Preparation method of porous conductive LiFePO4 positive plate used in lithium ion battery

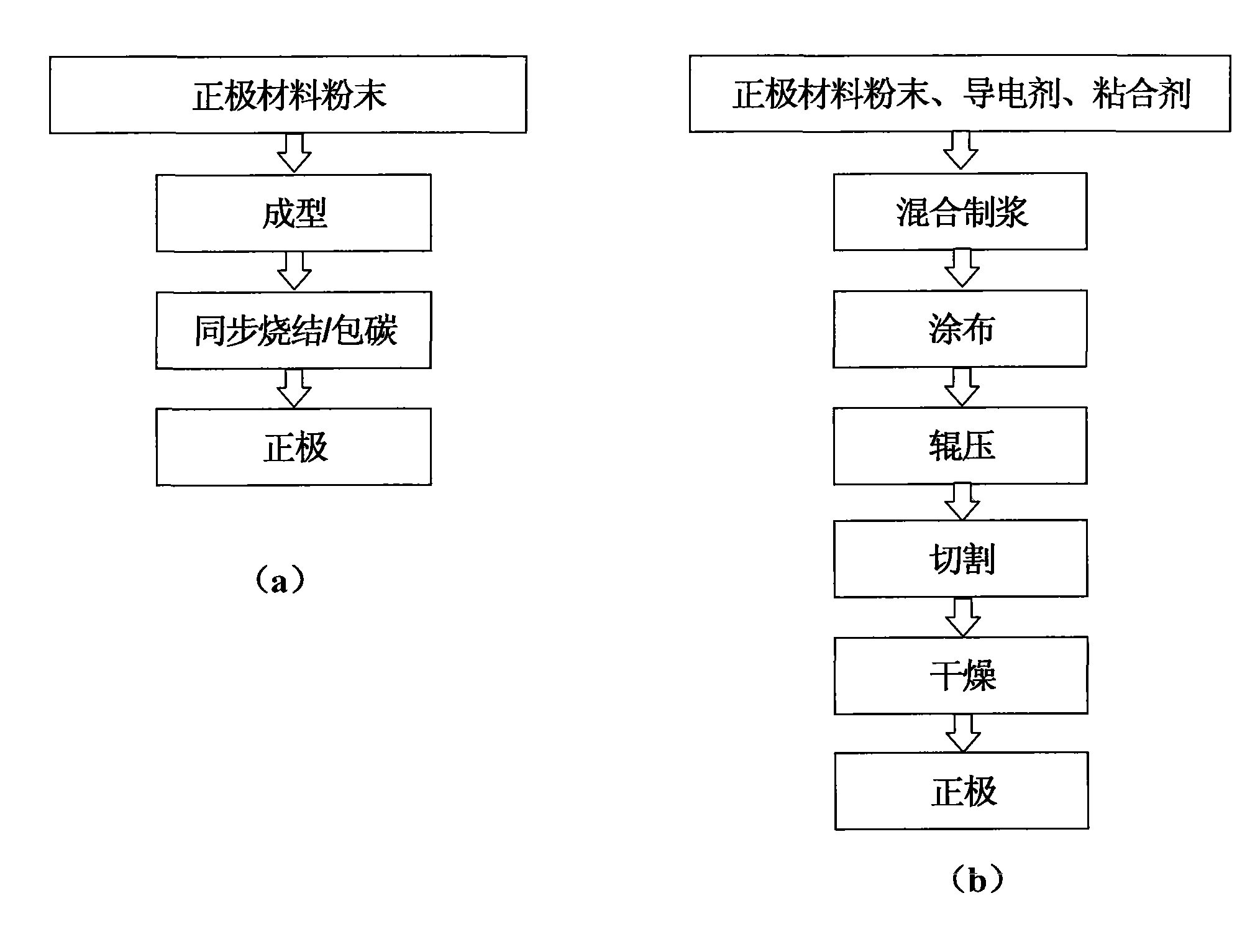

A lithium-ion battery, porous conductive technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of expensive adhesives and solvents for dissolving adhesives, shortening the traditional process, and lengthy and cumbersome processes for positive electrodes , to achieve the effects of low manufacturing cost, simplified process, and high mass-to-capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

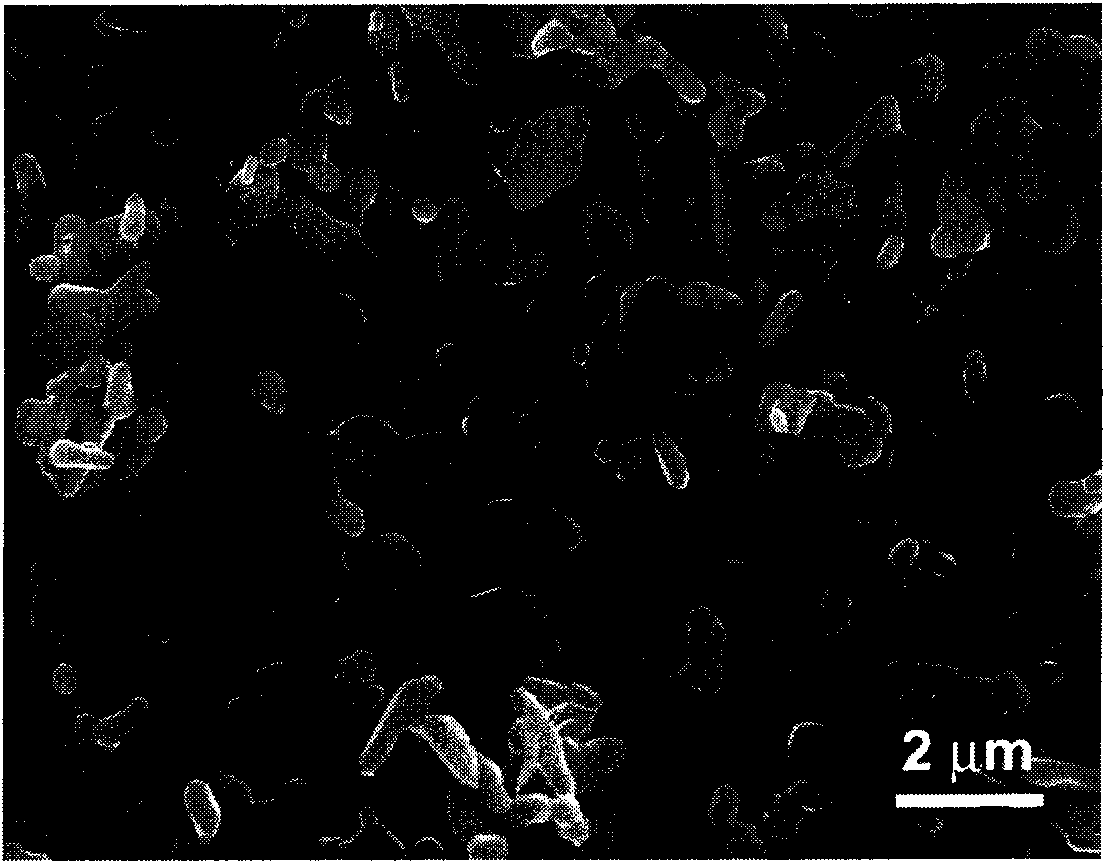

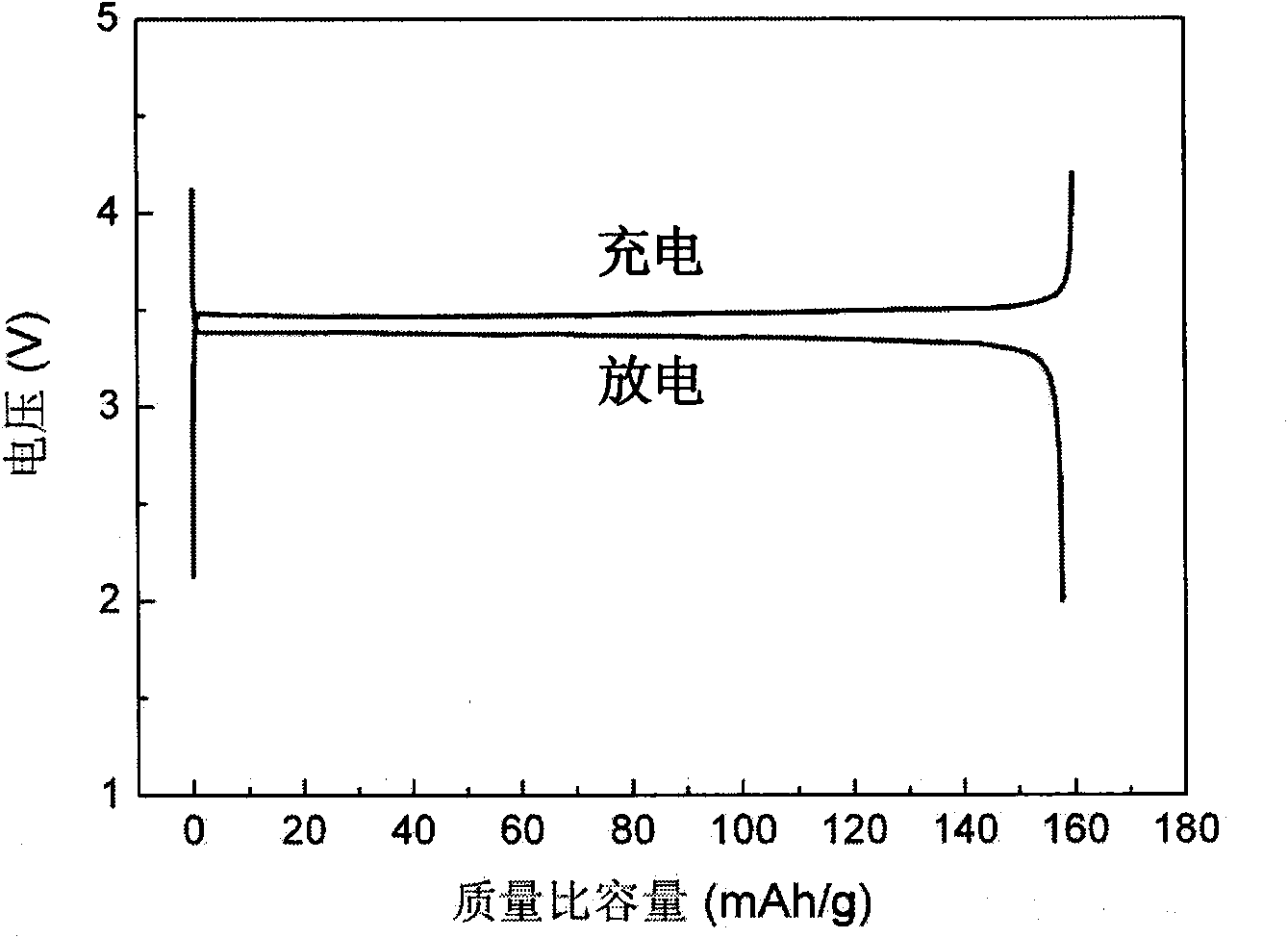

Embodiment 1

[0026] Put LiFePO under 20MPa pressure 4 The powder is cold-pressed into a green body, and the green body is placed in the constant temperature zone of the tube furnace, and then vacuumed for 1 hour (the vacuum degree reaches about 10Pa), after the air in the furnace is exhausted, nitrogen gas is introduced, and the temperature is raised to 700°C and then kept at constant temperature 15 min for sintering to make LiFePO 4 The particles are connected together, and then acetylene gas is introduced for chemical vapor deposition, and the LiFePO 4 A conductive carbon layer is coated on the particle, and the thickness of the conductive carbon film is about 4 nanometers. In the gas in the furnace, the volume percentage of acetylene gas is 10%, and the deposition time is 90 minutes. The sample after carbon deposition was cooled to room temperature with the furnace, and the porous conductive LiFePO was obtained. 4 Positive plate, conductive porous LiFePO 4 The porosity of the positi...

Embodiment 2

[0028] The difference is:

[0029] Put LiFePO under 30MPa pressure 4 The powder is cold-pressed into a green body, and the green body is placed in the constant temperature zone of the tube furnace, and then vacuumed for 1 hour (the vacuum degree reaches about 10Pa), after the air in the furnace is exhausted, nitrogen gas is introduced, and the temperature is raised to 580°C and then kept at a constant temperature 60 minutes for sintering to make LiFePO 4 The particles are connected together, and then acetylene gas is introduced for chemical vapor deposition, and the LiFePO 4 A conductive carbon layer is coated on the particle, and the thickness of the conductive carbon film is about 2 nanometers. In the gas in the furnace, the volume percentage of acetylene gas is 5%, and the deposition time is 3 hours. The sample after carbon deposition was cooled to room temperature with the furnace, and the porous conductive LiFePO was obtained. 4 Positive plate, porous conductive LiFeP...

Embodiment 3

[0031] The difference is:

[0032] Put LiFePO under 30MPa pressure 4 The powder is placed in the constant temperature zone of the tube furnace, then purged with argon for 2 hours, heated to 650°C and then sintered at a constant temperature for 30 minutes to make LiFePO 4 The particles are connected together, and then acetylene gas is introduced for chemical vapor deposition, and the LiFePO 4 A conductive carbon layer is coated on the particle, and the thickness of the conductive carbon film is about 3 nanometers. In the gas in the furnace, the volume percentage of acetylene gas is 20%, and the deposition time is 30 minutes. The sample after carbon deposition was cooled to room temperature with the furnace, and the porous conductive LiFePO was obtained. 4 Positive plate, porous conductive LiFePO 4 The porosity of the positive plate is about 28%. The first discharge efficiency was 94.8%, and the mass specific capacity of the positive plate was 159.3mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com