Preparation method of manganese-based compound positive pole material for secondary lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as acceleration, slow decomposition, and active material dissolution, and achieve low raw material costs, simple process routes, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

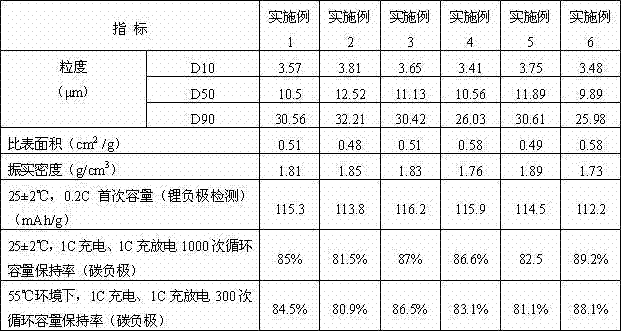

Examples

Embodiment 1

[0026] (1) Take Li 2 CO 3 , MnO 2 , Mn 3 o 4 , Nb 2 o 5 , Sb 2 o 3 Weighing according to the molar ratio of 0.545:0.88:0.333:0.01:0.005;

[0027] (2) Prepare a polyethylene glycol (PEG) solution with a mass percentage concentration of 0.1%;

[0028] (3) Mixed processing: press Li 2 CO 3 +Nb 2 o 5 +Sb 2 o 3 : Aluminum ball: 0.1% polyethylene glycol (PEG) solution = 1:2:1 mass ratio percentage, weighed, put into an inclined ball mill and mixed for 3 hours, and then dried at 300 ° C for 10 hours for drying. followed by manganese source MnO 2 , Mn 3 o 4 Then fully mixed and milled for 4 hours in the inclined ball mill of the aluminum ball medium;

[0029] (4) Roasting: Put the evenly mixed and ground materials into the saggar and send them into the continuous sintering roller tunnel kiln. 2h, then raise the temperature again, when the temperature reaches 720°C, roast at a constant temperature for 15h, then cool naturally to room temperature to obtain a semi-fini...

Embodiment 2

[0033] (1) Take Li 2 CO 3 , MnO 2 , Mn 3 o 4 , Nb 2 o 5 , Ga 2 o 3 Weighing with a molar ratio of 0.545:0.68:0.4:0.005:0.01;

[0034] (2) Prepare a polyethylene glycol (PEG) solution with a mass percentage concentration of 0.1%;

[0035] (3) Mixed processing: press Li 2 CO 3 +Nb 2 o 5 + Ga 2 o 3 : Aluminum ball: 0.1% polyethylene glycol (PEG) solution = 1:2:1 mass ratio percentage, weighed, put into an inclined ball mill and mixed for 3 hours, and then dried at 300 ° C for 10 hours for drying. followed by manganese source MnO 2 , Mn 3 o 4 Then fully mixed and milled for 4 hours in the inclined ball mill of the aluminum ball medium;

[0036] (4) Roasting: Put the evenly mixed and ground materials into the saggar and send them into the continuous sintering roller tunnel kiln. 2h, then raise the temperature again, when the temperature reaches 720°C, roast at a constant temperature for 15h, then cool naturally to room temperature to obtain a semi-finished produc...

Embodiment 3

[0040] (1) Take Li 2 CO 3 , MnO 2 , Mn 3 o 4 , Nb 2 o 5 , Ga 2 o 3 Weighing with a molar ratio of 0.545:0.98:0.3:0.005:0.01;

[0041] (2) Prepare a polyethylene glycol (PEG) solution with a mass percentage concentration of 0.1%;

[0042] (3) Mixed processing: press Li 2 CO 3 +Nb 2 o 5 + Ga 2 o 3 : Aluminum ball: 0.1% polyethylene glycol (PEG) solution = 1:2:1 mass ratio percentage, weighed, put into an inclined ball mill and mixed for 3 hours, and then dried at 300 ° C for 10 hours for drying. followed by manganese source MnO 2 , Mn 3 o 4 Then fully mixed and milled for 4 hours in the inclined ball mill of the aluminum ball medium;

[0043] (4) Roasting: Put the evenly mixed and ground materials into the saggar and send them into the continuous sintering roller tunnel kiln. 2h, then raise the temperature again, when the temperature reaches 720°C, roast at a constant temperature for 15h, then cool naturally to room temperature to obtain a semi-finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com