Prefabricated composite wall panel

A compound wall and prefabricated technology, which is applied in the direction of walls, buildings, building components, etc., can solve the problems of inconvenient transportation, difficult installation, base erosion and other problems of composite walls, so as to ensure construction safety and civilized construction, convenient transportation, The effect of increasing the fire resistance rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

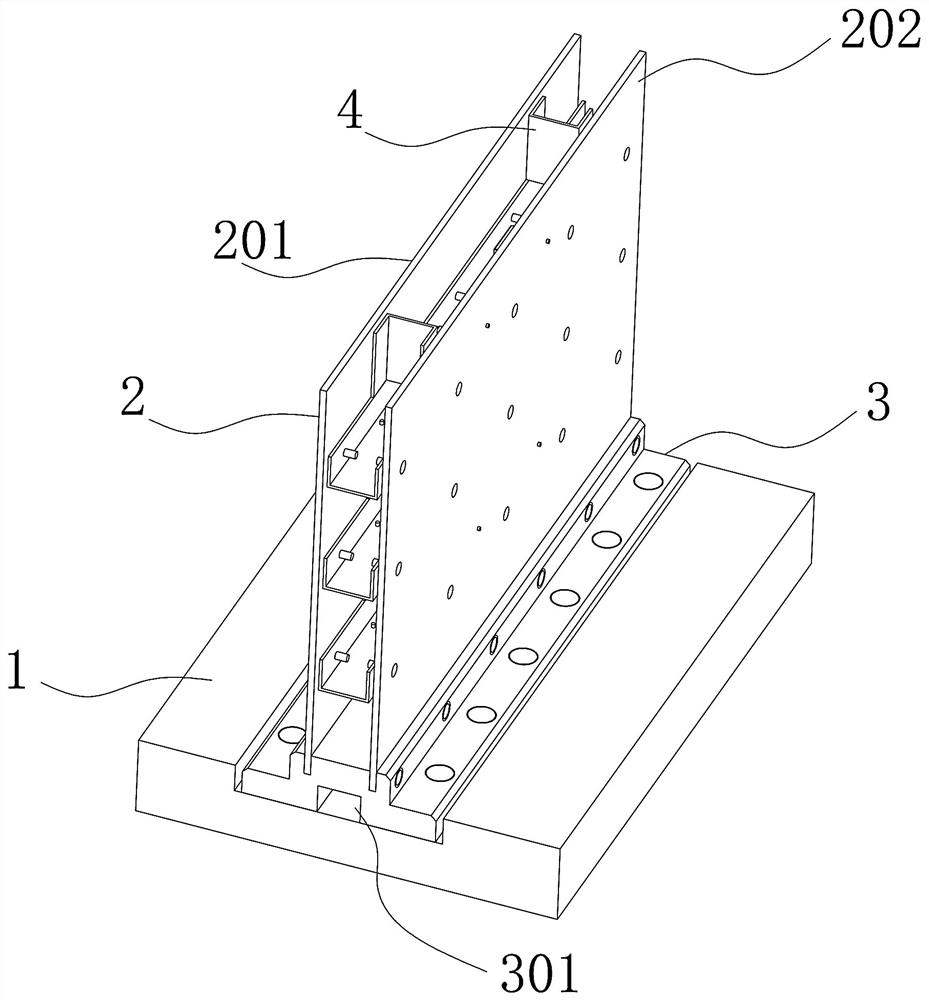

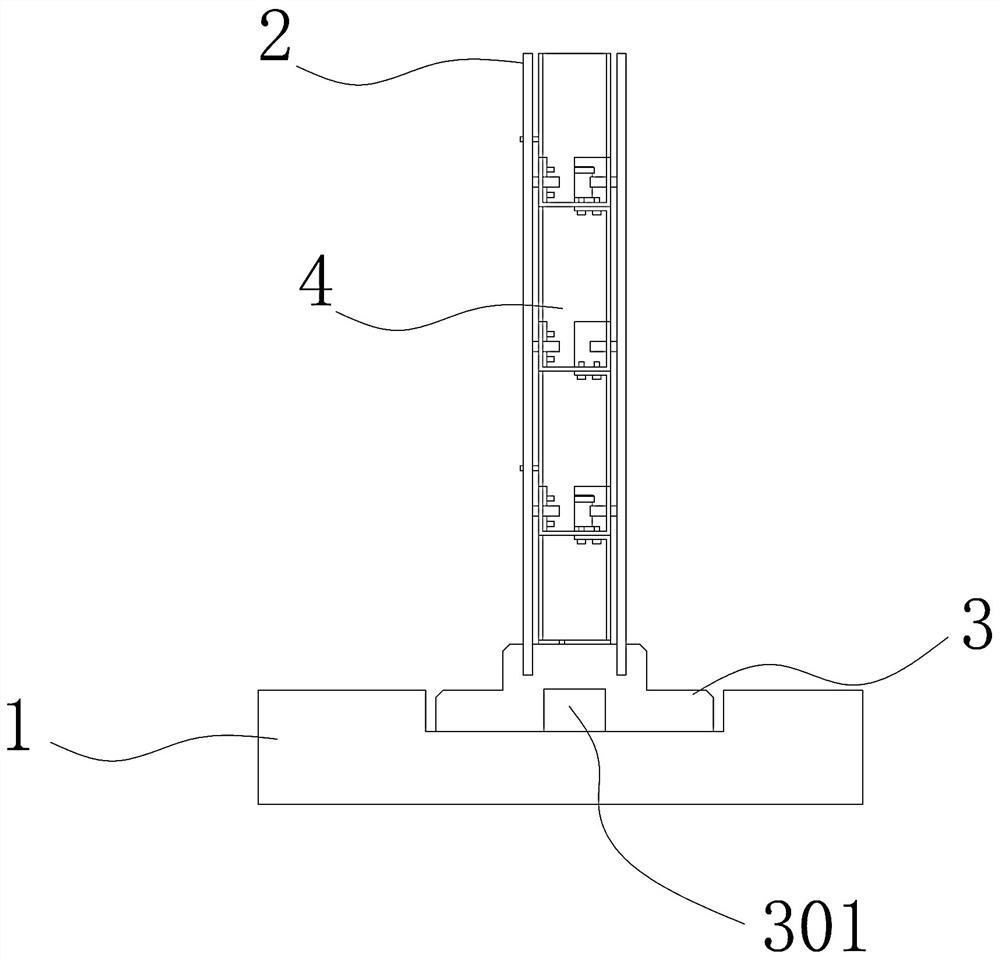

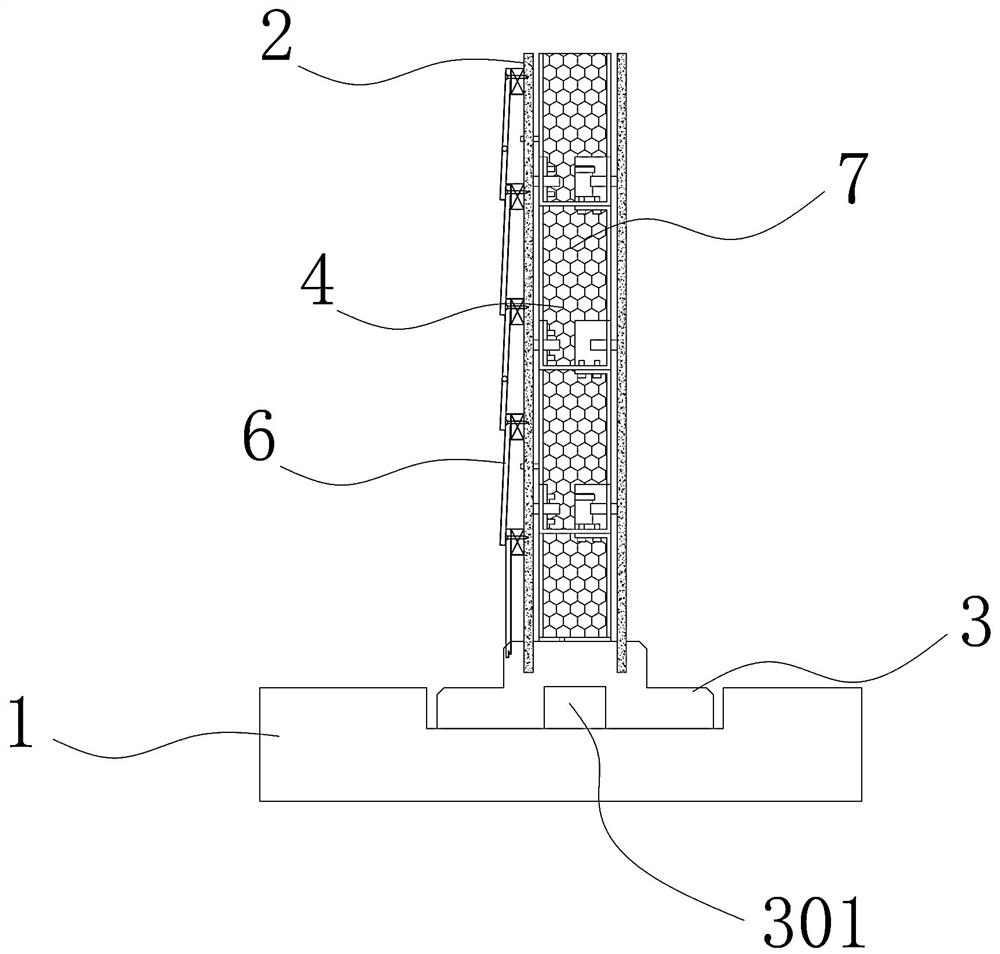

[0050] like Figure 1~17 As shown, an assembled composite wall panel includes a thermal insulation wall 2, the thermal insulation wall 2 includes a first wall panel 201 and a second wall panel 202, and the wall panel includes a straw board base layer 205 and a magnesite board 206 , the straw board base layer 205 and the magnesite board 206 are connected by hollow nuts 207 and locking bolts 209, the inside of the heat insulation wall 2 is provided with a keel frame 4, and the long nuts 208 are locked on the keel frame through the hollow nuts 207 4, a shock-absorbing pad 8 is provided between the wallboard and the keel frame 4, the long nut 208 passes through the shock-absorbing pad 8, a glass fiber mesh cloth 204 is provided on one side of the straw board base 205, and the glass The outer surface of the fiber mesh cloth 204 is coated with waterproof paint 203 .

[0051] From this structure, such as Figure 4~7 The structure shown can meet higher thermal insulation, heat insul...

Embodiment 2

[0069] Further illustrate in conjunction with embodiment 1, as Figure 1~13 As shown, the installation process of the composite wall of the household wall is as follows. First lay the foundation 1, open a groove on the foundation 1, fix the base 3 in the groove on the foundation 1 through the lock nut 302, and then vertically The skeleton 402 is installed on the base 3 through nuts, and then the horizontal skeleton 401 is stuck on each gap of the vertical skeleton 402, and the dehumidification box 5 is installed. After the dehumidification box 5 is installed, install electric wires, water pipes, and natural gas.

[0070] After installing wires, water pipes, and natural gas, install the first wallboard 201. The first wallboard 201 is installed with nuts. After the first wallboard 201 is installed, various sound insulation materials are added. The general sound insulation materials are block structures. , conveniently added on the keel frame 4, after the addition is completed, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com