A lithium-silicon battery electrode material, a preparation method thereof and a lithium-silicon battery

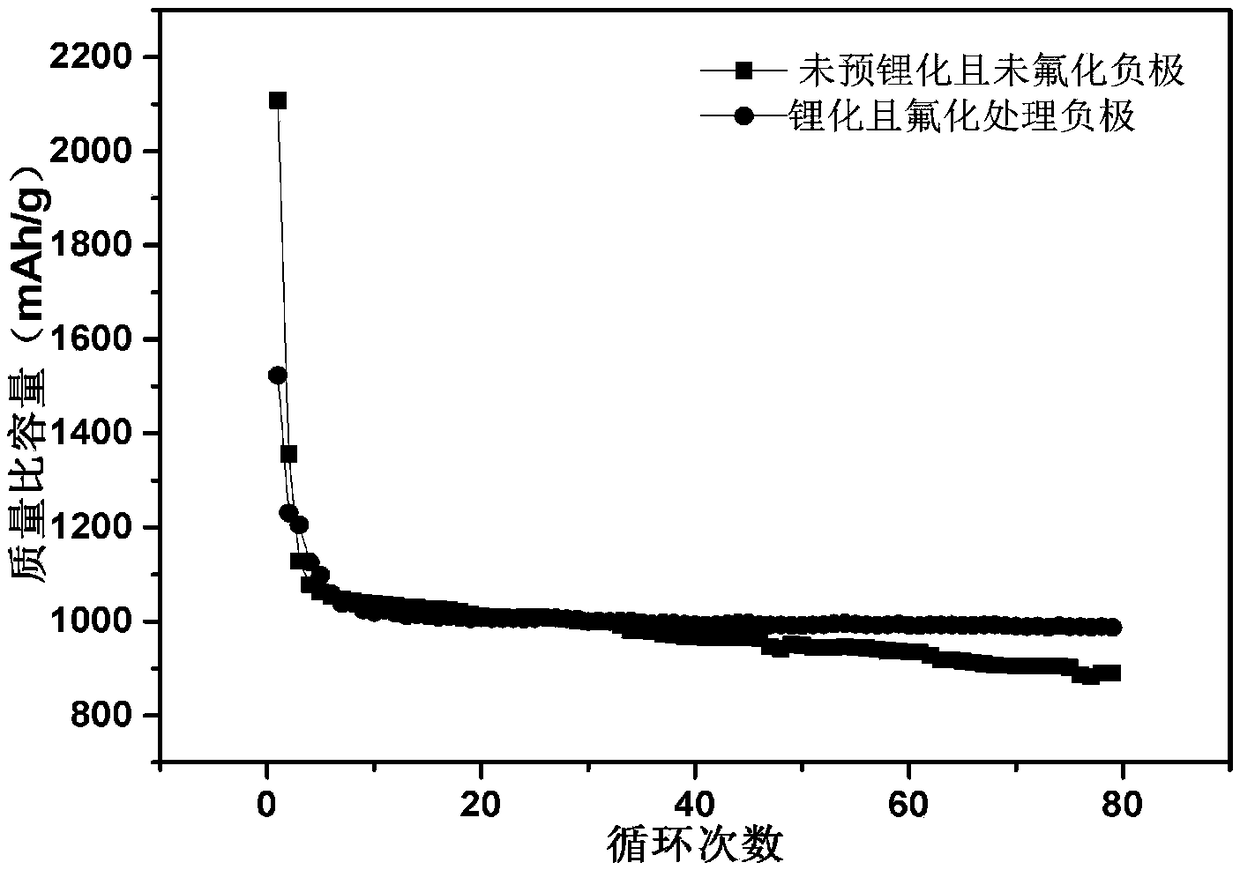

A technology for electrode materials and silicon batteries, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as unsatisfactory specific capacity of batteries, achieve improved cycle stability, high-quality ratio Capacity and the effect of prolonging the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the lithium-silicon battery electrode material described in the above technical solution, comprising the following steps:

[0031] (1) shearing and dispersing a mixture comprising silicon, carbon nanotubes, a binder and water to obtain an active slurry;

[0032] (2) Forming the active slurry in the step (1) at a high temperature on the surface of the substrate to obtain a silicon-carbon nanotube composite film; the temperature of the high-temperature film formation is 150-200° C.;

[0033] (3) performing a pre-lithiation treatment on the silicon-carbon nanotube composite film of the step (2), to obtain a lithiation modified film;

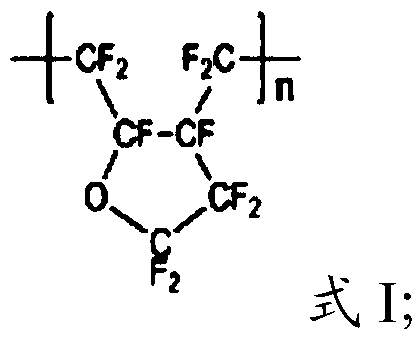

[0034] (4) Perform fluorination modification on the lithiated modified thin film in the step (3) to obtain a lithium-silicon battery electrode material.

[0035] In the invention, the mixture including silicon, carbon nanotube, binder and water is sheared and dispersed to obtain act...

Embodiment 1

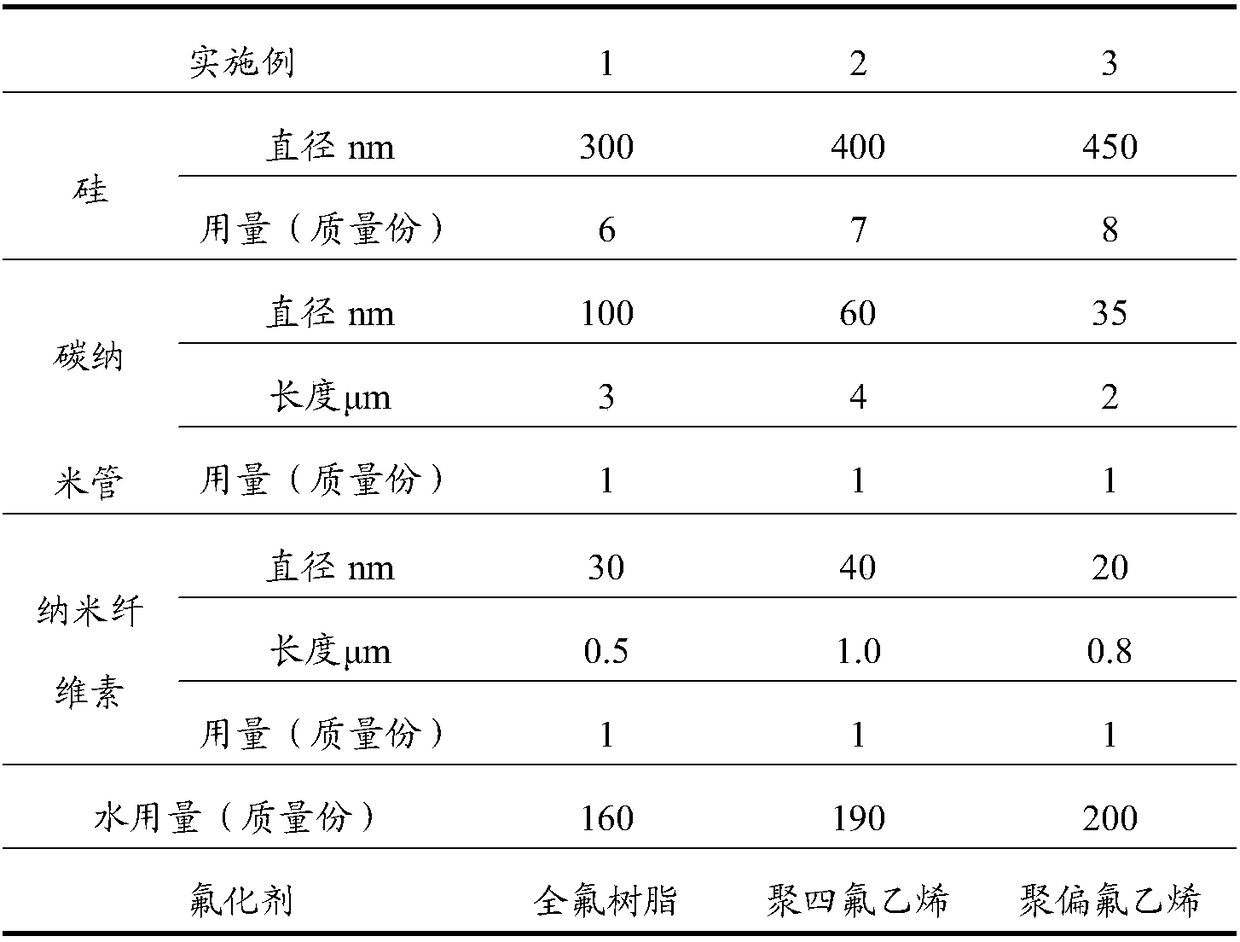

[0066] Mix silicon, carbon nanotubes, nanocellulose and deionized water according to Table 1, disperse at high-speed shear at 10,000r / min for 40 minutes, spray on a high-temperature aluminum plate at 150°C for high-temperature film formation, and obtain silicon-carbon nano Tube lamination film, cut The film sheet is spare.

[0067] Use the thin film obtained above as the negative electrode, use the lithium sheet as the counter electrode in the glove box, add the electrolyte dropwise, assemble it into a button-type half-cell without a diaphragm, and place it for 40 minutes to complete the pre-lithiation; then disassemble it in the glove box For the half-cell, take out the lithiated modified film, soak it in dimethyl carbonate (DMC) solution, then take out the film and wash it with ethanol, and then place it in ethanol for immersion for later use.

[0068] Prepare two tube furnaces, respectively numbered No. 1 tube furnace and No. 2 tube furnace. Connect the two tube furnaces ...

Embodiment 2~3

[0071] The lithium-silicon battery electrode material was prepared according to the method of Example 1, except that the amount of raw materials and the step parameters were different, as shown in Tables 1 and 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com