Cathodic active material as well as preparation method and battery thereof

A technology of negative electrode active material and crystal plane, which is applied in the field of negative electrode active material and its preparation and battery, can solve the problems of low tap density of lithium vanadium oxide and imperfect crystal shape of the material, and achieves excellent electrochemical performance, perfect crystal shape, The effect of high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides the preparation method of this kind of negative electrode active material, wherein, LiVO 2 The preparation steps of the material include:

[0026] (1) ball milling lithium source, vanadium source and carbon source to obtain a precursor;

[0027] (2) processing the precursor prepared in step (1) through isostatic pressing;

[0028] (3) Sinter the isostatically pressed precursor in step (2) under inert gas or reducing gas or vacuum conditions to obtain LiVO 2 .

[0029] Wherein, isostatic pressing is various isostatic pressing known to those skilled in the art, can be cold isostatic pressing or hot isostatic pressing, the pressure that the present invention adopts isostatic pressing is preferably 50-400MPa, more preferably 200-350MPa , After isostatic pressing treatment, the uniform contact between powder particles can be increased, which is conducive to the uniform diffusion of the reaction of substances during heat treatment.

[0...

Embodiment 1

[0041] (1) Preparation of negative electrode active material

[0042] 81.28 lithium carbonate, 163.69 grams of vanadium pentoxide, 22.8 grams of sucrose and 1.60 grams of titanium dioxide are placed in a ball mill jar, mixed with 280 milliliters of absolute ethanol, so that the reactant can be completely dispersed in ethanol, and the mixture is mixed on a planetary ball mill at 350 The precursor mixture was obtained after ball milling at a rotational speed of rpm for 8 hours. The precursor mixture was air-dried and ball-milled for 5 hours to obtain a dispersed powder, which was formed on a powder tablet press at 2 MPa, and the formed rough body was then pressed in an isostatic pressure of 300 MPa. After isostatic pressure treatment, put the mixture into a vacuum carbon tube furnace, first use inert gas to discharge the air in the furnace, and then use a mechanical pump or an oil diffusion pump to vacuumize, the vacuum degree is 10 -5 Below Pascal, the temperature starts to ri...

Embodiment 2

[0052] The negative electrode active material was prepared by the same method as in Example 1, except that the raw material in the ball mill tank also contained 2.88 grams of molybdenum trioxide, and the carbon content in the generated negative electrode active material was 0.010% by weight.

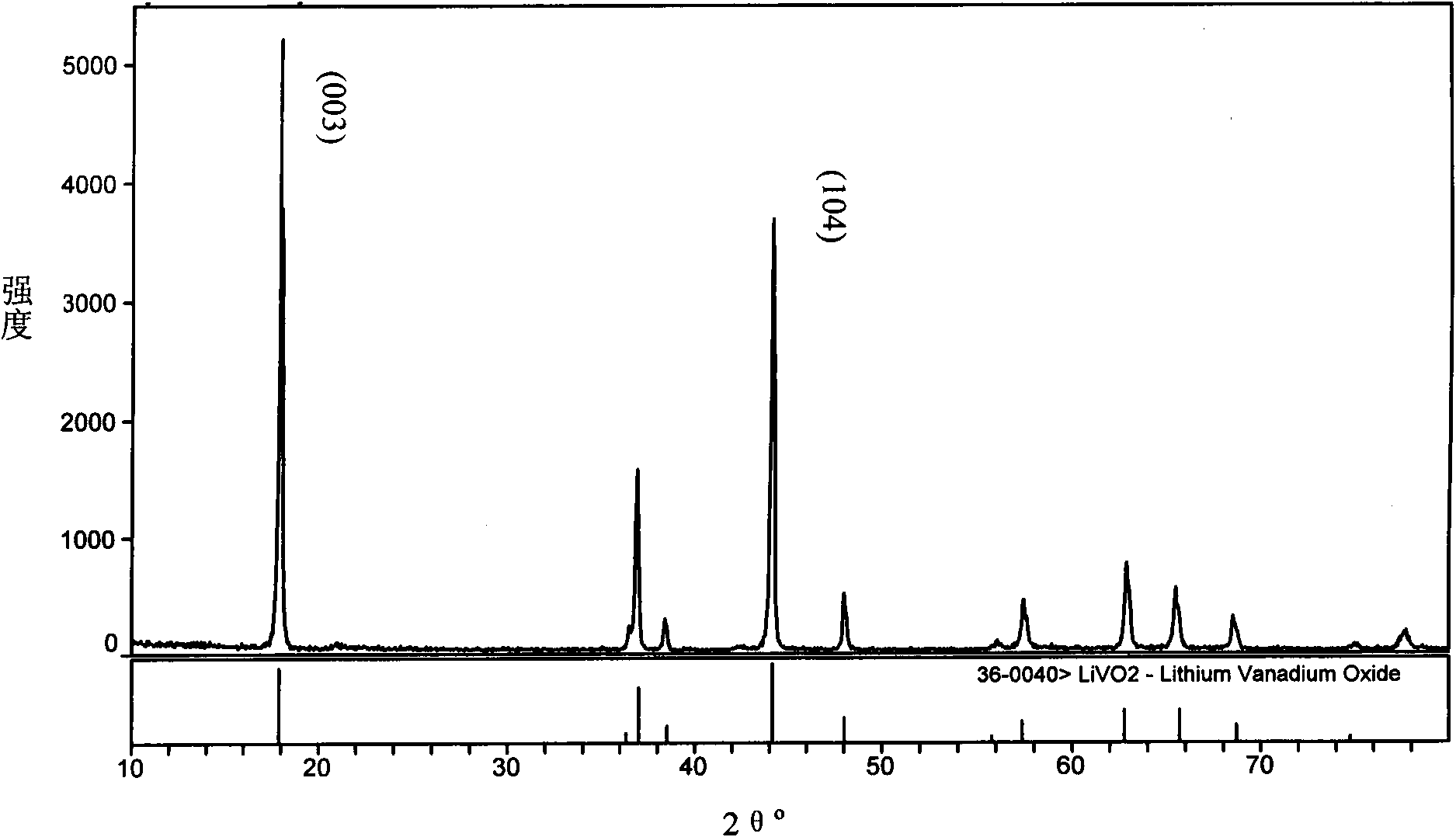

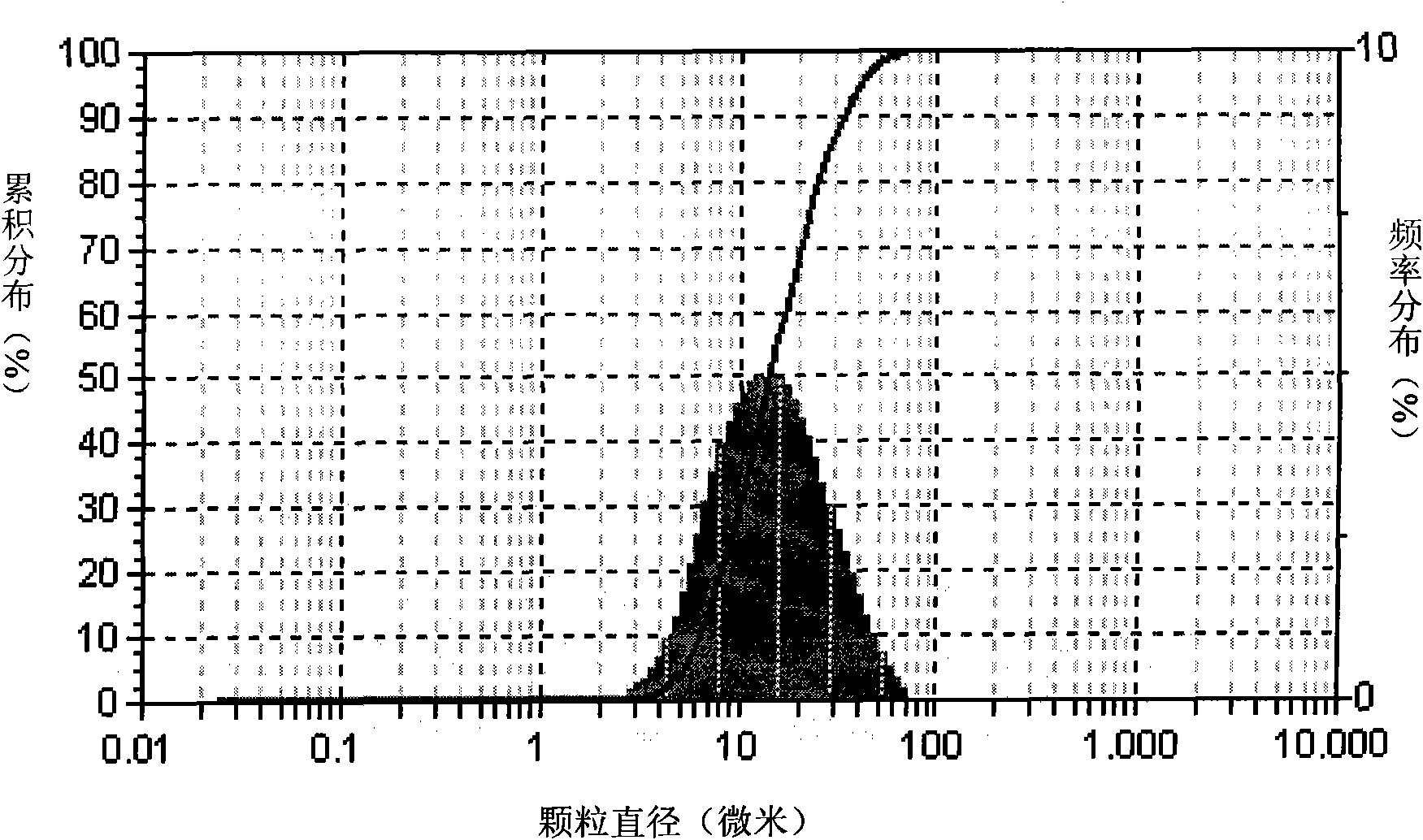

[0053] The tap density of the prepared negative electrode active material measured by the same method as in Example 1 is 2.12g / em3; LiVO 2 The 003 crystal plane diffraction peak intensity I 003 Diffraction peak intensity with 104 crystal plane I 104 The ratio is 1.221, and the FWHM of the 003 crystal plane diffraction peak is 0.199.

[0054] A battery was prepared by the same method as in Example 1, except that the negative electrode active material was the negative electrode active material prepared in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com