Integral erecting system for large sea-crossing arch bridge and construction method thereof

An integral and arch bridge technology, which is applied to the integral erection system of large-scale sea-crossing arch bridges and its construction field, can solve the problems of difficult control of key process quality, large amount of steel used in the cable buckle system, large amount of corrosion in seawater environment, etc. Good social and economic benefits, guaranteeing construction quality, and reducing the cost of temporary construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

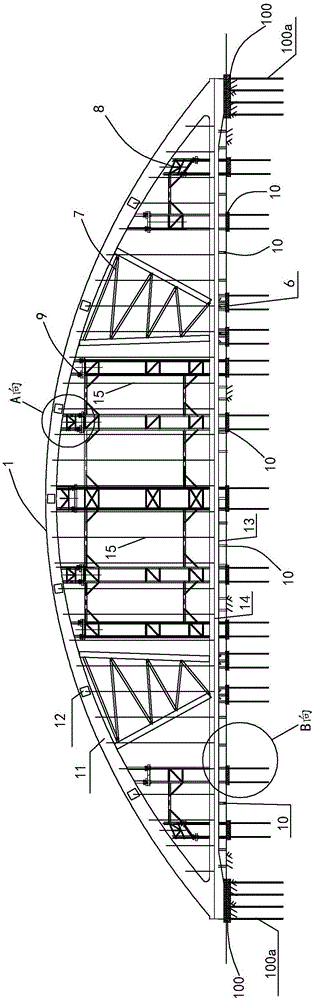

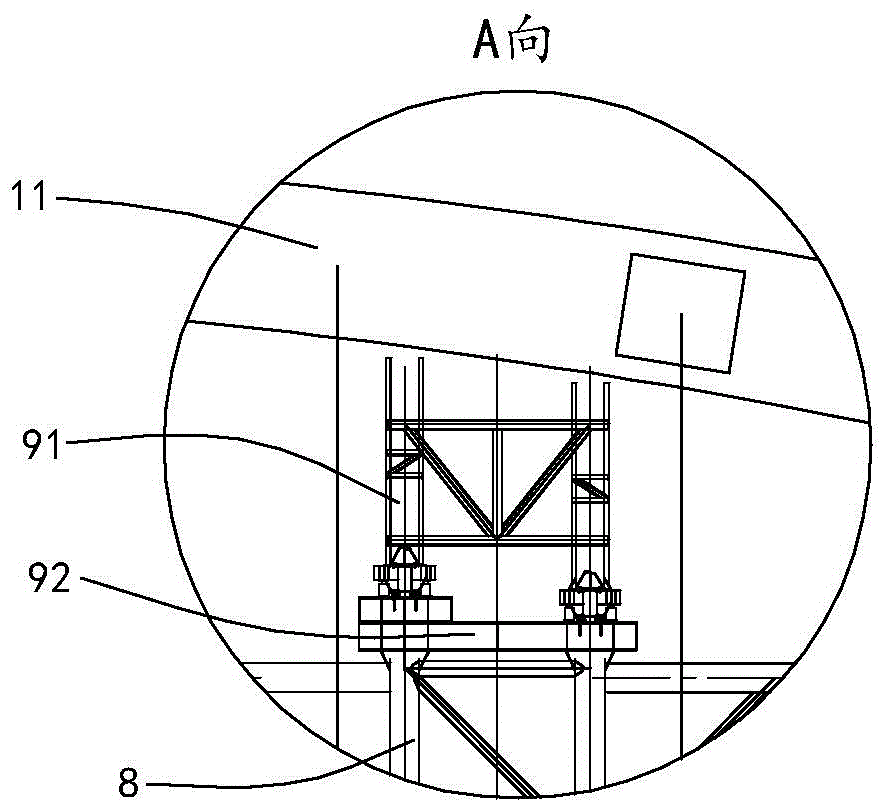

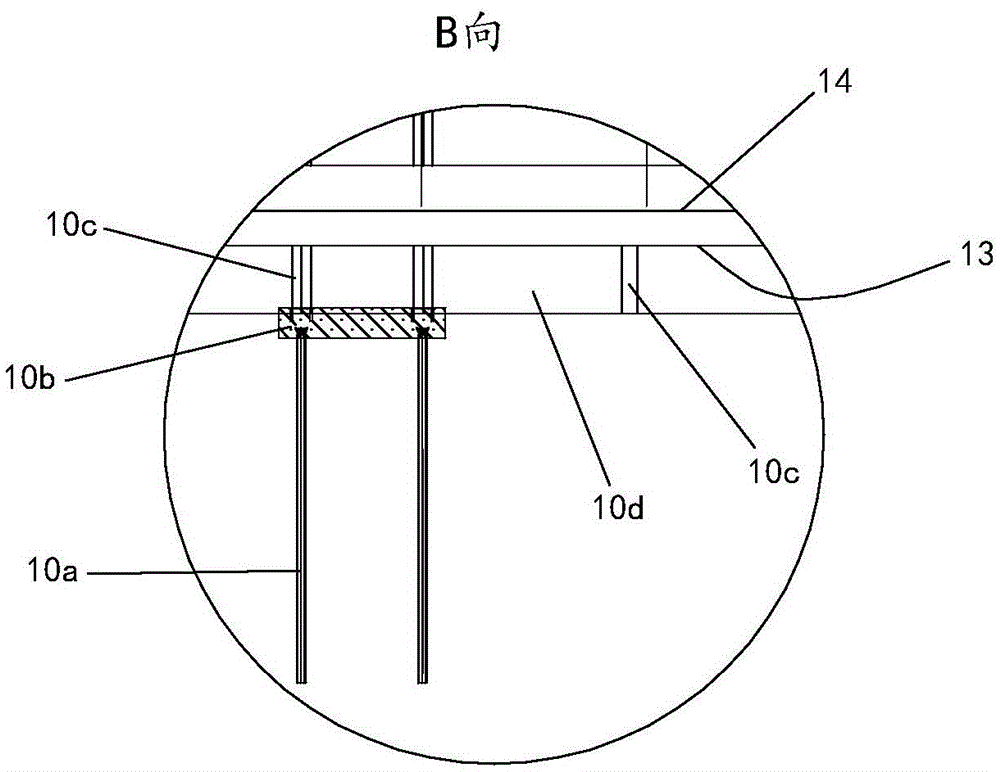

[0046] Such as Figure 1 to Figure 8 The overall erection system of a large-scale sea-crossing arch bridge is shown, wherein the arch bridge has an integral arch beam 1, and the integral arch beam 1 includes arc-shaped arch ribs 11, longitudinally arranged main girders 13, arch rib wind braces 12, flexible system Rod 14 and suspender 15, the arch rib 11 is a steel structure, the section height of the arch rib 11 changes along the direction of the bridge, and the arch rib 11 is provided with partitions and stiffeners to provide sufficient vertical, horizontal, and torsional rigidity for the overall lifting and floating transportation , the arch rib wind brace 12 is multiple, and the arch rib wind brace 12 is rigidly connected with the arch rib 11 to ensure the stability and wind resistance performance of the construction process and the bridge structure. The arch rib 11 and the arch rib wind brace 12 form an integral arch beam 1, the main beam 13 is a steel structure, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com