Composite anode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and composite anodes, applied in electrode manufacturing, battery electrodes, circuits, etc. Ionicity and other issues, to achieve the effect of improving electrochemical cycle performance, low cost, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

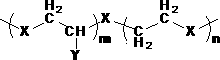

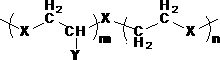

[0036] The composite anode material for lithium-ion batteries provided in this embodiment includes the anode active material Si and a cladding layer coated on the surface of Si. The cladding layer is a polymer with a network structure, and the polymer is composed of the following structural formula: The polymer precursors are cross-linked:

[0037]

[0038] Among them, X is -NH, Y is propenyl -CH=CH-CH 3 , m is 1-100, n is 10-1000, and the weight average molecular weight of the polymer is 500,000. The coating layer accounts for 5% by mass of the anode material.

Embodiment 2

[0040] The difference from Example 1 is: X is O, Y is -CH 2 O(CH 2 ) 3 Si (OCH 3 ) 3 , m is 1-100, n is 10-1000, and the weight average molecular weight of the polymer is 1000,000. The coating layer accounts for 7% by mass of the anode material.

[0041] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0043] The difference from Example 1 is: X is O, Y is acrylate, m is 1-100, n is 10-1000, and the weight average molecular weight of the polymer is 800,000. The coating layer accounts for 1% by mass of the anode material.

[0044] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com