A silicon-carbon composite material, a preparation method thereof and a lithium ion battery

A silicon-carbon composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as insufficient conductivity and incomplete coating, and achieve high initial efficiency, high mass specific capacity, and reduced The effect of ohmic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

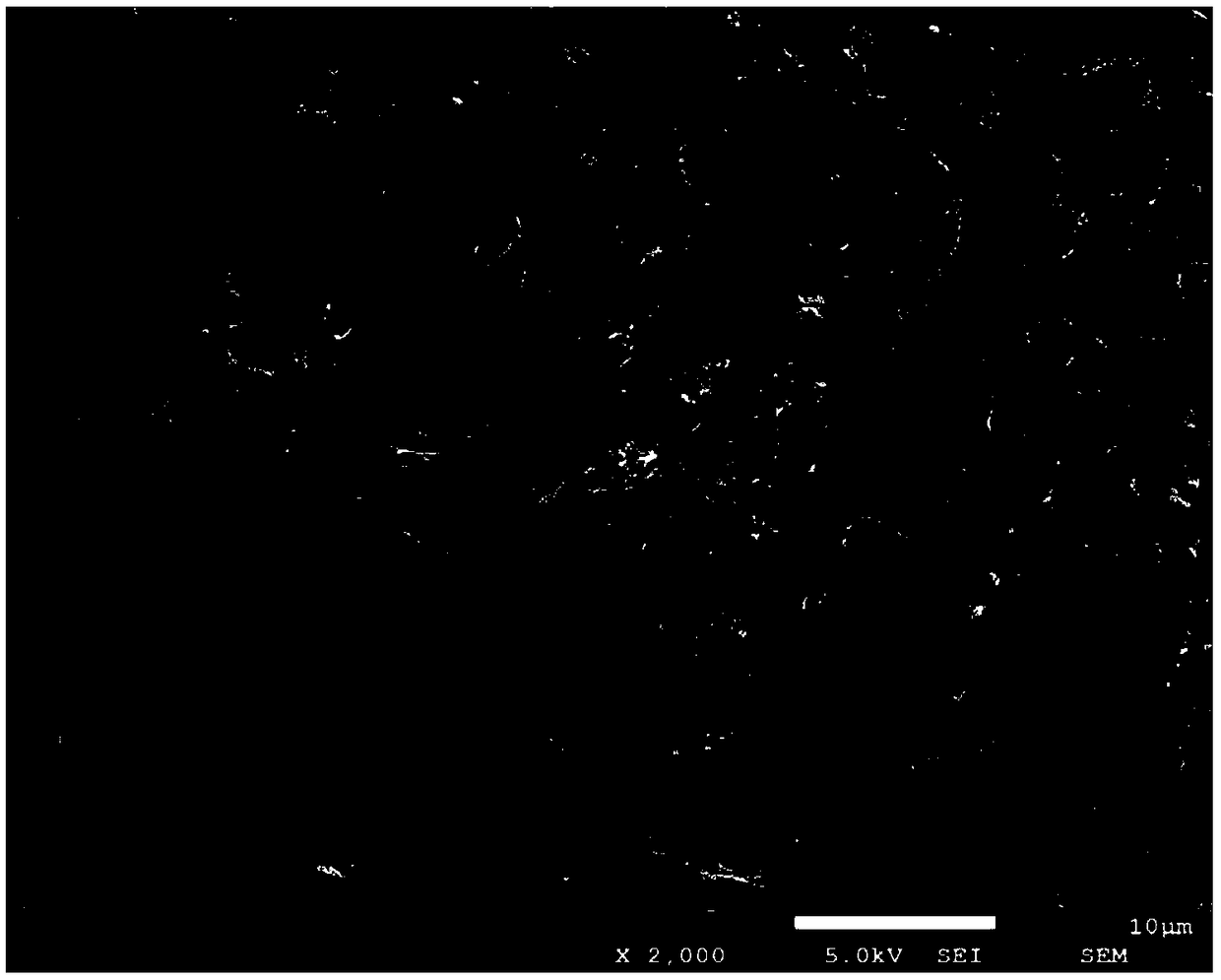

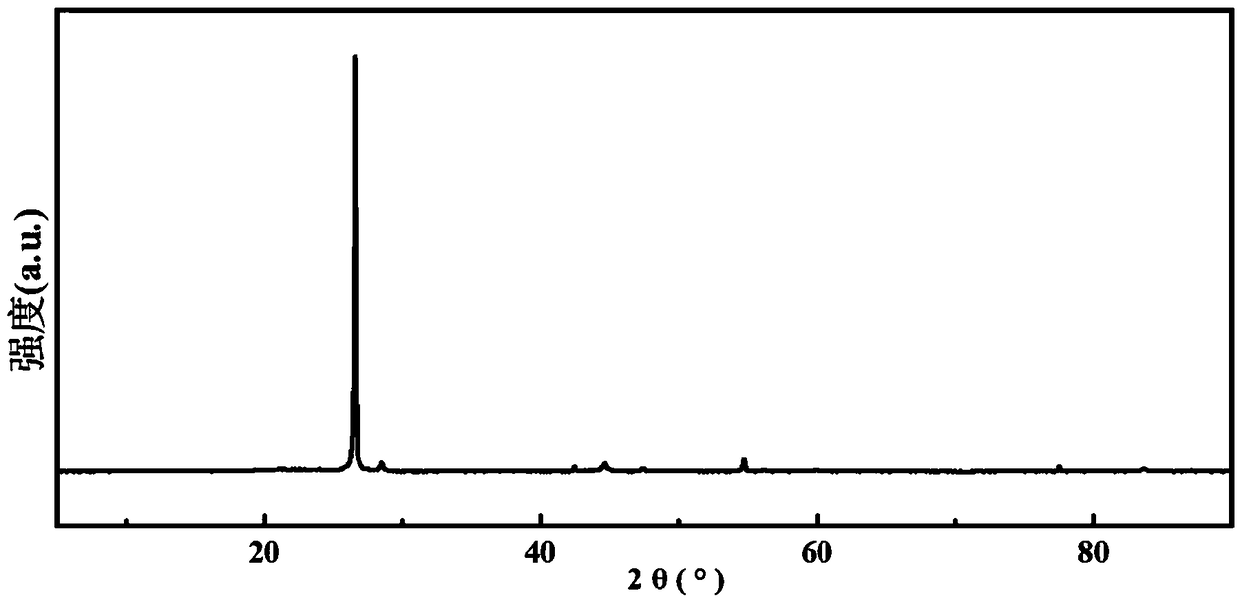

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing a silicon-carbon composite material, the method comprising the following steps:

[0027] (1) adding the base material to the ethanol mixture of nano-silicon, and uniformly dispersing to obtain a mixed solution;

[0028] (2) The mixed solution is spray-dried to obtain a precursor;

[0029] (3) Mix the precursor, carbon source and conductive agent, and then perform a calcination under the protection of nitrogen;

[0030] (4) Pulverize the primary sintered material obtained in step (3), then mix it with a carbon source and a conductive agent, perform secondary calcination under nitrogen protection, then pulverize it, and mix the pulverized material with graphite.

[0031] In the method of the present invention, in step (1), the matrix material can be selected from at least one of natural graphite, artificial graphite and mesocarbon microspheres.

[0032] In the method of the present invention, the particle size o...

preparation example 1

[0048] 1kg of crude silicon (Xuzhou Lingyun Silicon Industry Co., Ltd., average particle size 5 μm) is uniformly dispersed in 9kg of ethanol to obtain a mixed solution, and the obtained mixed solution is added to a nano sand mill. 2 Grinding for 8 hours under protection, wherein the mill speed is 1200 rpm, using 0.1 mm zirconium balls, to prepare nano-silicon slurry with an average particle size of 50 nm.

preparation example 2

[0050] 1 kg of asphalt particles (Jining Chenguang Coal Chemical Co., Ltd., softening point: 250°C) was coarsely pulverized by a mechanical pulverizer for 3 minutes (rotation speed: 15,000 rpm), and the obtained powder was finely pulverized by a jet pulverizer (inlet air pressure 0.8Mpa, pulverization pressure 0.7Mpa ), the average particle size of the asphalt powder obtained was 2.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com