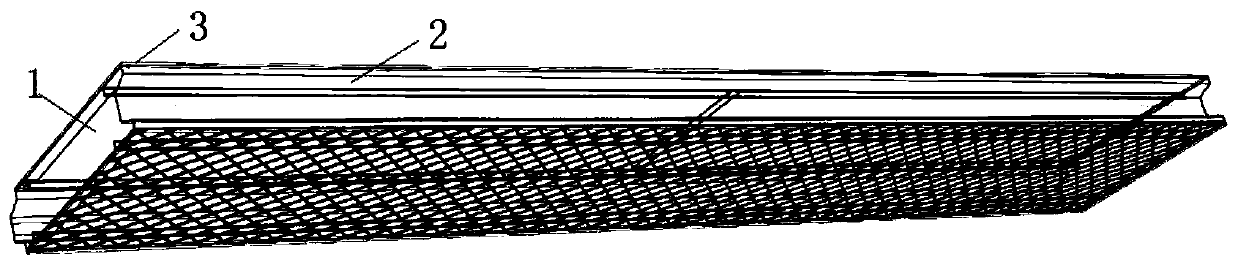

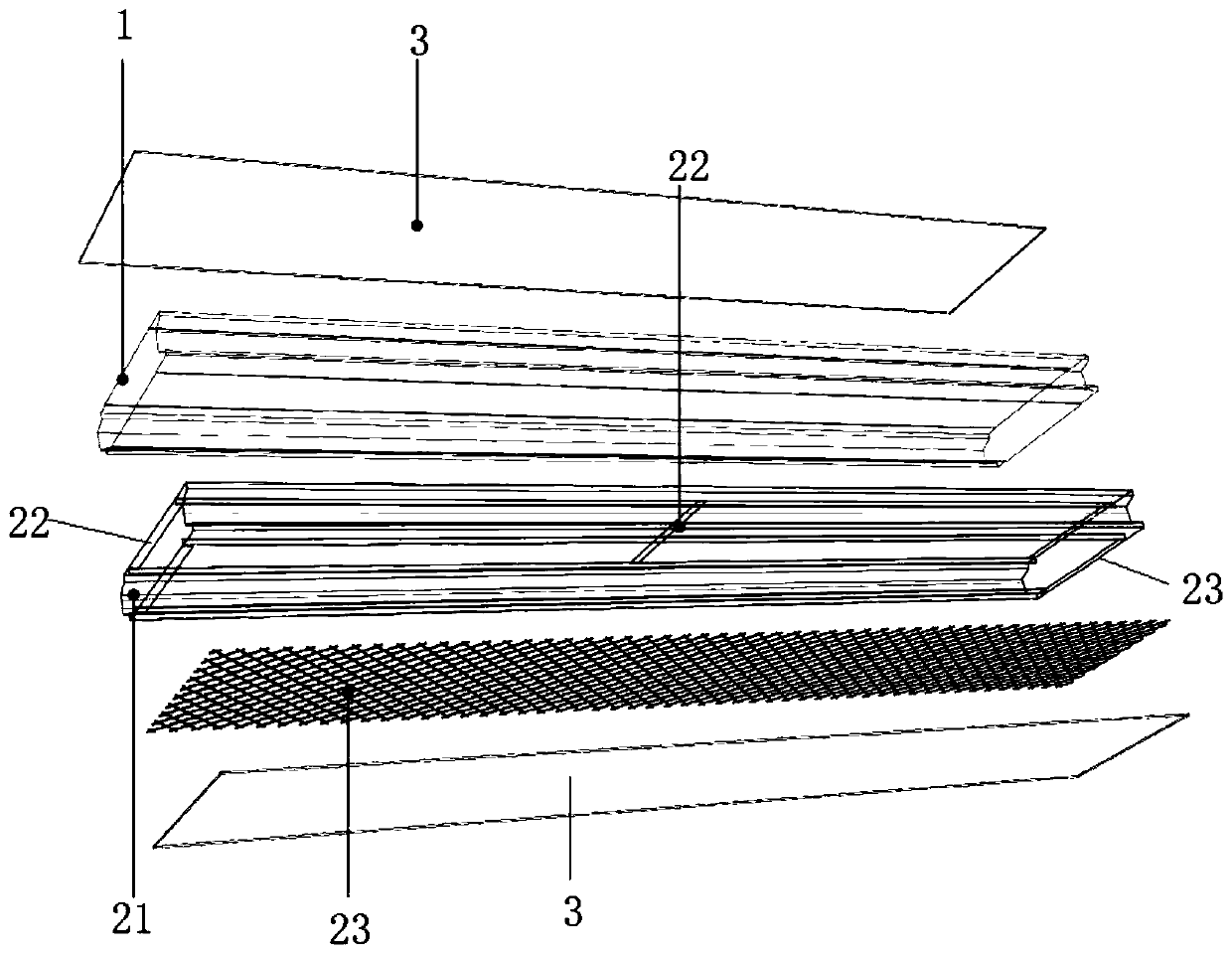

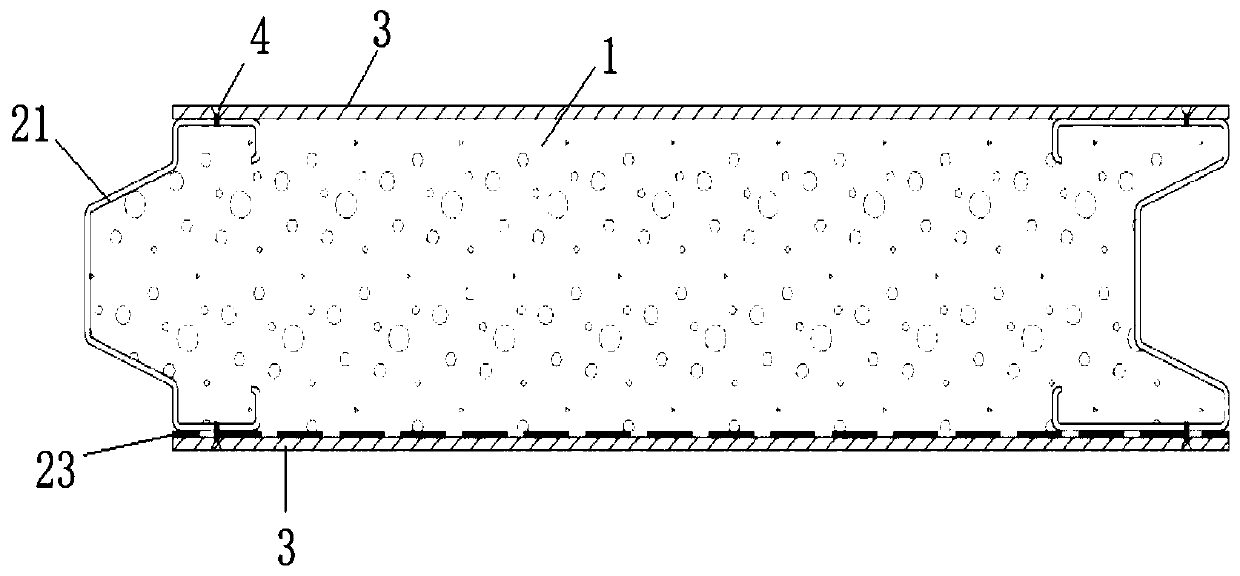

High-strength lightweight composite floor slab and floor system thereof

A high-strength and light-weight technology, used in floors, building components, buildings, etc., can solve the problems of heavy reinforced concrete floor itself, low technical requirements for on-site installation, and only one-time use, achieving rapid industrial construction, construction The effect of short cycle and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiment of the present application provides a high-strength lightweight composite floor slab and its floor layer system, which solves the problem that the reinforced concrete floor slab in the prior art has heavy weight, complex construction process, high technical requirements, long construction period, and can only be used once. Due to technical problems, the weight of the floor slab is greatly reduced, the construction process is simple, the technical requirements for on-site installation are low, the construction period is short, and it can be removed and reused, which meets the requirements of green environmental protection and civilized construction.

[0044] The technical solution in the embodiment of the present application is to solve the above-mentioned crosstalk problem, and the general idea is as follows:

[0045] Polystyrene particle foam concrete slab is currently the commonly used lightweight wallboard material. It is poured into polystyrene particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com