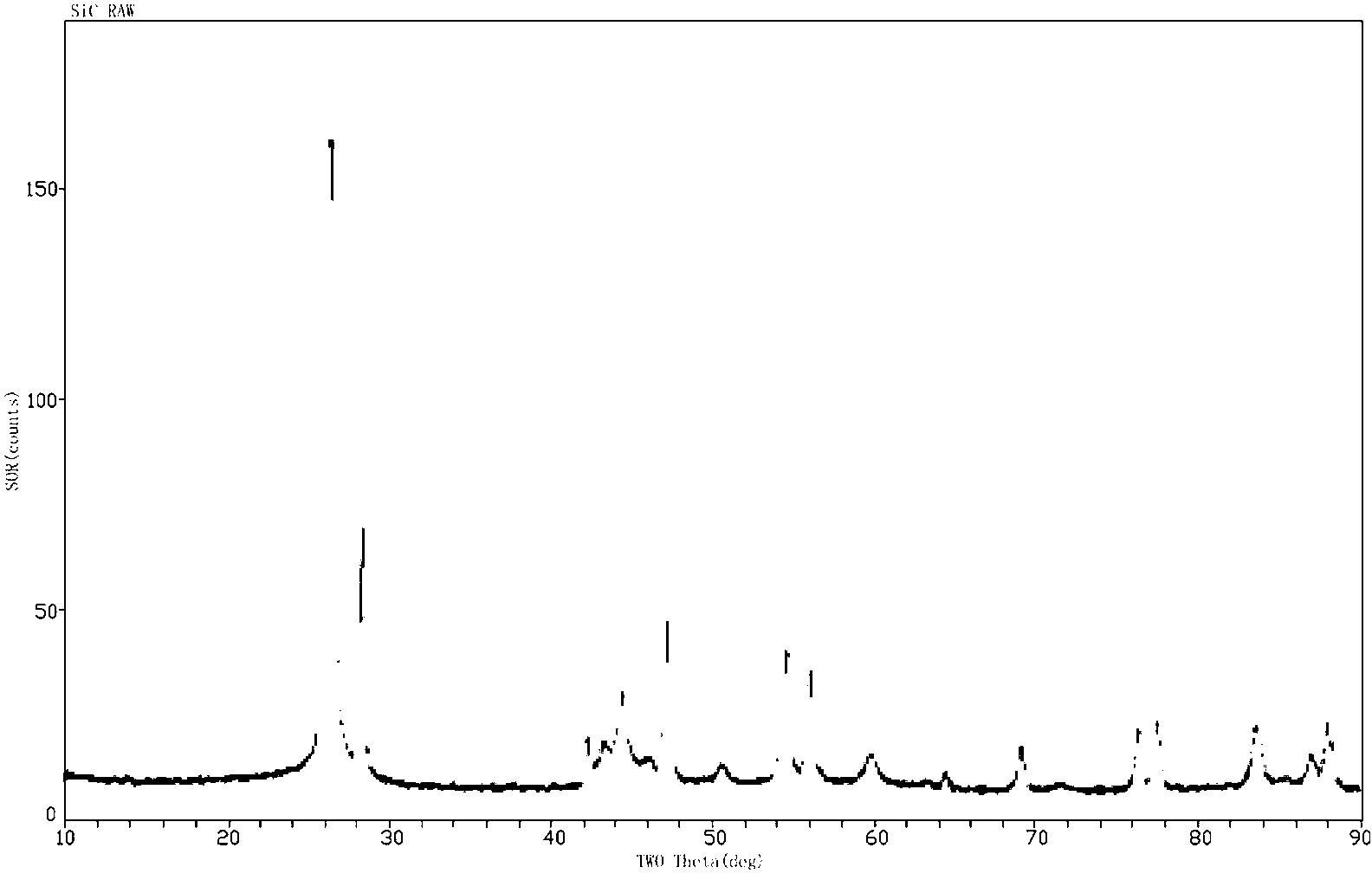

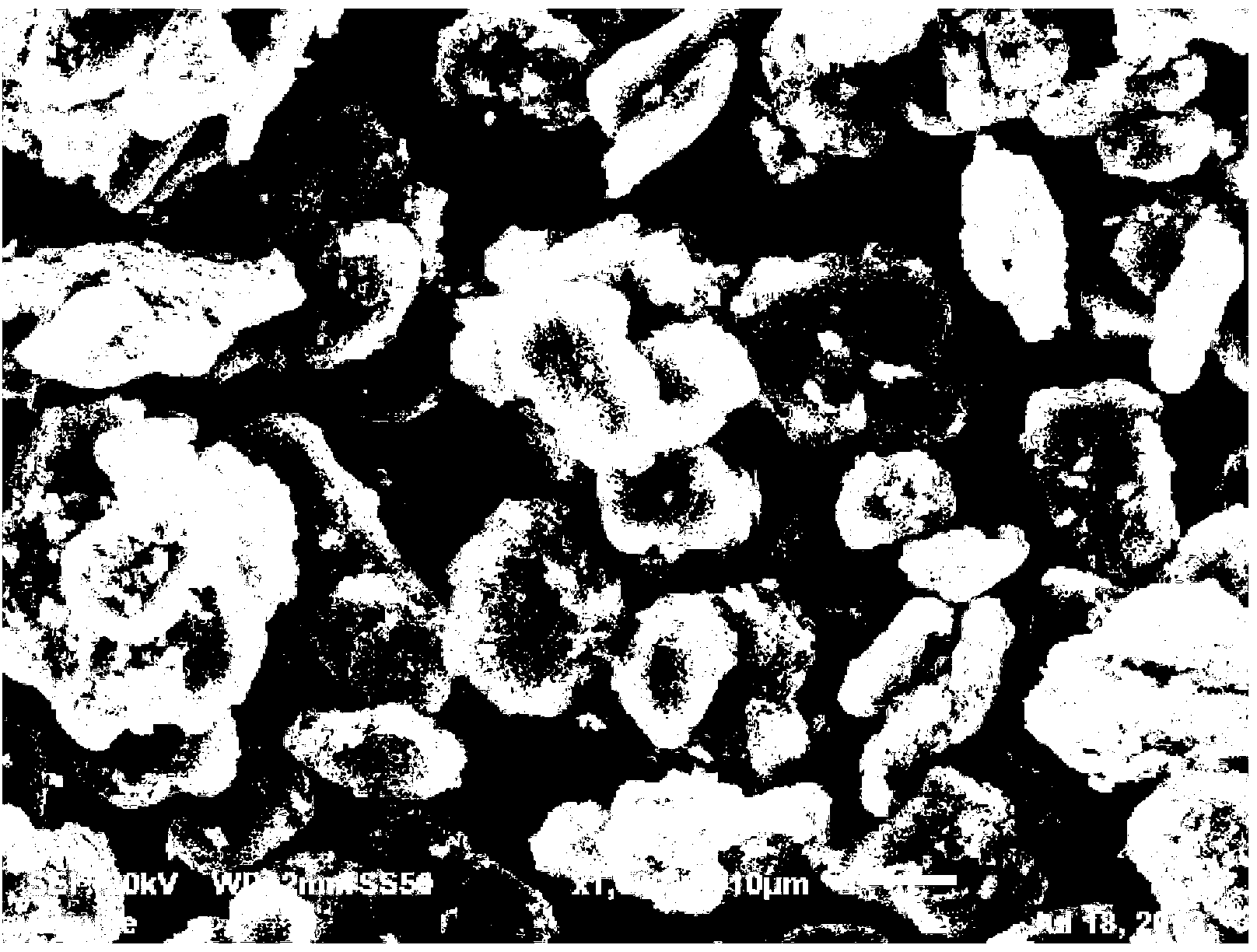

High-performance lithium ion battery silicon-carbon cathode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of materials science, can solve the problems of low conductivity, deactivation of some electrode areas, loss of electrical contact, etc., and achieve good cycle stability, improved cycle life, and high mass specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a high-performance lithium-ion battery silicon-carbon negative electrode material, comprising the steps of:

[0032] (1) Mix high-purity silica fume, micro-silicon fume and aluminum powder in a certain proportion, add alcohol as a dispersant, ultrasonically disperse for 30-120 minutes, transfer to a stainless steel ball mill tank for ball milling, and add 0.2-20mm Zirconia balls, the ratio of ball to material is 10:1~20:1, after removing the air, ball mill at 350~450r / min for 12~24h;

[0033] (2) The product of step (1) is vacuum-dried at 60-100°C for 1-24 hours, mechanically crushed; the product is sintered in nitrogen and / or argon, and sintered at 400-900°C for 1-2 hours under the protection of industrial nitrogen. 10 hours;

[0034] (3) Pickling, filtering, and vacuum-drying the product of step (2), specifically adding dilute HCl, stirring at room temperature for 10 minutes to 6 hours, filtering and washing until neutral;

[0035] (4) Carryin...

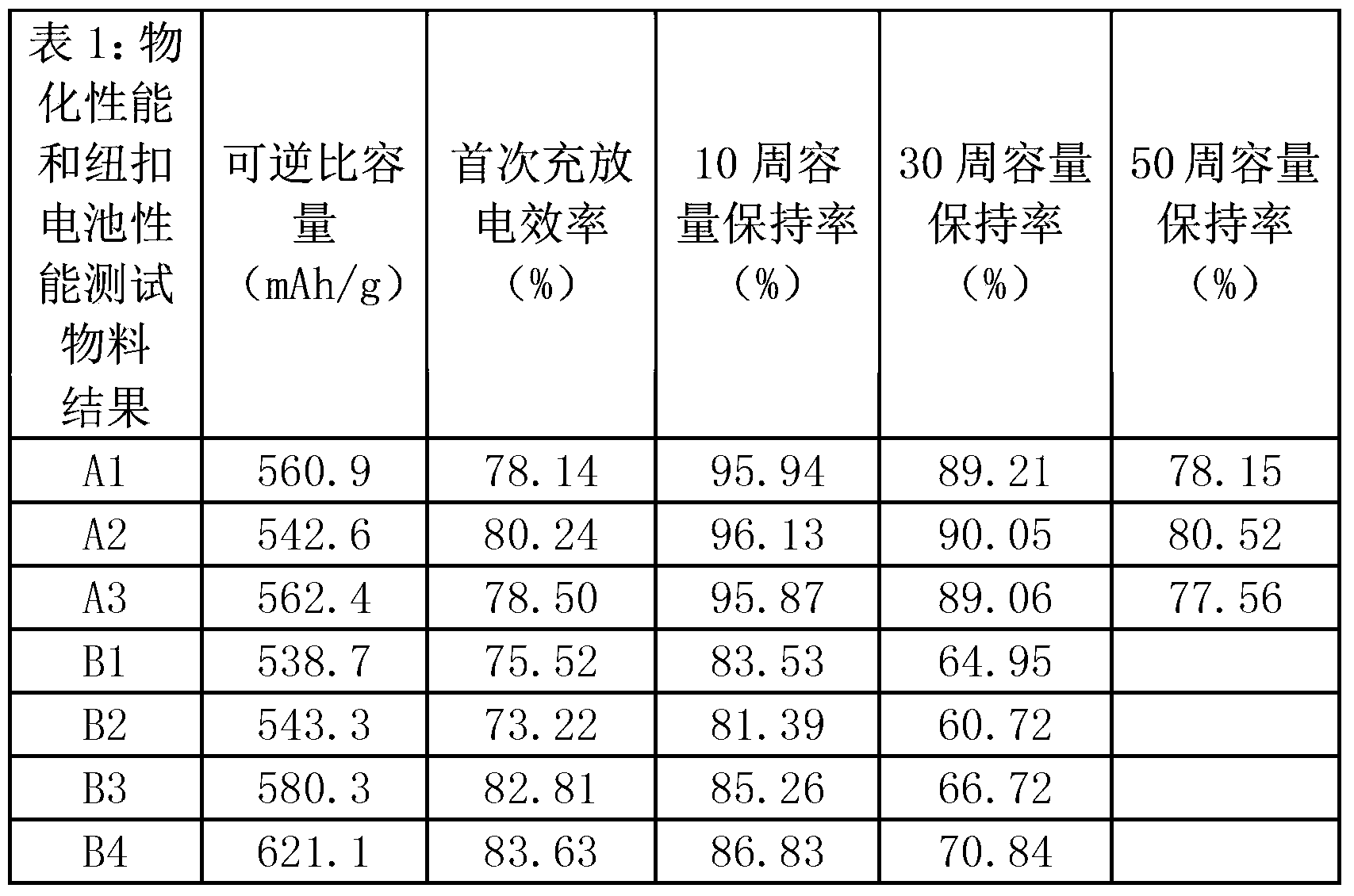

Embodiment 1

[0042] The components are as follows:

[0043] High-purity metal silicon powder: 11.0g (99.9%), with an average particle size of 1.0-2.5μm;

[0044] Micro silica fume: 4.8g (99%), average particle size 3-10μm;

[0045] Ultrafine metal aluminum powder: 2.2g (99%), average particle size 5-10μm;

[0046] Dilute HCl: 120g (10% mass concentration);

[0047] Carbon nanotube slurry: 40g (battery grade, 5% concentration in water system), with an average diameter of 20-30nm and an average aspect ratio of 8-12;

[0048] Natural graphite: 89g (spherical graphite, battery grade), the average particle size is 6-12μm, and the interlayer distance d002 is 0.3353-0.3354nm;

[0049] Sucrose: 25g (food grade).

[0050] The preparation method is as follows:

[0051] (1) Take high-purity metal silicon powder, micro-silica powder, and ultra-fine aluminum powder, and use 100ml alcohol as a dispersant to ultrasonically disperse for 1 hour;

[0052] (2) Transfer the above dispersion system into ...

Embodiment 2

[0061] The difference from Example 1 is that the "natural graphite" in the component is replaced by "mesophase carbon microspheres (MCMB)";

[0062] Others are the same as embodiment 1. The silicon-carbon negative electrode material obtained at last is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com