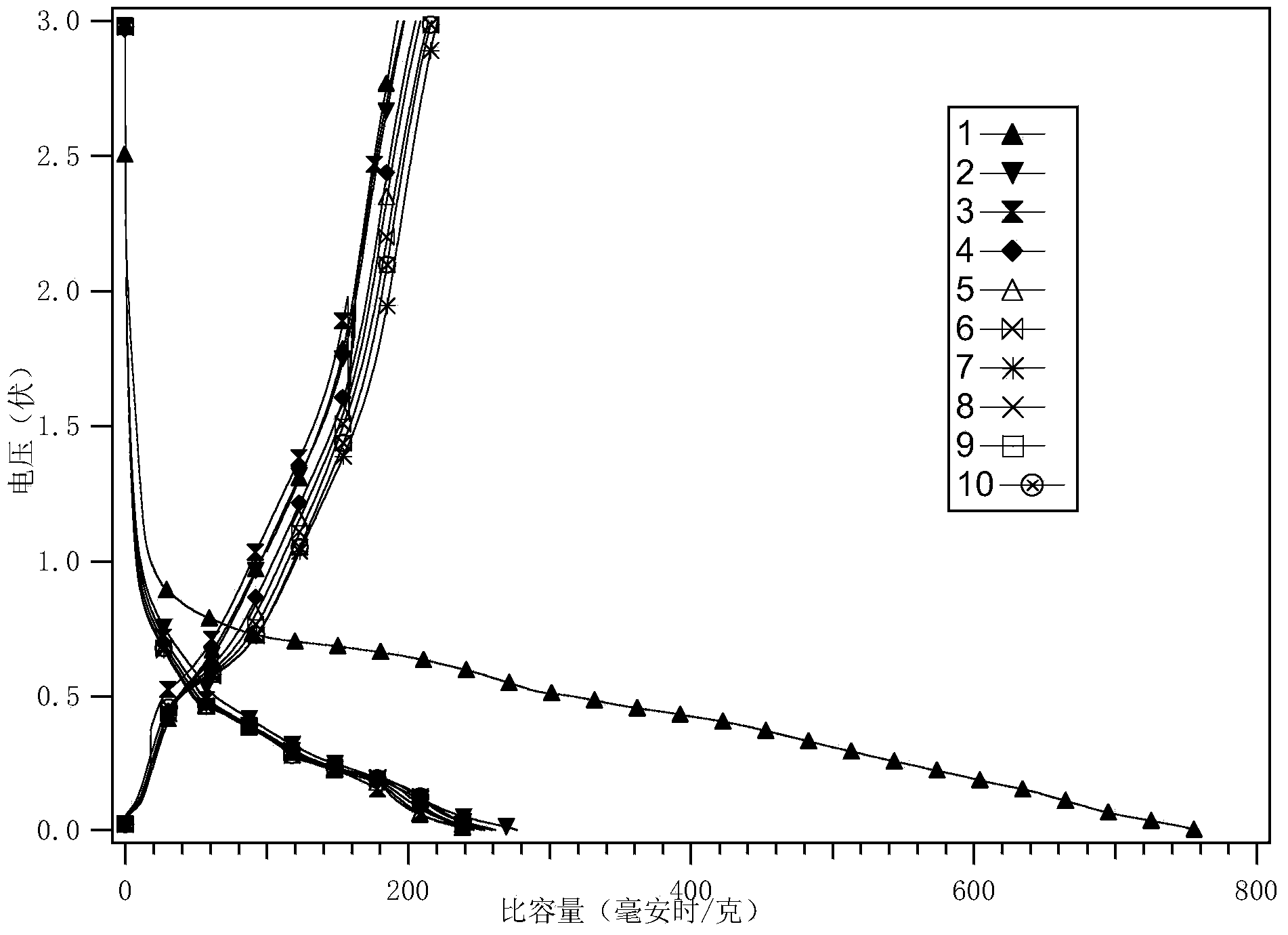

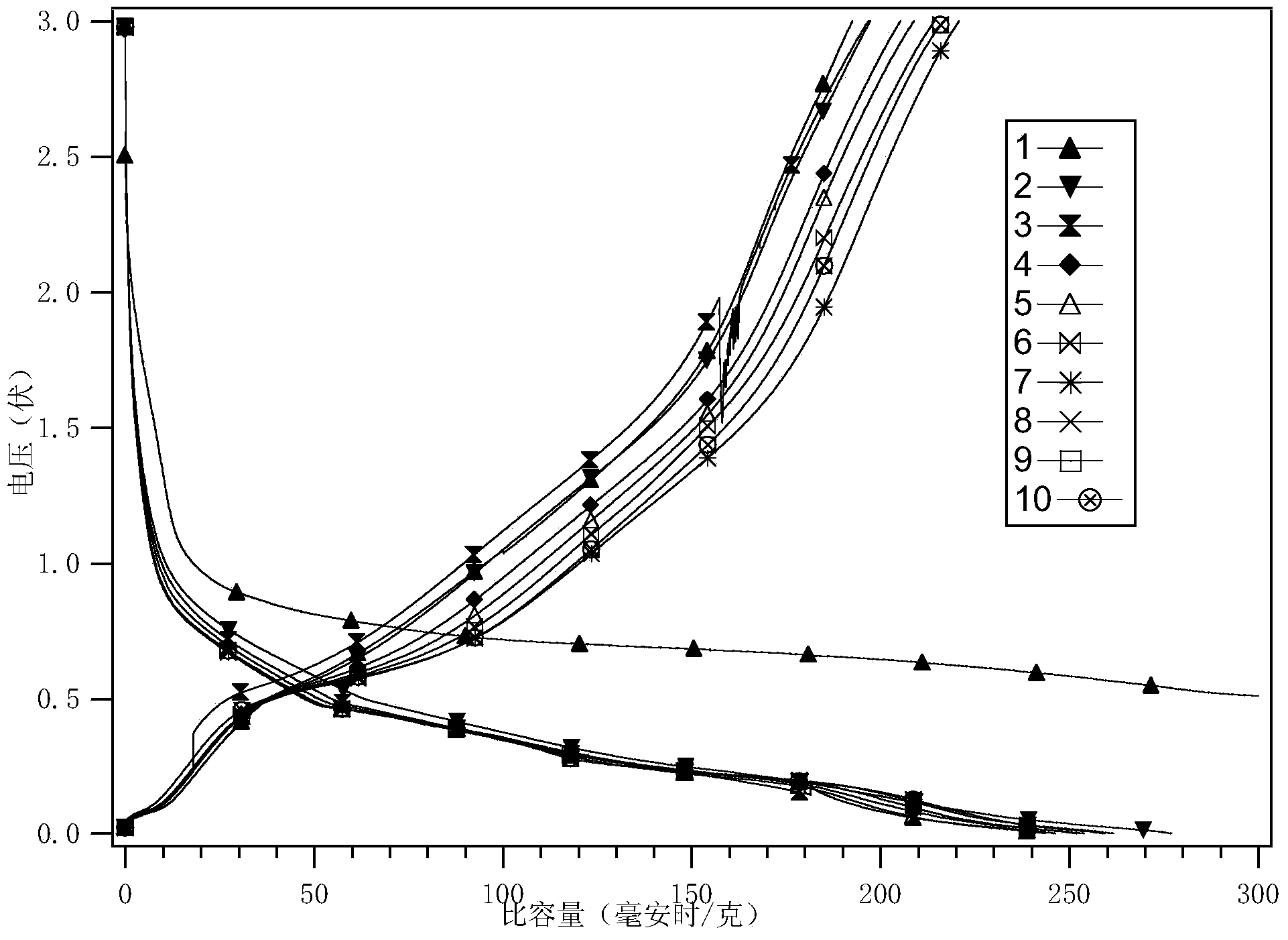

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

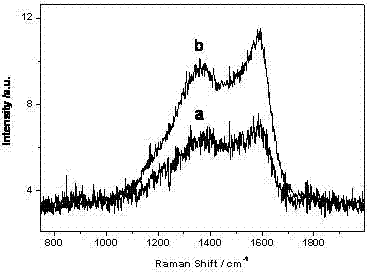

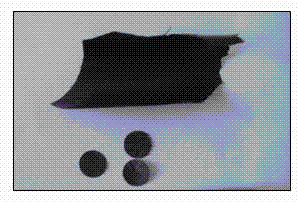

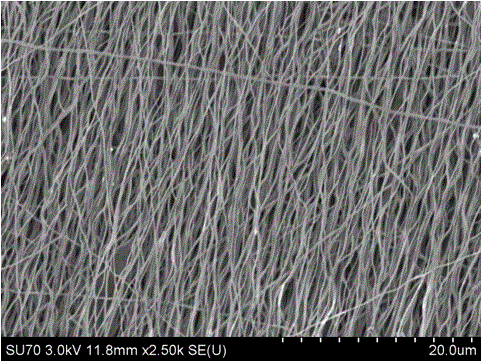

Preparation method for flexible graphene-modified knittable carbon nanofiber

InactiveCN103569997AImprove conductivity uniformityReduced electrode polarization effectMaterial nanotechnologyCell electrodesDimethyl formamideChemical industry

A preparation method for a flexible graphene-modified knittable carbon nanofiber belongs to the technical field of chemical industry. The preparation method comprises the following steps: at first, graphene oxide is taken to be placed in a container filled with DMF (Dimethyl Formamide) to obtain a graphene oxide saturated solution with the brown-yellow upper layer, then, polyacrylonitrile macromolecules are dissolved in the DMF to obtain a transparent macromolecular solution, the graphene oxide saturated solution and the macromolecular solution are mixed to obtain a precursor solution, a grapheme-modified polyacrylonitrile fiber is obtained through the electrostatic spinning technology or the melt spinning technology, the drying and stabilizing are performed, and at last, the carbon nanofiber is prepared from the dried polyacrylonitrile fiber in the inert gas environment or the vacuum condition. The carbon nanofiber prepared by the method can be applicable to lithium ion batteries or electrochemical capacitors, and besides, is also applicable to the fields of the war industry and the aerospace.

Owner:NORTHEAST NORMAL UNIVERSITY

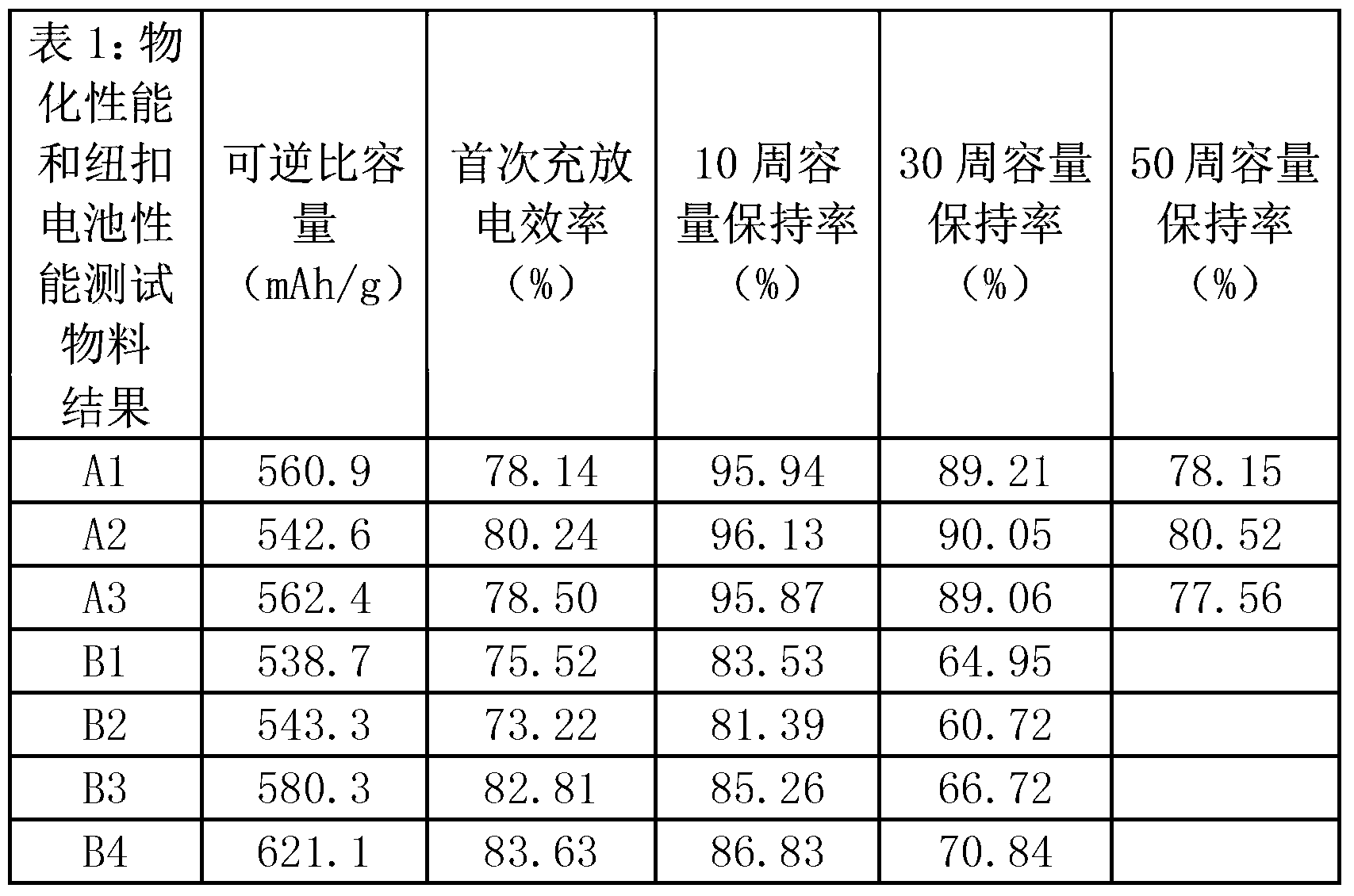

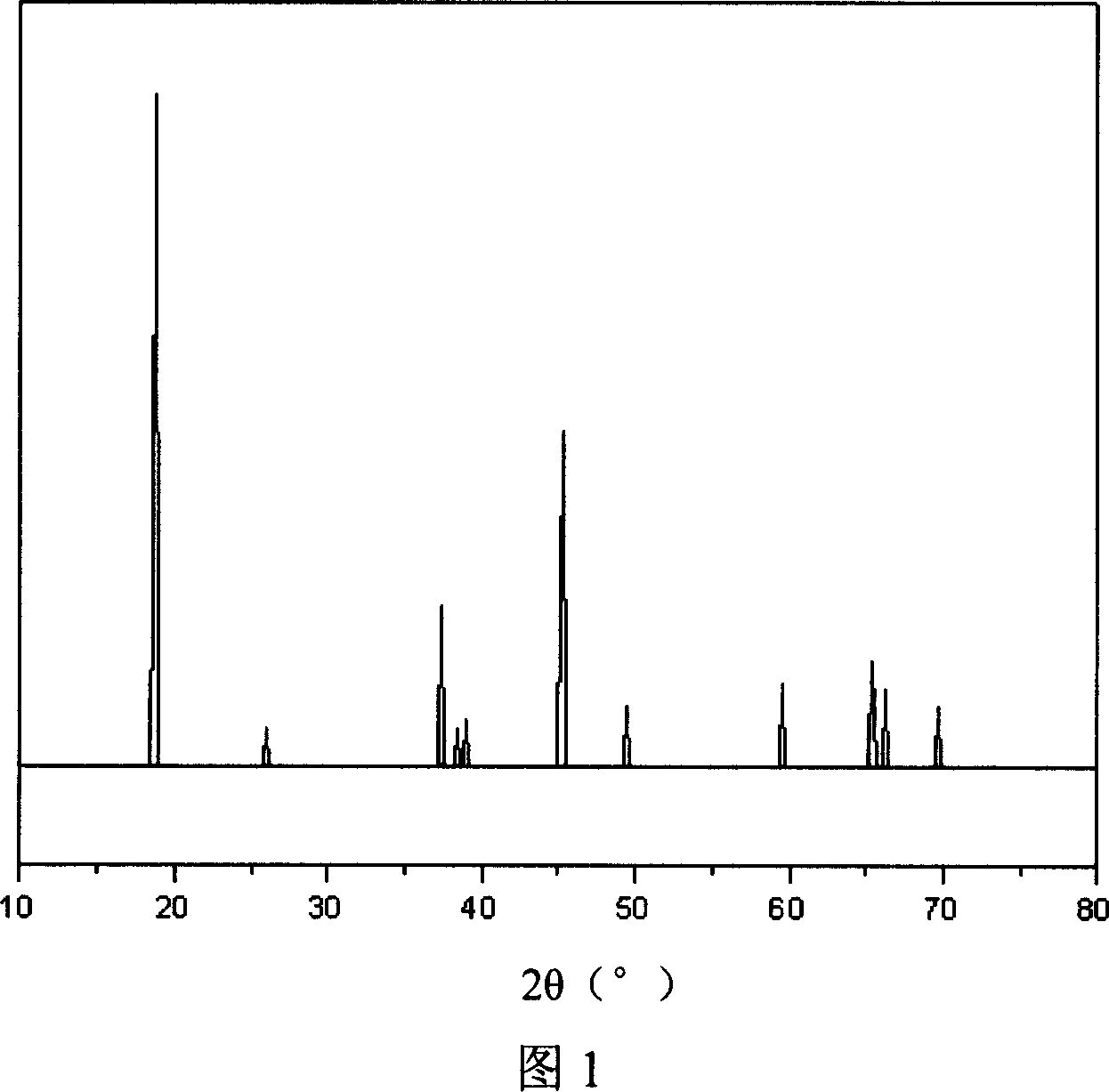

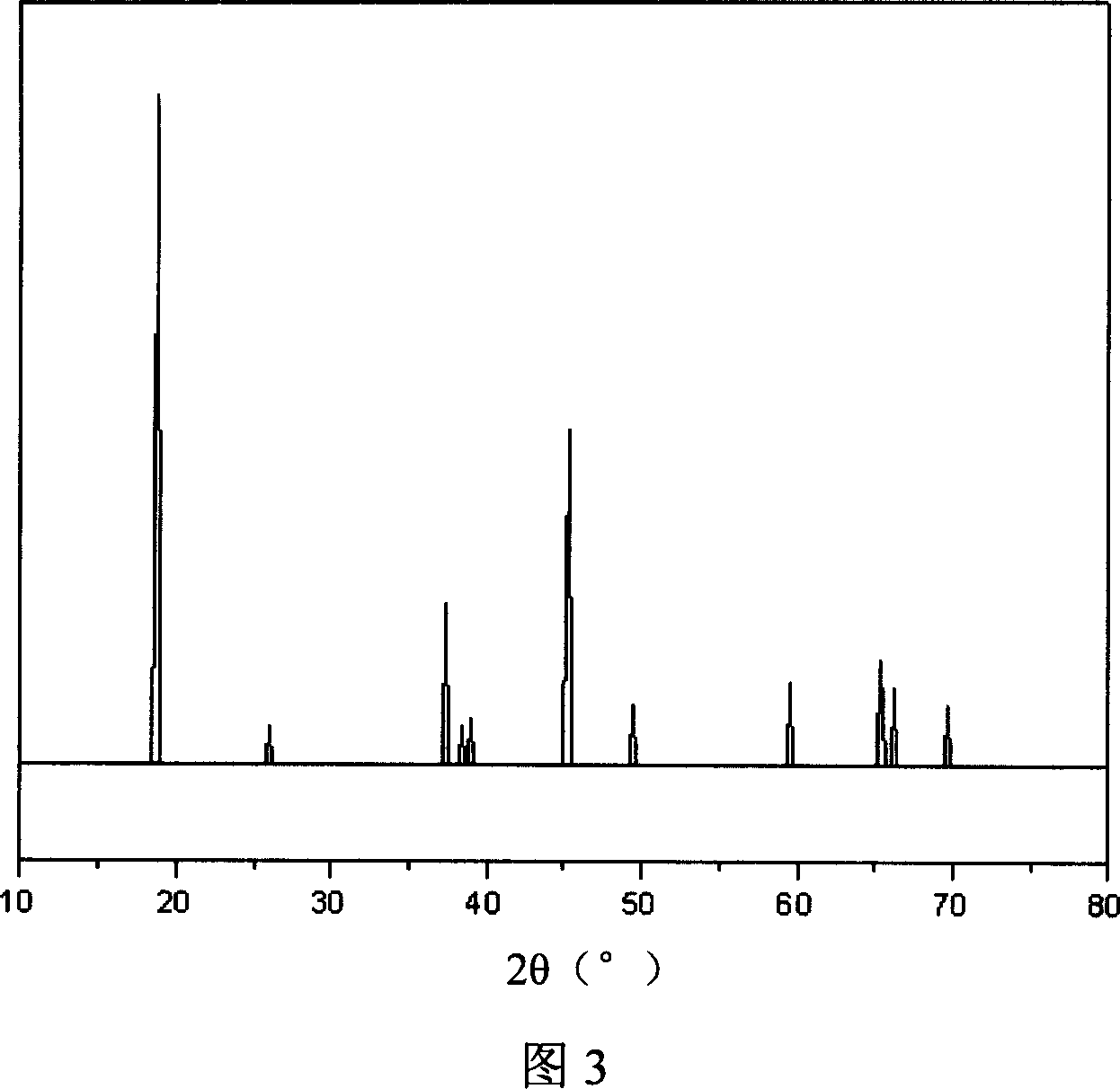

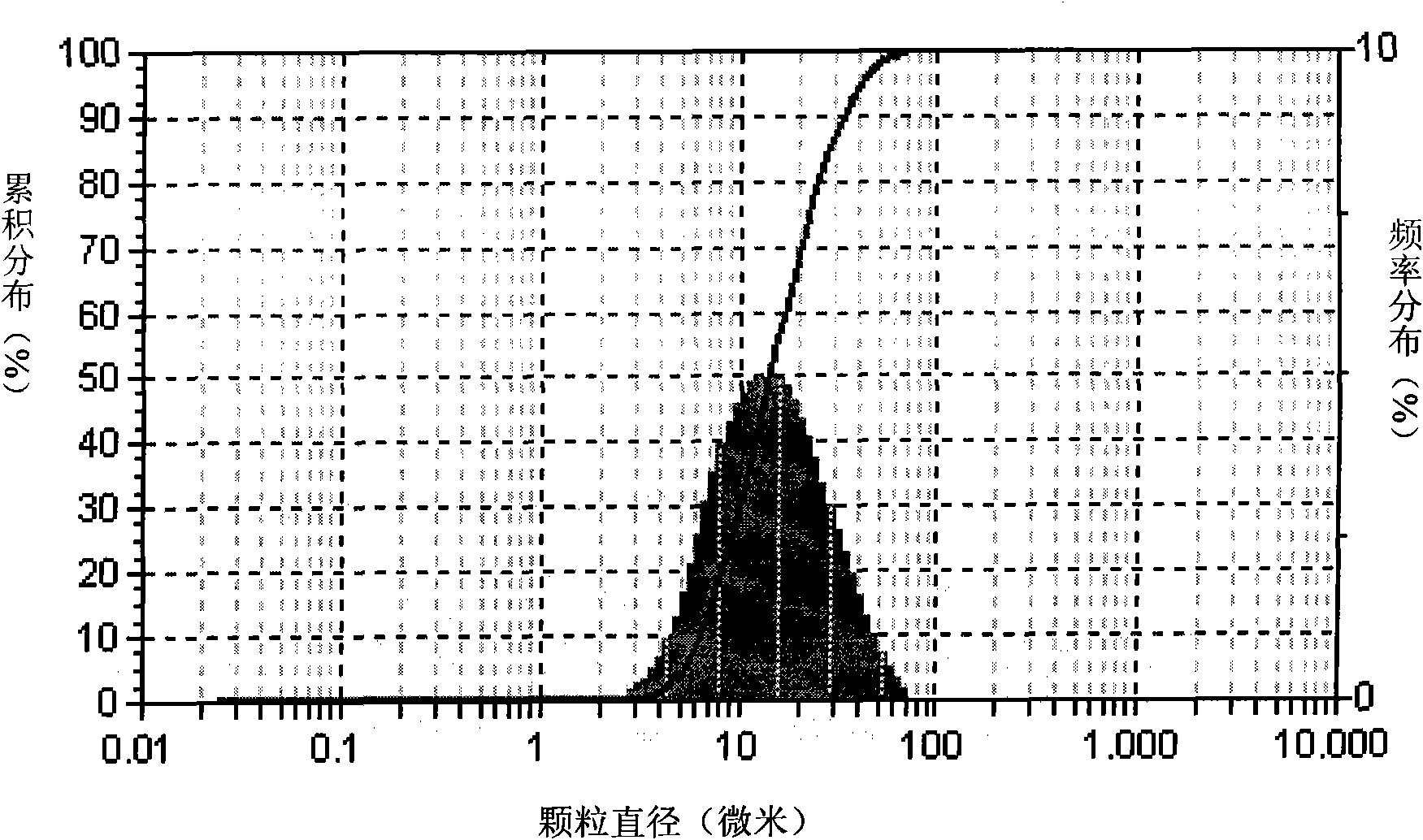

Preparation method of manganese-based compound positive pole material for secondary lithium ion battery

InactiveCN102820464AIncrease energy densityIncrease capacityCell electrodesChemistryCapacity efficiency

The invention provides a preparation method of a manganese-based compound positive pole material for a secondary lithium ion battery. The general constitution formula of the positive pole material is Li (LixMn2-x-yMy) O4 / Az, wherein x is more than or equal to 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 2, and z is more than or equal to 0 and less than or equal to 0.5; and M is a doped modified element, and A is an oxide of a coating element or a phthalocyanines large-ring transition metal complex. When the positive pole material is prepared, a lithium source and an M source are added into mixing equipment containing a medium and a dispersing agent to be mixed and dried; then the mixture and a manganese source are added into the mixing equipment containing the medium and the dispersing agent to be mixed and dried; then the new mixture is roasted and then is cooled to a room temperature; and the new mixture and an A source are added into the mixing equipment containing the medium and the dispersing agent to be mixed and dried, are roasted again, are cooled to the room temperature and are mixed and crushed to obtain the manganese-based compound positive pole material. The preparation method disclosed by the invention has the advantages of simple process, low raw material cost and processing cost, simple process route, short period and low energy consumption. The produced manganese-based compound positive pole material has the advantages of high energy density, mass specific capacity, power performance, high-temperature circulating performance and high-temperature storage performance; and the capacity efficiency of the material is high at -40 DEG C.

Owner:济宁市无界科技有限公司

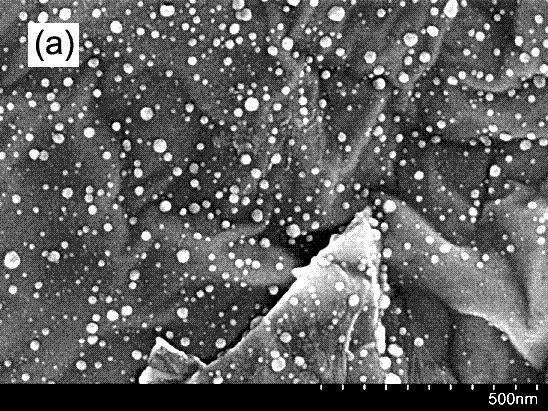

High-performance lithium ion battery silicon-carbon cathode material and preparation method thereof

The invention relates to a lithium ion battery high specific capacity silicon-carbon composite cathode material. The high-performance lithium ion battery silicon-carbon cathode material comprises a Si-SiOx / C / DC composite system with a specific surface area of 1-30 square meters per gram, wherein the composite system comprises C matrix, Si-SiOx compound stuck in the C matrix, carbon nanotube distributed in C matrix and Si-SiOx-C, and an organic pyrolytic carbon coating on the outermost layer. The high-performance lithium ion battery cathode material has high quality specific capacity, good cycle stability and long service life, and can be used as high energy density cell cathode material for portable mobile terminals and digital products.

Owner:ZHEJIANG WELLY ENERGY CORP

Anode material of lithium ion cell and preparation method thereof

ActiveCN101436666AImprove distributionEvenly distributedElectrode manufacturing processesCobalt compoundsLithium carbonatePhysical chemistry

The invention discloses a method for preparing lithium cobaltate positive pole material for a lithium ion cell and the obtained lithium cobaltate positive pole material. The method comprises the following steps: adopting a multiple-step synthesizing process; in a first synthesis, adopting excessive lithium so as to obtain larger lithium cobaltate particles at lower temperature; and before a second synthesis, adhering mixed powder of cobalt carbonate and lithium carbonate with small particle size and larger specific surface area to the one-step synthesized lithium cobaltate large particles through a mechanical granulation mode. The method can effectively improve the particle size and the tap density of the lithium cobaltate positive pole material so as to improve the compacted density and the volume specific capacity of the positive pole material.

Owner:广东风华新能源股份有限公司

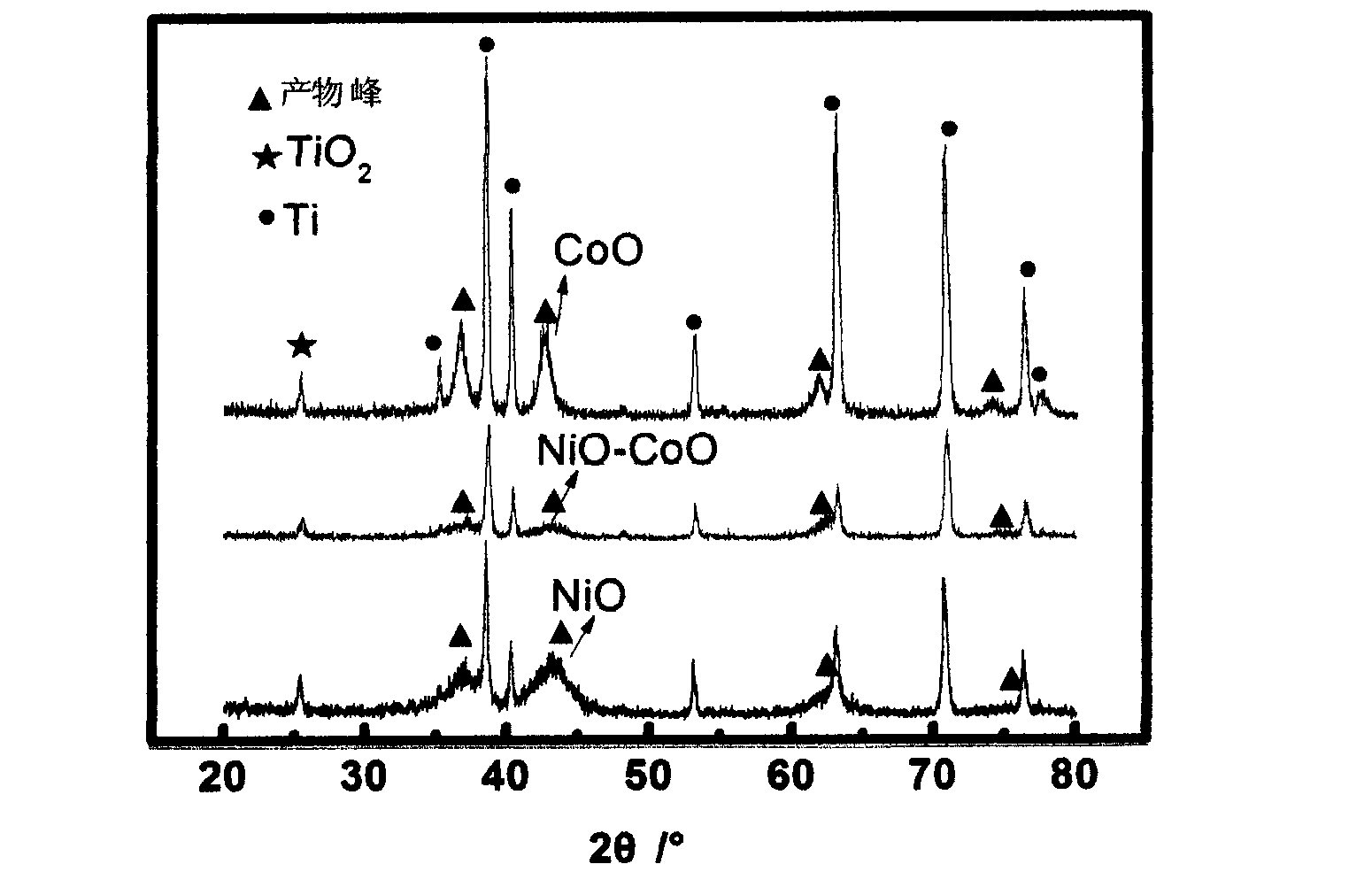

Cathode active substance for lithium ion battery, cathode material containing cathode active substance and lithium ion battery

InactiveCN102701160AHigher quality than capacityImprove conductivityTin compoundsCell electrodesAluminium-ion batterySodium-ion battery

The invention discloses a cathode ternary compound CuxMySz active substance for a lithium ion battery, a cathode material containing the substance and the lithium ion battery using the cathode material as a cathode. M in the chemical formula CuxMySz belongs to an IVB group, a VB group, a VIB group, a VIII group, an IIB group and an IVA group in a fourth period and a fifth period in periodic table of chemical element and is any one in metal elements of an IIIA group in third, fourth, fifth and sixth periods, such as Ti, Cr, Mo, Fe, Al, Ga, In, Tl, Sn and the like. The active substance has higher charge-discharge capacity which is about two times that of commonly used graphite material in the charge-discharge capacity, thereby being a novel lithium ion battery cathode material with good application prospect and high capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

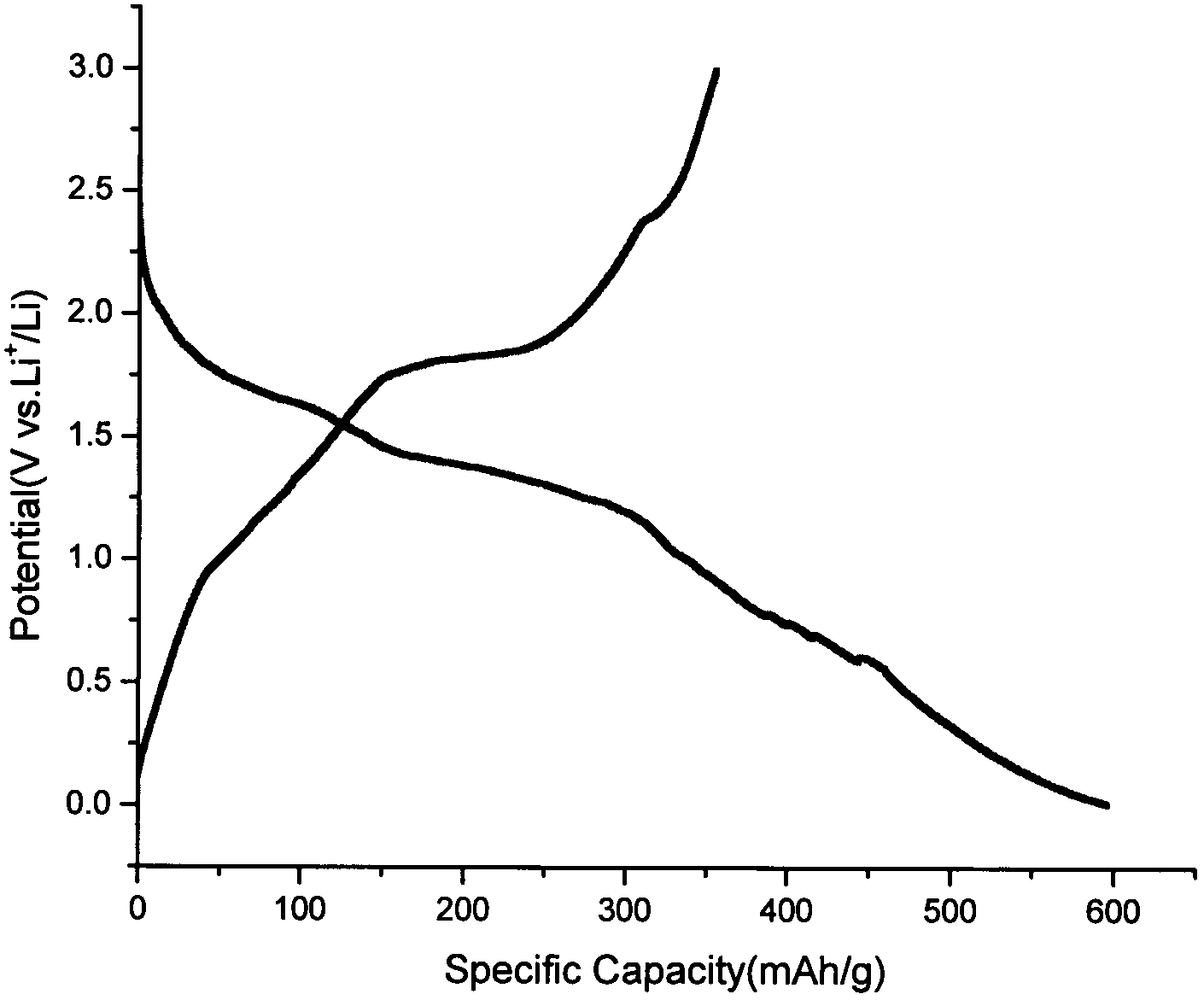

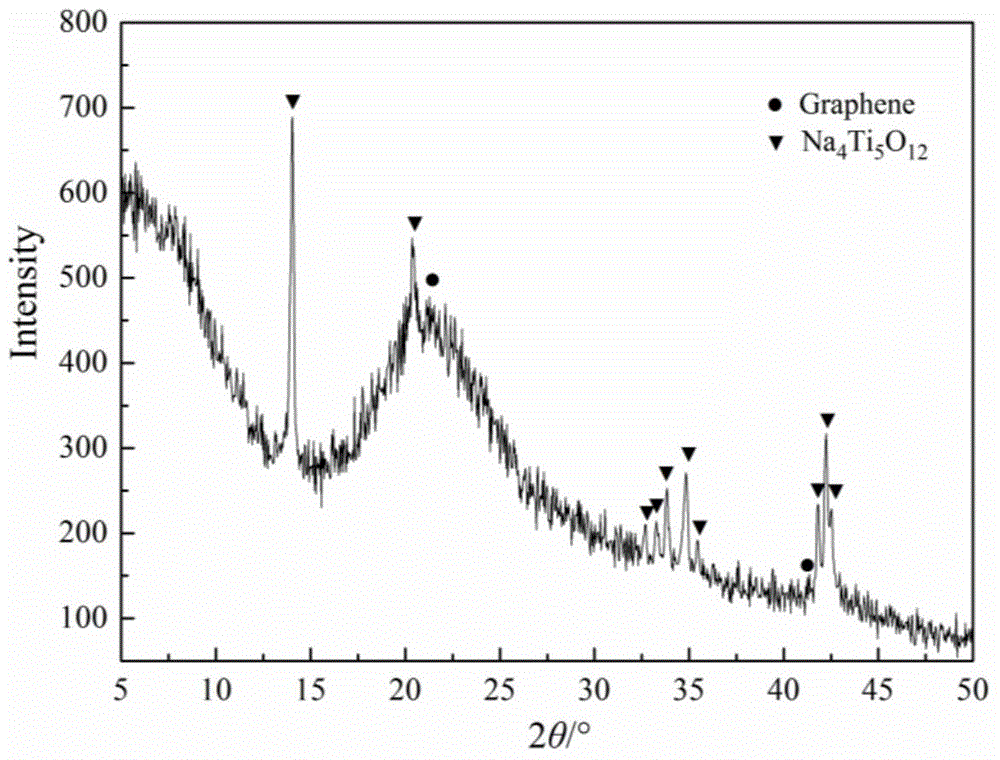

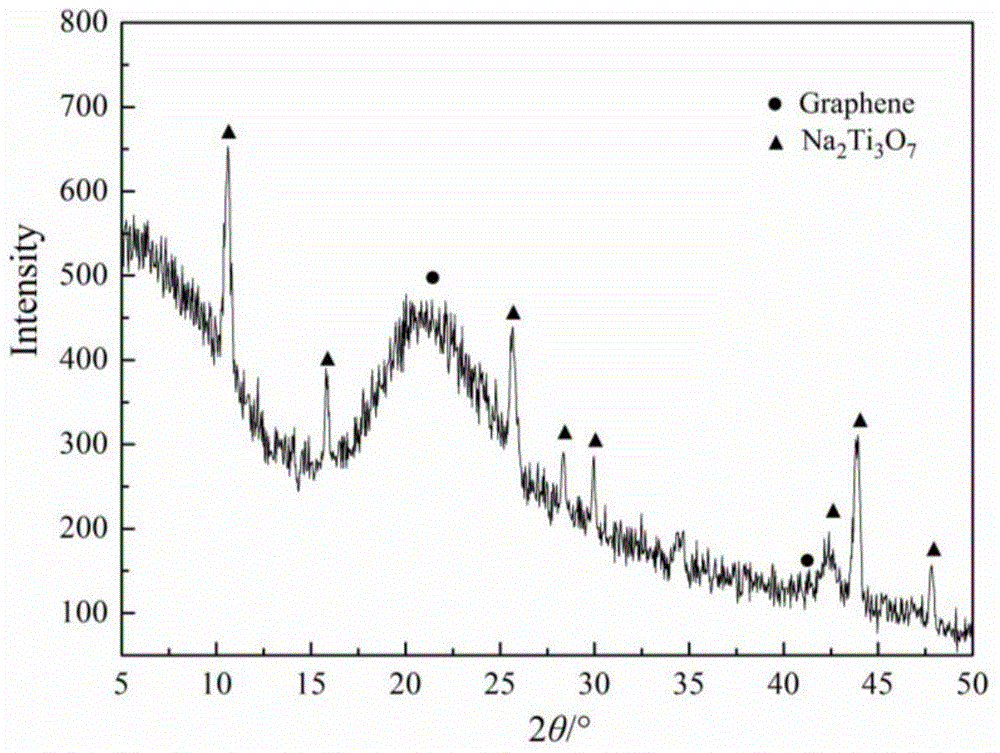

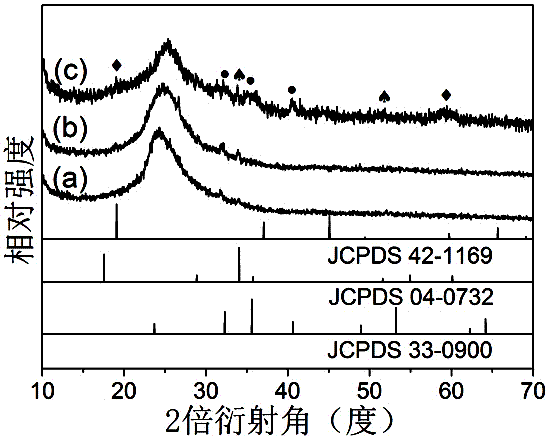

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

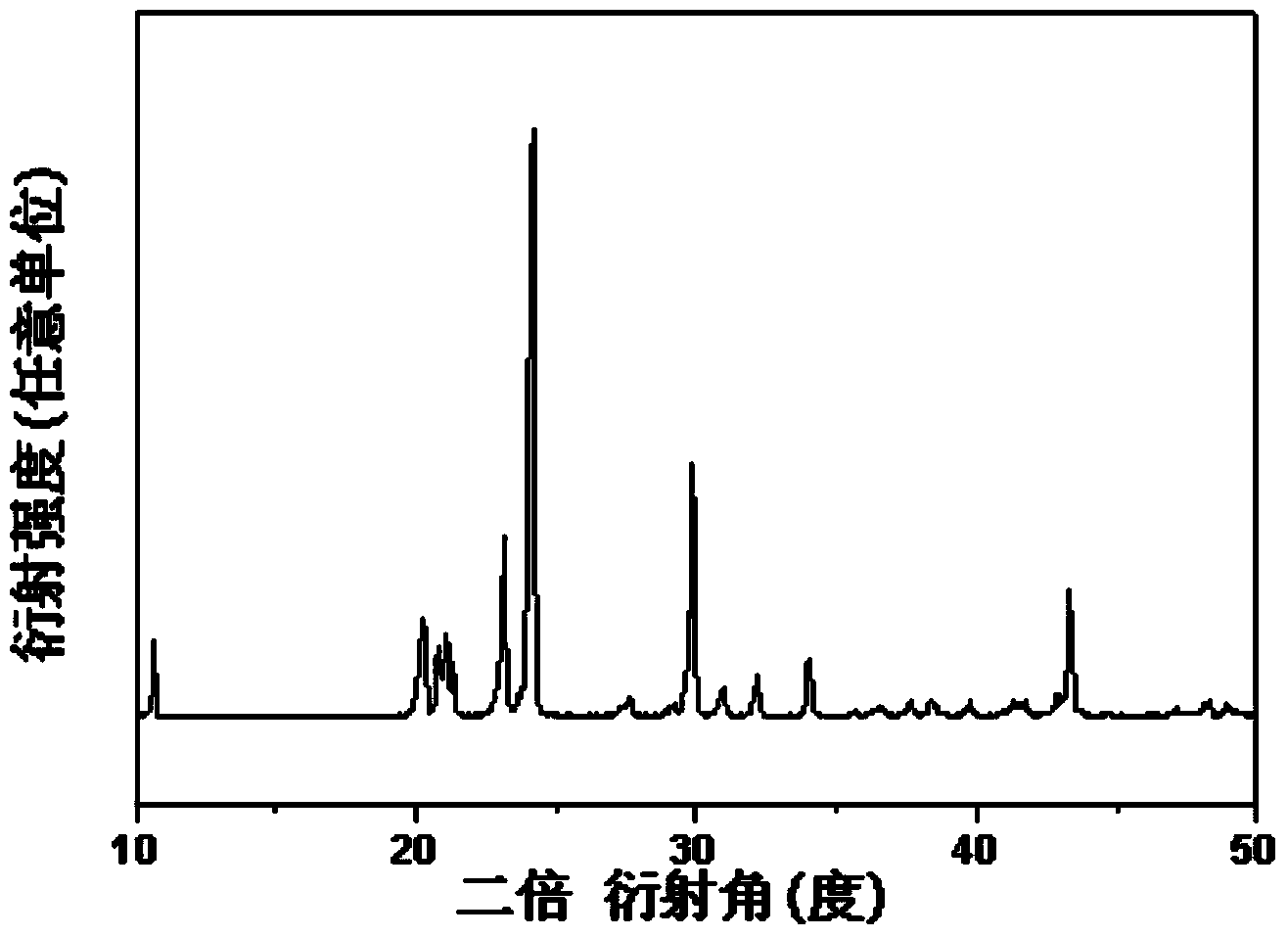

Sodium-ion intercalated Ti3C2 MXene material and preparation method thereof

ActiveCN109437172AMild preparation conditionsEasy to controlSecondary cellsNegative electrodesAluminiumLithium

The invention relates to a sodium-ion intercalated Ti3C2 MXene material and a preparation method thereof. The technical scheme includes that the preparation method includes the steps: matching materials titanium aluminum carbon powder, hydrochloric acid solution and lithium fluoride powder according to the weight ratio of (1.0-2.0):(2.0-4.0):1, performing water bath stirring in a polyethylene plastic container, and ultrasonically and centrifugally treating mixture to obtain solid I; alternately washing the solid I by the aid of deionized water and ethyl alcohol until liquid supernatant is neutral, and filtering mixture to prepare the Ti3C2 MXene material; placing the Ti3C2 MXene material into NaOH solution to perform water bath stirring, ultrasonically and centrifugally treating mixture, alternately washing the mixture by the aid of deionized water and ethyl alcohol until liquid supernatant is neutral, and performing vacuum drying to prepare the sodium-ion intercalated Ti3C2 MXene material. The preparation method has the advantages of mild preparation condition and easiness in control, and the prepared sodium-ion intercalated Ti3C2 MXene material is wide interlayer spacing and large in specific surface area and has higher mass specific capacity when being applied to lithium and sodium ion batteries.

Owner:WUHAN UNIV OF SCI & TECH

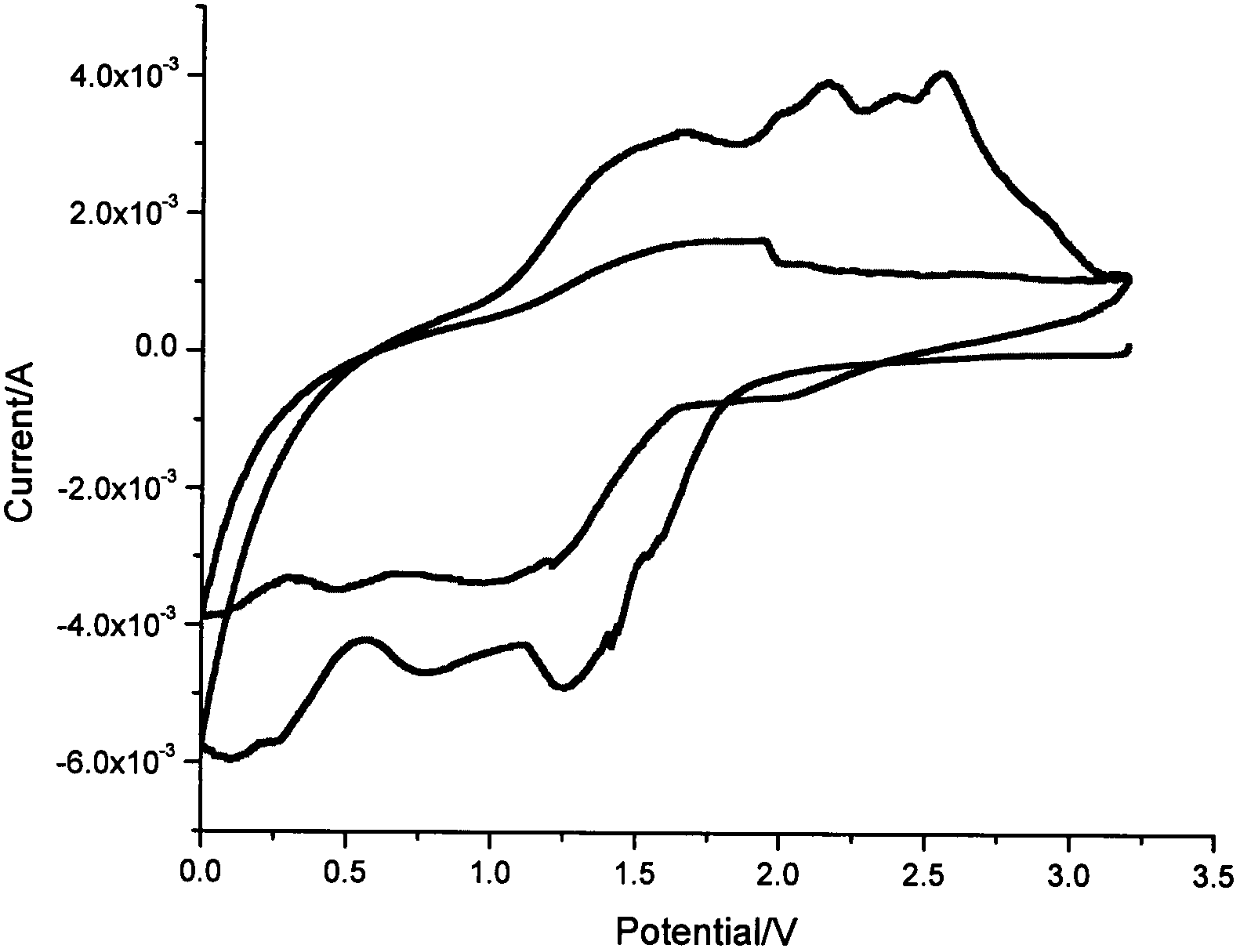

Organic cathode material for sodium ion battery

InactiveCN103456961AThe synthesis method is simpleReduce manufacturing costCell electrodesIonCharge and discharge

The invention discloses an organic cathode material for a sodium ion battery capable of being repeatedly charged and discharged, and belongs to the field of batteries. According to the organic cathode material for the sodium ion battery disclosed by the invention, an active substance of the organic cathode material is para-phthalate or a mixture of different para-phthalates; the chemical composition of the para-phthalate is C8H4O4.Rx, wherein R is Li, K, Rb, Cs, Mg, Ca, Sr, Ba, Ni, Cu, Sn, Fe, Zn, Cr, Al or Mn, and x is equal to 2 / 7, 1 / 3, 2 / 5, 1 / 2, 2 / 3, 1 or 2. The organic cathode material disclosed by the invention has low reaction potential, high quality specific capacity and excellent electrochemical cycle stability, and is simple in synthetic method and good in repeatability; the production cost is reduced, the requirement of sustainable development is met, and the organic cathode material has a wide application prospect in the field of sodium ion batteries.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparing process for positive electrode active material/carbon composite material of Li-ion battery

ActiveCN1990144AHigher quality than capacityHigh charge and discharge capacityElectrode manufacturing processesCarbon compositesEpoxy

A preparing method of lithium-ion battery positive active material / carbon composite material, the method includes: dissolving the carbon coated materials into solvent to getting the carbon coated materials solvent, then mixing and adglutinating the carbon coated materials solvent and the lithium-ion battery positive active material, said carbon coated materials are chosen on or more from sucrose, glucose, starch, lactose, sorbitol, maltose, phenolic resin, furfural resin, urea formaldehyde resin, polyvinyl alcohol, dene PTFE, polyacrylamide, water-soluble epoxide resin, said solvent is chosen one or more of water, acetone, ethanol and carbinol, said agglutination is processed in inert atmosphere. The quality and specific capacity of the lithium-ion battery complex positive material prepared through the method in the invention is higher, the multiplying power battery charging capability is good, it can be used to button, cylindrical and square lithium ion batteries widely.

Owner:BYD CO LTD

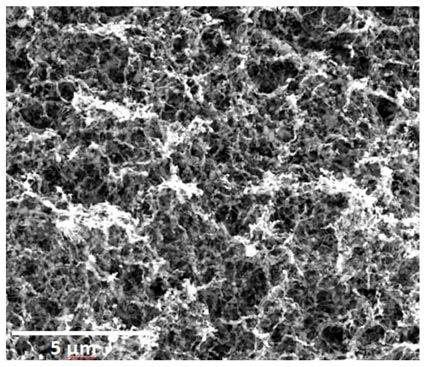

Preparation method of Ti3C2 MXene nano sheet material

ActiveCN111153405AEasy to operateShort timeMaterial nanotechnologyCell electrodesFreeze-dryingEngineering

The invention discloses a preparation method of a Ti3C2MXene nano sheet material. The preparation method comprises the following steps: step one, adding titanium-aluminum-carbon powder, a hydrofluoricacid solution and hexadecyl trimethyl ammonium bromide into a corrosion-resistant container, and stirring at 20-60 DEG C for 6-60 hours to obtain a CTAB (cetyl trimethyl ammonium bromide) intercalated Ti3C2 mixed solution; step two, carrying out a centrifugal treatment on the CTAB intercalation Ti3C2 mixed solution, washing with water until the supernate is neutral, filtering, and saving the precipitate namely a CTAB intercalation Ti3C2 multilayer material; and step three, adding water into the CTAB intercalated Ti3C2 multilayer material, carrying out an ultrasonic treatment for 30-120 minutes, and carrying out freeze-drying to obtain a CTAB intercalated Ti3C2 nano sheet powder material. The invention further discloses a Ti3C2MXene nano sheet material. The method has the beneficial effects of simple operation conditions, economy and high efficiency.

Owner:WUHAN UNIV OF SCI & TECH

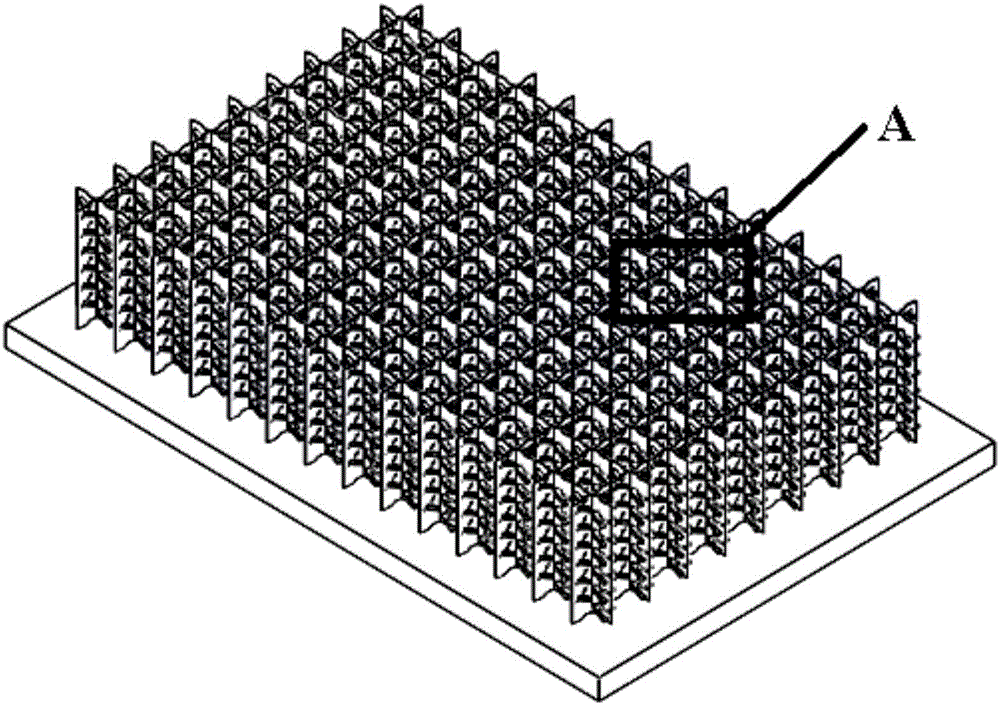

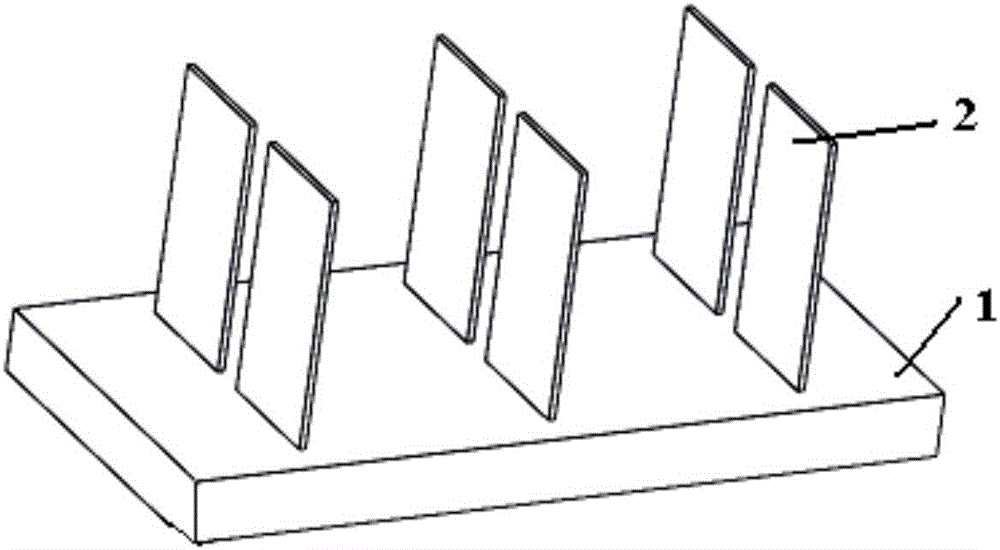

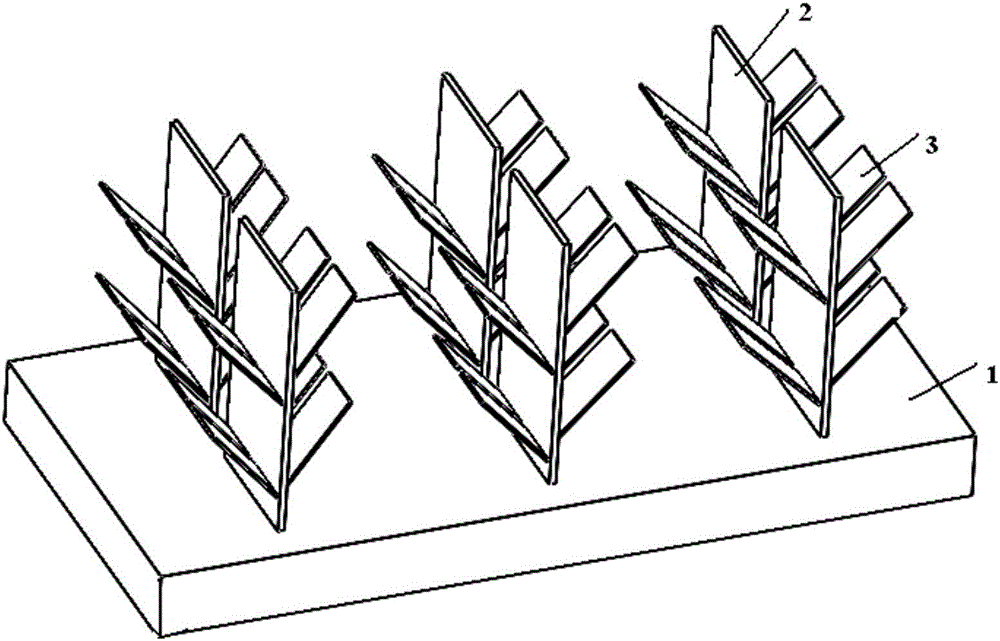

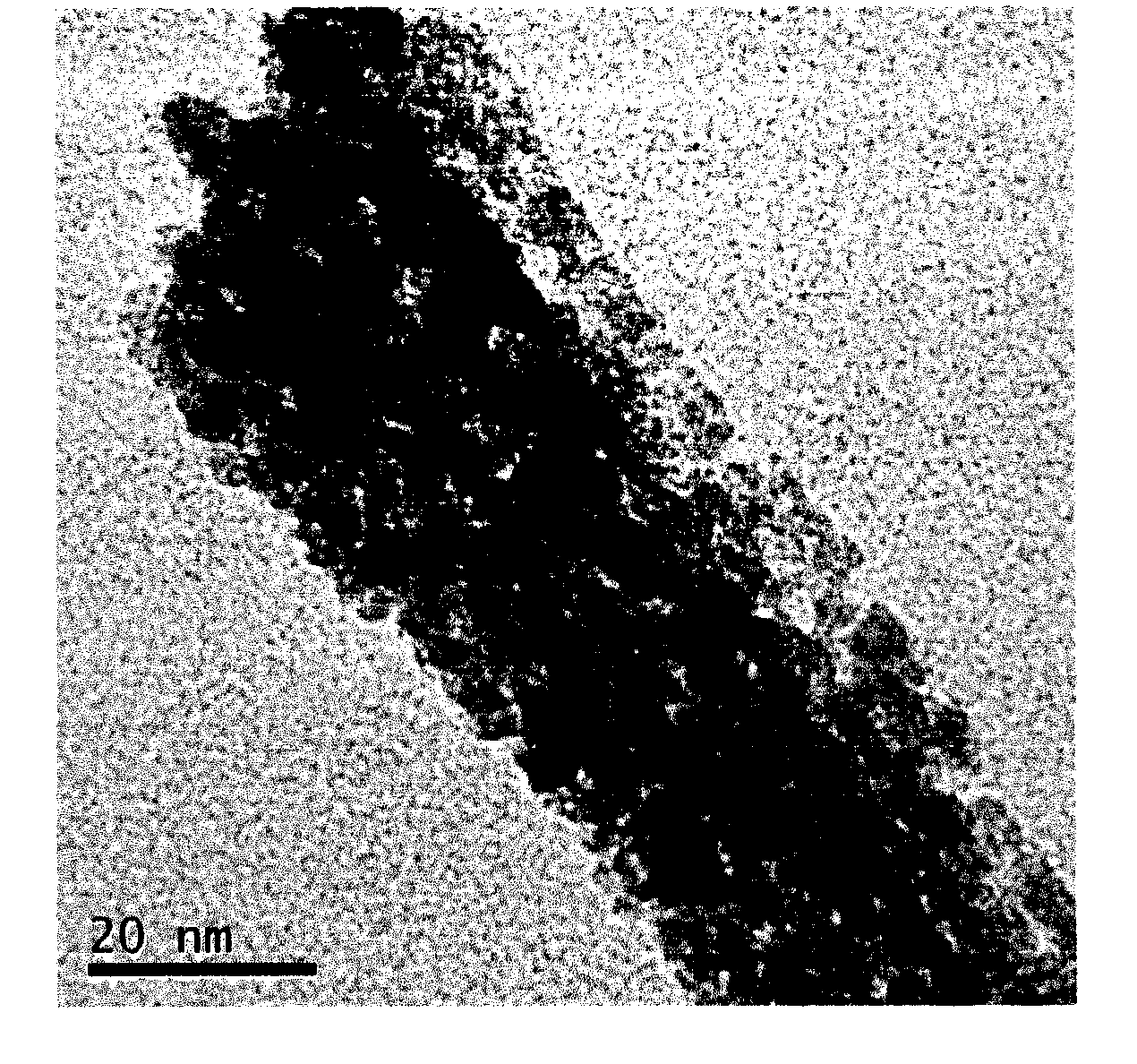

Pseudocapacitor anode based on three-dimensional multi-level nanostructure of cobalt-nickel sulfide core shell and preparation method of pseudocapacitor anode

ActiveCN106067383AHigher quality than capacityExcellent rate performanceHybrid capacitor electrodesHybrid/EDL manufacturePseudocapacitorCore shell

The invention discloses a pseudocapacitor anode based on a three-dimensional multi-level nanostructure of cobalt-nickel sulfide core shell and a preparation method of the pseudocapacitor anode. The anode comprises a foamed nickel substrate 1, cobalt-nickel sulfide nanosheets 2 positioned on the foamed nickel substrate 1 and distributed in an array manner and cobalt-nickel sulfide blades 3 connected to the two sides of the cobalt-nickel sulfide nanosheets 2 and distributed in a growing array manner, wherein the cobalt-nickel sulfide nanosheets 2 are perpendicular to the foamed nickel substrate 1; the cobalt-nickel sulfide blades 3 and the cobalt-nickel sulfide nanosheets 2 are in the opposite directions along the foamed nickel substrate 1 by 0 to 90 degrees. According to the disclosed anode structure, the cobalt-nickel sulfide nanosheet array is directly grown on the highly conductive foam nickel substrate, so that the anode has the very high electron mobility and is beneficial to realization of rapid charge and discharge; meanwhile, the cobalt-nickel sulfide blades are continuously grown on the nanosheet array in situ, so that the available active surface of an electrode can be expanded, the energy density of the electrode can be increased, and the action speed of an active material and an electrolyte can be increased.

Owner:重庆中科超容科技有限公司

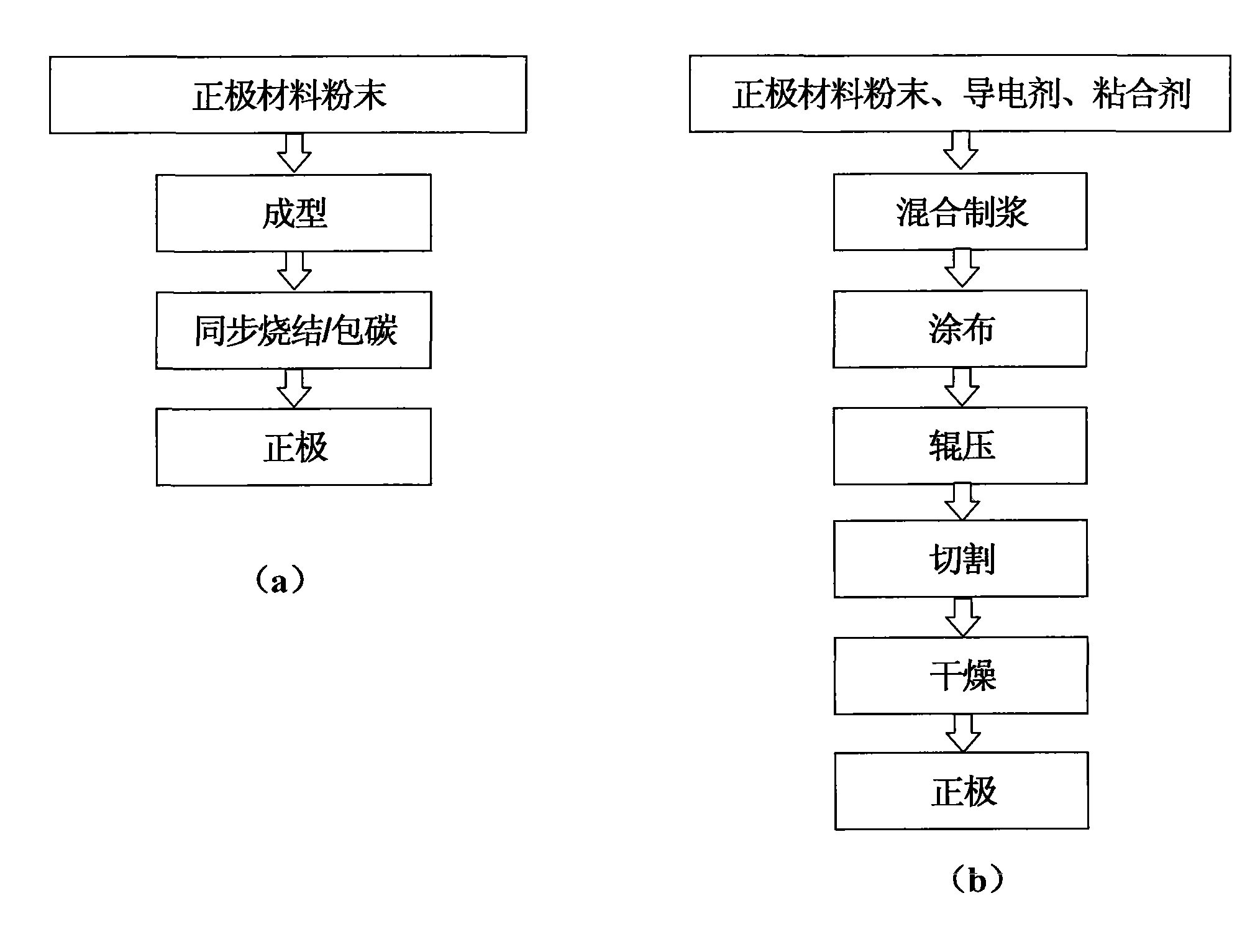

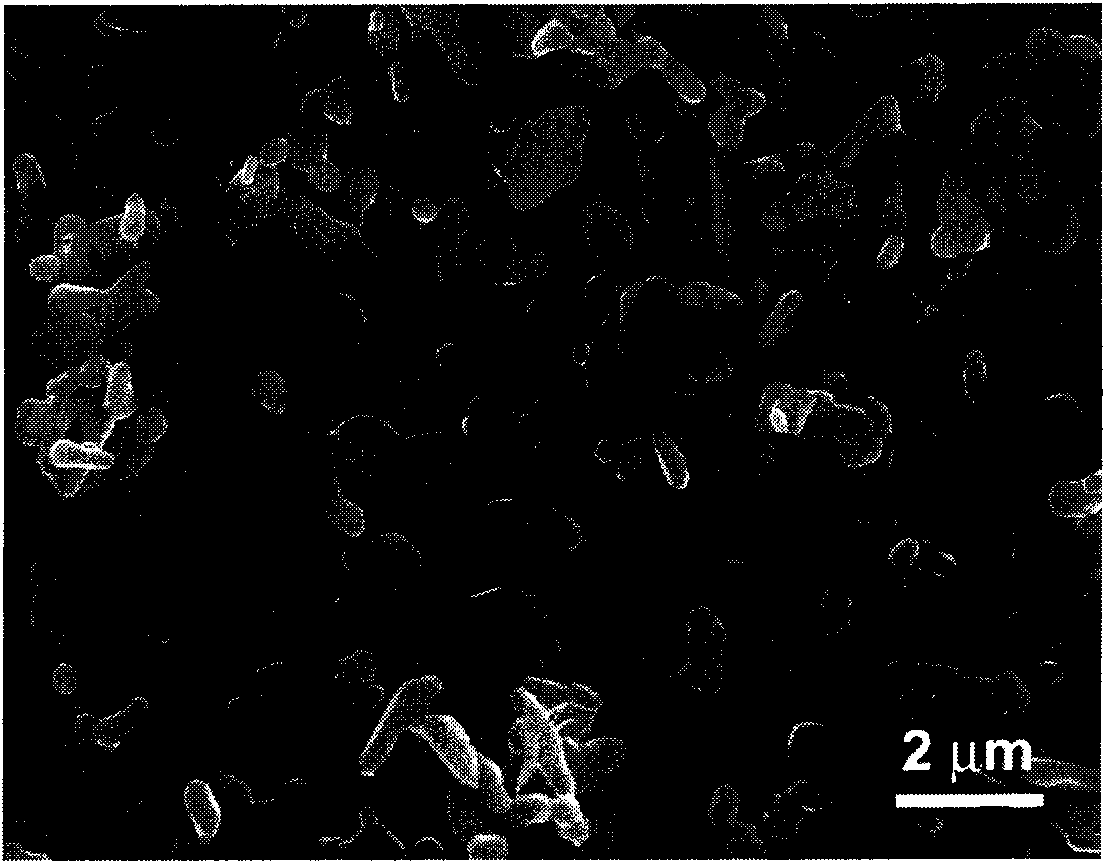

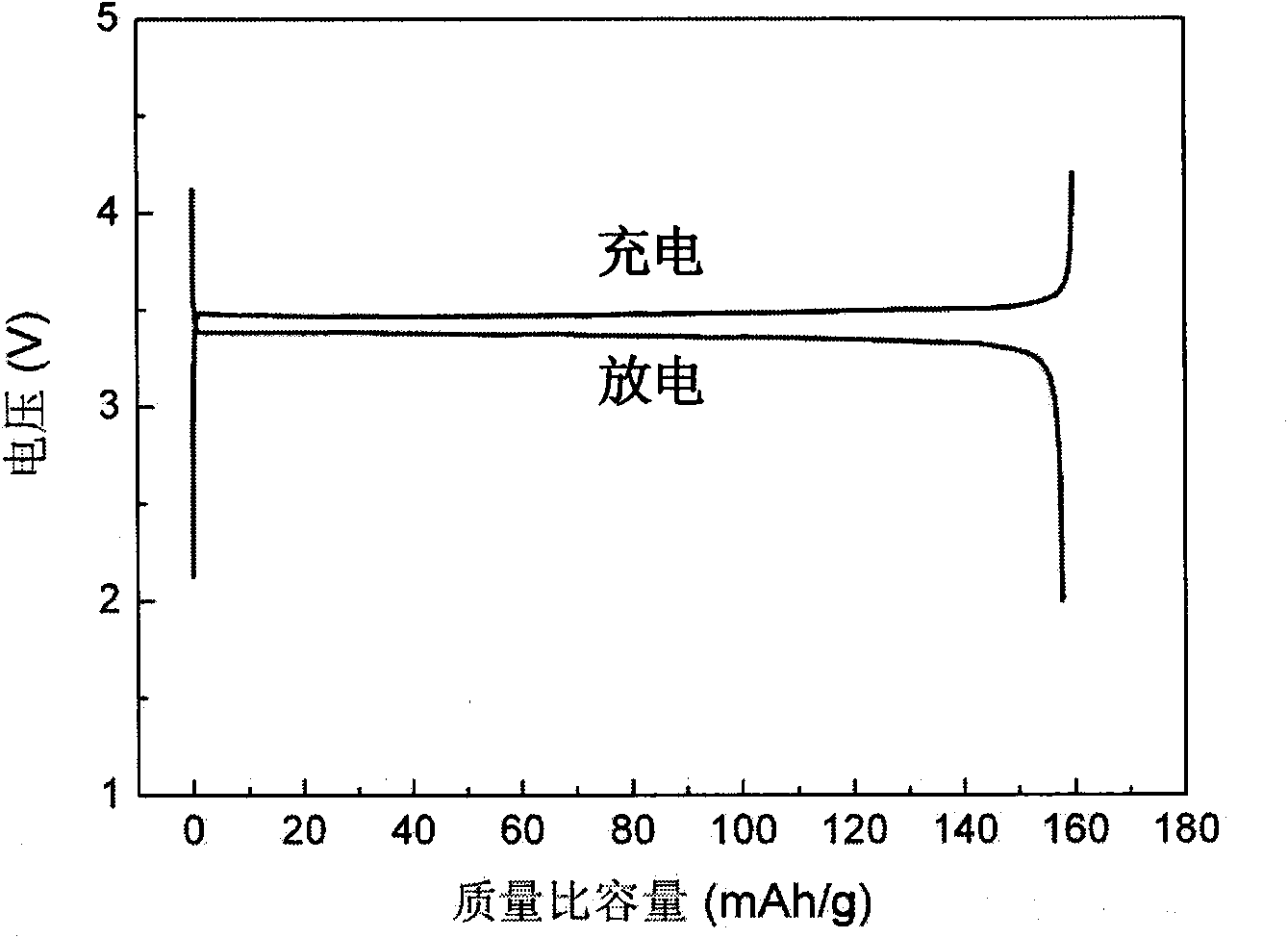

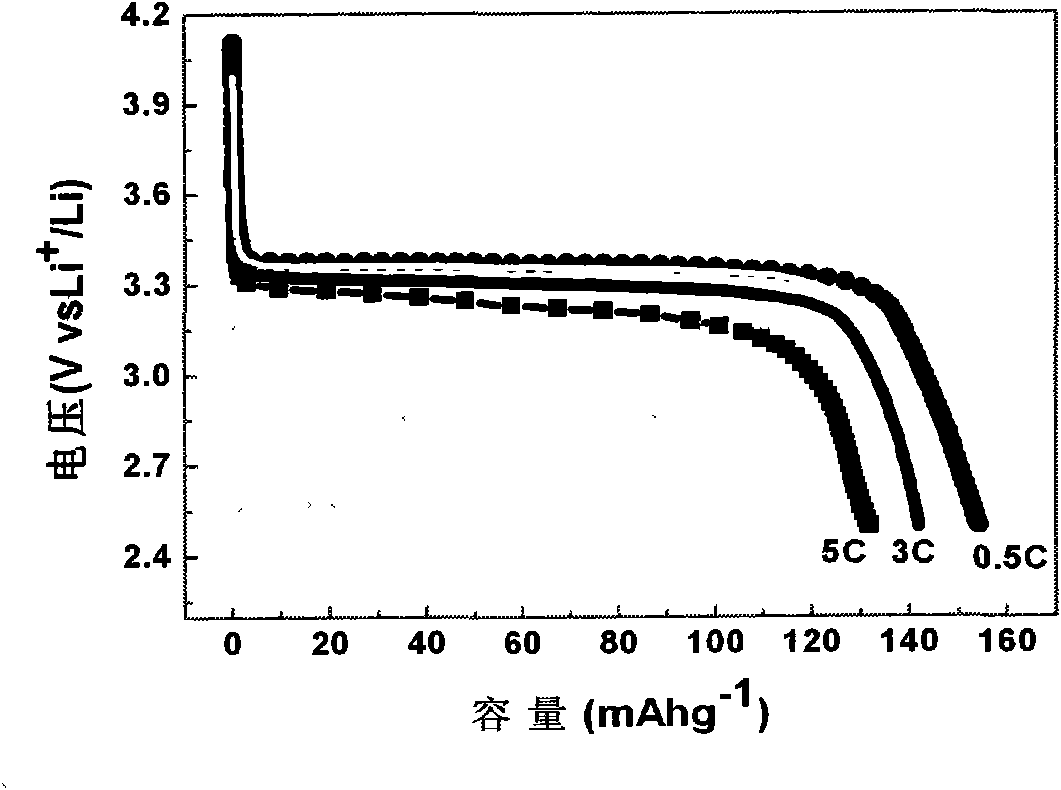

Preparation method of porous conductive LiFePO4 positive plate used in lithium ion battery

InactiveCN101853931ALow costReduce manufacturing costElectrode manufacturing processesCarbon filmAdhesive

The invention relates to the preparation technology of phosphate type positive plate used in lithium ion battery, in particular to a preparation method of adhesive free porous conductive LiFePO4 positive plate used in lithium ion battery. The method includes that LiFePO4 positive material powder subject to low temperature sintering and cold press moulding forms a porous structure, and then chemical vapor deposition method is adopted to uniformly coat a conductive carbon film on the LiFePO4 particle surface in porous structure, so as to obtain the porous conductive LiFePO4 positive plate. The invention can prepare the porous conductive LiFePO4 positive plate without using adhesive or solvent dissolving adhesive. The positive plate prepared by adopting the method has good conductivity and high discharge specific capacity. The invention has simple process and low positive plate manufacturing cost, greatly shortens the traditional process flow and solves the problems that the conventionalLiFePO4 positive plate preparation process is long and fussy, multiple process units as well as adhesive and solvent dissolving adhesive which are high in price are required.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

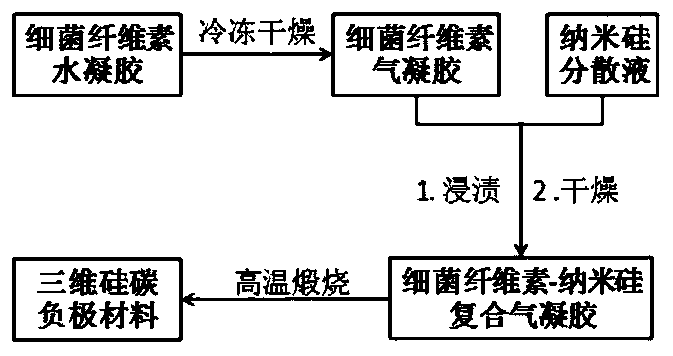

Three-dimensional silicon-carbon composite negative electrode material and preparation method and application thereof in lithium ion battery

ActiveCN111470486AGood plastic strainGood mechanical propertiesSiliconSecondary cellsCarbon compositesFreeze-drying

The invention provides a three-dimensional silicon-carbon composite negative electrode material as well as a preparation method and application thereof in a lithium ion battery. The preparation methodcomprises the following steps: step 1, freeze-drying bacterial cellulose hydrogel to obtain aerogel, then soaking the aerogel in a nano-silicon source dispersion liquid, and drying after sufficient absorption to obtain bacterial cellulose / nano-silicon composite aerogel; and 2, carrying out high-temperature cracking on the bacterial cellulose / nano-silicon composite aerogel in an inert atmosphere at a high-temperature cracking temperature of 700-1200 DEG C, and naturally cooling to obtain the three-dimensional silicon-carbon composite negative electrode material; the three-dimensional carbon nanofibers derived from bacterial cellulose after carrying out high-temperature cracking are interlinked, and has good shaping strain and excellent mechanical properties, and the obtained three-dimensional carbon nanofiber has a porous network structure, so that the three-dimensional carbon nanofiber can fully accommodate volume expansion of a silicon-based material in charging and discharging processes, and the cycle and rate performance of the material is further improved.

Owner:SHAANXI COAL & CHEM TECH INST

Method for synthesizing lithium iron phosphate material by adopting electrostatic spinning

InactiveCN102392311AImprove the performance of high rate charge and dischargeHigher quality than capacityCell electrodesFilament/thread formingHigh ratePolyvinyl alcohol

The invention belongs to a method for synthesizing a lithium iron phosphate material by adopting electrostatic spinning. The selected compounds comprise an iron source compound which is selected from one or a mixture of two of FeC2O4, Fe2O3 and FePO4, a lithium source compound which is selected from one or a mixture of two of LiH2PO4, Li2CO3, Li2HPO4 and LiOH, a phosphate radical containing compound which is selected from one or a mixture of two of LiH2PO4, (NH4)2HPO4, NH4H2PO4 and H3PO4, a polymer which is selected from one or two of polyvinyl alcohol, polyacrylonitrile and polyvinylpyrrolidone, and a solvent used by polymer solution which is selected from one or a mixture of more than two of water, ethanol, glycol, acetic acid and isopropanol. The lithium iron phosphate in a nano structure is prepared by preparing spinning solution, preparing a lithium iron phosphate precursor and drying and calcining the lithium iron phosphate precursor. The method has the following beneficial effects: the high-rate charge / discharge performance of the lithium iron phosphate and the specific capacity of charge / discharge under low temperature are improved; and the new method is provided for synthesizing lithium iron phosphate.

Owner:长春劲能科技集团有限公司

Method for preparing fluorine- and -nitrogen-doped graphene-like laminated material

InactiveCN108492996AHigher quality than capacityImprove cycle stabilityHybrid capacitor electrodesLithium chlorideArgon atmosphere

The invention discloses a method for preparing a fluorine- and-nitrogen-co-doped graphene-like laminated material, which is characterized in that glucosamine hydrochloride and polyvinylidene fluorideare mixed and evenly ball-milled in a salt template of a lithium chloride and potassium chloride mixed material; carbonization is performed under an argon atmosphere; acid washing and water washing are performed; and finally vacuum drying is performed to obtain the fluorine- and nitrogen-doped graphene-like laminated material. The fluorine- and -nitrogen co-doped graphene-like laminated material is obtained by one-step carbonization by means of the salt template method, wherein the graphene-like laminated layer is thin, fluorine and nitrogen elements are evenly distributed, the dimensional stability is good, and the repeatability is good. The content of thefluorine and nitrogen elements can be adjusted according to the adding amount of the polyvinylidene fluoride. The method is simple, canachieve one-step synthesis, and is moderate in carbonization temperature; the prepared fluorine- and-nitrogen-doped graphene-like laminated material has high mass specific capacity, good cycle stability and good electrical conductivity. The invention has good prospect in the application to supercapacitor energy storage materials.

Owner:DONGHUA UNIV

Lithium ion battery self-supporting silicon-based anode material with multilayered film and preparation method of anode material

ActiveCN106058209AGood flexibilityRelieve deformationCell electrodesSecondary cellsInjection volumeMass ratio

The invention discloses a lithium ion battery self-supporting silicon-based anode material with a multilayered film and a preparation method of the anode material. The anode material is made from silicon nano-particles and carbon nano-fibers through compounding, wherein the mass ratio of silicon to carbon is 1:0.5-1:6 and the thickness ratio of a carbon fiber layer to a silicon-carbon compound fiber layer is 1:1-1:5. The preparation method comprises the following steps: dispersing a mixture formed from silicon nano-particles / an organic high-molecular polymer and an organic high-molecular polymer in an organic agent, respectively, and performing fully stirring to obtain an uniform suspension and solution; through control of the injection volume and time of electrostatic spinning, obtaining a multilayered periodic structure of carbon-carbon silicon compound-carbon-carbon silicon compound...-carbon; and performing carbonization treatment in the protective atmosphere to obtain the lithium ion battery self-supporting silicon-based anode material with a multilayered film. The anode material has characteristics of self-supporting, high capacity, good cyclic stability and simple preparation.

Owner:ZHEJIANG UNIV

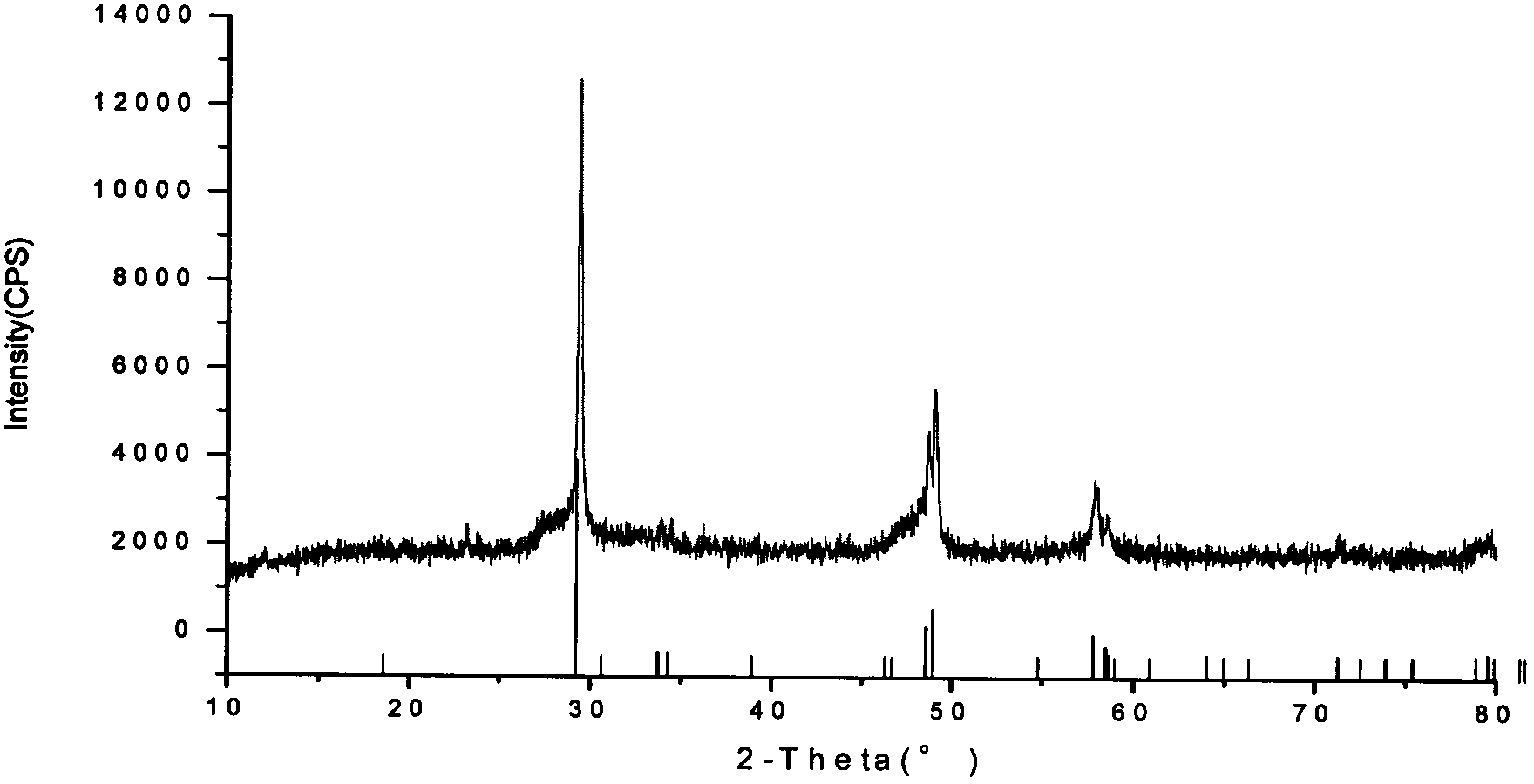

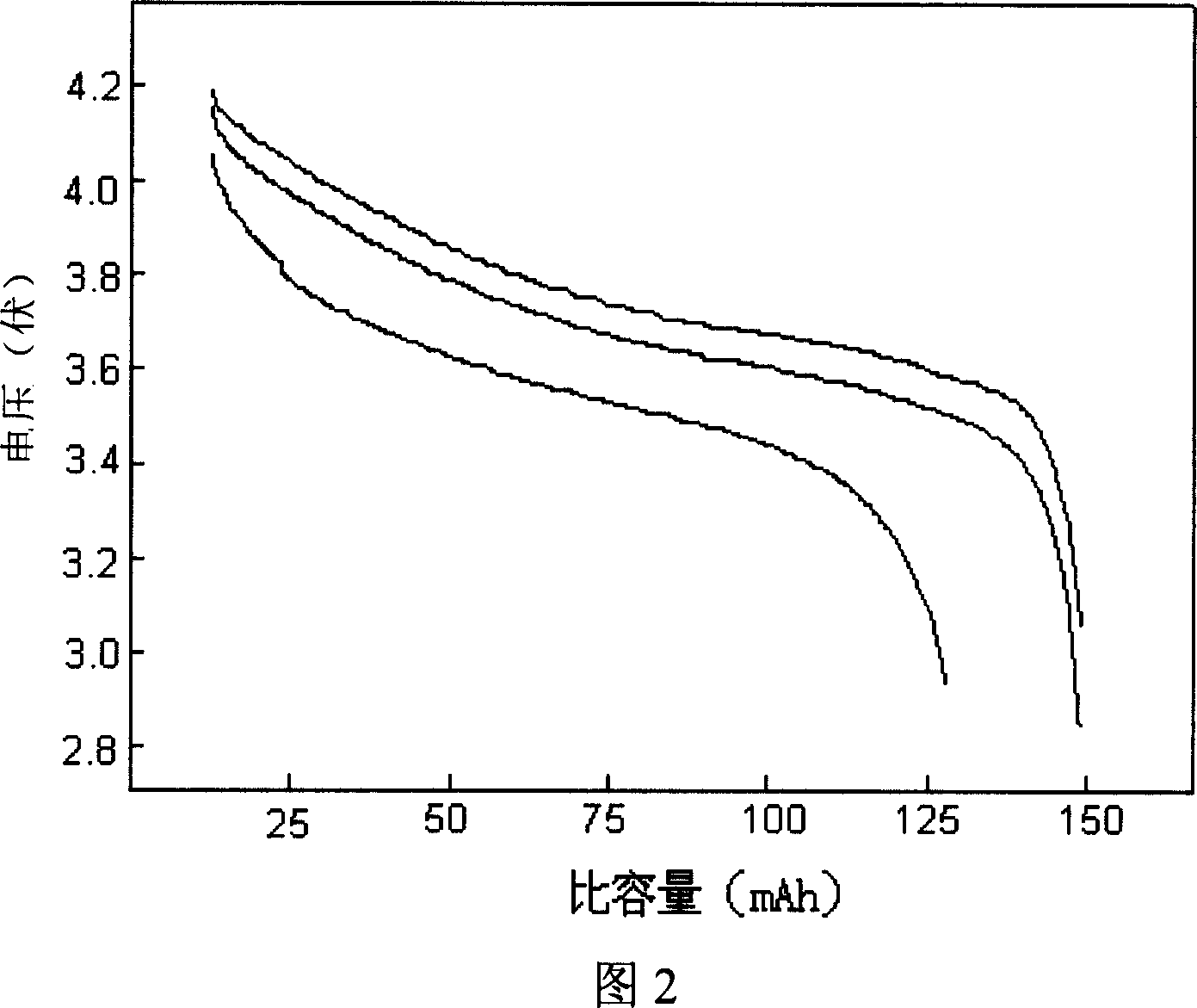

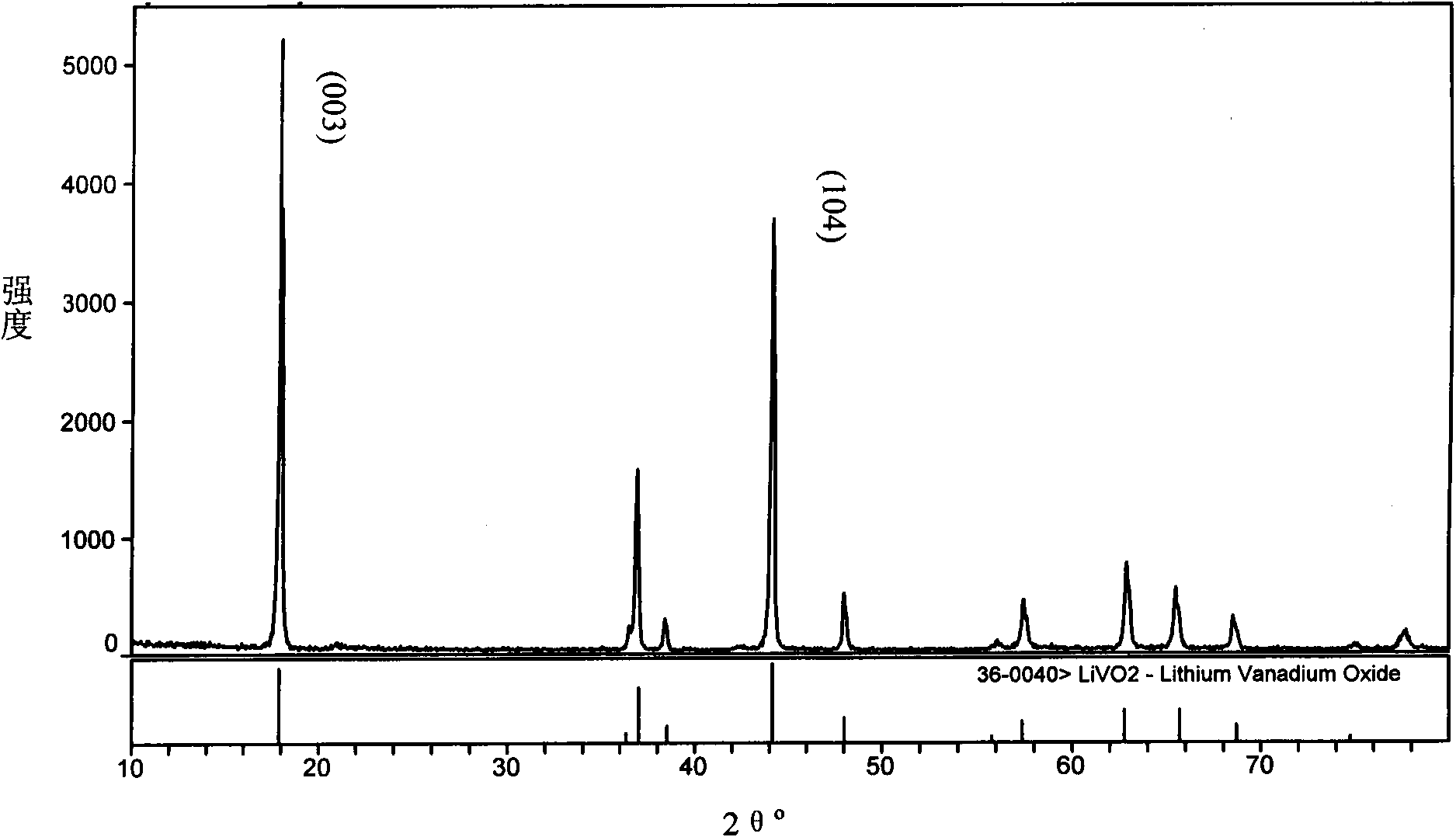

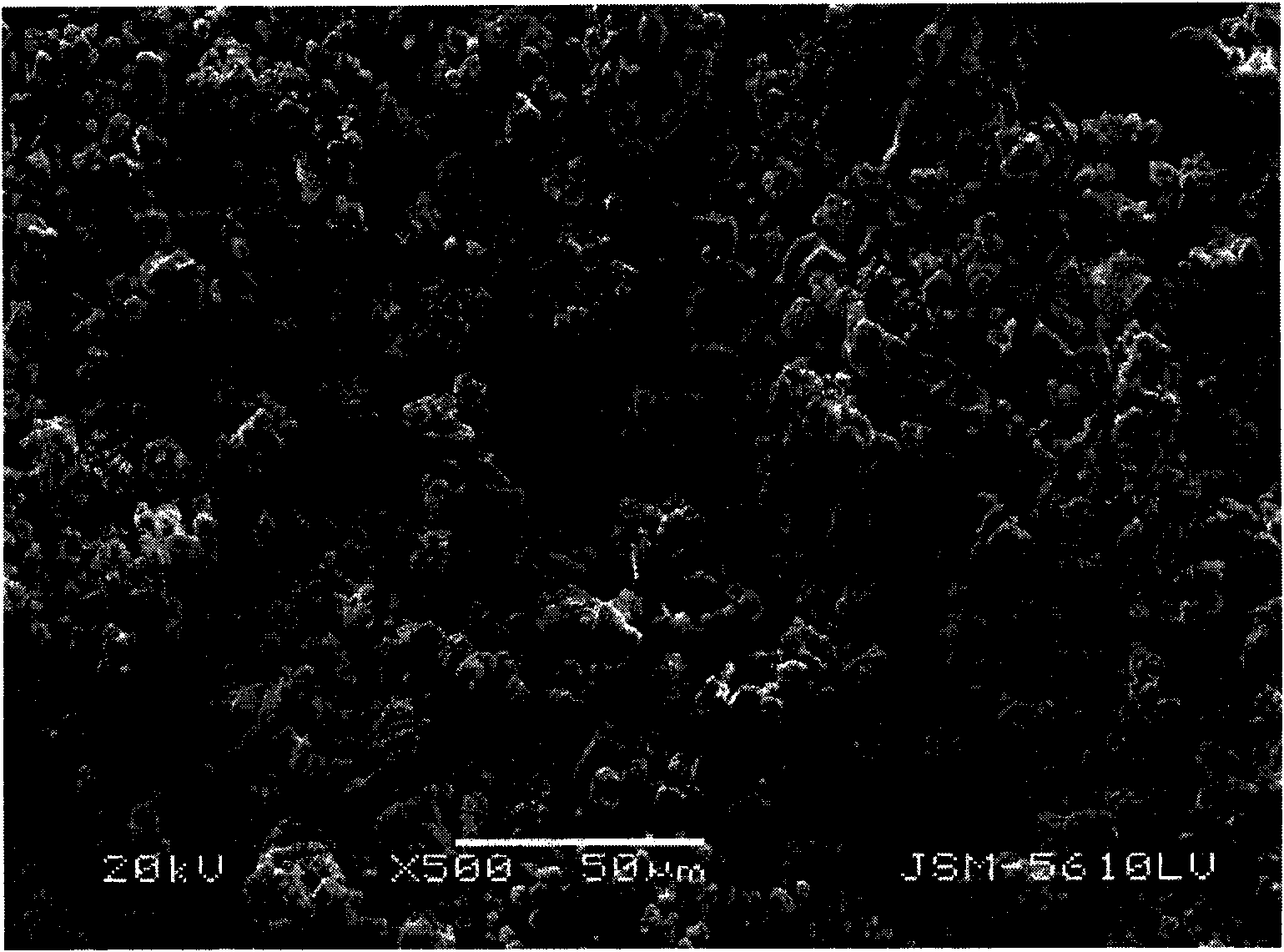

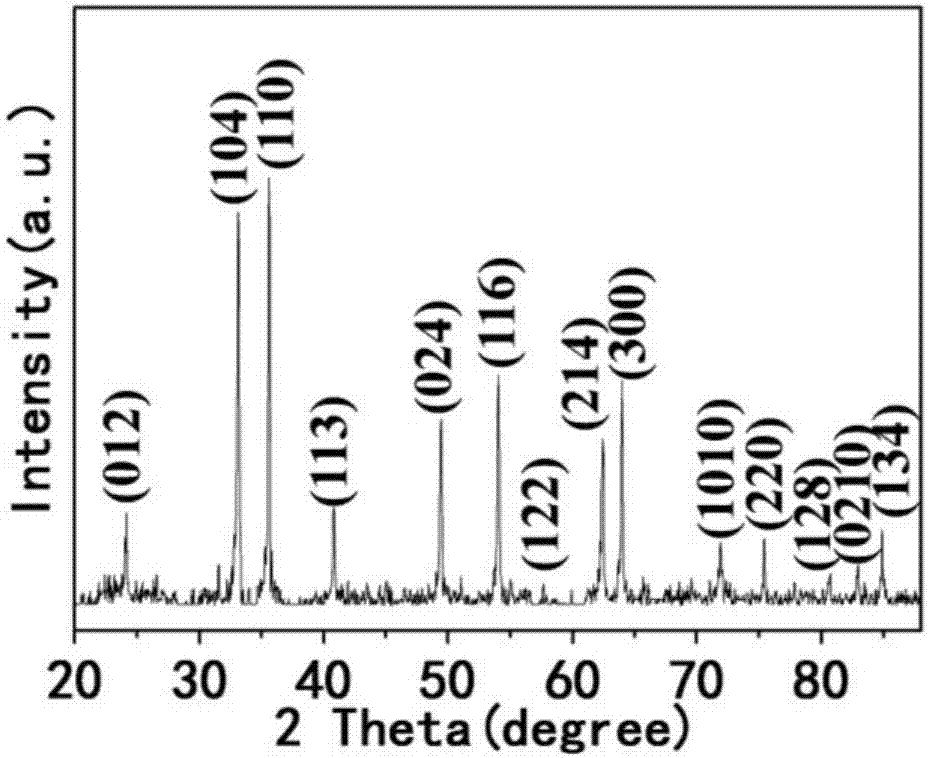

Cathodic active material as well as preparation method and battery thereof

InactiveCN101853939AHigh tap densityGood crystal shapeElectrode manufacturing processesFinal product manufactureMass ratioFull width at half maximum

The invention provides a cathodic active material comprising LiVO2, wherein the tap density of a LiVO2 material is 1.5 to 2.2g / cm3, the ratio of the intensity I003 of the diffraction peak of a 003 crystal face to the intensity I104 of the diffraction peak of a 104 crystal face is 0.9 to 1.8, and the full width at half maximum of the diffraction peak of the 003 crystal face is 0.17 to 0.25. The material has large tap density, perfect crystal form and superior electrochemical performance, and the capacity of the mass ratio of the prepared battery is very large and can reach 339mAh / g, which is beneficial to the development of traditional small-sized and light-duty batteries and meets the development requirements of the traditional battery. Moreover, the invention provides a preparation method of the material. The process is simple, solves the corrosion of a traditional preparation method to equipment well, enhances the rate of finished products, saves the cost and is beneficial to the industrial scale.

Owner:BYD CO LTD

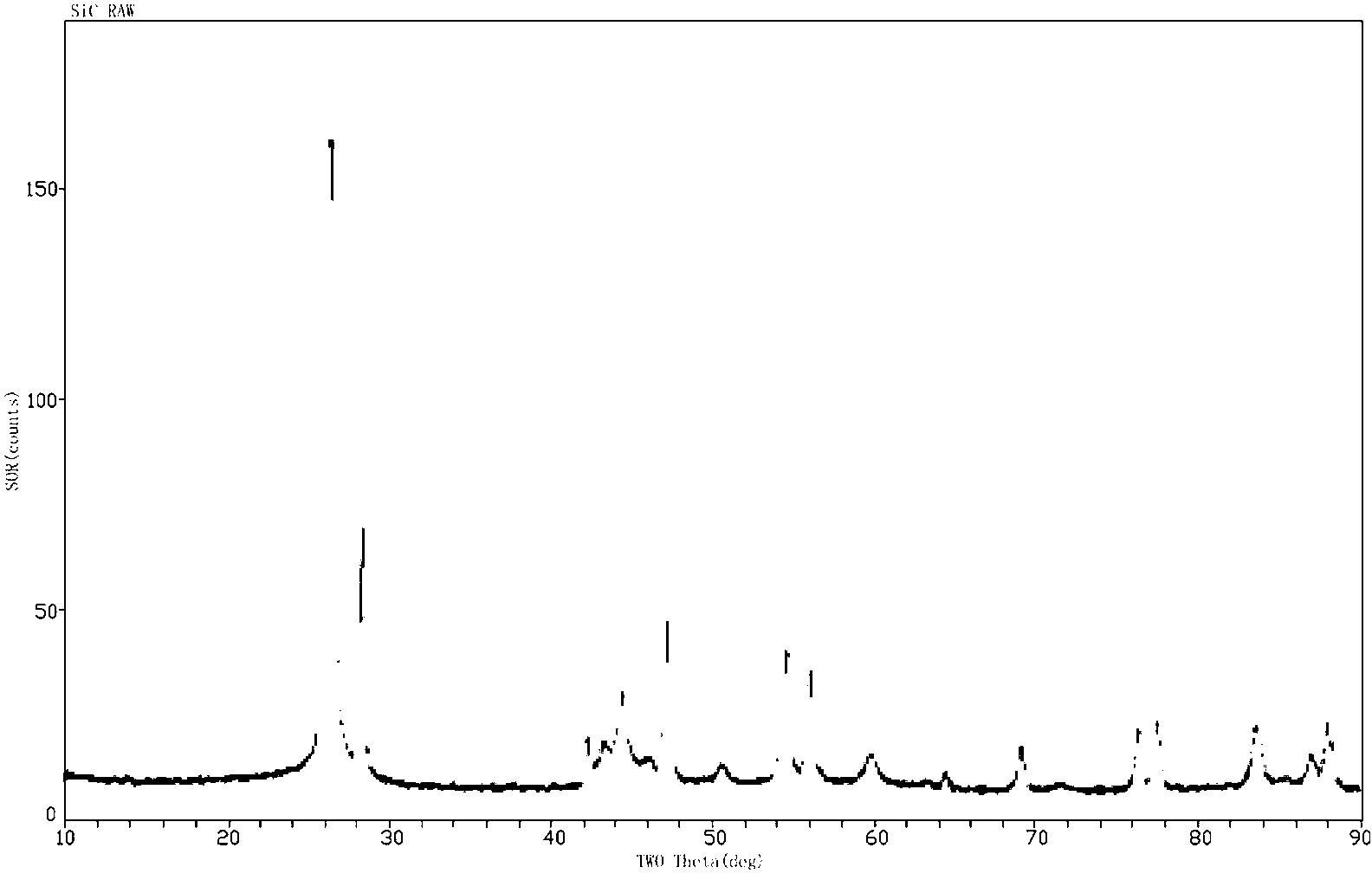

Tin oxide/alumina doped carbon composite material and preparation method thereof

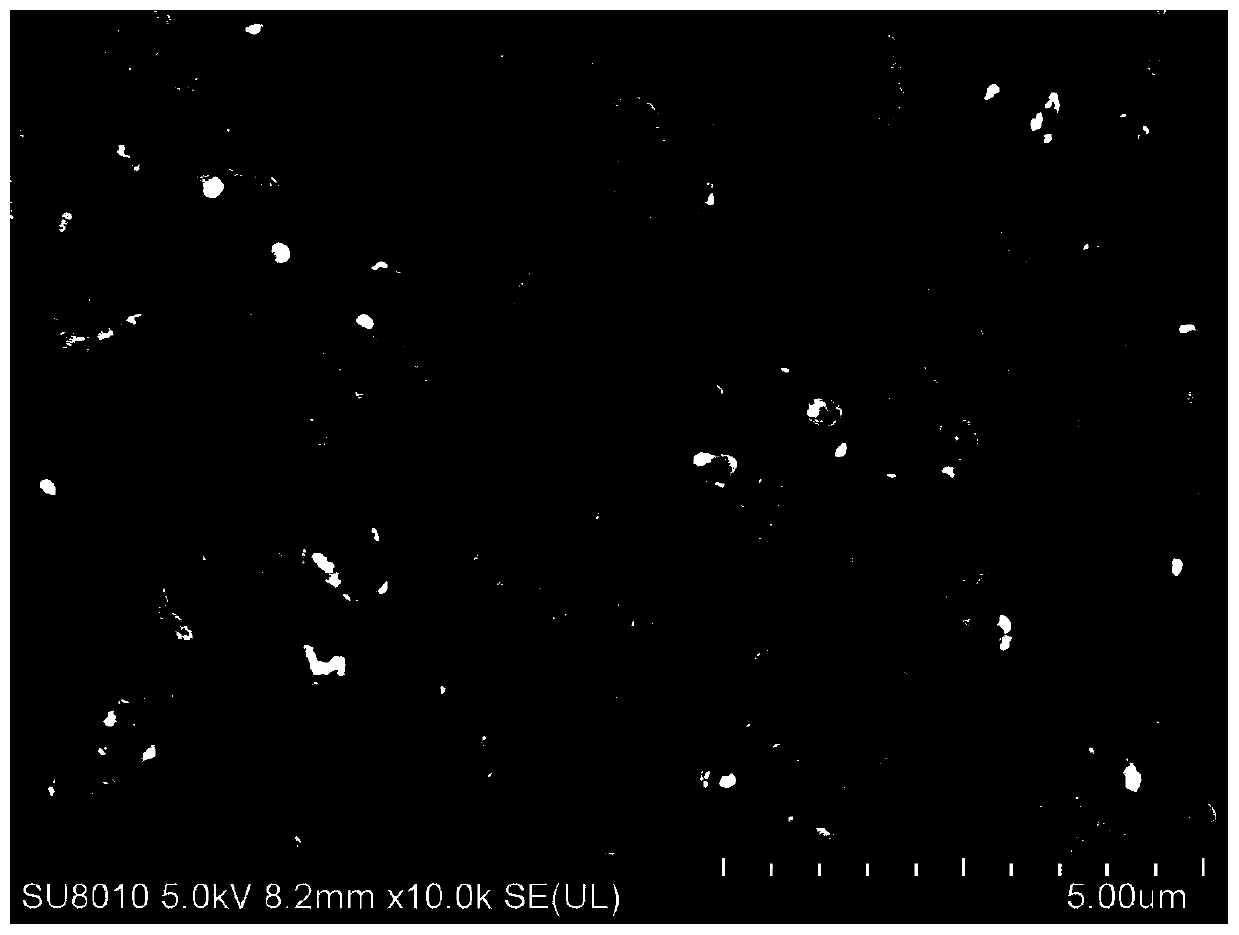

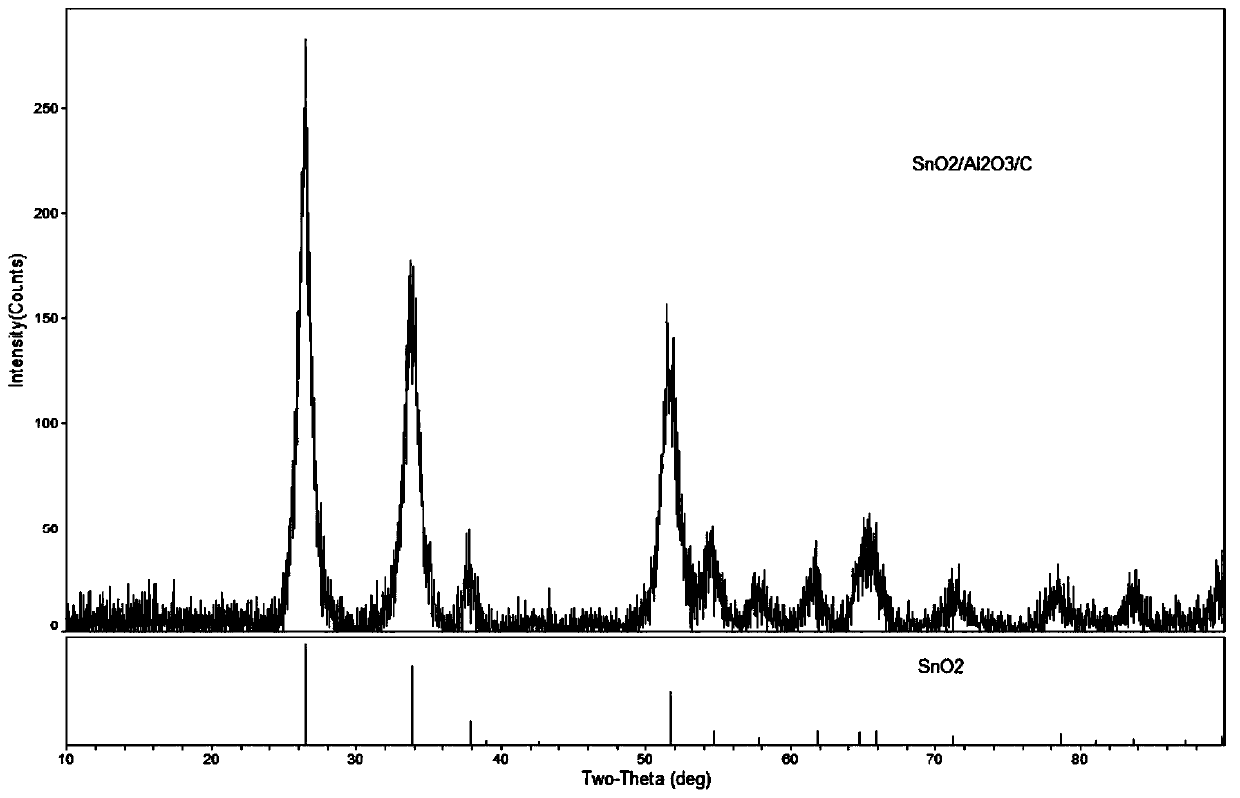

ActiveCN110336035AAlleviate volume expansionImprove stabilitySecondary cellsNegative electrodesTin dioxideCarbon composites

The invention belongs to the technical field of electrochemistry, in particular to a tin oxide / alumina doped carbon composite material and a preparation method thereof. The invention provides a preparation method of a tin dioxide / alumina doped carbon composite material, which comprises the following steps: S1, mixing urea and a tin-containing precursor to complete dissolution to obtain mixed solution; and S2, carrying out hydrothermal reaction on the mixed solution and drying the product to obtain tin dioxide nanoparticles, carrying out dry grinding, and adding carbon for ball milling to obtain a tin dioxide / alumina doped carbon composite material. The invention also provides a tin dioxide / alumina doped carbon composite material prepared by the method. The invention provides the tin dioxide / alumina doped carbon composite material and the preparation method thereof, which solve the problem that the existing lithium-ion battery anode material causes quick capacity depletion and poor cycle performance of batteries due to serious volume expansion effect.

Owner:GUANGDONG UNIV OF TECH

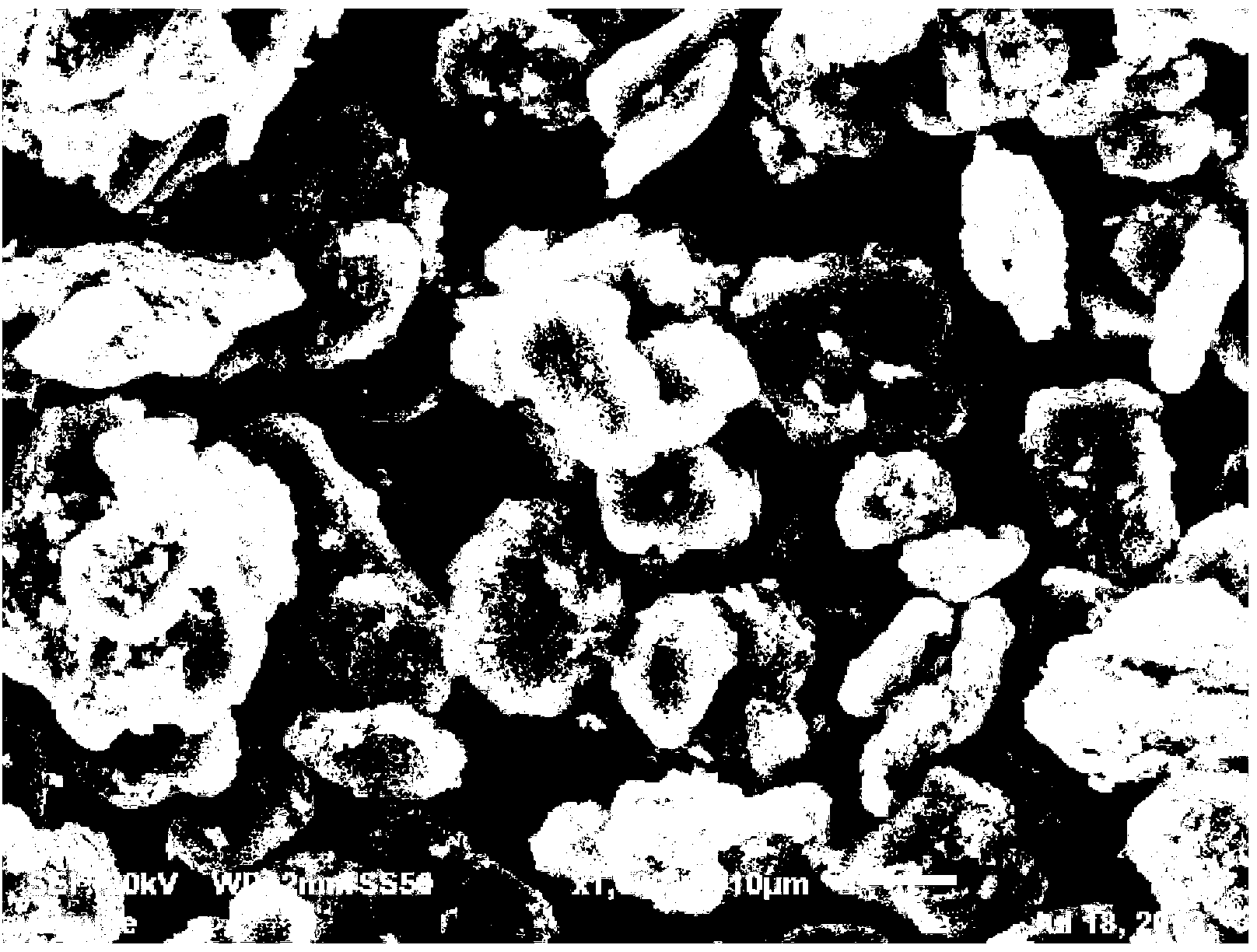

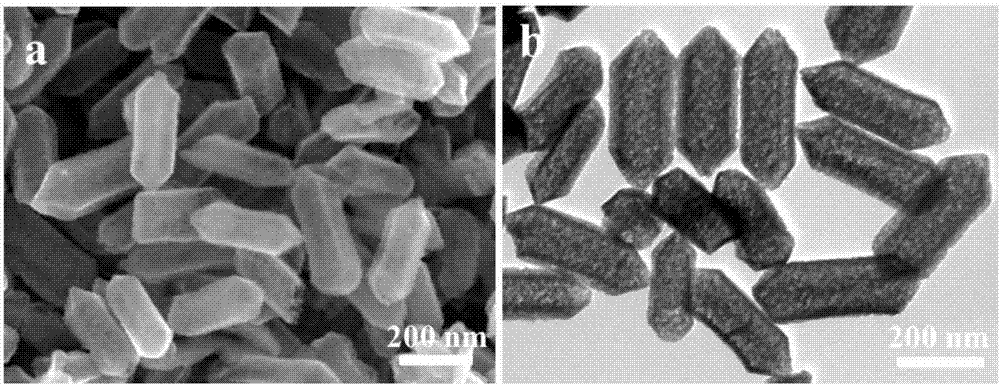

Preparation and application method for hollow porous nano alpha-Fe2O3 hexagonal prism material

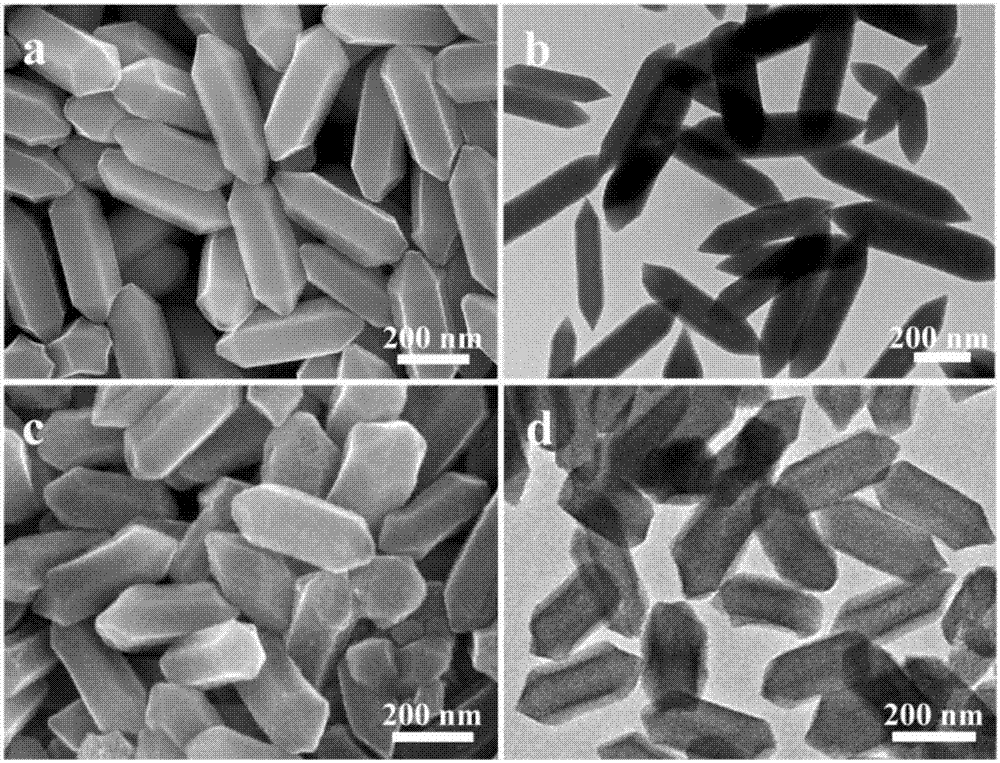

ActiveCN107381499AQuality improvementImproved magnification performanceMaterial nanotechnologyCell electrodesEtchingMetal-organic framework

The invention discloses a preparation and application method for a nano-hollow-porous alpha-Fe2O3 hexagonal prism material, and belongs to the field of energy materials. The method includes the steps of firstly, preparing a nano Fe-MIL-88A metal-organic-framework material (MOFs) hexagonal prism material; secondly, processing by using sodium hydroxide, and through the process of self-etching, obtaining a nano material of a hollow MOFs @ Fe (OH) 3 structure; finally, conducting heat treatment in the air to obtain a hollow porous nano Fe2O3 hexagonal prism anode material. The method has the advantages of being simple in method and equipment, controllable in process parameter, high in repeatability, abundant in raw material needed by preparation, low in cost and convenient in large-scale. The prepared hollow porous nano Fe2O3 hexagonal prism anode material has high specific capacity and good cyclic stability, is an ideal anode material for a lithium ion battery, and can be widely used in the fields of portable electronic equipment, electric vehicles, aerospace technologies, national defense industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

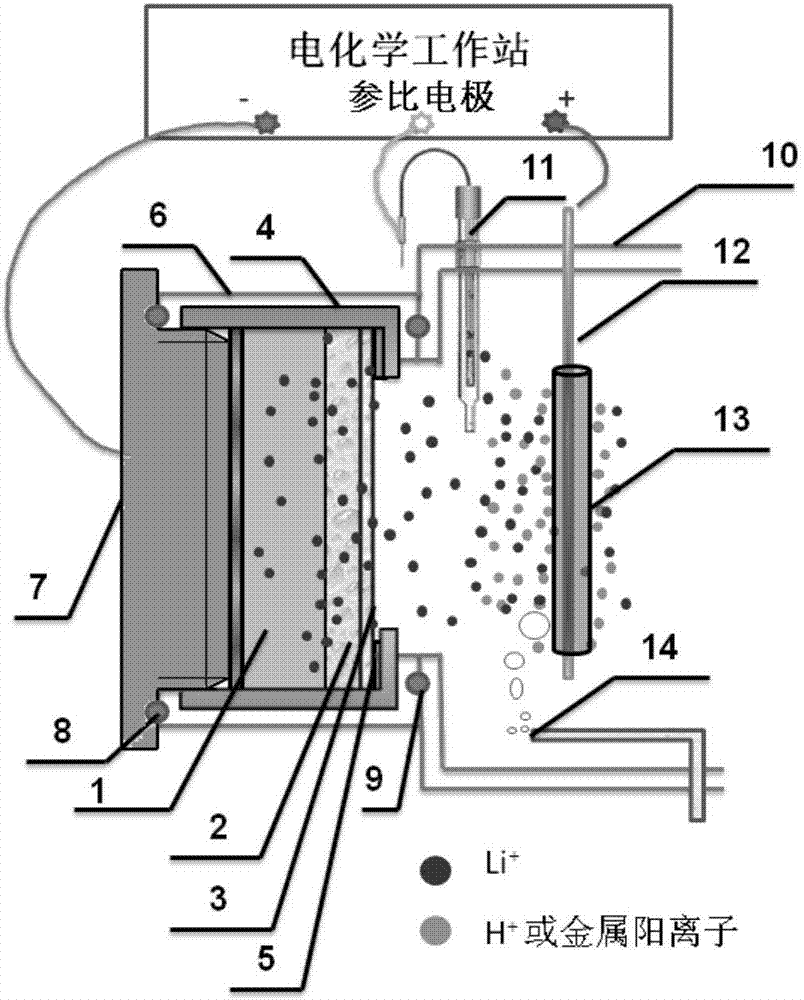

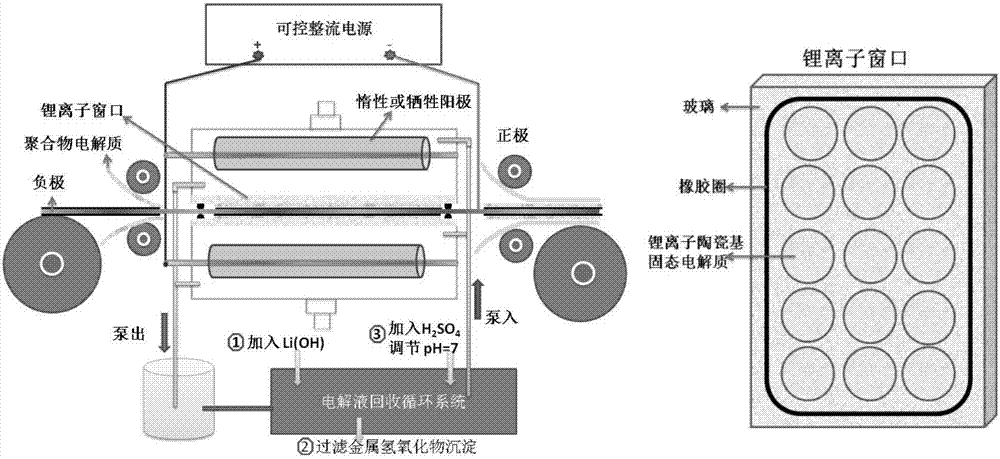

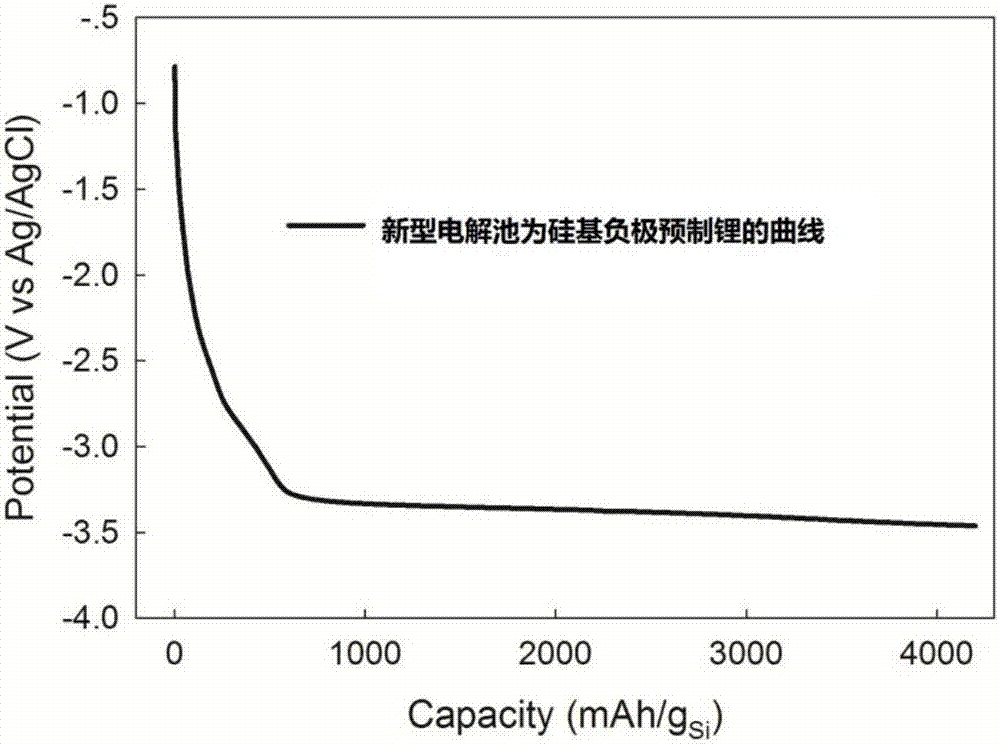

Lithium ion energy storage device, and method and electrolytic tank apparatus for prefabricating lithium for negative electrode of lithium ion energy storage device

InactiveCN106972192AChemically stableLow costHybrid capacitor electrodesFinal product manufactureSolid state electrolytePolymer

The invention discloses a lithium ion energy storage device, and a method and an electrolytic tank apparatus for prefabricating lithium for a negative electrode of the lithium ion energy storage device. By adopting a lithium ion semi-battery type design, a gel polymer electrolyte is attached between a lithium battery negative electrode material and a ceramic-based solid-state electrolyte thin film in a coating manner, so as to provide high ionic conduction; after lithium prefabricating is performed, the gel polymer electrolyte and a lithium battery negative electrode can be loaded into a complete battery together to manufacture a polymer lithium battery; in addition, a positive electrode of the electrolytic tank adopts a lithium ion water solution as an electrolyte and a lithium source; the lithium source is wide in raw materials which can be lithium brine or waste lithium battery lithium recycling water solution; and therefore, the obtained lithium ion energy storage device is environment friendly, free of toxicity, stable in chemical property, free of strict storage and transportation equipment, and capable of lowering cost of lithium prefabricating.

Owner:JIANGSU UNIV

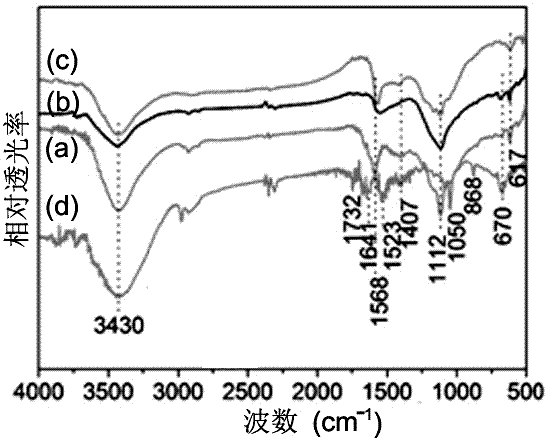

Reduced graphene oxide/manganese oxide compound and preparation method thereof

ActiveCN107104002AThe synthesis method is simpleLow costHybrid capacitor electrodesHybrid/EDL manufactureSynthesis methodsSupercapacitor

The invention relates to a reduced graphene oxide / manganese oxide compound and a preparation method thereof, and belongs to the technical field of preparation of nano-compound materials and super-capacitor electrode materials. An rGO / MnO<x> nano-compound is composed of an rGO nanosheet and MnO<x> particles embedded on the nanosheet; the size of the MnO<x> particles is 10-90 nm; x in the MnO<x> is 1.33-2; the mass percentage content of the MnO<x> is 20-40%; and the MnO<x> component is a mixture that MnO<2>, Mn<3>O<4> and Mn<2>O<3> coexist. The invention further provides a preparation method of the reduced graphene oxide / manganese oxide compound and the purpose therefore, used for the electrode material of a super-capacitor. An rGO / MnO<x> nano-compound synthesis method is simple and low in cost; scale industrial production is facilitated; and the rGO / MnO<x> nano-compound has relatively high specific discharge capacity and good rate capability, and is suitable for being used as the electrode material of the super-capacitor.

Owner:深圳凯烽达科技有限公司

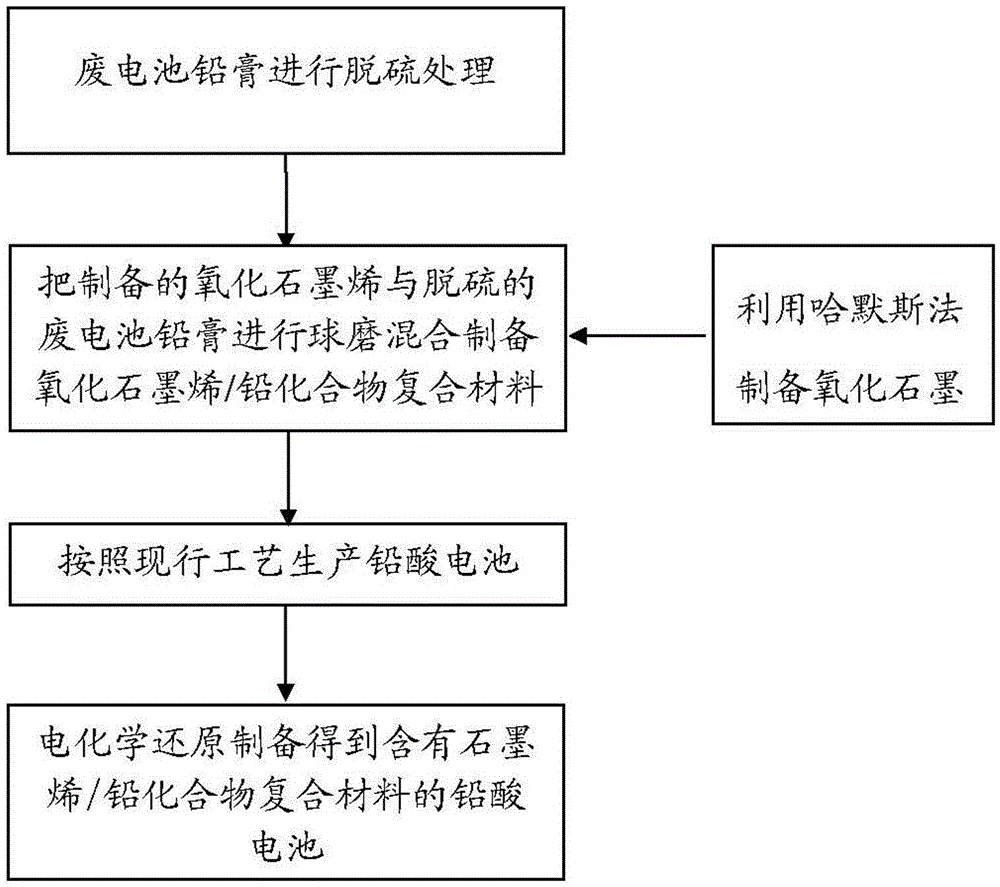

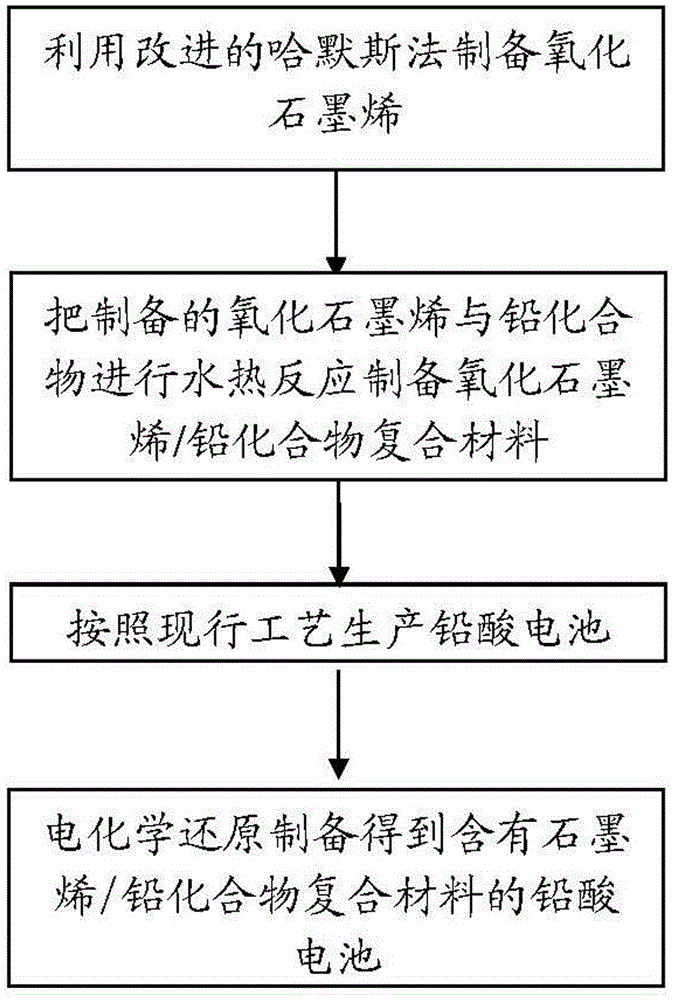

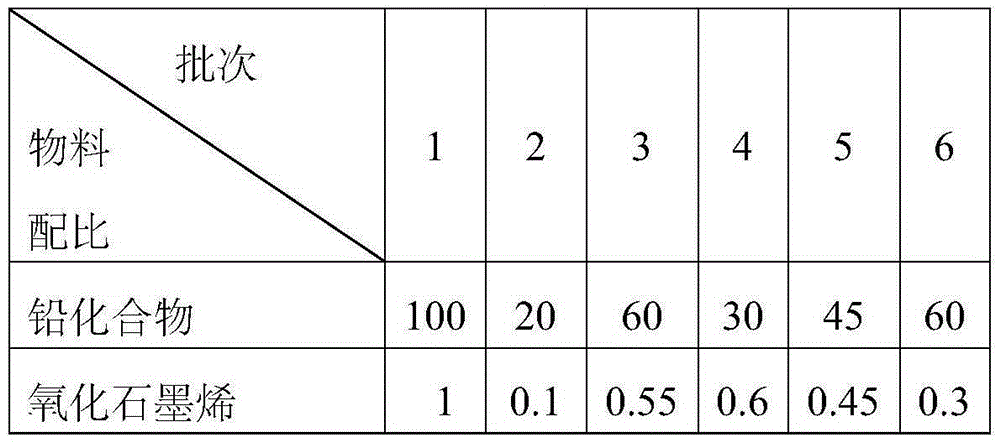

Preparation method for graphene/lead compound composite material and lead-acid battery

ActiveCN105428613AGood dispersionIncrease the effective contact areaLead-acid accumulatorsCell electrodesGrapheneElectrode material

The invention provides a preparation method for a graphene / lead compound composite material. A production method for a lead-acid battery comprises: firstly, performing hydrothermal reaction mixing or ball-milling mixing on a lead compound and graphene oxide to obtain a graphene oxide / lead compound composite material; secondly, assembling the lead-acid battery by taking the graphene oxide / lead compound composite material as an electrode material additive; and thirdly, performing electrochemical reduction on the lead-acid battery to obtain the lead-acid battery containing the graphene / lead compound composite material. The lead-acid battery produced with the method contains the graphene / lead compound composite material, so that the agglomeration of the graphene is avoided, uniform dispersion of the graphene and the lead compound is realized, and the graphene and the lead compound can be uniformly mixed; and moreover, a graphene / lead compound superbattery is easily obtained through the electrochemical reduction, so that the charge acceptance capability of the battery is remarkably improved and the cyclic life of the battery is remarkably prolonged.

Owner:湖北雄韬电源科技有限公司

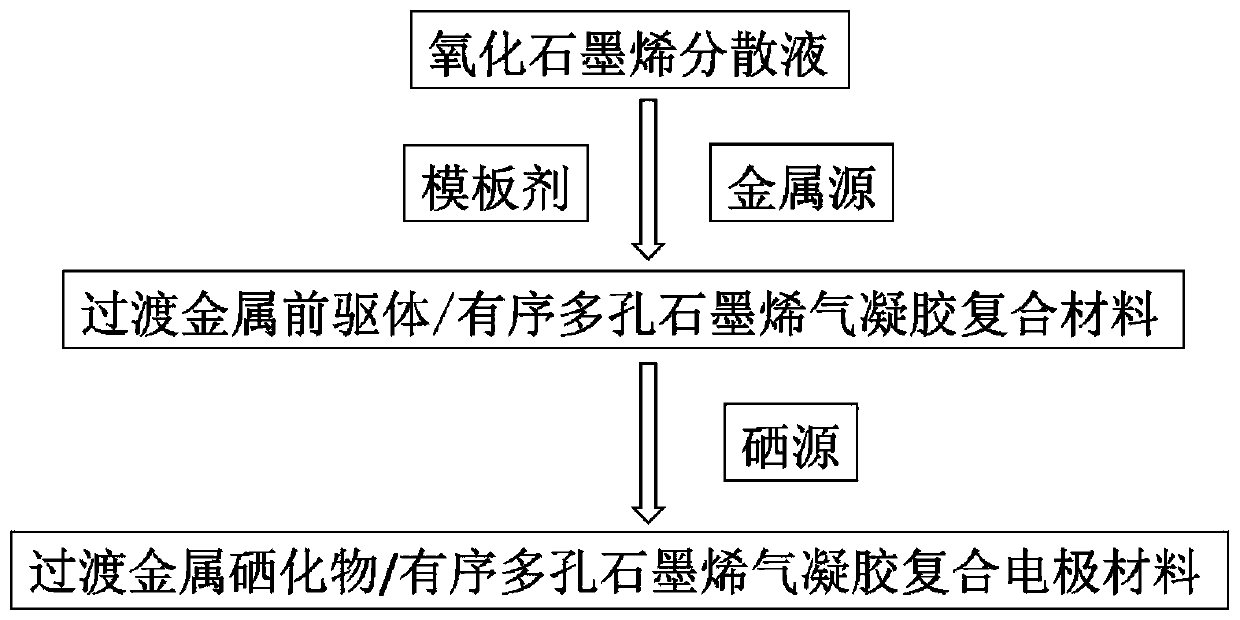

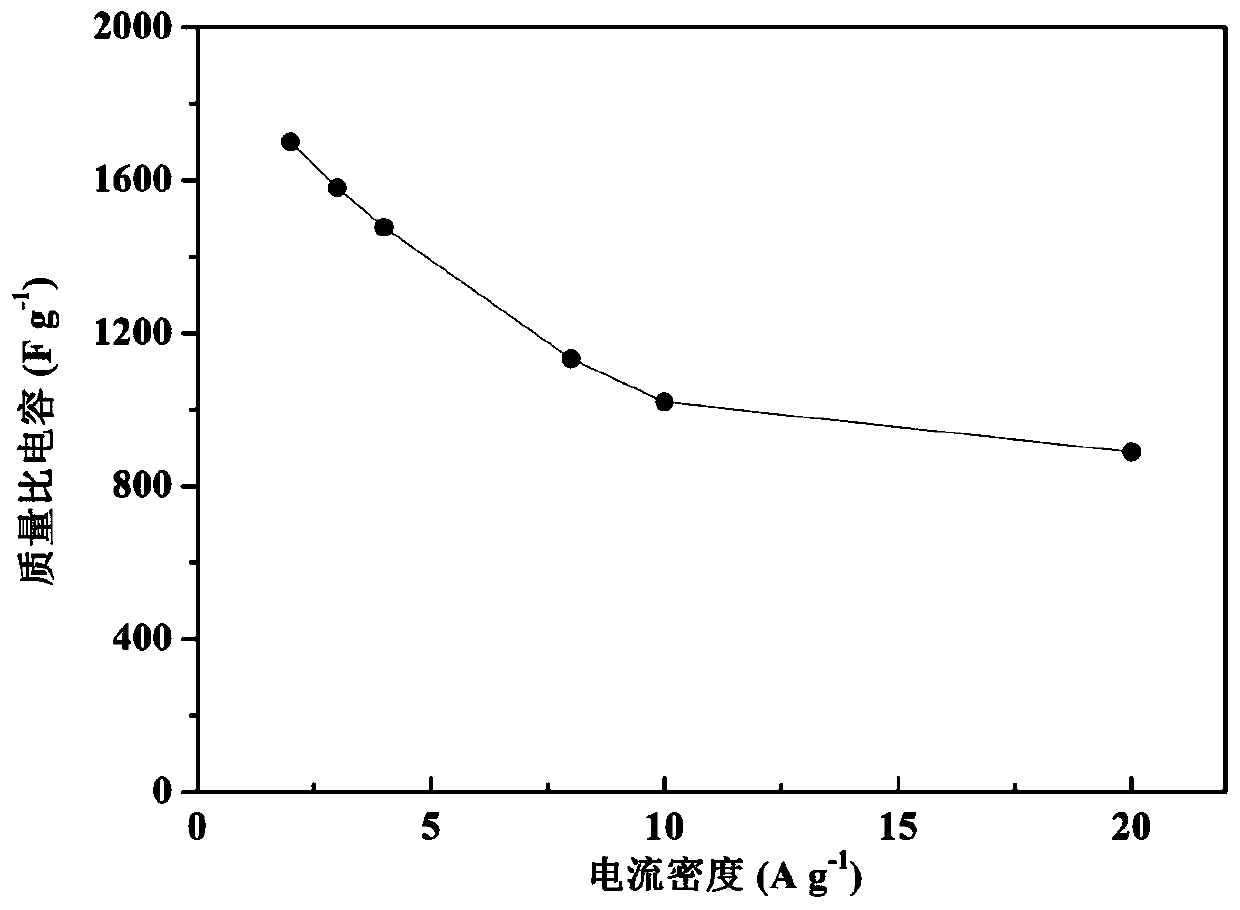

Transition metal selenide/ordered porous graphene aerogel composite electrode material and preparation method thereof

ActiveCN110581026ASimple preparation processEasy to operateHybrid capacitor electrodesCell electrodesPorous grapheneComposite electrode

The invention belongs to the technical field of materials and discloses a transition metal selenide / ordered porous graphene aerogel composite electrode material and a preparation method thereof. The transition metal selenide / ordered porous graphene aerogel composite electrode material is prepared through a two-step method. The preparation method is rapid and simple in technological process and lowin cost; the obtained energy storage electrode material has excellent electrochemical performance and is convenient for industrial application. The transition metal selenide / ordered porous graphene aerogel composite electrode material prepared has a porous network structure, has the mass capacity of 1701F / g, has excellent rate capability and cycling stability, and can be applied to electrodes ofsupercapacitors and batteries.

Owner:BINZHOU UNIV

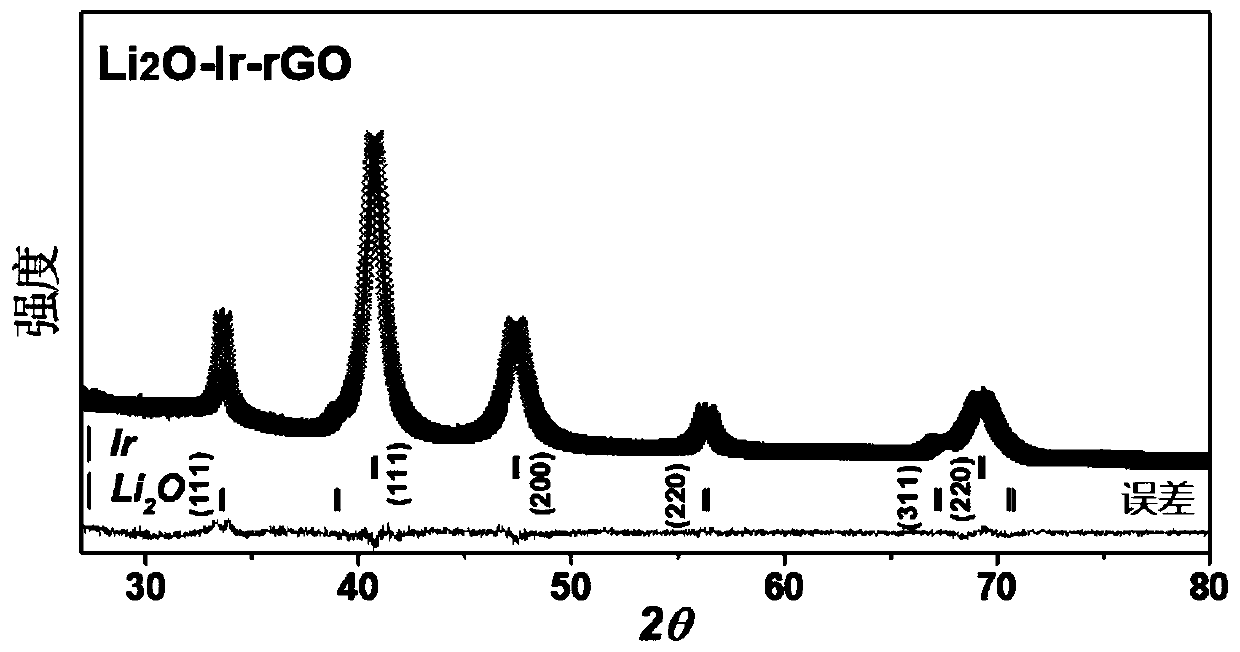

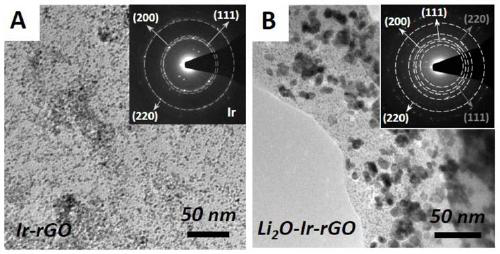

Closed lithium ion battery positive electrode based on oxyanion oxidation/reduction, and preparation method of closed lithium ion battery positive electrode

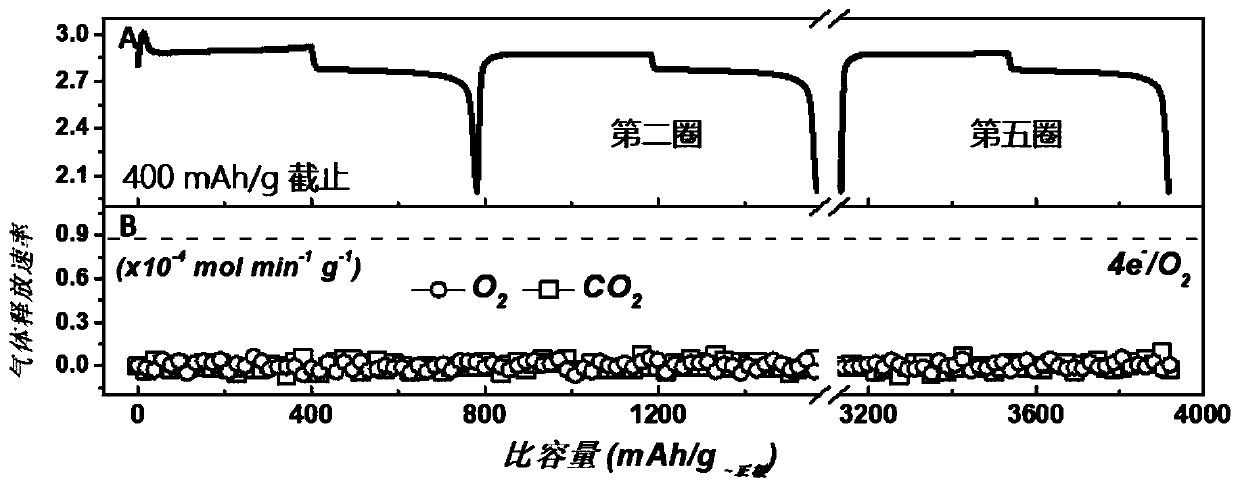

PendingCN111477840AStable working environmentLarge positive capacitySecondary cellsPositive electrodesLithium oxidePtru catalyst

The invention discloses an oxygen anion oxidation / reduction-based closed lithium ion battery positive electrode and a preparation method thereof. The positive electrode takes lithium oxide as an active material and is converted between lithium oxide and lithium peroxide or lithium superoxide under the action of a catalyst, wherein the process is carried out in a solid phase state, the active material is lithium oxide under a full discharge condition, the active material is lithium peroxide or the lithium superoxide under a full charge condition, and the catalyst is a noble metal simple substance / oxide, a transition metal oxide or a carbon / noble metal alloy. Compared with the prior art, the oxygen anion oxidation / reduction-based closed lithium ion battery positive electrode has the following advantages that (1) high mass specific capacity is achieved by utilizing redox of an oxygen element with relatively small stoichiometry, and a stable battery working environment is ensured by adopting a closed battery structure; and (2) the positive electrode of the battery is large in capacity and high in reversibility.

Owner:NANJING UNIV

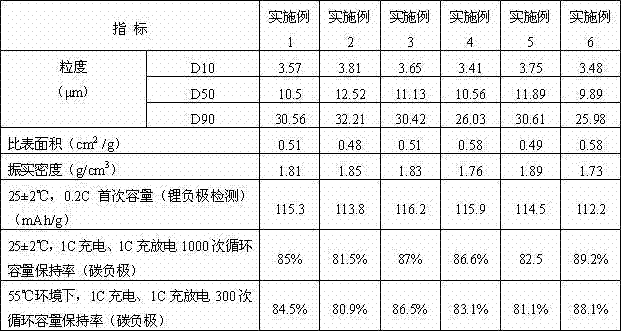

A silicon-carbon composite material, a preparation method thereof and a lithium ion battery

ActiveCN109216689AImprove stabilityImprove performanceSecondary cellsNegative electrodesCarbon layerCarbon composites

The invention relates to the field of electrochemistry and negative electrode material of lithium ion battery, and discloses a silicon-carbon composite material, a preparation method thereof and a lithium ion battery. The silicon-carbon composite material comprises a matrix material, nano-silicon loaded on the surface of the matrix material and a coating carbon layer coated on an outer layer, wherein the coating carbon layer comprises an amorphous carbon layer and a conductive agent dispersed in the amorphous carbon layer. The silicon-carbon composite material of the invention is used as the negative electrode active material of the lithium ion battery, and the prepared lithium electron battery has good first-time efficiency and cycle stability, and obviously good comprehensive performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

Battery anode and primary cell as well as preparation method thereof

InactiveCN101355151AHigher quality than capacityIncrease energy densityNon-aqueous electrolyte cellsPrimary cell electrodesActive matterDiiron Trioxide

The invention provides a positive electrode for a primary cell, comprising a collector body and a positive material loaded on the collector body. The positive material comprises a positive active matter, a conductive agent and a bonding agent, wherein the positive active matter is ferric oxide and / or ferroferric oxide. The primary cell prepared by the positive electrode has the advantages of higher mass specific capacity and energy density and longer service life.

Owner:BYD CO LTD

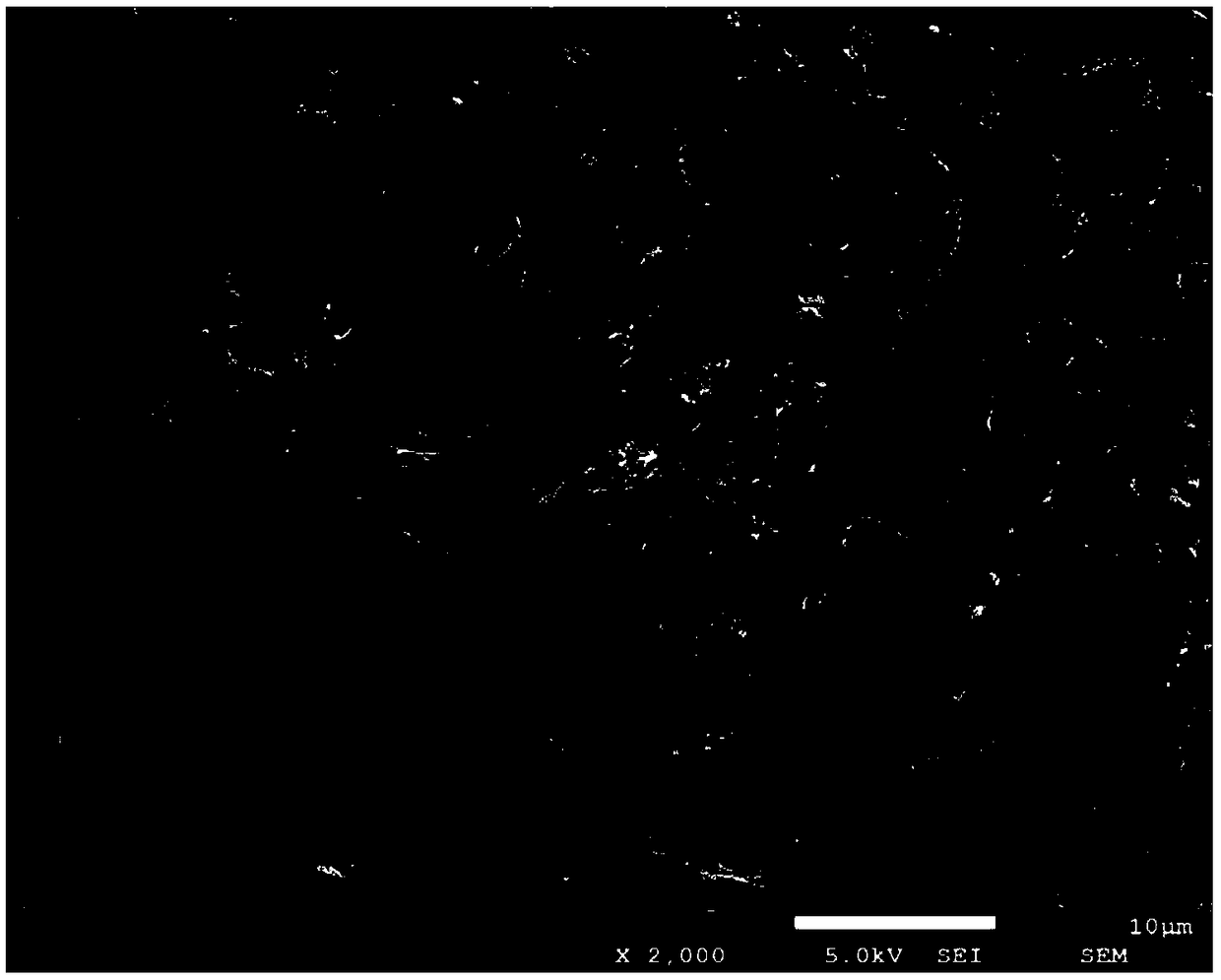

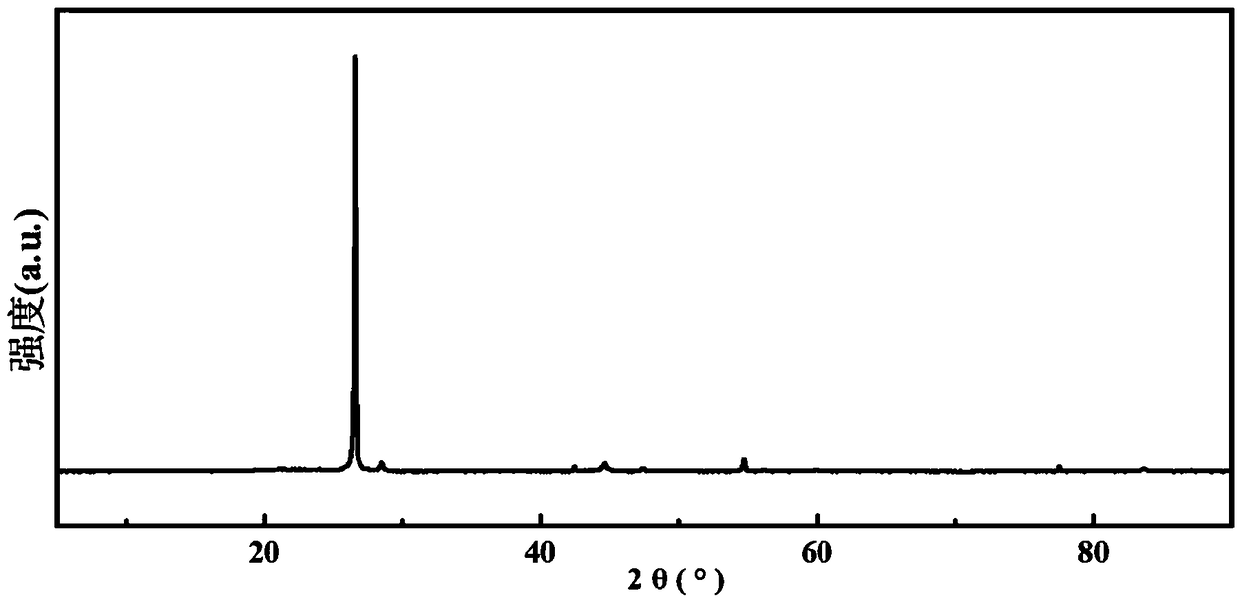

A lithium-silicon battery electrode material, a preparation method thereof and a lithium-silicon battery

ActiveCN109256544AAvoid chalkingImprove cycle stabilityMaterial nanotechnologyCell electrodesComposite filmSilicon alloy

The invention relates to the technical field of lithium ion batteries, in particular to a lithium silicon battery electrode material, a preparation method thereof and a lithium silicon battery. The lithium-silicon battery electrode material provided by the invention comprises silicon. Carbon nanotube composite film, lithium silicon alloy and lithium fluoride, the lithium silicon alloy doped with the interior of the carbon nanotube composite film, wherein the lithium fluoride is doped with the Surface of the silicon-carbon nanotube composite film; The Si-Silicon-Carbon nanotube composite film have porous structure. The lithium-silicon battery prepared by using the electrode material provided by the invention has high mass specific capacity.

Owner:河南克莱威纳米碳材料有限公司

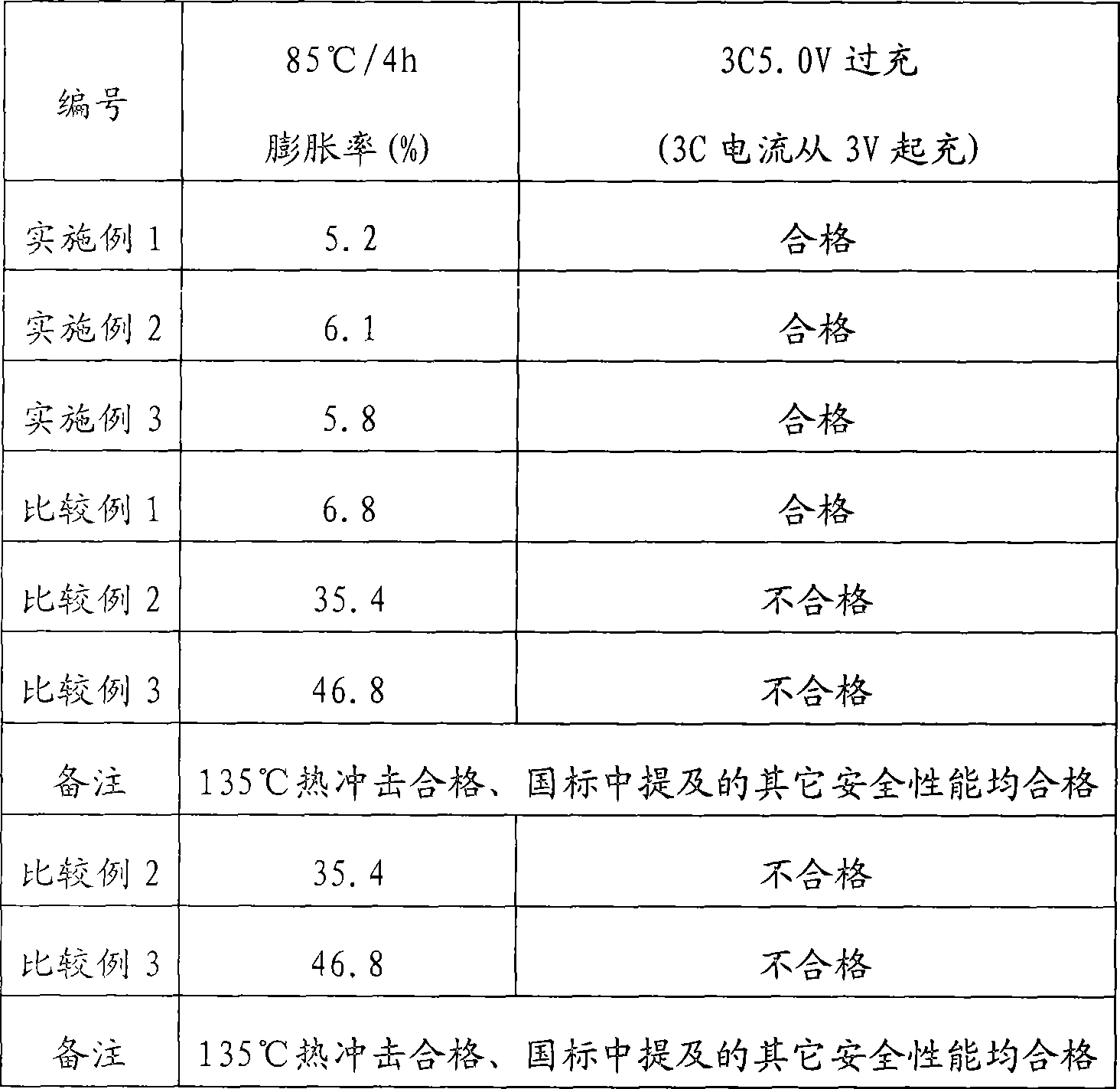

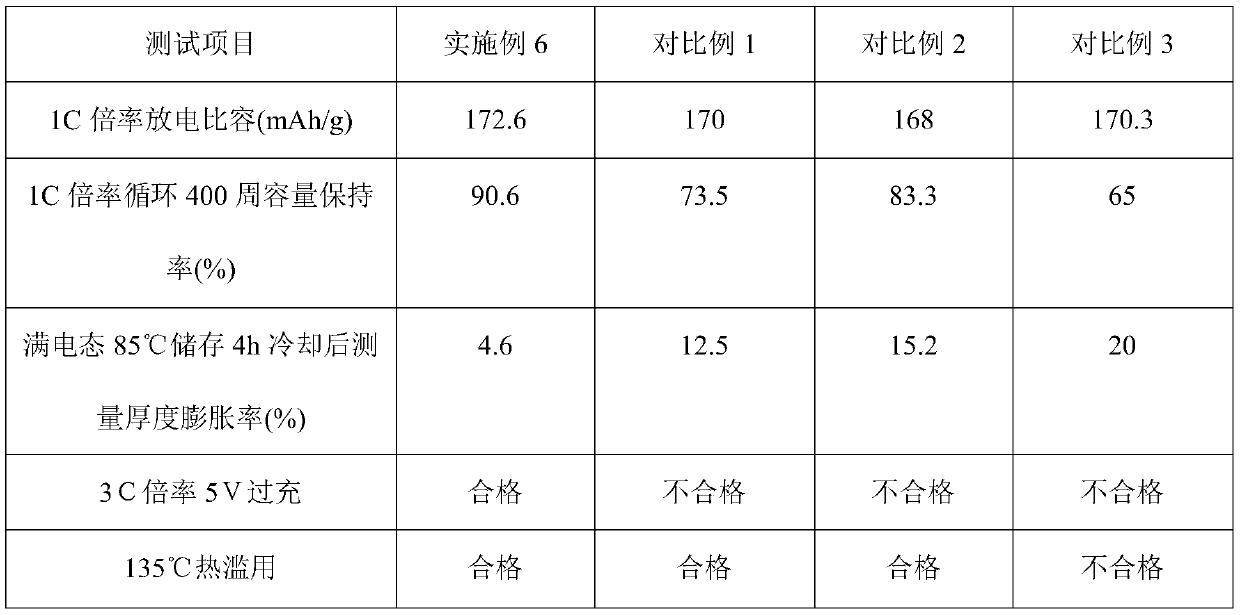

Positive electrode material preparation method and prepared positive electrode material

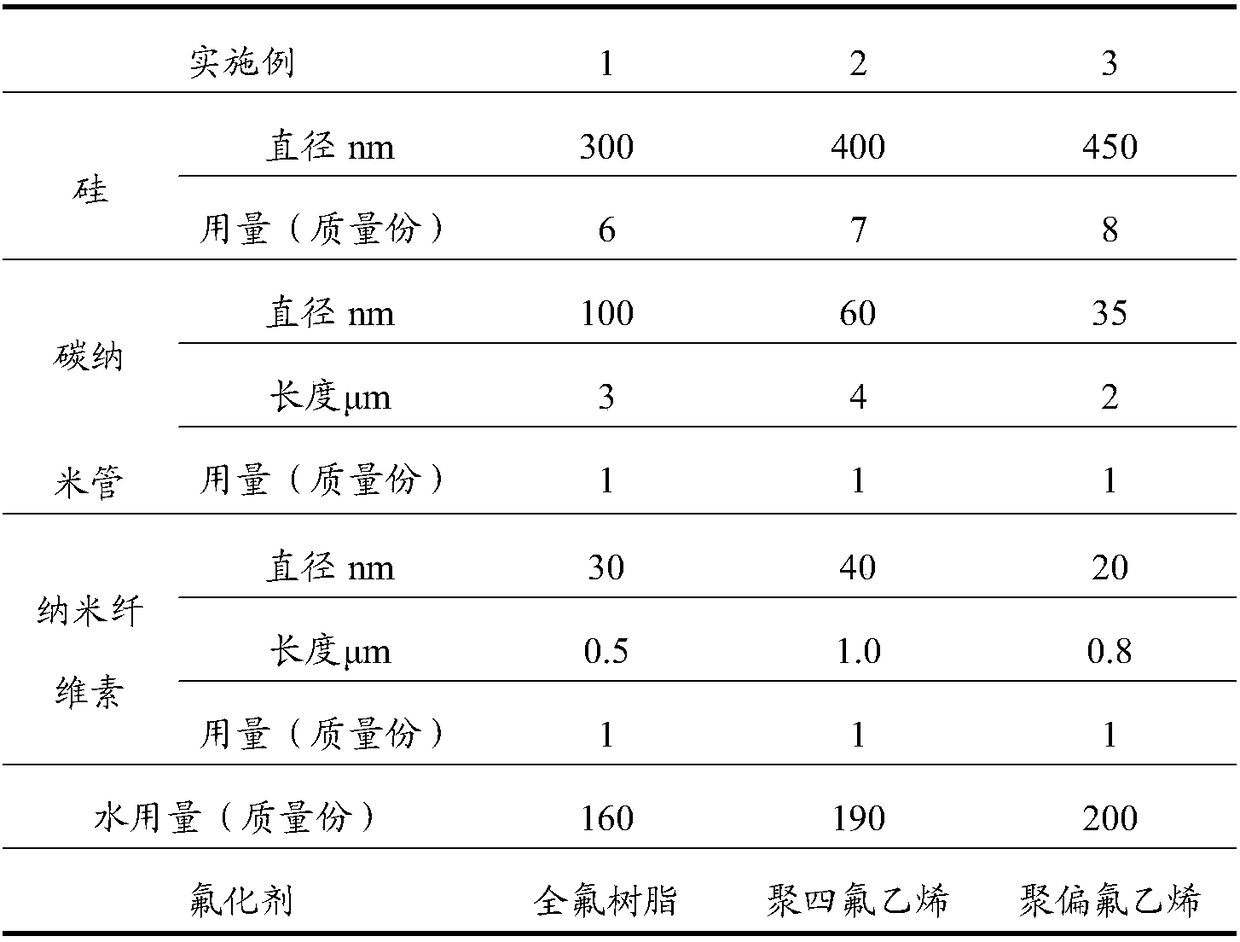

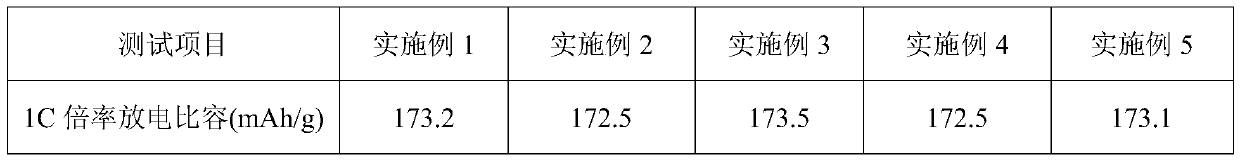

ActiveCN110518209AHigh specific capacityIncrease energy densityCell electrodesSecondary cellsHigh temperature storageManganese

The invention provides a positive electrode material preparation method, which comprises the steps of A, performing mixing treatment and sintering treatment on a first lithium source and a doped cobalt source to obtain a material A; B, performing mixing treatment and sintering treatment on a second lithium source, a nickel-manganese-cobalt ternary precursor and nickel oxide to obtain a material B;C, performing mixing treatment and sintering treatment on the material A, the material B and a coating agent, wherein doping elements for doping the cobalt source comprise at least one of Mg, Al, Tiand Zr and Sb, and the coating agent comprises at least one of aluminum oxide, lanthanum oxide and yttrium oxide and nickel oxide. The positive electrode material prepared according to the positive electrode material preparation method has the advantages of high specific capacity, good cycle performance, small high-temperature storage thickness expansion rate, high energy density and the like, andcan meet the requirements of the market on the positive electrode material for the high-capacity high-performance lithium ion battery.

Owner:广东风华新能源股份有限公司

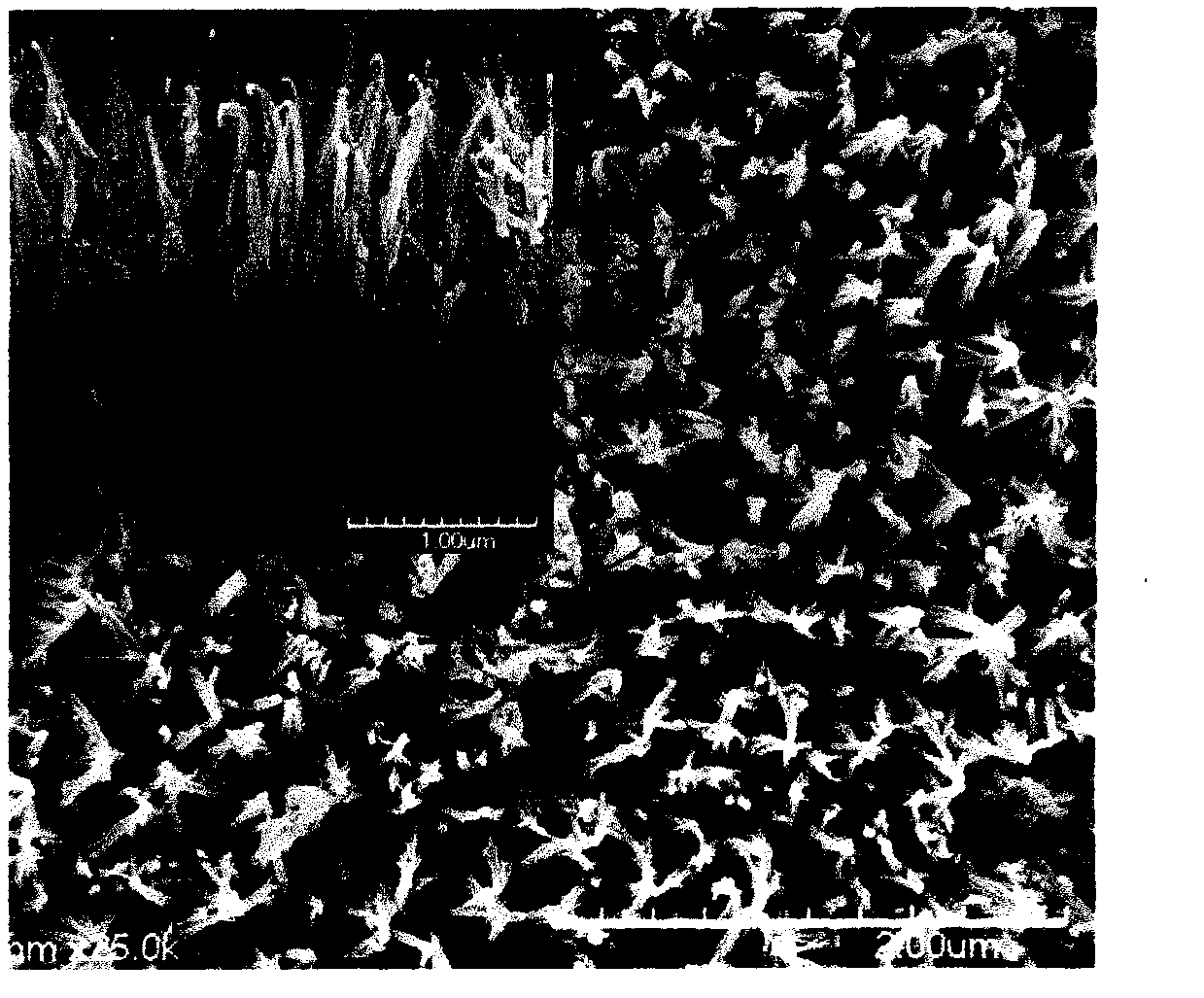

High-performance nickel-cobalt oxide composite nanowire film for super capacitor

InactiveCN102709060AIncrease transfer rateShortened diffusion channelElectrolytic capacitorsHybrid capacitor electrodesCapacitanceNickel salt

The invention discloses a high-performance nickel-cobalt oxide composite nanowire film for a super capacitor. Nickel salt and cobalt salt are used as raw materials, the nickel-cobalt composite nanowire film is generated on a metal titanium substrate, wherein the molar ratio of nickel salt and cobalt salt is 1-5:1-5. The film not only has the advantages of larger specific surface area, simplification in electrode preparation process, alkaline environment stability and the like, but also has excellent super capacitance performance, such as high quality specific capacity and favorable cycle performance, and is an excellent electrode material for the super capacitor in electrochemistry.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com