Preparing process for positive electrode active material/carbon composite material of Li-ion battery

A cathode active material, lithium ion battery technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem that the cathode material cannot take into account the specific capacity and rate discharge performance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is used to illustrate the preparation method of the positive electrode active material / carbon composite material for a lithium ion battery provided by the present invention.

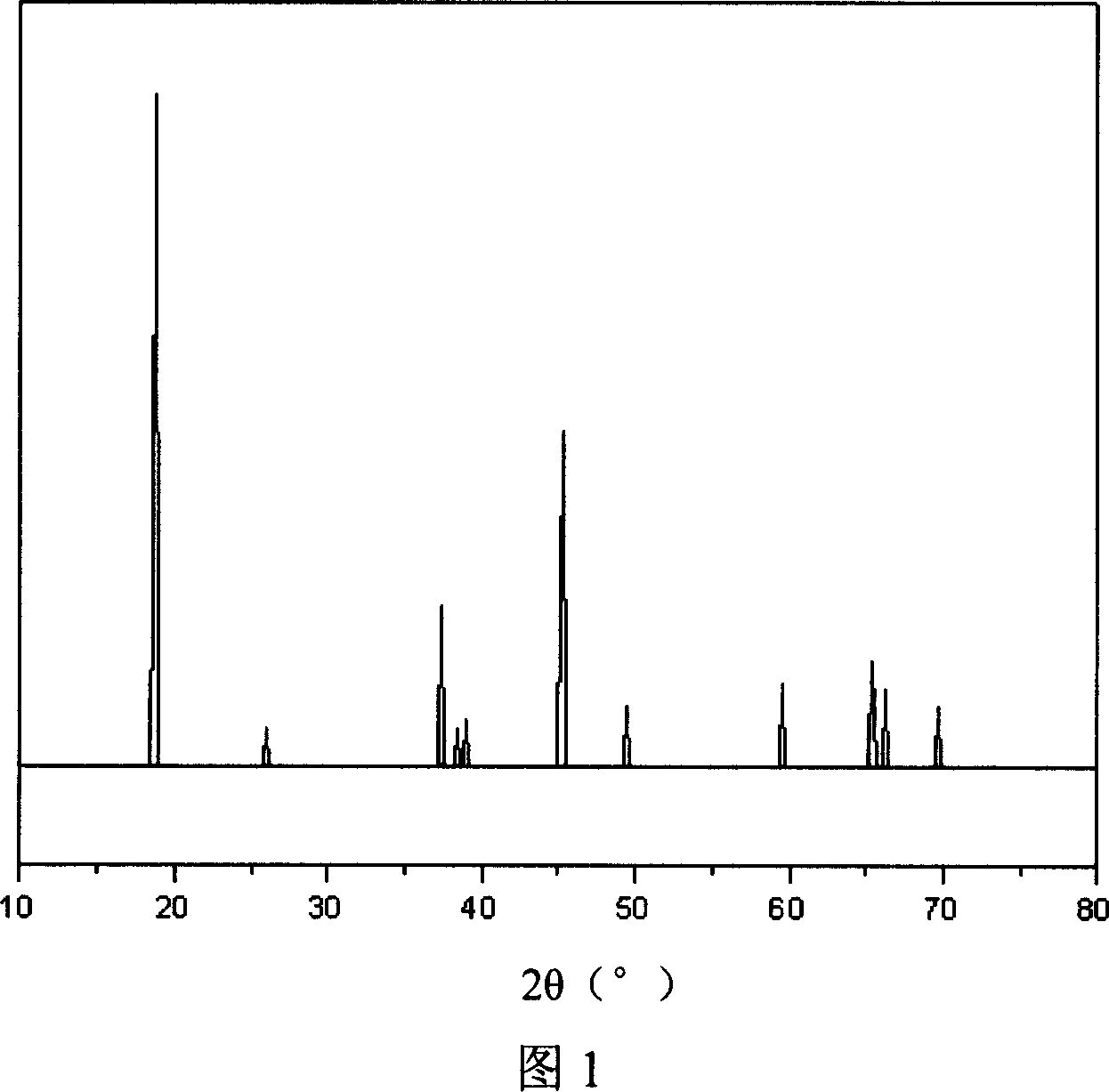

[0037] Dissolve 19 g of phenolic resin in acetone, and then mix with 100 g of LiCoO 2 (Particle diameter is 5.2-14.6 microns) mixed and ball milled for 2 hours, the obtained mixture was removed from the solvent, and then sintered at 800°C for 6 hours under the protection of nitrogen to obtain LiCoO 2 / carbon composite. Figure 1 is the LiCoO 2 / XRD spectrum of the carbon composite material, the peak at 2θ=26.14 in the figure is the characteristic peak of carbon, which shows that the prepared product is LiCoO 2 and carbon, and the peaks of 2θ=18.96 and 2θ=45.28 indicate that carbon does not enter the lattice, but is coated in LiCoO 2 s surface. LiCoO 2 The coating amount of surface carbon is LiCoO 2 1% by weight of the positive electrode active material.

Embodiment 2

[0039] This example is used to illustrate the preparation method of the positive electrode active material / carbon composite material for a lithium ion battery provided by the present invention.

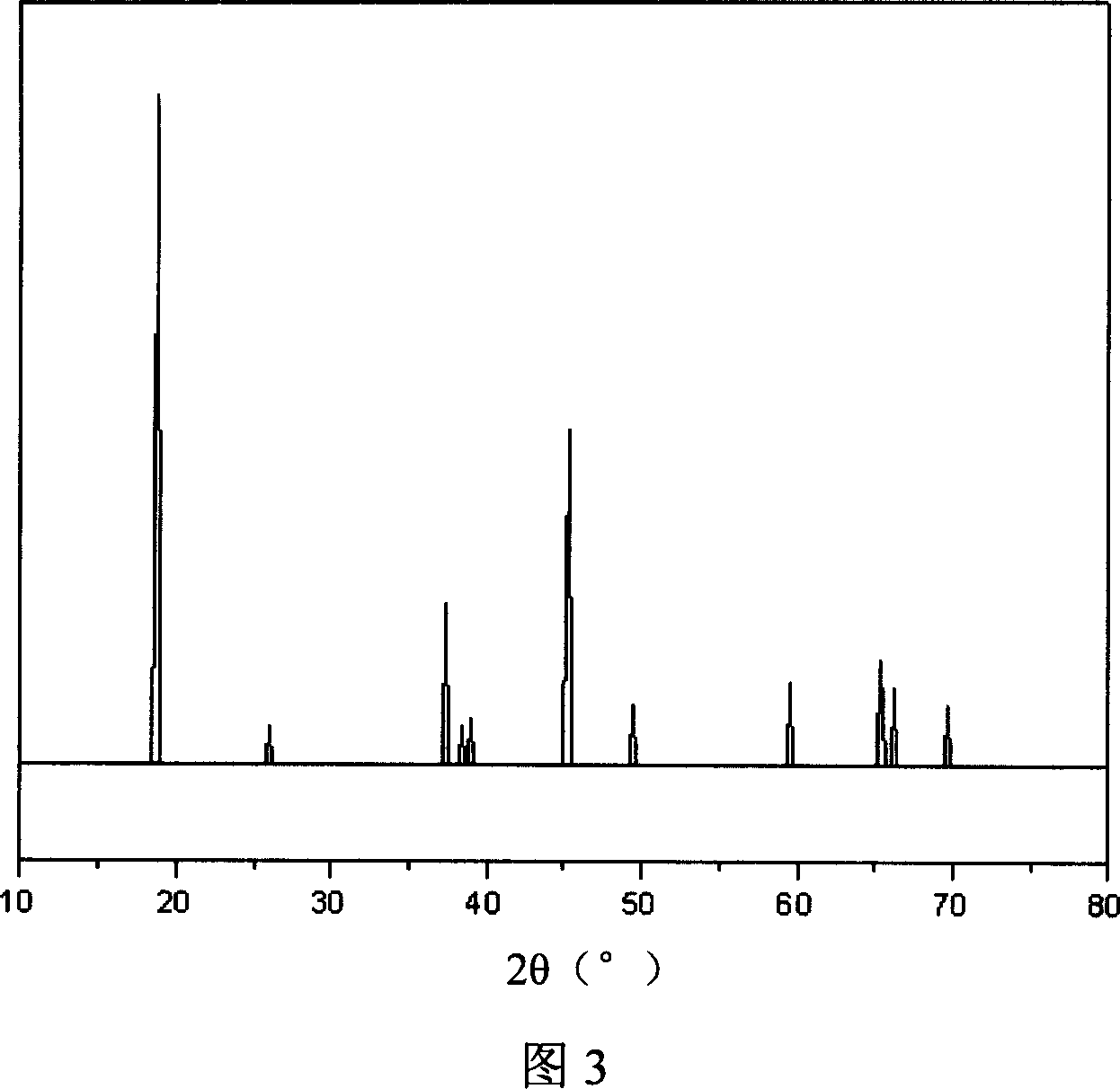

[0040] Dissolve 11 g of polyacrylamide in alcohol, then mix with 100 g of LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 (Particle diameter is 5.6-13.8 microns) mixed and ball milled for 2 hours, the obtained mixture is removed from the solvent, and then sintered at 800°C for 2 hours under the protection of nitrogen to obtain LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 / carbon composite. Figure 3 is the LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 The XRD pattern of / carbon composite material, the peak at 2θ=26.14 places in the figure is the characteristic peak of carbon, and this shows that the product prepared is LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 and carbon, and the peaks of 2θ=18.68 and 2θ=44.46 indicate that carbon did not enter LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 lattice, but coated in LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 surface. The...

Embodiment 3

[0042] This example is used to illustrate the preparation method of the positive electrode active material / carbon composite material for a lithium ion battery provided by the present invention.

[0043] 21 g of furfural resin was dissolved in methanol, and then mixed with 100 g of LiMn 2 o 4 (Particle diameter is 5.6-14.2 microns) mixed and ball milled for 2 hours, the resulting mixture was removed from the solvent and then sintered at 800°C for 2 hours under the protection of nitrogen to obtain LiMn 2 o 4 / carbon composite. Figure 5 is the LiMn 2 o 4 The XRD pattern of / carbon composite material, the peak at 2θ=26.14 places in the figure is the characteristic peak of carbon, and this shows that the product prepared is LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 and carbon, and the peaks of 2θ=18.78 and 2θ=44.14 indicate that carbon did not enter LiMn 2 o 4 lattice, but coated in LiMn 2 o 4 surface. The coating amount of carbon is LiMn 2 o 4 1% by weight of the positive electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com