Cathode active substance for lithium ion battery, cathode material containing cathode active substance and lithium ion battery

A negative electrode active material, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of poor electrical conductivity, limited application, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] CuFeS 2 as negative electrode active material

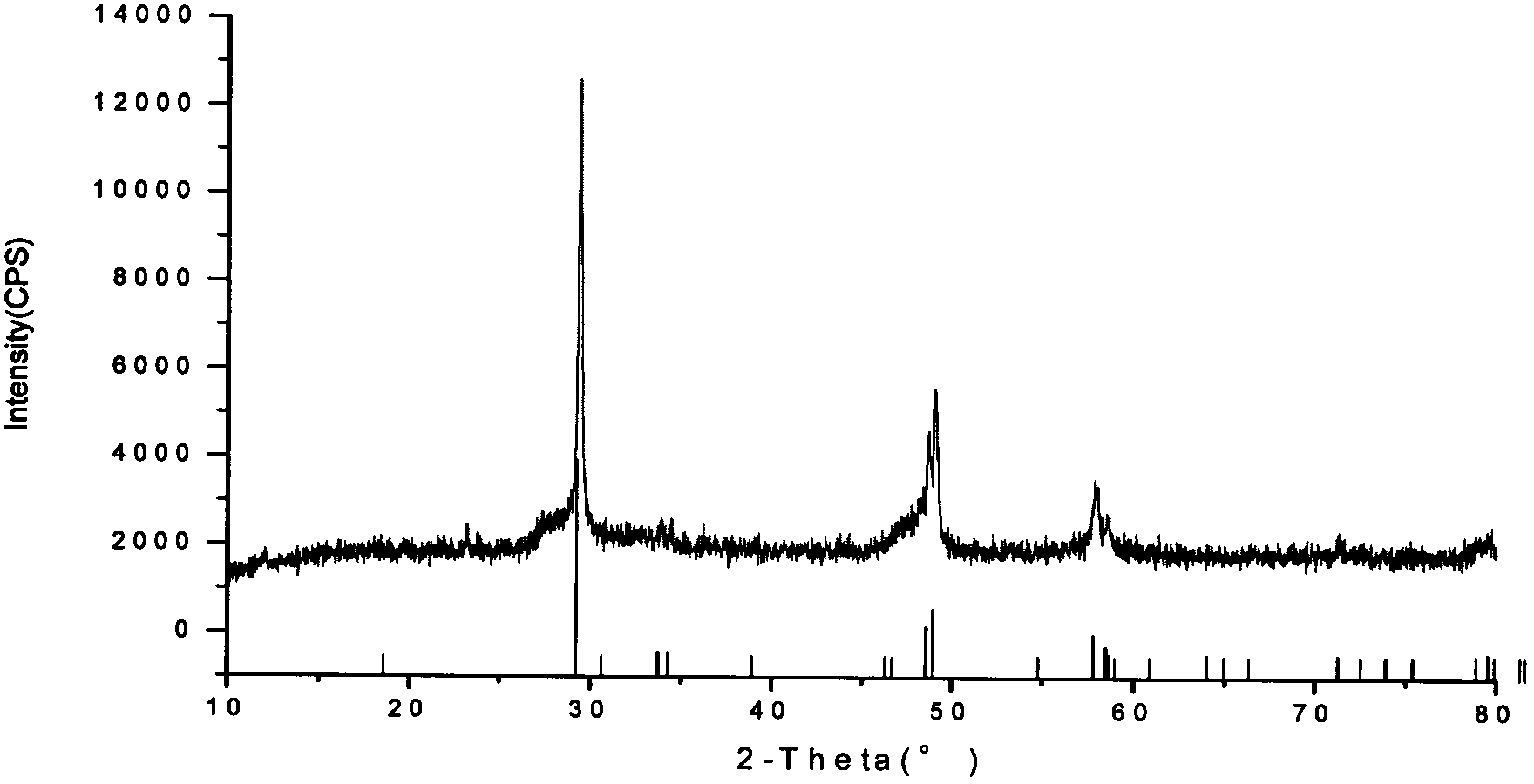

[0044] CuFeS prepared by solvothermal method 2 powder, figure 1 CuFeS 2 Powder XRD and CuFeS 2 The comparison chart of the standard spectrum (JCPDS card No.24-0211). The red curve in the figure is CuFeS 2 XRD spectrum of the powder, the black histogram is CuFeS 2 standard map. Comparative illustration of synthesized CuFeS 2 The powder has high purity and good crystallinity.

[0045] The electrochemical properties of the negative electrode active material can be determined by the following test methods:

[0046] 1. Preparation of negative electrode material electrode sheet. Negative electrode active material Cu x m y S z , the binder and the conductive agent are mixed according to a certain ratio (such as 80:10:10), and an appropriate amount of 1-methyl-2-pyrrolidone (NMP) is added, ground with an agate mortar, and fully stirred to a paste slurry. Coat it evenly on the copper foil (about 200um thick) (us...

Embodiment 2

[0055] CuTi 2 S 4 as negative electrode active material

[0056] Preparation of spinel-type CuTi by solvothermal method 2 S 4 Powder, assembled into test cell according to embodiment 1, test CuTi 2 S 4 electrochemical performance.

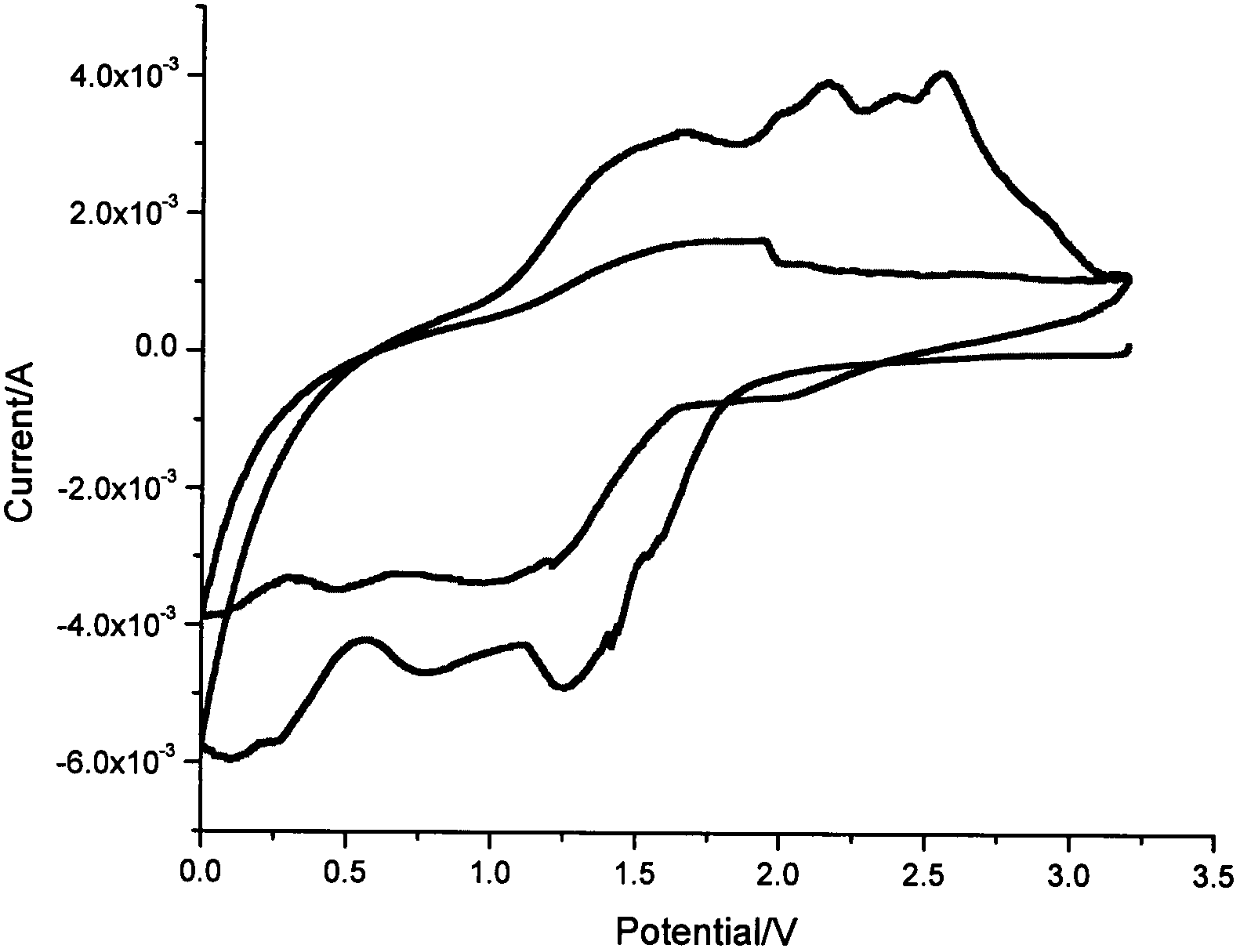

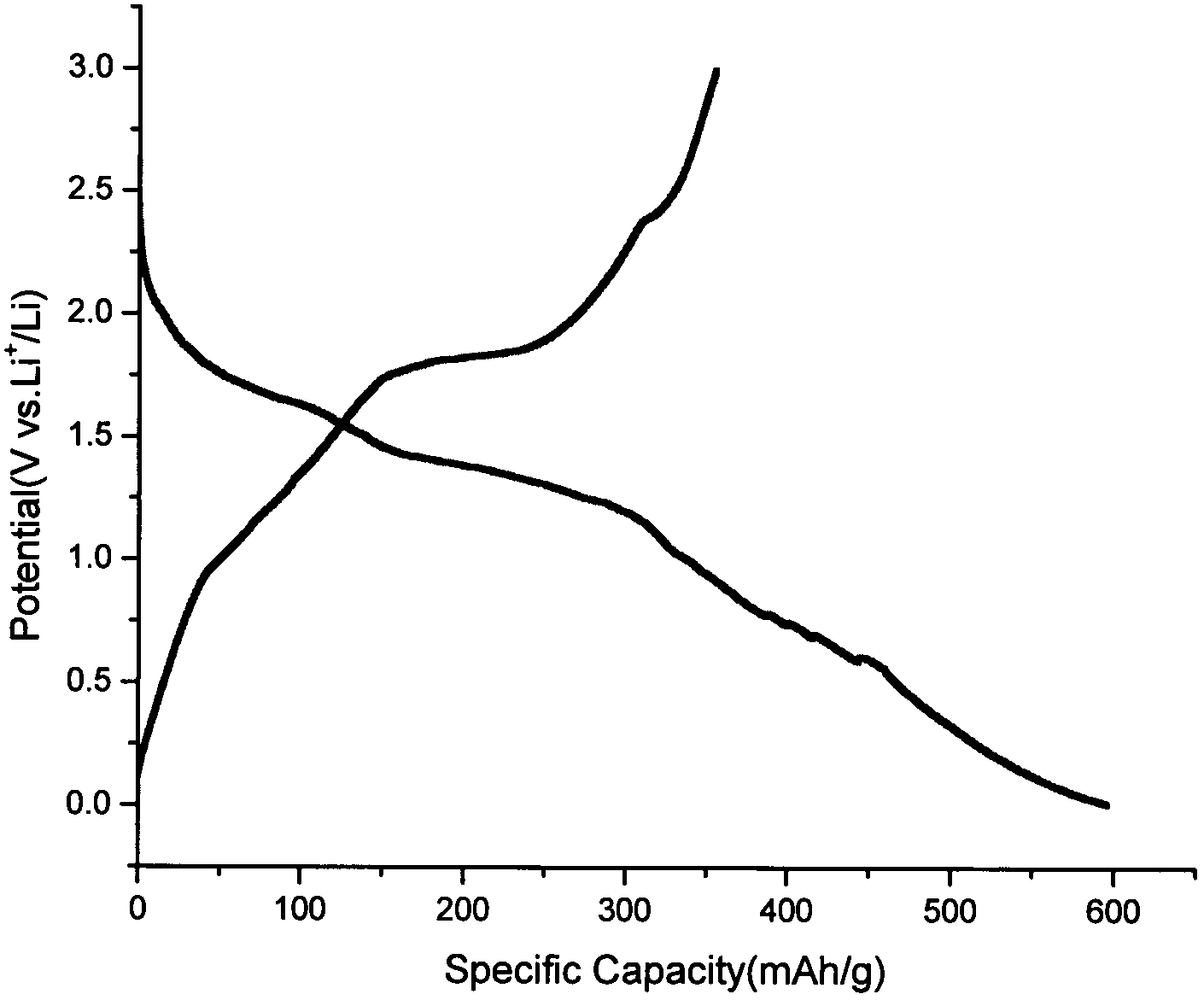

[0057] At a scan rate of 0.001 V / s, a cyclic voltammetry test was performed at 0.1 V to 3.0 V (testing instrument such as: electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.), model: CHI660D). The first cycle test results show that there are two oxidation peaks at 0.35V and 0.6V, and there is a broad reduction peak at 2.0V~2.4V. Charge and discharge test between 0.1V~3.0V and 0.5V~3.0V with 0.04mA current (testing instrument such as: BTS high-precision battery testing system (manufactured by China Xinwei Electronics Co., Ltd.), model: CT-3008W- 5V10mA-S1). The 0.1V~3.0V cycle results show that the first discharge specific capacity is 746mAh / g, and after 10 cycles, the discharge specific capacity is lower than 100mAh...

Embodiment 3

[0060] CuCr 2 S 4 as negative electrode active material

[0061] Preparation of spinel-type CuCr by solvothermal method 2 S 4 Powder, assembled into test cell according to embodiment 1, test CuCr 2 S 4 electrochemical performance.

[0062] At a scan rate of 0.001 V / s, a cyclic voltammetry test was performed at 0.1 V to 3.0 V (testing instrument such as: electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.), model: CHI660D). The first cycle test results show that there are two oxidation peaks at 0.35V and 0.6V, and there is a broad reduction peak at 2.0V~2.4V. Use 0.04mA current to conduct charge and discharge test between 0.1V~3.0V and 0.5V~3.0V (testing instrument such as: BTS high-precision battery detection system (manufactured by China Xinwei Electronics Co., Ltd.), model: CT-3008W- 5V10mA-S1). The 0.1V~3.0V cycle results show that the first discharge specific capacity is 746mAh / g, and after 10 cycles, the discharge specific capacity is lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com