Method for synthesizing lithium iron phosphate material by adopting electrostatic spinning

A technology of lithium iron phosphate and electrospinning, which is applied in the direction of spinning solution preparation, filament/wire forming, circuit, etc., can solve the problem of large particle size, achieve the effect of increasing mass specific capacity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] FeC 2 o 4 , LiH 2 PO 4 Add it to an aqueous polyvinyl alcohol solution with a mass ratio concentration of 4%, and mix at 25° C. for 1 hour. Among them Li + : Fe 2+ :PO 4 3- The molar ratio of FeC is 0.9:1:1; FeC 2 o 4 , LiH 2 PO 4 The total mass is 0.1 g, and the mass of the polyvinyl alcohol aqueous solution is 40 g. After stirring, a spinning dope was prepared. The prepared electrospinning stock solution was added into the syringe, and the spinning voltage was set to 5KV; the solidification distance was 3cm; the feeding speed of the solution was controlled to be 10mL / h. The one-dimensional nanowire precursor of lithium iron phosphate was prepared in this way. After drying the prepared lithium iron phosphate precursor at 50 °C, place it under N 2 Calcined at 550° C. for 24 hours in an atmosphere protection furnace, and cooled naturally to room temperature to prepare a one-dimensional nanostructured lithium iron phosphate material.

Embodiment 2

[0025] FeC 2 o 4 , Li 2 CO 3 , NH4 h 2 PO 4 Add it into a polyvinyl alcohol ethanol solution with a mass ratio concentration of 50%, and mix at 50° C. for 24 hours. Among them Li + : Fe 2+ :PO 4 3- The molar ratio of FeC is 1:1:1; FeC 2 o 4 , Li 2 CO 3 , NH 4 h 2 PO 4 The total mass is 10g, and the mass of the polyvinyl alcohol ethanol solution is 1g. After stirring, a spinning dope was prepared. The prepared electrospinning stock solution was added into the syringe, and the spinning voltage was set to 30KV; the solidification distance was 25cm; the feeding speed of the solution was controlled to be 0.01mL / h. The lithium iron phosphate precursor was thus prepared. The prepared lithium iron phosphate precursor was dried at 80°C, placed in an Ar atmosphere protection furnace, calcined at 850°C for 1 hour, and naturally cooled to room temperature to prepare a one-dimensional nanostructured lithium iron phosphate material.

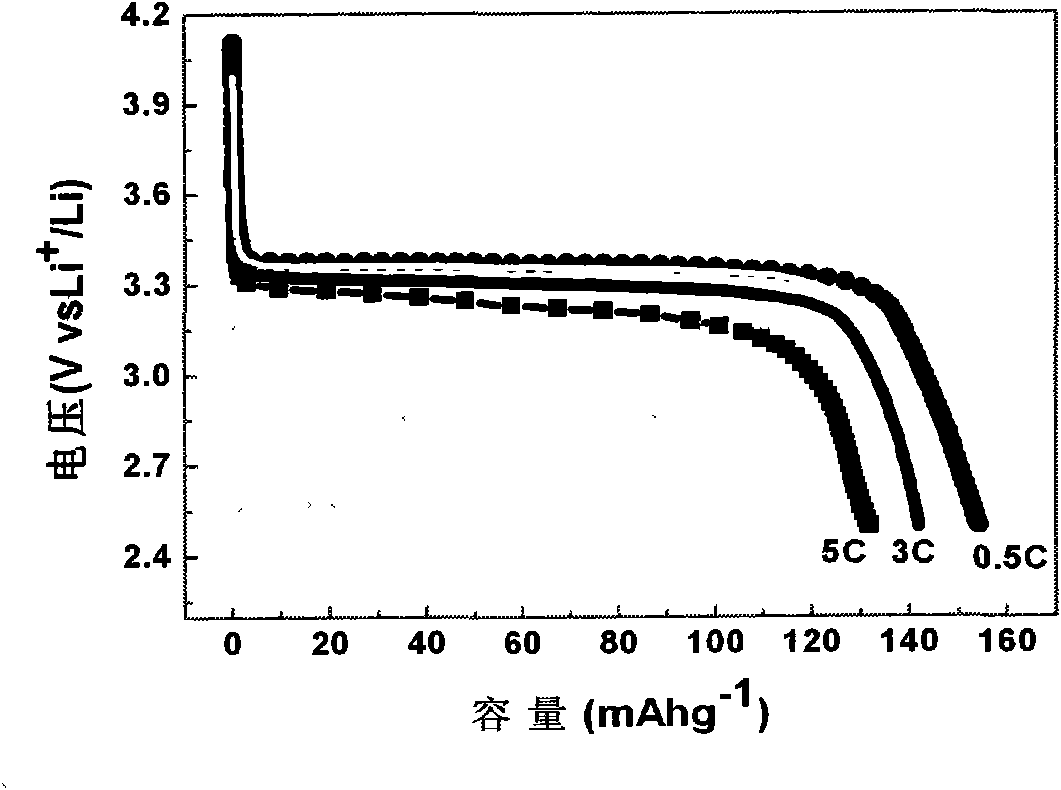

[0026] The synthesized lithium ferrou...

Embodiment 3

[0028] Will Fe 2 o 3 , Li 2 HPO 4 Add it into an ethylene glycol solution with a mass fraction of 15% polyvinylpyrrolidone, and mix at 80° C. for 12 hours. Among them Li + : Fe 2+ :PO 4 3- The molar ratio of Fe is 1.1:1:1; Fe 2 o 3 , Li 2 HPO 4 The total mass is 5g, and the mass of the polyvinyl alcohol aqueous solution is 50g. After stirring, the electrospinning stock solution was prepared. The prepared electrospinning stock solution was added into the syringe, and the spinning voltage was set to 10KV; the solidification distance was 6cm; the feeding speed of the solution was controlled to be 5mL / h. The lithium iron phosphate precursor was thus prepared. After the prepared lithium iron phosphate precursor was dried at 75 °C, it was placed in H 2 Calcined at 600° C. for 23 hours in an atmosphere protection furnace, and cooled naturally to room temperature to prepare nanostructured lithium iron phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com