Preparation method for flexible graphene-modified knittable carbon nanofiber

A technology of carbon nanofiber and graphene, which is applied in the chemical industry to achieve the effects of large mass specific capacity, extended cycle life, and excellent high-current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

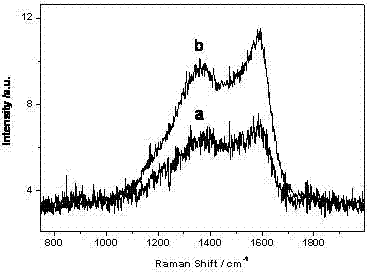

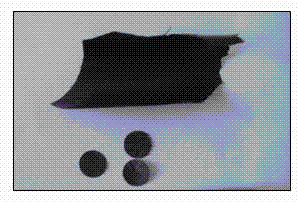

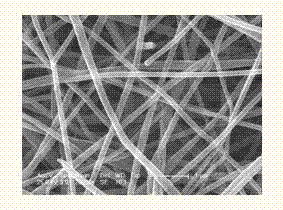

Embodiment 1

[0031] 1.5 g of polyacrylonitrile with a molecular weight of 70,000 was dissolved in 14 ml of DMF solution, and after a clear solution was obtained under magnetic stirring, 1 ml of graphene oxide in DMF solution was added until the two solutions were mixed evenly. Transfer the prepared precursor solution to a plastic container with a metal needle on the tip of the container, and connect it to a power supply device that can provide high-voltage static electricity. Under the action of an electric field force of 10KV, a blend of graphene oxide and polyacrylonitrile is obtained. Precursor nanofibers, the precursor nanofibers are in the air atmosphere tubular quartz tube, from room temperature to 270 °C at a rate of 5 °C per minute, and then in a nitrogen atmosphere at a rate of 10 °C per minute to 1100 °C to obtain graphene modification of carbon nanofibers.

Embodiment 2

[0033]1.5g of polyacrylonitrile with a molecular weight of 70,000 is dissolved in 20ml of graphene oxide saturated DMF solution, and under electric stirring, a clear precursor solution is obtained, which is transferred to a plastic container with a metal pillow on the tip of the container. Provide a high-voltage electrostatic power supply connection. Under the action of an electric field force of 20KV, the precursor nanofibers blended with graphene oxide and polyacrylonitrile are obtained. The precursor nanofibers are transferred to a tubular quartz tube, and the precursor nanofibers are transferred from room temperature to The temperature rises from 5°C to 600°C per minute, and after passing in hydrogen for one hour, continue to pass in argon to 1100°C to obtain graphene-modified carbon nanofibers.

Embodiment 3

[0035] 1.5g of polyacrylonitrile with a molecular weight of 70,000 is dissolved in 20ml of graphene oxide saturated DMF solution, and under electric stirring, a clear precursor solution is obtained, which is transferred to a plastic container with a metal pillow on the tip of the container. Provide a high-voltage electrostatic power supply connection. Under the action of an electric field force of 20KV, the precursor nanofibers blended with graphene oxide and polyacrylonitrile are obtained. The precursor nanofibers are in a tubular quartz tube in a nitrogen atmosphere. 2°C to 270°C, transferred to a tube furnace with an argon atmosphere, and then raised to 2700°C at a rate of 5°C per minute to obtain graphene-modified carbon nanofibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com