Closed lithium ion battery positive electrode based on oxyanion oxidation/reduction, and preparation method of closed lithium ion battery positive electrode

A lithium-ion battery and oxygen anion technology, applied in the field of electrochemistry, can solve the problems of complex lithium-air battery structure and implementation difficulties, and achieve the effects of high-quality specific capacity, large capacity, and high reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

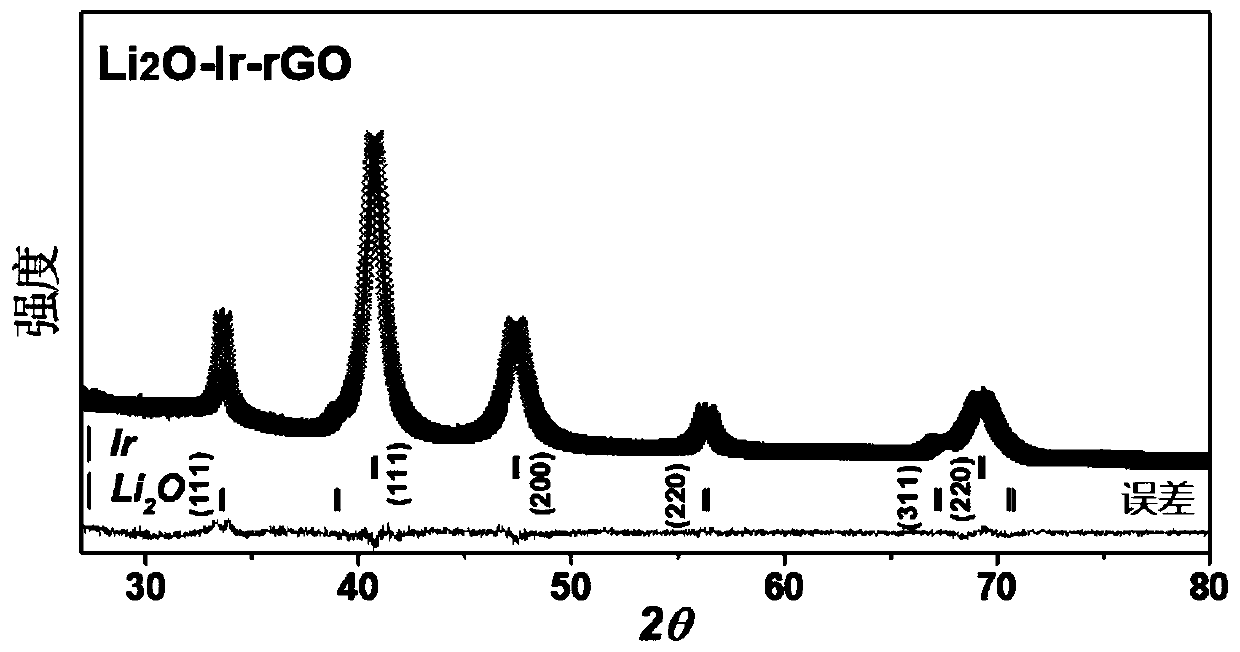

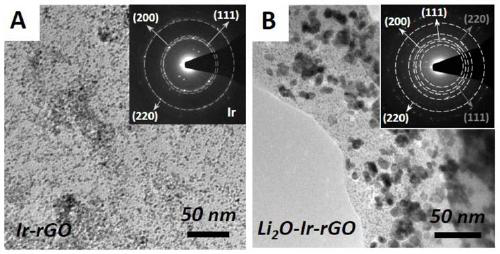

[0029] Weigh 30 mg of iridium chloride, 192 mg of citric acid, and 10 mg of graphene oxide, add them into 24 ml of benzyl alcohol, mix them in a closed container, and ultrasonicate for 1 hour. The uniformly mixed solution was transferred to a high-pressure reactor, and the temperature was raised to 160° C. at a constant speed, kept for 5 hours and then cooled naturally, and the solution was continuously stirred during the whole process. The resulting jelly was centrifuged and washed and dried with a mixed solvent of ethanol and acetone to obtain an elemental iridium / graphene composite material. Thermogravimetric analysis showed that the loading of elemental iridium was 66.73%.

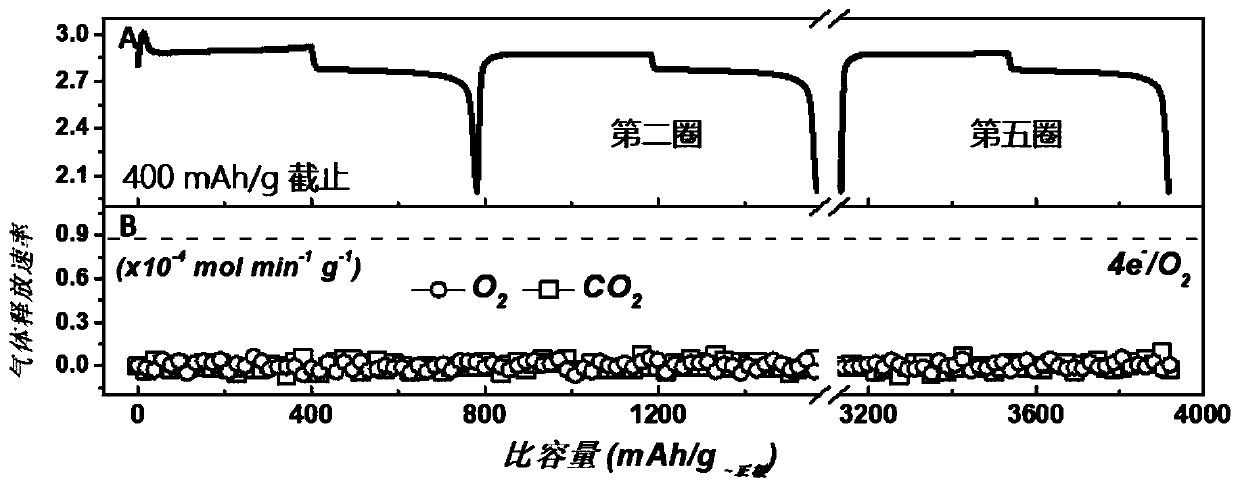

[0030] Weigh 15 mg of elemental iridium / graphene composite material and 35 mg of lithium oxide, and mix the elemental iridium / graphene catalyst and lithium oxide active material in an inert gas atmosphere by mechanical ball milling. The ratio of catalyst to active material is 3:7. The inert gas is ni...

Embodiment 2

[0038] The positive electrode prepared in Example 1 and the lithium-silicon alloy negative electrode were assembled into a battery, specifically:

[0039]The silicon negative plate was prepared by coating film method. Weigh silicon powder, conductive carbon black super P and sodium alginate binder according to the mass ratio of 60:20:20, add an appropriate amount of deionized water, and mix and stir to obtain a uniform slurry. The mixed slurry was coated on a copper foil current collector, and vacuum-dried at 80° C. to obtain a silicon negative electrode. Cut the silicon electrodes into discs with a tablet press. In a glove box with an argon atmosphere, use an R2032 button battery, and first package the silicon negative electrode in the order of negative electrode shell, spring leaf, gasket, metal lithium, separator, silicon electrode, and positive electrode shell. Use the current density of 0.05C (1C=4200mAh / g) to pretreat the silicon negative electrode for 3 cycles, and th...

Embodiment 3

[0043] The simple iridium / graphene composite material was prepared according to the method in Example 1.

[0044] During the preparation of the electrode, the active material was replaced with lithium peroxide. Weigh 10 mg of elemental iridium / graphene composite material and 40 mg of lithium peroxide, and mix the elemental iridium / graphene catalyst and lithium peroxide active material in an inert gas atmosphere by mechanical ball milling. The ratio of catalyst to active material is 1:4. The inert gas is nitrogen or argon. The ball milling time was 125 hours. Finally, the positive electrode active powder is obtained.

[0045] Transfer the positive electrode active powder to an argon atmosphere, grind and mix the positive electrode active powder and binder evenly at a mass ratio of 8:2, add an appropriate amount of N-methylpyrrolidone, stir evenly, and coat on the aluminum foil current collector . The electrodes were dried under vacuum conditions to obtain a closed lithium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com