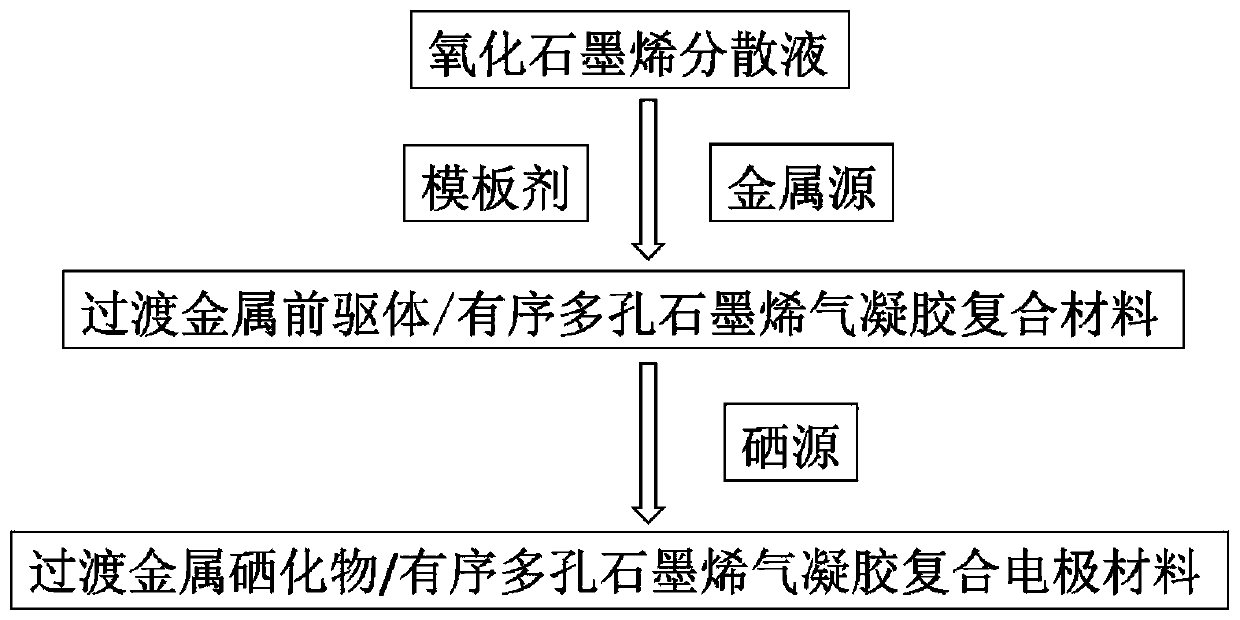

Transition metal selenide/ordered porous graphene aerogel composite electrode material and preparation method thereof

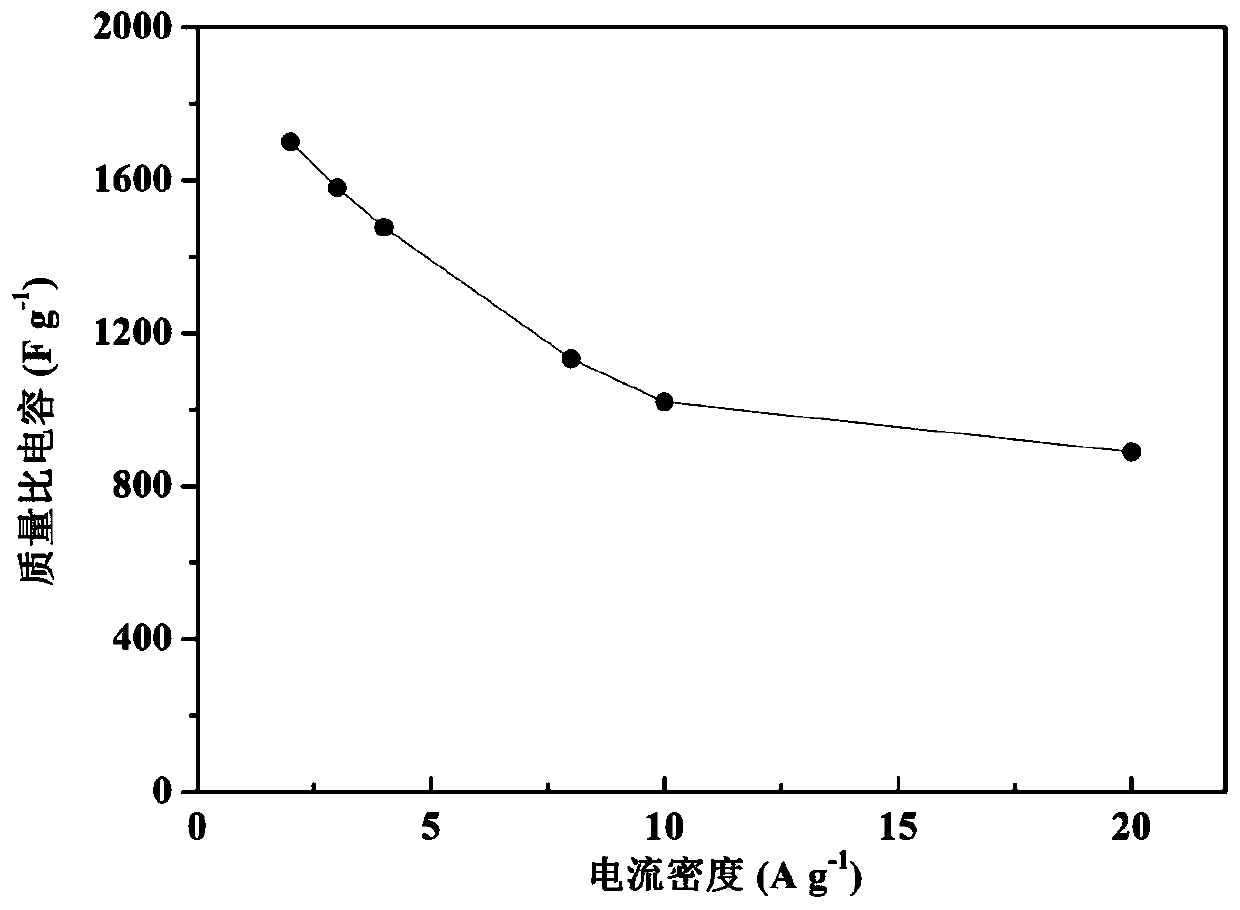

A graphene aerogel, porous graphene technology, applied in the field of materials, can solve problems such as difficulty in meeting the performance requirements of supercapacitors, and achieve the effects of easy industrial application, good rate performance and cycle stability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A transition metal selenide / ordered porous graphene airgel composite electrode material and a preparation method thereof, comprising the following steps:

[0032] In the first step, 80 mg of nickel chloride hexahydrate was dissolved in 30 mL of graphene oxide dispersion (3 mg / mL), ultrasonically obtained for 1 hour to obtain a uniformly dispersed suspension, and then a piece of melamine foam (30 mg / mL) was cut and washed clean ×30×5mm) for 30 minutes. Then transfer the reaction mixture and the above-mentioned melamine foam into a reaction kettle, and then put the reaction kettle into an oven, and react at 90° C. for 5 hours to synthesize a transition metal-graphene oxide-template hydrogel. Then the obtained hydrogel was placed in a hydriodic acid solution with a concentration of 37% to remove melamine foam. It was washed and then freeze-dried for 60 hours to obtain transition metal precursor / ordered porous graphene airgel.

[0033] The second step: place the selenium ...

Embodiment 2

[0039] In the first step, 80 mg of nickel chloride hexahydrate was dissolved in 30 mL of graphene oxide dispersion (3 mg / mL), and ultrasonicated for 1 hour to obtain a uniformly dispersed suspension. A piece of cut and washed melamine foam (30×30×5 mm) was then inserted into it for an immersion time of 50 minutes. Then the reaction mixture was transferred to a reaction kettle, and then the reaction kettle was put into an oven, and reacted at 85° C. for 8 hours to synthesize a transition metal-graphene oxide-template hydrogel. Then the obtained hydrogel was placed in a hydriodic acid solution with a concentration of 37% to remove melamine foam. It was washed and then freeze-dried for 60 hours to obtain transition metal precursor / ordered porous graphene airgel.

[0040] The second step: place the selenium powder and the transition metal precursor / ordered porous graphene airgel obtained above on the two ends of the magnetic boat, and in the tube furnace, Ar / H 2 (9:1) atmosphere...

Embodiment 3

[0042]In the first step, 60 mg of nickel chloride hexahydrate was dissolved in 25 mL of graphene oxide dispersion (6 mg / mL), and ultrasonicated for 1 hour to obtain a uniformly dispersed suspension. A piece of washed melamine foam (30 x 30 x 5 mm) was then inserted into it for an immersion time of 50 minutes. Then the reaction mixture was transferred to a reaction kettle, and then the reaction kettle was put into an oven, and reacted at 85° C. for 8 hours to synthesize a transition metal-graphene oxide-template hydrogel. Then the obtained hydrogel was placed in a hydriodic acid solution with a concentration of 37% to remove melamine foam. It was washed and then freeze-dried for 60 hours to obtain transition metal precursor / ordered porous graphene airgel.

[0043] The second step: place the selenium powder and the transition metal precursor / ordered porous graphene airgel obtained above on the two ends of the magnetic boat, and in the tube furnace, Ar / H 2 (9:1) atmosphere, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com