Tin oxide/alumina doped carbon composite material and preparation method thereof

A carbon composite material, tin dioxide technology, applied in the field of electrochemistry, can solve the problems of poor cycle performance and battery capacity depletion, achieve good stability, excellent rate performance, and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

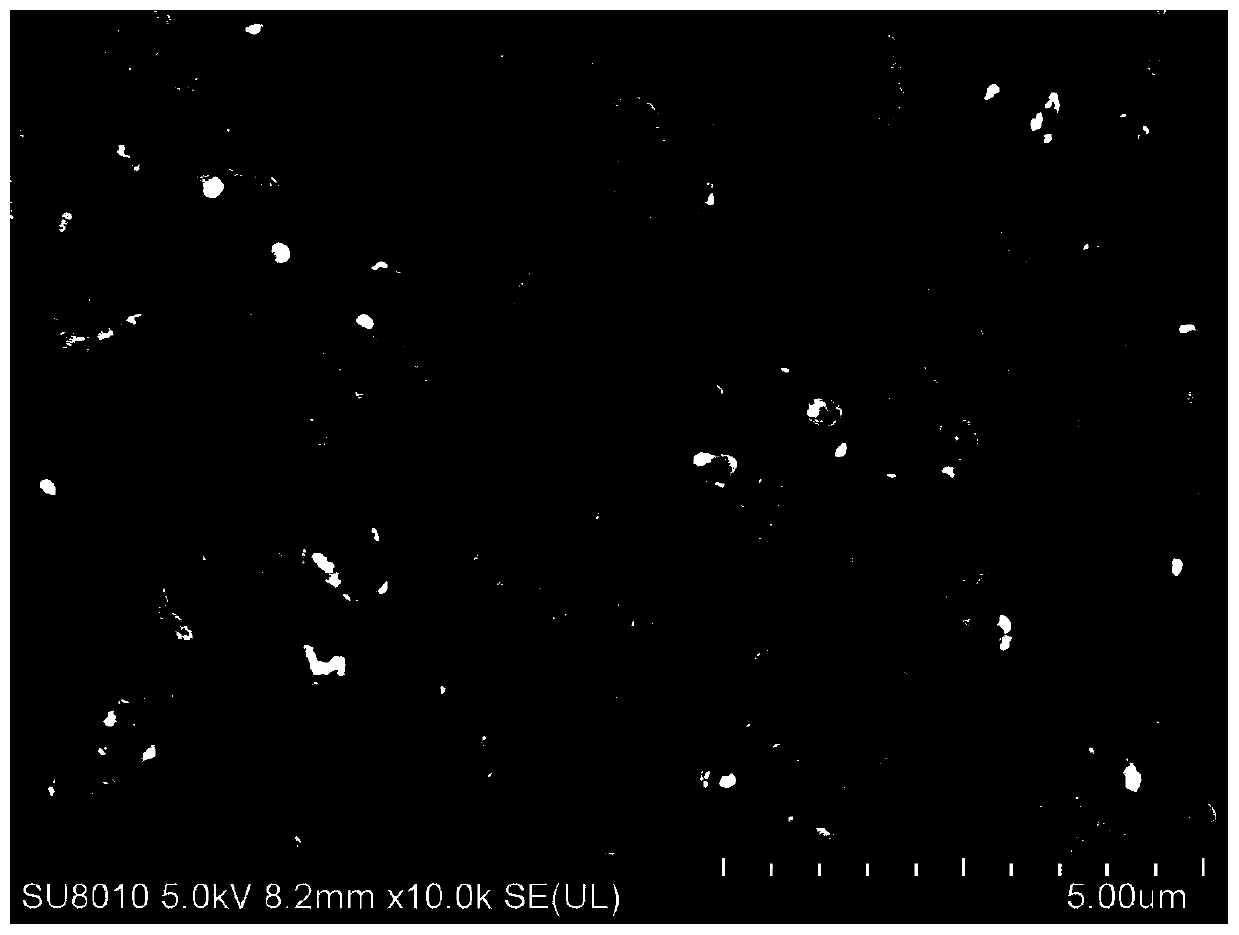

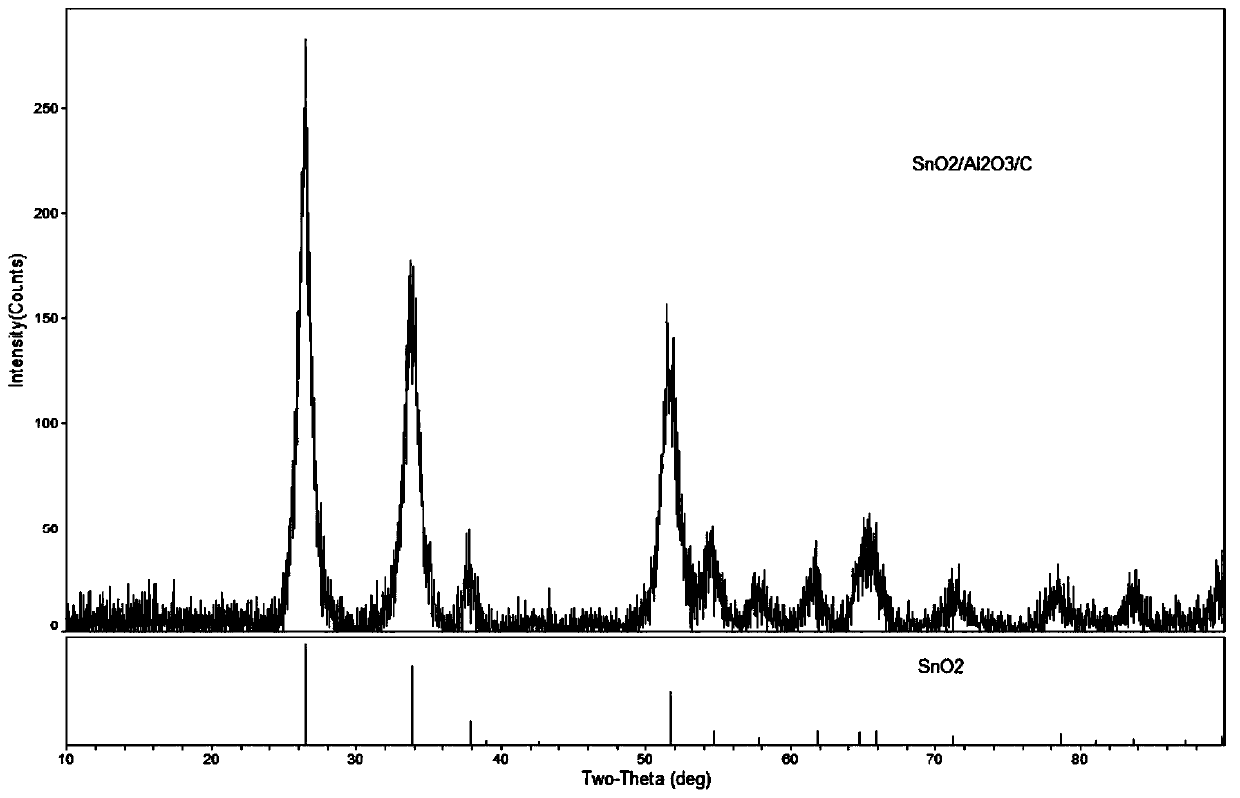

Embodiment 1

[0034] Add 180ml of absolute ethanol to 220ml of deionized water to make a mixed solution, add 2.4g of urea and 0.95g of potassium stannate trihydrate and stir until completely dissolved. Pour the dissolved solution into a 100ml polytetrafluoroethylene liner, put it into an autoclave for hydrothermal reaction, and keep it at 150°C for 24h. After cooling down to room temperature, the obtained precipitate was centrifuged and washed with deionized water, and dried at 80° C. to obtain a white powder of tin dioxide nanoparticles. Put 0.5g of tin dioxide nanoparticles and 0.03g of alumina into a ball mill jar for intermittent ball milling for 30 minutes, add 0.09g of carbon after 30 hours and continue ball milling for 5 hours to obtain a tin dioxide / alumina doped carbon composite material.

[0035] Example 1 is configured according to the ratio of 8:1:1 and the prepared tin dioxide / alumina doped carbon composite material, acetylene black and binding agent (PVDF) are mixed, and are u...

Embodiment 2

[0040] Add 180ml of absolute ethanol to 220ml of deionized water to make a mixed solution, add 2.4g of urea and 0.95g of potassium stannate trihydrate and stir until completely dissolved. Pour the dissolved solution into a 100ml polytetrafluoroethylene liner, put it into an autoclave for hydrothermal reaction, and keep it at 150°C for 24h. After cooling down to room temperature, the obtained precipitate was centrifuged and washed with deionized water, and dried at 80° C. to obtain a white powder of tin dioxide nanoparticles. Put 0.5g of tin dioxide nanoparticles and 0.028g of alumina into a ball mill jar for intermittent ball milling for 30 minutes, add 0.028g of carbon after 30 hours and continue ball milling for 5 hours to obtain a tin dioxide / alumina doped carbon composite material.

[0041] Example 2 is configured according to the ratio of 7:1.5:1.5 and the prepared tin dioxide / alumina doped carbon composite material, acetylene black and binding agent (PVDF) are mixed, and...

Embodiment 3

[0043] Add 180ml of absolute ethanol to 220ml of deionized water to make a mixed solution, add 2.4g of urea and 0.95g of potassium stannate trihydrate and stir until completely dissolved. Pour the dissolved solution into a 100ml polytetrafluoroethylene liner, put it into an autoclave for hydrothermal reaction, and keep it at 150°C for 24h. After cooling down to room temperature, the obtained precipitate was centrifuged and washed with deionized water, and dried at 80° C. to obtain a white powder of tin dioxide nanoparticles. Put 0.5g of tin dioxide nanoparticles and 0.07g of alumina into a ball mill jar for intermittent ball milling for 30 minutes, add 0.14g of carbon after 30 hours and continue ball milling for 5 hours to obtain a tin dioxide / alumina doped carbon composite material.

[0044] Example 3 is configured according to the ratio of 7:1.5:1.5 and the prepared tin dioxide / alumina doped carbon composite material, acetylene black and binding agent (PVDF) are mixed, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com